AM

Adrian Mariano

Mon, Nov 18, 2024 2:50 AM

Good luck with following the calculations---I think my calculations are

pretty obscure when divorced from the approach and a diagram. Basically

you need to figure out at what radius the side length of an n-gon is

exactly double the side length of a 2-n gon at radius R. Then that gives

you the position you need to rotate to, and you have to do some trig to

figure out the angle of rotation. The "extra" business is about oversizing

the shape for later intersection with a cylinder. Part of the reason I

favor Bob's projection approach is that ultimately it is just much simpler

conceptually and hence the computations are much more straight forward.

On Sun, Nov 17, 2024 at 9:26 PM Caddiy via Discuss <

discuss@lists.openscad.org> wrote:

Yes, my tilt calculation was simple - too simple, because it didn’t work

properly and didn’t work at all for other spline angles, as I found to my

dismay.

I’ll have to study your code to see if I can glean something from it.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Good luck with following the calculations---I think my calculations are

pretty obscure when divorced from the approach and a diagram. Basically

you need to figure out at what radius the side length of an n-gon is

exactly double the side length of a 2-n gon at radius R. Then that gives

you the position you need to rotate to, and you have to do some trig to

figure out the angle of rotation. The "extra" business is about oversizing

the shape for later intersection with a cylinder. Part of the reason I

favor Bob's projection approach is that ultimately it is just much simpler

conceptually and hence the computations are much more straight forward.

On Sun, Nov 17, 2024 at 9:26 PM Caddiy via Discuss <

discuss@lists.openscad.org> wrote:

> Yes, my tilt calculation was simple - too simple, because it didn’t work

> properly and didn’t work at all for other spline angles, as I found to my

> dismay.

>

> I’ll have to study your code to see if I can glean something from it.

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

M

mikeonenine@web.de

Mon, Nov 18, 2024 3:17 AM

Basically you need to figure out at what radius the side length of an n-gon is exactly double the side length of a 2-n gon at radius R.

That’s interesting. It’s similar to what I was trying to do. I did have the feeling the problem was caused by a discrepancy somewhere in the circumference of the thing.

The "extra" business is about oversizing the shape for later intersection with a cylinder.

Yes, I had to do that too. It’s inevitable if the splines are tilted.

Adrian Mariano wrote:

> Basically you need to figure out at what radius the side length of an n-gon is exactly double the side length of a 2-n gon at radius R.

That’s interesting. It’s similar to what I was trying to do. I did have the feeling the problem was caused by a discrepancy somewhere in the circumference of the thing.

> The "extra" business is about oversizing the shape for later intersection with a cylinder.

Yes, I had to do that too. It’s inevitable if the splines are tilted.

AM

Adrian Mariano

Mon, Nov 18, 2024 3:22 AM

You have to measure the radius of the two polygons by their internal

length, so there is a cos(180/n) or cos(180/2n) factor there. A nice

thing about Bob's approach is that when you project onto a cylinder, you

naturally construct the model at the correct size and shape with the points

on the cylinder, so then if you don't mind a polygonal result (or at larger

tooth counts it really doesn't matter) there's no reason to bother

intersecting with a cylinder. It's already round enough.

On Sun, Nov 17, 2024 at 10:17 PM Caddiy via Discuss <

discuss@lists.openscad.org> wrote:

Adrian Mariano wrote:

Basically you need to figure out at what radius the side length of an

n-gon is exactly double the side length of a 2-n gon at radius R.

That’s interesting. It’s similar to what I was trying to do. I did have

the feeling the problem was caused by a discrepancy somewhere in the

circumference of the thing.

The "extra" business is about oversizing the shape for later intersection

with a cylinder.

Yes, I had to do that too. It’s inevitable if the splines are tilted.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

You have to measure the radius of the two polygons by their internal

length, so there is a cos(180/n) or cos(180/2n) factor there. A nice

thing about Bob's approach is that when you project onto a cylinder, you

naturally construct the model at the correct size and shape with the points

on the cylinder, so then if you don't mind a polygonal result (or at larger

tooth counts it really doesn't matter) there's no reason to bother

intersecting with a cylinder. It's already round enough.

On Sun, Nov 17, 2024 at 10:17 PM Caddiy via Discuss <

discuss@lists.openscad.org> wrote:

> Adrian Mariano wrote:

>

> Basically you need to figure out at what radius the side length of an

> n-gon is exactly double the side length of a 2-n gon at radius R.

