M

mikeonenine@web.de

Sun, Nov 17, 2024 7:37 AM

I think it's tough to tell what the angles are in the fixed view like that

due to the distortion from perspective. In my code the triangles that form

the teeth are constructed with the specified angle, but then they end up

getting projected at a different angle depending on the cone angle you

pick. Furthermore, there's the question of where the angle is measured. I

think the wikipedia page suggested it is measured relative to the cylinder

axis, but I'd normally expect tooth angle to be measured on the tooth,

which means the slope of the tooth will also lead to a change in the

effective angle. (Maybe this factor is what you're talking about?) I

decided for my implementation to treat the requested angle as "nominal" and

not worry about these various deviations. As long as you pick the same

angle (and other parameters) for both sides of the joint, the parts will

mate. And if you don't like the angle you get---change it.

On Sun, Nov 17, 2024 at 12:15 AM Caddiy via Discuss <

discuss@lists.openscad.org> wrote:

I’ve had a look at some of the codes posted above and actually got one to

work. But the question remains:

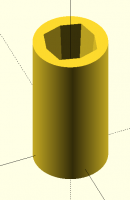

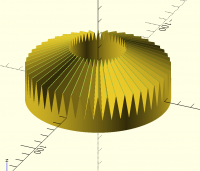

In the image below, 60° triangles parallel to the z-axis linear_extruded

to the origin give an angle of 90° between the flanks of a spline, which

can be seen when one looks along a ridge towards the origin.

Are these then 60° splines or 90° splines?

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Immediately after posting, I thought I should have simply said that the angle between the flanks of a spline viewed perpendicular to the axis of the ring of splines is not the same as the angle around the ridge of the spline = on the tooth. So your guess was right. I too would think that the angle on the tooth would be what counts in practise. Unfortunately, Wikipedia is not very clear on that. I wonder what our resident engineer/machinist would say. Or maybe it’s actually the angle of the cutting tool - that would be the angle between the flanks of adjacent splines? Then only one tool would be needed.

Could be of interest for BOSL, as 60° and 90° seem to be the standard angles, so it would be good to know how/where they are measured. With increasing numbers of splines, the discrepancy between the two frames of reference rapidly decreases.

I have a concept that seems promising, but doing the trigonometry is like trying to swing from tree to tree in a dense jungle in a fog, so I have given up for the time being.

Adrian Mariano wrote:

> I think it's tough to tell what the angles are in the fixed view like that

> due to the distortion from perspective. In my code the triangles that form

> the teeth are constructed with the specified angle, but then they end up

> getting projected at a different angle depending on the cone angle you

> pick. Furthermore, there's the question of where the angle is measured. I

> think the wikipedia page suggested it is measured relative to the cylinder

> axis, but I'd normally expect tooth angle to be measured on the tooth,

> which means the slope of the tooth will also lead to a change in the

> effective angle. (Maybe this factor is what you're talking about?) I

> decided for my implementation to treat the requested angle as "nominal" and

> not worry about these various deviations. As long as you pick the same

> angle (and other parameters) for both sides of the joint, the parts will

> mate. And if you don't like the angle you get---change it.

>

> On Sun, Nov 17, 2024 at 12:15 AM Caddiy via Discuss <

> discuss@lists.openscad.org> wrote:

>

> > I’ve had a look at some of the codes posted above and actually got one to

> > work. But the question remains:

> >

> > In the image below, 60° triangles parallel to the z-axis linear_extruded

> > to the origin give an angle of 90° between the flanks of a spline, which

> > can be seen when one looks along a ridge towards the origin.

> >

> > Are these then 60° splines or 90° splines?

> >

> > ---

> >

> > OpenSCAD mailing list

> > To unsubscribe send an email to discuss-leave@lists.openscad.org

Immediately after posting, I thought I should have simply said that the angle between the flanks of a spline viewed perpendicular to the axis of the ring of splines is not the same as the angle around the ridge of the spline = on the tooth. So your guess was right. I too would think that the angle on the tooth would be what counts in practise. Unfortunately, Wikipedia is not very clear on that. I wonder what our resident engineer/machinist would say. Or maybe it’s actually the angle of the cutting tool - that would be the angle between the flanks of adjacent splines? Then only one tool would be needed.

Could be of interest for BOSL, as 60° and 90° seem to be the standard angles, so it would be good to know how/where they are measured. With increasing numbers of splines, the discrepancy between the two frames of reference rapidly decreases.

I have a concept that seems promising, but doing the trigonometry is like trying to swing from tree to tree in a dense jungle in a fog, so I have given up for the time being.