>

> That’s interesting. It’s similar to what I was trying to do. I did have

> the feeling the problem was caused by a discrepancy somewhere in the

> circumference of the thing.

>

> The "extra" business is about oversizing the shape for later intersection

> with a cylinder.

>

> Yes, I had to do that too. It’s inevitable if the splines are tilted.

>

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

M

mikeonenine@web.de

Mon, Nov 18, 2024 3:43 AM

You have to measure the radius of the two polygons by their internal

length, so there is a cos(180/n) or cos(180/2n) factor there.

The distance from the centre to the middle of a side rather than to an angle?

A nice thing about Bob's approach is that when you project onto a cylinder, you

naturally construct the model at the correct size and shape with the points

on the cylinder, so then if you don't mind a polygonal result (or at larger

tooth counts it really doesn't matter) there's no reason to bother

intersecting with a cylinder.

It shouldn’t be too difficult to correct for an exact spline angle.

Intersecting with a cylinder is perhaps not the purist’s approach, but it is on a level of proficiency that I can cope with.

Adrian Mariano wrote:

> You have to measure the radius of the two polygons by their internal

> length, so there is a cos(180/n) or cos(180/2n) factor there.

The distance from the centre to the middle of a side rather than to an angle?

> A nice thing about Bob's approach is that when you project onto a cylinder, you \

> naturally construct the model at the correct size and shape with the points \

> on the cylinder, so then if you don't mind a polygonal result (or at larger \

> tooth counts it really doesn't matter) there's no reason to bother \

> intersecting with a cylinder.

It shouldn’t be too difficult to correct for an exact spline angle.

Intersecting with a cylinder is perhaps not the purist’s approach, but it is on a level of proficiency that I can cope with.

AM

Adrian Mariano

Mon, Nov 18, 2024 4:43 AM

Yes, the distances are to the center of the sides, not to corners. Think

about arranging 2n triangles (alternating point up/point down) on a regular

2n-gon. You need the side length of the 2n-gon, which you will want to

compute based on the distance to the center of the side. The rotation is

around the line halfway up the triangle, which is why you want to work

based on distance to center of side and not distance to corner. You then

compute the distance to the regular n-gon as distance to side and that

rotation can then be calculated.

I could not figure out how to make this construction work for nonzero cone

angles. It was one of the reasons I switched to Bob's method. I'm not

sure I agree that this approach is any less "pure."

By correction for spline angle do you mean to create teeth that actually

have the nominal angle? I'm not sure such correction is as easy as you

think, because suppose you say, the triangle is tilted at angle theta, and

therefore I need to apply this certain correction to find the right

adjusted tooth angle. You make this adjustment...and oops, the tilt angle

of the triangle is now different with the new tooth angle. So you still

don't have the desired result.

On Sun, Nov 17, 2024 at 10:43 PM Caddiy via Discuss <

discuss@lists.openscad.org> wrote:

Adrian Mariano wrote:

You have to measure the radius of the two polygons by their internal

length, so there is a cos(180/n) or cos(180/2n) factor there.

The distance from the centre to the middle of a side rather than to an

angle?

A nice thing about Bob's approach is that when you project onto a

cylinder, you

naturally construct the model at the correct size and shape with the

points

on the cylinder, so then if you don't mind a polygonal result (or at

larger

tooth counts it really doesn't matter) there's no reason to bother

intersecting with a cylinder.

It shouldn’t be too difficult to correct for an exact spline angle.

Intersecting with a cylinder is perhaps not the purist’s approach, but it

is on a level of proficiency that I can cope with.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Yes, the distances are to the center of the sides, not to corners. Think

about arranging 2n triangles (alternating point up/point down) on a regular

2n-gon. You need the side length of the 2n-gon, which you will want to

compute based on the distance to the center of the side. The rotation is

around the line halfway up the triangle, which is why you want to work

based on distance to center of side and not distance to corner. You then

compute the distance to the regular n-gon as distance to side and that

rotation can then be calculated.

I could not figure out how to make this construction work for nonzero cone

angles. It was one of the reasons I switched to Bob's method. I'm not

sure I agree that this approach is any less "pure."

By correction for spline angle do you mean to create teeth that actually

have the nominal angle? I'm not sure such correction is as easy as you

think, because suppose you say, the triangle is tilted at angle theta, and

therefore I need to apply this certain correction to find the right

adjusted tooth angle. You make this adjustment...and oops, the tilt angle

of the triangle is now different with the new tooth angle. So you still

don't have the desired result.

On Sun, Nov 17, 2024 at 10:43 PM Caddiy via Discuss <

discuss@lists.openscad.org> wrote:

> Adrian Mariano wrote:

>

> You have to measure the radius of the two polygons by their internal

> length, so there is a cos(180/n) or cos(180/2n) factor there.

>

> The distance from the centre to the middle of a side rather than to an

> angle?

>

> A nice thing about Bob's approach is that when you project onto a

> cylinder, you

> naturally construct the model at the correct size and shape with the

> points

> on the cylinder, so then if you don't mind a polygonal result (or at

> larger

> tooth counts it really doesn't matter) there's no reason to bother

> intersecting with a cylinder.

>

> It shouldn’t be too difficult to correct for an exact spline angle.

>

> Intersecting with a cylinder is perhaps not the purist’s approach, but it

> is on a level of proficiency that I can cope with.

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

RW

Raymond West

Mon, Nov 18, 2024 11:33 AM

On 17/11/2024 21:44, Adrian Mariano via Discuss wrote:

Ray, so if I understand your description, you have the blank you're

grinding mounted at an angle and you then use your 60 deg grinding

wheel to grind the groove, which due to the angled mount, tapers from

full depth at the edge to zero depth in the center. Is that right?

If the answer is yes, then it appears to me that the result is NOT a

60 deg angle on the teeth, because the cutter meets the workpiece at

an angle, the effective tooth angle is modified by that angle at which

the blank is tilted.

Yes, it is is 60 degree perpendicular to the path of the bottom of the

groove. It does not matter in many cases, since two identical units will

still mesh with each other and self centre. Back in the day, if

precision fitting was required, then most likely Prussian blue and hand

scraping would be the requirement. It would be possible to fine adjust

the angle, (increase it) by having the wheel at at a slight angle to the

traversing path (but then you get slightly curved flanks.) Since the

angle of the groove to the centre is shallow, the difference from 60

degree, say, will be small, but could be significant in high load

situations. A simple way to overcome that, with minimum effort, if it is

not essential that both parts have identically shaped mating surfaces,

would be to generate one, and difference from the other, so to speak,

but I don't think that would be a design for a Hirth joint.

Of course, similar 'errors' occur all over the place, thread cutting for

example, where the 60degree thread angle, in many cases, pays no

attention to the thread pitch.

On 17/11/2024 21:44, Adrian Mariano via Discuss wrote:

> Ray, so if I understand your description, you have the blank you're

> grinding mounted at an angle and you then use your 60 deg grinding

> wheel to grind the groove, which due to the angled mount, tapers from

> full depth at the edge to zero depth in the center. Is that right?

> If the answer is yes, then it appears to me that the result is NOT a

> 60 deg angle on the teeth, because the cutter meets the workpiece at

> an angle, the effective tooth angle is modified by that angle at which

> the blank is tilted.

Yes, it is is 60 degree perpendicular to the path of the bottom of the

groove. It does not matter in many cases, since two identical units will

still mesh with each other and self centre. Back in the day, if

precision fitting was required, then most likely Prussian blue and hand

scraping would be the requirement. It would be possible to fine adjust

the angle, (increase it) by having the wheel at at a slight angle to the

traversing path (but then you get slightly curved flanks.) Since the

angle of the groove to the centre is shallow, the difference from 60

degree, say, will be small, but could be significant in high load

situations. A simple way to overcome that, with minimum effort, if it is

not essential that both parts have identically shaped mating surfaces,

would be to generate one, and difference from the other, so to speak,

but I don't think that would be a design for a Hirth joint.

Of course, similar 'errors' occur all over the place, thread cutting for

example, where the 60degree thread angle, in many cases, pays no

attention to the thread pitch.

GH

gene heskett

Mon, Nov 18, 2024 1:54 PM

On 11/18/24 06:33, Raymond West via Discuss wrote:

On 17/11/2024 21:44, Adrian Mariano via Discuss wrote:

Ray, so if I understand your description, you have the blank you're

grinding mounted at an angle and you then use your 60 deg grinding

wheel to grind the groove, which due to the angled mount, tapers from

full depth at the edge to zero depth in the center. Is that right? If

the answer is yes, then it appears to me that the result is NOT a 60

deg angle on the teeth, because the cutter meets the workpiece at an

angle, the effective tooth angle is modified by that angle at which

the blank is tilted.