AM

Adrian Mariano

Sun, Nov 17, 2024 1:16 PM

I did ponder the idea of trying to compute a correction factor to the tooth

angle, but given the uncertainty about what the right angle actually is,

and also uncertainty on my part about how to actually compute that

correction factor, I didn't pursue this idea. Wouldn't angle between

adjacent flanks be equivalent to angle on the tooth, which is basically the

other angle between flanks? In the case of no cone angle these angles

must be the same because the part mates with itself.

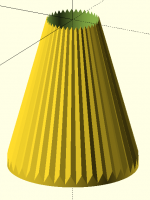

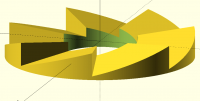

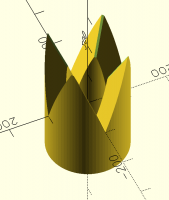

Another thing is that my code supports skewing the teeth so you can make

teeth with one face vertical, for example. This distorts the angle. I

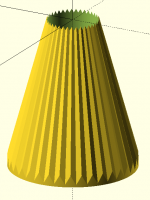

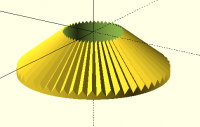

didn't see a compelling reason the angle needs to be "correct". Here an

example of what you get if you ask for 60 degrees with maximal skew:

[image: image.png]

If I change the tooth angle to try to achieve actual 60 deg at the tops I

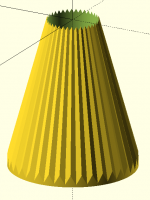

get something like this

[image: image.png]

Note that the tooth height has radically changed. From a design

perspective, I think it's maybe nicer for a user to be able to skew the

teeth while keeping the tooth height fixed, rather than having these

parameters coupled.

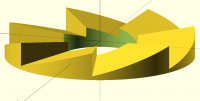

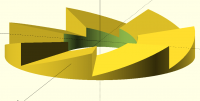

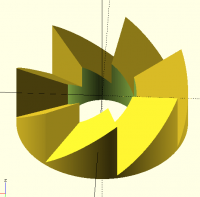

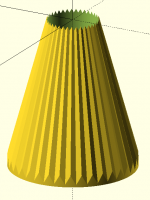

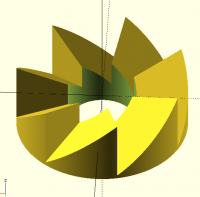

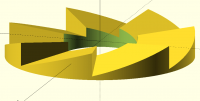

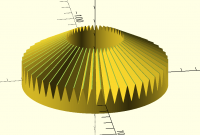

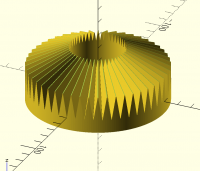

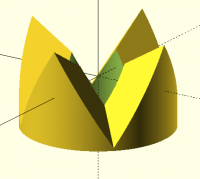

In the case of very high cone angle (here 75 deg), weird stuff happens and

I get shapes like this:

[image: image.png]

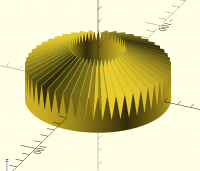

where the adjacent teeth flanks become coplanar, and then if I push cone

angle higher (85 deg here) the "valley" between the teeth becomes a second

ridge

[image: image.png]

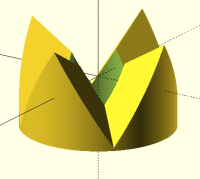

It's not clear if forms like this are useful for anything. The

construction still works, producing a mating shape that looks like this:

[image: image.png]

But clearly the tooth angle measured at the tooth ridge or the complement

of the angle between the flanks is wildly different from the requested 60

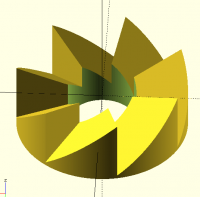

deg. I'll note also that the very high cone angles look less weird when

the tooth count is high, though the tooth angle is still wildly different

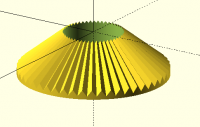

from what was requested. This is 75 deg angle with lots of teeth:

[image: image.png]

I'm not going to show another image, but if I line it up along a ridge by

eye the tooth ridge angle looks like around 120 deg. But note how the

triangles running around the baes actually look like 60 deg triangles.