Yes, it is is 60 degree perpendicular to the path of the bottom of the

groove. It does not matter in many cases, since two identical units will

still mesh with each other and self centre. Back in the day, if

precision fitting was required, then most likely Prussian blue and hand

scraping would be the requirement. It would be possible to fine adjust

the angle, (increase it) by having the wheel at at a slight angle to the

traversing path (but then you get slightly curved flanks.) Since the

angle of the groove to the centre is shallow, the difference from 60

degree, say, will be small, but could be significant in high load

situations. A simple way to overcome that, with minimum effort, if it is

not essential that both parts have identically shaped mating surfaces,

would be to generate one, and difference from the other, so to speak,

but I don't think that would be a design for a Hirth joint.

Of course, similar 'errors' occur all over the place, thread cutting for

example, where the 60degree thread angle, in many cases, pays no

attention to the thread pitch.

This is something I've contemplated in actual machining, where there are

different tools depending on the tpi, but there is quite a broad range

of threads that can be cut with the same carbide chip, in my case from

1/2-13 to something in the 3/8-50 range using G76, including a couple

cases of taper for squeezing a rosette socket onto a ball screw. Been

working that way for a decade+ in my 11x54 Sheldon of WW-II vintage. I

would assume any pitch ramping needed would be incorporated in the

larger tooling I've never acquired. I did early on buy a 60 degree

cutter for bigger holes, but have never used it, lots of math involved

as but it is .750" in diameter. I'd assume a 1" hole would be the

smallest it could cut threads in. Big limited by the Y table of ones

mill. At least 5.5" on my grizzly go704. I have a bigger mill but it

hasn't the torque to turn that thing.

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

On 11/18/24 06:33, Raymond West via Discuss wrote:

>

> On 17/11/2024 21:44, Adrian Mariano via Discuss wrote:

>> Ray, so if I understand your description, you have the blank you're

>> grinding mounted at an angle and you then use your 60 deg grinding

>> wheel to grind the groove, which due to the angled mount, tapers from

>> full depth at the edge to zero depth in the center. Is that right? If

>> the answer is yes, then it appears to me that the result is NOT a 60

>> deg angle on the teeth, because the cutter meets the workpiece at an

>> angle, the effective tooth angle is modified by that angle at which

>> the blank is tilted.

>

>

> Yes, it is is 60 degree perpendicular to the path of the bottom of the

> groove. It does not matter in many cases, since two identical units will

> still mesh with each other and self centre. Back in the day, if

> precision fitting was required, then most likely Prussian blue and hand

> scraping would be the requirement. It would be possible to fine adjust

> the angle, (increase it) by having the wheel at at a slight angle to the

> traversing path (but then you get slightly curved flanks.) Since the

> angle of the groove to the centre is shallow, the difference from 60

> degree, say, will be small, but could be significant in high load

> situations. A simple way to overcome that, with minimum effort, if it is

> not essential that both parts have identically shaped mating surfaces,

> would be to generate one, and difference from the other, so to speak,

> but I don't think that would be a design for a Hirth joint.

>

> Of course, similar 'errors' occur all over the place, thread cutting for

> example, where the 60degree thread angle, in many cases, pays no

> attention to the thread pitch.

>

This is something I've contemplated in actual machining, where there are

different tools depending on the tpi, but there is quite a broad range

of threads that can be cut with the same carbide chip, in my case from

1/2-13 to something in the 3/8-50 range using G76, including a couple

cases of taper for squeezing a rosette socket onto a ball screw. Been

working that way for a decade+ in my 11x54 Sheldon of WW-II vintage. I

would assume any pitch ramping needed would be incorporated in the

larger tooling I've never acquired. I did early on buy a 60 degree

cutter for bigger holes, but have never used it, lots of math involved

as but it is .750" in diameter. I'd assume a 1" hole would be the

smallest it could cut threads in. Big limited by the Y table of ones

mill. At least 5.5" on my grizzly go704. I have a bigger mill but it

hasn't the torque to turn that thing.

Cheers, Gene Heskett, CET.