On Sun, Nov 17, 2024 at 2:38 AM Caddiy via Discuss <

discuss@lists.openscad.org> wrote:

Adrian Mariano wrote:

I think it's tough to tell what the angles are in the fixed view like that

due to the distortion from perspective. In my code the triangles that form

the teeth are constructed with the specified angle, but then they end up

getting projected at a different angle depending on the cone angle you

pick. Furthermore, there's the question of where the angle is measured. I

think the wikipedia page suggested it is measured relative to the cylinder

axis, but I'd normally expect tooth angle to be measured on the tooth,

which means the slope of the tooth will also lead to a change in the

effective angle. (Maybe this factor is what you're talking about?) I

decided for my implementation to treat the requested angle as "nominal" and

not worry about these various deviations. As long as you pick the same

angle (and other parameters) for both sides of the joint, the parts will

mate. And if you don't like the angle you get---change it.

On Sun, Nov 17, 2024 at 12:15 AM Caddiy via Discuss <

discuss@lists.openscad.org> wrote:

I’ve had a look at some of the codes posted above and actually got one to

work. But the question remains:

In the image below, 60° triangles parallel to the z-axis linear_extruded

to the origin give an angle of 90° between the flanks of a spline, which

can be seen when one looks along a ridge towards the origin.

Are these then 60° splines or 90° splines?

OpenSCAD mailing list To unsubscribe send an email to

discuss-leave@lists.openscad.org

Immediately after posting, I thought I should have simply said that the

angle between the flanks of a spline viewed perpendicular to the axis of

the ring of splines is not the same as the angle around the ridge of the

spline = on the tooth. So your guess was right. I too would think that the

angle on the tooth would be what counts in practise. Unfortunately,

Wikipedia is not very clear on that. I wonder what our resident

engineer/machinist would say. Or maybe it’s actually the angle of the

cutting tool - that would be the angle between the flanks of adjacent

splines? Then only one tool would be needed.

Could be of interest for BOSL, as 60° and 90° seem to be the standard

angles, so it would be good to know how/where they are measured. With

increasing numbers of splines, the discrepancy between the two frames of

reference rapidly decreases.

I have a concept that seems promising, but doing the trigonometry is like

trying to swing from tree to tree in a dense jungle in a fog, so I have

given up for the time being.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

I did ponder the idea of trying to compute a correction factor to the tooth

angle, but given the uncertainty about what the right angle actually is,

and also uncertainty on my part about how to actually compute that

correction factor, I didn't pursue this idea. Wouldn't angle between

adjacent flanks be equivalent to angle on the tooth, which is basically the

other angle between flanks? In the case of no cone angle these angles

must be the same because the part mates with itself.

Another thing is that my code supports skewing the teeth so you can make

teeth with one face vertical, for example. This distorts the angle. I

didn't see a compelling reason the angle needs to be "correct". Here an

example of what you get if you ask for 60 degrees with maximal skew:

[image: image.png]

If I change the tooth angle to try to achieve actual 60 deg at the tops I

get something like this

[image: image.png]

Note that the tooth height has radically changed. From a design

perspective, I think it's maybe nicer for a user to be able to skew the

teeth while keeping the tooth height fixed, rather than having these

parameters coupled.

In the case of very high cone angle (here 75 deg), weird stuff happens and

I get shapes like this:

[image: image.png]

where the adjacent teeth flanks become coplanar, and then if I push cone

angle higher (85 deg here) the "valley" between the teeth becomes a second

ridge

[image: image.png]

It's not clear if forms like this are useful for anything. The

construction still works, producing a mating shape that looks like this:

[image: image.png]

But clearly the tooth angle measured at the tooth ridge or the complement

of the angle between the flanks is wildly different from the requested 60

deg. I'll note also that the very high cone angles look less weird when

the tooth count is high, though the tooth angle is still wildly different

from what was requested. This is 75 deg angle with lots of teeth:

[image: image.png]

I'm not going to show another image, but if I line it up along a ridge by

eye the tooth ridge angle looks like around 120 deg. But note how the

triangles running around the baes actually look like 60 deg triangles.

On Sun, Nov 17, 2024 at 2:38 AM Caddiy via Discuss <

discuss@lists.openscad.org> wrote:

> Adrian Mariano wrote:

>

> I think it's tough to tell what the angles are in the fixed view like that

> due to the distortion from perspective. In my code the triangles that form

> the teeth are constructed with the specified angle, but then they end up

> getting projected at a different angle depending on the cone angle you

> pick. Furthermore, there's the question of where the angle is measured. I

> think the wikipedia page suggested it is measured relative to the cylinder

> axis, but I'd normally expect tooth angle to be measured on the tooth,

> which means the slope of the tooth will also lead to a change in the

> effective angle. (Maybe this factor is what you're talking about?) I

> decided for my implementation to treat the requested angle as "nominal" and

> not worry about these various deviations. As long as you pick the same

> angle (and other parameters) for both sides of the joint, the parts will

> mate. And if you don't like the angle you get---change it.

>

> On Sun, Nov 17, 2024 at 12:15 AM Caddiy via Discuss <

> discuss@lists.openscad.org> wrote:

>

> I’ve had a look at some of the codes posted above and actually got one to

> work. But the question remains:

>

> In the image below, 60° triangles parallel to the z-axis linear_extruded

> to the origin give an angle of 90° between the flanks of a spline, which

> can be seen when one looks along a ridge towards the origin.

>

> Are these then 60° splines or 90° splines?

> ------------------------------

>

> OpenSCAD mailing list To unsubscribe send an email to

> discuss-leave@lists.openscad.org

>

> Immediately after posting, I thought I should have simply said that the

> angle between the flanks of a spline viewed perpendicular to the axis of

> the ring of splines is not the same as the angle around the ridge of the

> spline = on the tooth. So your guess was right. I too would think that the

> angle on the tooth would be what counts in practise. Unfortunately,

> Wikipedia is not very clear on that. I wonder what our resident

> engineer/machinist would say. Or maybe it’s actually the angle of the

> cutting tool - that would be the angle between the flanks of adjacent

> splines? Then only one tool would be needed.

>

> Could be of interest for BOSL, as 60° and 90° seem to be the standard

> angles, so it would be good to know how/where they are measured. With

> increasing numbers of splines, the discrepancy between the two frames of

> reference rapidly decreases.

>

> I have a concept that seems promising, but doing the trigonometry is like

> trying to swing from tree to tree in a dense jungle in a fog, so I have

> given up for the time being.

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

MM

Michael Möller

Sun, Nov 17, 2024 1:22 PM

I did ponder the idea of trying to compute a correction factor to the

tooth angle, but given the uncertainty about what the right angle actually

is, and also uncertainty on my part about how to actually compute that

correction factor, I didn't pursue this idea. Wouldn't angle between

adjacent flanks be equivalent to angle on the tooth, which is basically the

other angle between flanks? In the case of no cone angle these angles

must be the same because the part mates with itself.

Another thing is that my code supports skewing the teeth so you can make

teeth with one face vertical, for example. This distorts the angle. I

didn't see a compelling reason the angle needs to be "correct". Here an

example of what you get if you ask for 60 degrees with maximal skew:

[image: image.png]

If I change the tooth angle to try to achieve actual 60 deg at the tops I

get something like this

[image: image.png]

Note that the tooth height has radically changed. From a design

perspective, I think it's maybe nicer for a user to be able to skew the

teeth while keeping the tooth height fixed, rather than having these

parameters coupled.

In the case of very high cone angle (here 75 deg), weird stuff happens and

I get shapes like this:

[image: image.png]

where the adjacent teeth flanks become coplanar, and then if I push cone

angle higher (85 deg here) the "valley" between the teeth becomes a second

ridge

[image: image.png]

It's not clear if forms like this are useful for anything. The

construction still works, producing a mating shape that looks like this:

[image: image.png]

But clearly the tooth angle measured at the tooth ridge or the complement

of the angle between the flanks is wildly different from the requested 60

deg. I'll note also that the very high cone angles look less weird when

the tooth count is high, though the tooth angle is still wildly different

from what was requested. This is 75 deg angle with lots of teeth:

[image: image.png]

I'm not going to show another image, but if I line it up along a ridge by

eye the tooth ridge angle looks like around 120 deg. But note how the

triangles running around the baes actually look like 60 deg triangles.

On Sun, Nov 17, 2024 at 2:38 AM Caddiy via Discuss <

discuss@lists.openscad.org> wrote:

Adrian Mariano wrote:

I think it's tough to tell what the angles are in the fixed view like

that due to the distortion from perspective. In my code the triangles that

form the teeth are constructed with the specified angle, but then they end

up getting projected at a different angle depending on the cone angle you

pick. Furthermore, there's the question of where the angle is measured. I

think the wikipedia page suggested it is measured relative to the cylinder

axis, but I'd normally expect tooth angle to be measured on the tooth,

which means the slope of the tooth will also lead to a change in the

effective angle. (Maybe this factor is what you're talking about?) I

decided for my implementation to treat the requested angle as "nominal" and

not worry about these various deviations. As long as you pick the same

angle (and other parameters) for both sides of the joint, the parts will

mate. And if you don't like the angle you get---change it.