--

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

JD

John David

Mon, Nov 18, 2024 3:21 PM

Also, as someone had mentioned before, it would be good to be able to

modify the tooth profile so it is rounded at the bottom, and truncated at

the top - this relieves potential stress points on the bottom of the teeth,

and allows a little clearance for dust, etc., on the top, and its mating

surface.

Gene, best of success machining a few. Should be a challenge to set up the

first time, but crankable once the details are worked out. Please share

pictures if you go ahead with machining them.

Cheers!

EBo --

On Mon, Nov 18, 2024 at 8:54 AM gene heskett via Discuss <

discuss@lists.openscad.org> wrote:

On 11/18/24 06:33, Raymond West via Discuss wrote:

On 17/11/2024 21:44, Adrian Mariano via Discuss wrote:

Ray, so if I understand your description, you have the blank you're

grinding mounted at an angle and you then use your 60 deg grinding

wheel to grind the groove, which due to the angled mount, tapers from

full depth at the edge to zero depth in the center. Is that right? If

the answer is yes, then it appears to me that the result is NOT a 60

deg angle on the teeth, because the cutter meets the workpiece at an

angle, the effective tooth angle is modified by that angle at which

the blank is tilted.

Yes, it is is 60 degree perpendicular to the path of the bottom of the

groove. It does not matter in many cases, since two identical units will

still mesh with each other and self centre. Back in the day, if

precision fitting was required, then most likely Prussian blue and hand

scraping would be the requirement. It would be possible to fine adjust

the angle, (increase it) by having the wheel at at a slight angle to the

traversing path (but then you get slightly curved flanks.) Since the

angle of the groove to the centre is shallow, the difference from 60

degree, say, will be small, but could be significant in high load

situations. A simple way to overcome that, with minimum effort, if it is

not essential that both parts have identically shaped mating surfaces,

would be to generate one, and difference from the other, so to speak,

but I don't think that would be a design for a Hirth joint.

Of course, similar 'errors' occur all over the place, thread cutting for

example, where the 60degree thread angle, in many cases, pays no

attention to the thread pitch.

This is something I've contemplated in actual machining, where there are

different tools depending on the tpi, but there is quite a broad range

of threads that can be cut with the same carbide chip, in my case from

1/2-13 to something in the 3/8-50 range using G76, including a couple

cases of taper for squeezing a rosette socket onto a ball screw. Been

working that way for a decade+ in my 11x54 Sheldon of WW-II vintage. I

would assume any pitch ramping needed would be incorporated in the

larger tooling I've never acquired. I did early on buy a 60 degree

cutter for bigger holes, but have never used it, lots of math involved

as but it is .750" in diameter. I'd assume a 1" hole would be the

smallest it could cut threads in. Big limited by the Y table of ones

mill. At least 5.5" on my grizzly go704. I have a bigger mill but it

hasn't the torque to turn that thing.

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Also, as someone had mentioned before, it would be good to be able to

modify the tooth profile so it is rounded at the bottom, and truncated at

the top - this relieves potential stress points on the bottom of the teeth,

and allows a little clearance for dust, etc., on the top, and its mating

surface.

Gene, best of success machining a few. Should be a challenge to set up the

first time, but crankable once the details are worked out. Please share

pictures if you go ahead with machining them.

Cheers!

EBo --

On Mon, Nov 18, 2024 at 8:54 AM gene heskett via Discuss <

discuss@lists.openscad.org> wrote:

> On 11/18/24 06:33, Raymond West via Discuss wrote:

> >

> > On 17/11/2024 21:44, Adrian Mariano via Discuss wrote:

> >> Ray, so if I understand your description, you have the blank you're

> >> grinding mounted at an angle and you then use your 60 deg grinding

> >> wheel to grind the groove, which due to the angled mount, tapers from

> >> full depth at the edge to zero depth in the center. Is that right? If

> >> the answer is yes, then it appears to me that the result is NOT a 60

> >> deg angle on the teeth, because the cutter meets the workpiece at an

> >> angle, the effective tooth angle is modified by that angle at which

> >> the blank is tilted.