On Sun, Nov 17, 2024 at 12:15 AM Caddiy via Discuss <

discuss@lists.openscad.org> wrote:

I’ve had a look at some of the codes posted above and actually got one to

work. But the question remains:

In the image below, 60° triangles parallel to the z-axis linear_extruded

to the origin give an angle of 90° between the flanks of a spline, which

can be seen when one looks along a ridge towards the origin.

Are these then 60° splines or 90° splines?

OpenSCAD mailing list To unsubscribe send an email to

discuss-leave@lists.openscad.org

Immediately after posting, I thought I should have simply said that the

angle between the flanks of a spline viewed perpendicular to the axis of

the ring of splines is not the same as the angle around the ridge of the

spline = on the tooth. So your guess was right. I too would think that the

angle on the tooth would be what counts in practise. Unfortunately,

Wikipedia is not very clear on that. I wonder what our resident

engineer/machinist would say. Or maybe it’s actually the angle of the

cutting tool - that would be the angle between the flanks of adjacent

splines? Then only one tool would be needed.

Could be of interest for BOSL, as 60° and 90° seem to be the standard

angles, so it would be good to know how/where they are measured. With

increasing numbers of splines, the discrepancy between the two frames of

reference rapidly decreases.

I have a concept that seems promising, but doing the trigonometry is like

trying to swing from tree to tree in a dense jungle in a fog, so I have

given up for the time being.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

søn. 17. nov. 2024 14.17 skrev Adrian Mariano via Discuss <

discuss@lists.openscad.org>:

> I did ponder the idea of trying to compute a correction factor to the

> tooth angle, but given the uncertainty about what the right angle actually

> is, and also uncertainty on my part about how to actually compute that

> correction factor, I didn't pursue this idea. Wouldn't angle between

> adjacent flanks be equivalent to angle on the tooth, which is basically the

> other angle between flanks? In the case of no cone angle these angles

> must be the same because the part mates with itself.

>

> Another thing is that my code supports skewing the teeth so you can make

> teeth with one face vertical, for example. This distorts the angle. I

> didn't see a compelling reason the angle needs to be "correct". Here an

> example of what you get if you ask for 60 degrees with maximal skew:

>

> [image: image.png]

> If I change the tooth angle to try to achieve actual 60 deg at the tops I

> get something like this

>

> [image: image.png]

> Note that the tooth height has radically changed. From a design

> perspective, I think it's maybe nicer for a user to be able to skew the

> teeth while keeping the tooth height fixed, rather than having these

> parameters coupled.

>

> In the case of very high cone angle (here 75 deg), weird stuff happens and

> I get shapes like this:

>

> [image: image.png]

> where the adjacent teeth flanks become coplanar, and then if I push cone

> angle higher (85 deg here) the "valley" between the teeth becomes a second

> ridge

>

> [image: image.png]

> It's not clear if forms like this are useful for anything. The

> construction still works, producing a mating shape that looks like this:

>

> [image: image.png]

> But clearly the tooth angle measured at the tooth ridge or the complement

> of the angle between the flanks is wildly different from the requested 60

> deg. I'll note also that the very high cone angles look less weird when

> the tooth count is high, though the tooth angle is still wildly different

> from what was requested. This is 75 deg angle with lots of teeth:

>

> [image: image.png]

> I'm not going to show another image, but if I line it up along a ridge by

> eye the tooth ridge angle looks like around 120 deg. But note how the

> triangles running around the baes actually look like 60 deg triangles.

>

> On Sun, Nov 17, 2024 at 2:38 AM Caddiy via Discuss <

> discuss@lists.openscad.org> wrote:

>

>> Adrian Mariano wrote:

>>

>> I think it's tough to tell what the angles are in the fixed view like

>> that due to the distortion from perspective. In my code the triangles that

>> form the teeth are constructed with the specified angle, but then they end

>> up getting projected at a different angle depending on the cone angle you

>> pick. Furthermore, there's the question of where the angle is measured. I

>> think the wikipedia page suggested it is measured relative to the cylinder

>> axis, but I'd normally expect tooth angle to be measured on the tooth,

>> which means the slope of the tooth will also lead to a change in the

>> effective angle. (Maybe this factor is what you're talking about?) I

>> decided for my implementation to treat the requested angle as "nominal" and

>> not worry about these various deviations. As long as you pick the same

>> angle (and other parameters) for both sides of the joint, the parts will

>> mate. And if you don't like the angle you get---change it.

>>

>> On Sun, Nov 17, 2024 at 12:15 AM Caddiy via Discuss <

>> discuss@lists.openscad.org> wrote:

>>

>> I’ve had a look at some of the codes posted above and actually got one to

>> work. But the question remains:

>>

>> In the image below, 60° triangles parallel to the z-axis linear_extruded

>> to the origin give an angle of 90° between the flanks of a spline, which

>> can be seen when one looks along a ridge towards the origin.

>>

>> Are these then 60° splines or 90° splines?

>> ------------------------------

>>

>> OpenSCAD mailing list To unsubscribe send an email to

>> discuss-leave@lists.openscad.org

>>

>> Immediately after posting, I thought I should have simply said that the

>> angle between the flanks of a spline viewed perpendicular to the axis of

>> the ring of splines is not the same as the angle around the ridge of the

>> spline = on the tooth. So your guess was right. I too would think that the

>> angle on the tooth would be what counts in practise. Unfortunately,

>> Wikipedia is not very clear on that. I wonder what our resident

>> engineer/machinist would say. Or maybe it’s actually the angle of the

>> cutting tool - that would be the angle between the flanks of adjacent

>> splines? Then only one tool would be needed.

>>

>> Could be of interest for BOSL, as 60° and 90° seem to be the standard

>> angles, so it would be good to know how/where they are measured. With

>> increasing numbers of splines, the discrepancy between the two frames of

>> reference rapidly decreases.

>>

>> I have a concept that seems promising, but doing the trigonometry is like

>> trying to swing from tree to tree in a dense jungle in a fog, so I have

>> given up for the time being.

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

MM

Michael Möller

Sun, Nov 17, 2024 1:23 PM

I did ponder the idea of trying to compute a correction factor to the

tooth angle, but given the uncertainty about what the right angle actually

is, and also uncertainty on my part about how to actually compute that

correction factor, I didn't pursue this idea. Wouldn't angle between

adjacent flanks be equivalent to angle on the tooth, which is basically the

other angle between flanks? In the case of no cone angle these angles

must be the same because the part mates with itself.

Another thing is that my code supports skewing the teeth so you can make

teeth with one face vertical, for example. This distorts the angle. I

didn't see a compelling reason the angle needs to be "correct". Here an

example of what you get if you ask for 60 degrees with maximal skew:

[image: image.png]

If I change the tooth angle to try to achieve actual 60 deg at the tops I

get something like this

[image: image.png]

Note that the tooth height has radically changed. From a design

perspective, I think it's maybe nicer for a user to be able to skew the

teeth while keeping the tooth height fixed, rather than having these

parameters coupled.

In the case of very high cone angle (here 75 deg), weird stuff happens

and I get shapes like this:

[image: image.png]

where the adjacent teeth flanks become coplanar, and then if I push cone

angle higher (85 deg here) the "valley" between the teeth becomes a second

ridge

[image: image.png]

It's not clear if forms like this are useful for anything. The

construction still works, producing a mating shape that looks like this:

[image: image.png]

But clearly the tooth angle measured at the tooth ridge or the complement

of the angle between the flanks is wildly different from the requested 60

deg. I'll note also that the very high cone angles look less weird when

the tooth count is high, though the tooth angle is still wildly different

from what was requested. This is 75 deg angle with lots of teeth:

[image: image.png]

I'm not going to show another image, but if I line it up along a ridge by

eye the tooth ridge angle looks like around 120 deg. But note how the

triangles running around the baes actually look like 60 deg triangles.

On Sun, Nov 17, 2024 at 2:38 AM Caddiy via Discuss <

discuss@lists.openscad.org> wrote:

Adrian Mariano wrote:

I think it's tough to tell what the angles are in the fixed view like

that due to the distortion from perspective. In my code the triangles that

form the teeth are constructed with the specified angle, but then they end

up getting projected at a different angle depending on the cone angle you

pick. Furthermore, there's the question of where the angle is measured. I

think the wikipedia page suggested it is measured relative to the cylinder

axis, but I'd normally expect tooth angle to be measured on the tooth,

which means the slope of the tooth will also lead to a change in the

effective angle. (Maybe this factor is what you're talking about?) I

decided for my implementation to treat the requested angle as "nominal" and

not worry about these various deviations. As long as you pick the same

angle (and other parameters) for both sides of the joint, the parts will

mate. And if you don't like the angle you get---change it.

On Sun, Nov 17, 2024 at 12:15 AM Caddiy via Discuss <

discuss@lists.openscad.org> wrote:

I’ve had a look at some of the codes posted above and actually got one

to work. But the question remains:

In the image below, 60° triangles parallel to the z-axis linear_extruded

to the origin give an angle of 90° between the flanks of a spline, which

can be seen when one looks along a ridge towards the origin.

Are these then 60° splines or 90° splines?