> >

> >

> > Yes, it is is 60 degree perpendicular to the path of the bottom of the

> > groove. It does not matter in many cases, since two identical units will

> > still mesh with each other and self centre. Back in the day, if

> > precision fitting was required, then most likely Prussian blue and hand

> > scraping would be the requirement. It would be possible to fine adjust

> > the angle, (increase it) by having the wheel at at a slight angle to the

> > traversing path (but then you get slightly curved flanks.) Since the

> > angle of the groove to the centre is shallow, the difference from 60

> > degree, say, will be small, but could be significant in high load

> > situations. A simple way to overcome that, with minimum effort, if it is

> > not essential that both parts have identically shaped mating surfaces,

> > would be to generate one, and difference from the other, so to speak,

> > but I don't think that would be a design for a Hirth joint.

> >

> > Of course, similar 'errors' occur all over the place, thread cutting for

> > example, where the 60degree thread angle, in many cases, pays no

> > attention to the thread pitch.

> >

> This is something I've contemplated in actual machining, where there are

> different tools depending on the tpi, but there is quite a broad range

> of threads that can be cut with the same carbide chip, in my case from

> 1/2-13 to something in the 3/8-50 range using G76, including a couple

> cases of taper for squeezing a rosette socket onto a ball screw. Been

> working that way for a decade+ in my 11x54 Sheldon of WW-II vintage. I

> would assume any pitch ramping needed would be incorporated in the

> larger tooling I've never acquired. I did early on buy a 60 degree

> cutter for bigger holes, but have never used it, lots of math involved

> as but it is .750" in diameter. I'd assume a 1" hole would be the

> smallest it could cut threads in. Big limited by the Y table of ones

> mill. At least 5.5" on my grizzly go704. I have a bigger mill but it

> hasn't the torque to turn that thing.

>

> Cheers, Gene Heskett, CET.

> --

> "There are four boxes to be used in defense of liberty:

> soap, ballot, jury, and ammo. Please use in that order."

> -Ed Howdershelt (Author, 1940)

> If we desire respect for the law, we must first make the law respectable.

> - Louis D. Brandeis

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

RW

Raymond West

Mon, Nov 18, 2024 6:45 PM

I've done a few extra calculations, and for a slope of 4.2885 degrees

then 60 degrees becomes 59.861 perpendicular to the horizontal. Since

the angles on both pieces will be the same, then afaik, they will still

mesh with the flanks of the teeth contacting each other. The teeth on

the sample that I printed were 90 degrees, and the slope was 2.4881

degrees, which would give a much less change in angle. In practice, for

sharper teeth, then simply flatten the peaks a bit more, if they tend to

bottom out. Fwiw, it is unlikely that I will be building aircraft

engines/whatever, not even for Boeing.

On 18/11/2024 11:33, Raymond West via Discuss wrote:

On 17/11/2024 21:44, Adrian Mariano via Discuss wrote:

Ray, so if I understand your description, you have the blank you're

grinding mounted at an angle and you then use your 60 deg grinding

wheel to grind the groove, which due to the angled mount, tapers from

full depth at the edge to zero depth in the center. Is that right?

If the answer is yes, then it appears to me that the result is NOT a

60 deg angle on the teeth, because the cutter meets the workpiece at

an angle, the effective tooth angle is modified by that angle at

which the blank is tilted.

Yes, it is is 60 degree perpendicular to the path of the bottom of the

groove. It does not matter in many cases, since two identical units

will still mesh with each other and self centre. Back in the day, if

precision fitting was required, then most likely Prussian blue and

hand scraping would be the requirement. It would be possible to fine

adjust the angle, (increase it) by having the wheel at at a slight

angle to the traversing path (but then you get slightly curved

flanks.) Since the angle of the groove to the centre is shallow, the

difference from 60 degree, say, will be small, but could be

significant in high load situations. A simple way to overcome that,

with minimum effort, if it is not essential that both parts have

identically shaped mating surfaces, would be to generate one, and

difference from the other, so to speak, but I don't think that would

be a design for a Hirth joint.

Of course, similar 'errors' occur all over the place, thread cutting

for example, where the 60degree thread angle, in many cases, pays no

attention to the thread pitch.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

I've done a few extra calculations, and for a slope of 4.2885 degrees

then 60 degrees becomes 59.861 perpendicular to the horizontal. Since

the angles on both pieces will be the same, then afaik, they will still

mesh with the flanks of the teeth contacting each other. The teeth on

the sample that I printed were 90 degrees, and the slope was 2.4881

degrees, which would give a much less change in angle. In practice, for

sharper teeth, then simply flatten the peaks a bit more, if they tend to

bottom out. Fwiw, it is unlikely that I will be building aircraft

engines/whatever, not even for Boeing.