OpenSCAD mailing list To unsubscribe send an email to

discuss-leave@lists.openscad.org

Immediately after posting, I thought I should have simply said that the

angle between the flanks of a spline viewed perpendicular to the axis of

the ring of splines is not the same as the angle around the ridge of the

spline = on the tooth. So your guess was right. I too would think that the

angle on the tooth would be what counts in practise. Unfortunately,

Wikipedia is not very clear on that. I wonder what our resident

engineer/machinist would say. Or maybe it’s actually the angle of the

cutting tool - that would be the angle between the flanks of adjacent

splines? Then only one tool would be needed.

Could be of interest for BOSL, as 60° and 90° seem to be the standard

angles, so it would be good to know how/where they are measured. With

increasing numbers of splines, the discrepancy between the two frames of

reference rapidly decreases.

I have a concept that seems promising, but doing the trigonometry is

like trying to swing from tree to tree in a dense jungle in a fog, so I

have given up for the time being.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

søn. 17. nov. 2024 14.22 skrev Michael Möller <private2michael@gmail.com>:

>

>

>

> søn. 17. nov. 2024 14.17 skrev Adrian Mariano via Discuss <

> discuss@lists.openscad.org>:

>

>> I did ponder the idea of trying to compute a correction factor to the

>> tooth angle, but given the uncertainty about what the right angle actually

>> is, and also uncertainty on my part about how to actually compute that

>> correction factor, I didn't pursue this idea. Wouldn't angle between

>> adjacent flanks be equivalent to angle on the tooth, which is basically the

>> other angle between flanks? In the case of no cone angle these angles

>> must be the same because the part mates with itself.

>>

>> Another thing is that my code supports skewing the teeth so you can make

>> teeth with one face vertical, for example. This distorts the angle. I

>> didn't see a compelling reason the angle needs to be "correct". Here an

>> example of what you get if you ask for 60 degrees with maximal skew:

>>

>> [image: image.png]

>> If I change the tooth angle to try to achieve actual 60 deg at the tops I

>> get something like this

>>

>> [image: image.png]

>> Note that the tooth height has radically changed. From a design

>> perspective, I think it's maybe nicer for a user to be able to skew the

>> teeth while keeping the tooth height fixed, rather than having these

>> parameters coupled.

>>

>> In the case of very high cone angle (here 75 deg), weird stuff happens

>> and I get shapes like this:

>>

>> [image: image.png]

>> where the adjacent teeth flanks become coplanar, and then if I push cone

>> angle higher (85 deg here) the "valley" between the teeth becomes a second

>> ridge

>>

>> [image: image.png]

>> It's not clear if forms like this are useful for anything. The

>> construction still works, producing a mating shape that looks like this:

>>

>> [image: image.png]

>> But clearly the tooth angle measured at the tooth ridge or the complement

>> of the angle between the flanks is wildly different from the requested 60

>> deg. I'll note also that the very high cone angles look less weird when

>> the tooth count is high, though the tooth angle is still wildly different

>> from what was requested. This is 75 deg angle with lots of teeth:

>>

>> [image: image.png]

>> I'm not going to show another image, but if I line it up along a ridge by

>> eye the tooth ridge angle looks like around 120 deg. But note how the

>> triangles running around the baes actually look like 60 deg triangles.

>>

>> On Sun, Nov 17, 2024 at 2:38 AM Caddiy via Discuss <

>> discuss@lists.openscad.org> wrote:

>>

>>> Adrian Mariano wrote:

>>>

>>> I think it's tough to tell what the angles are in the fixed view like

>>> that due to the distortion from perspective. In my code the triangles that

>>> form the teeth are constructed with the specified angle, but then they end

>>> up getting projected at a different angle depending on the cone angle you

>>> pick. Furthermore, there's the question of where the angle is measured. I

>>> think the wikipedia page suggested it is measured relative to the cylinder

>>> axis, but I'd normally expect tooth angle to be measured on the tooth,

>>> which means the slope of the tooth will also lead to a change in the

>>> effective angle. (Maybe this factor is what you're talking about?) I

>>> decided for my implementation to treat the requested angle as "nominal" and

>>> not worry about these various deviations. As long as you pick the same

>>> angle (and other parameters) for both sides of the joint, the parts will

>>> mate. And if you don't like the angle you get---change it.

>>>

>>> On Sun, Nov 17, 2024 at 12:15 AM Caddiy via Discuss <

>>> discuss@lists.openscad.org> wrote:

>>>

>>> I’ve had a look at some of the codes posted above and actually got one

>>> to work. But the question remains:

>>>

>>> In the image below, 60° triangles parallel to the z-axis linear_extruded

>>> to the origin give an angle of 90° between the flanks of a spline, which

>>> can be seen when one looks along a ridge towards the origin.