On 18/11/2024 11:33, Raymond West via Discuss wrote:

>

> On 17/11/2024 21:44, Adrian Mariano via Discuss wrote:

>> Ray, so if I understand your description, you have the blank you're

>> grinding mounted at an angle and you then use your 60 deg grinding

>> wheel to grind the groove, which due to the angled mount, tapers from

>> full depth at the edge to zero depth in the center. Is that right?

>> If the answer is yes, then it appears to me that the result is NOT a

>> 60 deg angle on the teeth, because the cutter meets the workpiece at

>> an angle, the effective tooth angle is modified by that angle at

>> which the blank is tilted.

>

>

> Yes, it is is 60 degree perpendicular to the path of the bottom of the

> groove. It does not matter in many cases, since two identical units

> will still mesh with each other and self centre. Back in the day, if

> precision fitting was required, then most likely Prussian blue and

> hand scraping would be the requirement. It would be possible to fine

> adjust the angle, (increase it) by having the wheel at at a slight

> angle to the traversing path (but then you get slightly curved

> flanks.) Since the angle of the groove to the centre is shallow, the

> difference from 60 degree, say, will be small, but could be

> significant in high load situations. A simple way to overcome that,

> with minimum effort, if it is not essential that both parts have

> identically shaped mating surfaces, would be to generate one, and

> difference from the other, so to speak, but I don't think that would

> be a design for a Hirth joint.

>

> Of course, similar 'errors' occur all over the place, thread cutting

> for example, where the 60degree thread angle, in many cases, pays no

> attention to the thread pitch.

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

AM

Adrian Mariano

Mon, Nov 18, 2024 9:04 PM

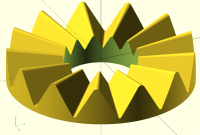

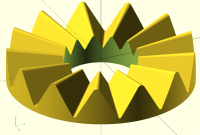

Rounded teeth? You mean like this?

[image: image.png]

As I've said, my code does rounding.

On Mon, Nov 18, 2024 at 10:22 AM John David via Discuss <

discuss@lists.openscad.org> wrote:

Also, as someone had mentioned before, it would be good to be able to

modify the tooth profile so it is rounded at the bottom, and truncated at

the top - this relieves potential stress points on the bottom of the teeth,

and allows a little clearance for dust, etc., on the top, and its mating

surface.

Gene, best of success machining a few. Should be a challenge to set up

the first time, but crankable once the details are worked out. Please

share pictures if you go ahead with machining them.

Cheers!

EBo --

On Mon, Nov 18, 2024 at 8:54 AM gene heskett via Discuss <

discuss@lists.openscad.org> wrote:

On 11/18/24 06:33, Raymond West via Discuss wrote:

On 17/11/2024 21:44, Adrian Mariano via Discuss wrote:

Ray, so if I understand your description, you have the blank you're

grinding mounted at an angle and you then use your 60 deg grinding

wheel to grind the groove, which due to the angled mount, tapers from

full depth at the edge to zero depth in the center. Is that right? If

the answer is yes, then it appears to me that the result is NOT a 60

deg angle on the teeth, because the cutter meets the workpiece at an

angle, the effective tooth angle is modified by that angle at which

the blank is tilted.

Yes, it is is 60 degree perpendicular to the path of the bottom of the

groove. It does not matter in many cases, since two identical units

still mesh with each other and self centre. Back in the day, if

precision fitting was required, then most likely Prussian blue and hand

scraping would be the requirement. It would be possible to fine adjust

the angle, (increase it) by having the wheel at at a slight angle to

traversing path (but then you get slightly curved flanks.) Since the

angle of the groove to the centre is shallow, the difference from 60

degree, say, will be small, but could be significant in high load

situations. A simple way to overcome that, with minimum effort, if it

not essential that both parts have identically shaped mating surfaces,

would be to generate one, and difference from the other, so to speak,

but I don't think that would be a design for a Hirth joint.

Of course, similar 'errors' occur all over the place, thread cutting

example, where the 60degree thread angle, in many cases, pays no

attention to the thread pitch.

This is something I've contemplated in actual machining, where there are

different tools depending on the tpi, but there is quite a broad range

of threads that can be cut with the same carbide chip, in my case from

1/2-13 to something in the 3/8-50 range using G76, including a couple

cases of taper for squeezing a rosette socket onto a ball screw. Been

working that way for a decade+ in my 11x54 Sheldon of WW-II vintage. I

would assume any pitch ramping needed would be incorporated in the

larger tooling I've never acquired. I did early on buy a 60 degree

cutter for bigger holes, but have never used it, lots of math involved

as but it is .750" in diameter. I'd assume a 1" hole would be the

smallest it could cut threads in. Big limited by the Y table of ones

mill. At least 5.5" on my grizzly go704. I have a bigger mill but it

hasn't the torque to turn that thing.

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Rounded teeth? You mean like this?

[image: image.png]

As I've said, my code does rounding.

On Mon, Nov 18, 2024 at 10:22 AM John David via Discuss <

discuss@lists.openscad.org> wrote:

> Also, as someone had mentioned before, it would be good to be able to

> modify the tooth profile so it is rounded at the bottom, and truncated at

> the top - this relieves potential stress points on the bottom of the teeth,

> and allows a little clearance for dust, etc., on the top, and its mating

> surface.

>

> Gene, best of success machining a few. Should be a challenge to set up

> the first time, but crankable once the details are worked out. Please

> share pictures if you go ahead with machining them.

>

> Cheers!

>

> EBo --

>

> On Mon, Nov 18, 2024 at 8:54 AM gene heskett via Discuss <

> discuss@lists.openscad.org> wrote:

>

>> On 11/18/24 06:33, Raymond West via Discuss wrote:

>> >

>> > On 17/11/2024 21:44, Adrian Mariano via Discuss wrote:

>> >> Ray, so if I understand your description, you have the blank you're

>> >> grinding mounted at an angle and you then use your 60 deg grinding

>> >> wheel to grind the groove, which due to the angled mount, tapers from

>> >> full depth at the edge to zero depth in the center. Is that right? If

>> >> the answer is yes, then it appears to me that the result is NOT a 60

>> >> deg angle on the teeth, because the cutter meets the workpiece at an

>> >> angle, the effective tooth angle is modified by that angle at which

>> >> the blank is tilted.

>> >

>> >

>> > Yes, it is is 60 degree perpendicular to the path of the bottom of the

>> > groove. It does not matter in many cases, since two identical units

>> will

>> > still mesh with each other and self centre. Back in the day, if

>> > precision fitting was required, then most likely Prussian blue and hand

>> > scraping would be the requirement. It would be possible to fine adjust

>> > the angle, (increase it) by having the wheel at at a slight angle to

>> the

>> > traversing path (but then you get slightly curved flanks.) Since the

>> > angle of the groove to the centre is shallow, the difference from 60

>> > degree, say, will be small, but could be significant in high load

>> > situations. A simple way to overcome that, with minimum effort, if it

>> is

>> > not essential that both parts have identically shaped mating surfaces,

>> > would be to generate one, and difference from the other, so to speak,

>> > but I don't think that would be a design for a Hirth joint.

>> >

>> > Of course, similar 'errors' occur all over the place, thread cutting

>> for

>> > example, where the 60degree thread angle, in many cases, pays no

>> > attention to the thread pitch.

>> >

>> This is something I've contemplated in actual machining, where there are

>> different tools depending on the tpi, but there is quite a broad range

>> of threads that can be cut with the same carbide chip, in my case from

>> 1/2-13 to something in the 3/8-50 range using G76, including a couple

>> cases of taper for squeezing a rosette socket onto a ball screw. Been

>> working that way for a decade+ in my 11x54 Sheldon of WW-II vintage. I

>> would assume any pitch ramping needed would be incorporated in the

>> larger tooling I've never acquired. I did early on buy a 60 degree

>> cutter for bigger holes, but have never used it, lots of math involved

>> as but it is .750" in diameter. I'd assume a 1" hole would be the

>> smallest it could cut threads in. Big limited by the Y table of ones

>> mill. At least 5.5" on my grizzly go704. I have a bigger mill but it

>> hasn't the torque to turn that thing.

>>

>> Cheers, Gene Heskett, CET.

>> --

>> "There are four boxes to be used in defense of liberty:

>> soap, ballot, jury, and ammo. Please use in that order."

>> -Ed Howdershelt (Author, 1940)

>> If we desire respect for the law, we must first make the law respectable.

>> - Louis D. Brandeis

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>