>>>

>>> Are these then 60° splines or 90° splines?

>>> ------------------------------

>>>

>>> OpenSCAD mailing list To unsubscribe send an email to

>>> discuss-leave@lists.openscad.org

>>>

>>> Immediately after posting, I thought I should have simply said that the

>>> angle between the flanks of a spline viewed perpendicular to the axis of

>>> the ring of splines is not the same as the angle around the ridge of the

>>> spline = on the tooth. So your guess was right. I too would think that the

>>> angle on the tooth would be what counts in practise. Unfortunately,

>>> Wikipedia is not very clear on that. I wonder what our resident

>>> engineer/machinist would say. Or maybe it’s actually the angle of the

>>> cutting tool - that would be the angle between the flanks of adjacent

>>> splines? Then only one tool would be needed.

>>>

>>> Could be of interest for BOSL, as 60° and 90° seem to be the standard

>>> angles, so it would be good to know how/where they are measured. With

>>> increasing numbers of splines, the discrepancy between the two frames of

>>> reference rapidly decreases.

>>>

>>> I have a concept that seems promising, but doing the trigonometry is

>>> like trying to swing from tree to tree in a dense jungle in a fog, so I

>>> have given up for the time being.

>>> _______________________________________________

>>> OpenSCAD mailing list

>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

>

SP

Sanjeev Prabhakar

Sun, Nov 17, 2024 1:43 PM

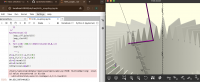

with 75 deg tooth angle 10 deg cone angle

[image: Screenshot 2024-11-17 at 7.03.48 PM.png]

with 80 deg tooth angle and 10 deg cone angle (lot of distortion)

[image: Screenshot 2024-11-17 at 7.11.04 PM.png]

On Sun, 17 Nov 2024 at 18:47, Adrian Mariano via Discuss <

discuss@lists.openscad.org> wrote:

I did ponder the idea of trying to compute a correction factor to the

tooth angle, but given the uncertainty about what the right angle actually

is, and also uncertainty on my part about how to actually compute that

correction factor, I didn't pursue this idea. Wouldn't angle between

adjacent flanks be equivalent to angle on the tooth, which is basically the

other angle between flanks? In the case of no cone angle these angles

must be the same because the part mates with itself.

Another thing is that my code supports skewing the teeth so you can make

teeth with one face vertical, for example. This distorts the angle. I

didn't see a compelling reason the angle needs to be "correct". Here an

example of what you get if you ask for 60 degrees with maximal skew:

[image: image.png]

If I change the tooth angle to try to achieve actual 60 deg at the tops I

get something like this

[image: image.png]

Note that the tooth height has radically changed. From a design

perspective, I think it's maybe nicer for a user to be able to skew the

teeth while keeping the tooth height fixed, rather than having these

parameters coupled.

In the case of very high cone angle (here 75 deg), weird stuff happens and

I get shapes like this:

[image: image.png]

where the adjacent teeth flanks become coplanar, and then if I push cone

angle higher (85 deg here) the "valley" between the teeth becomes a second

ridge

[image: image.png]

It's not clear if forms like this are useful for anything. The

construction still works, producing a mating shape that looks like this:

[image: image.png]

But clearly the tooth angle measured at the tooth ridge or the complement

of the angle between the flanks is wildly different from the requested 60

deg. I'll note also that the very high cone angles look less weird when

the tooth count is high, though the tooth angle is still wildly different

from what was requested. This is 75 deg angle with lots of teeth:

[image: image.png]

I'm not going to show another image, but if I line it up along a ridge by

eye the tooth ridge angle looks like around 120 deg. But note how the

triangles running around the baes actually look like 60 deg triangles.

On Sun, Nov 17, 2024 at 2:38 AM Caddiy via Discuss <

discuss@lists.openscad.org> wrote:

Adrian Mariano wrote:

I think it's tough to tell what the angles are in the fixed view like

that due to the distortion from perspective. In my code the triangles that

form the teeth are constructed with the specified angle, but then they end

up getting projected at a different angle depending on the cone angle you

pick. Furthermore, there's the question of where the angle is measured. I

think the wikipedia page suggested it is measured relative to the cylinder

axis, but I'd normally expect tooth angle to be measured on the tooth,

which means the slope of the tooth will also lead to a change in the

effective angle. (Maybe this factor is what you're talking about?) I

decided for my implementation to treat the requested angle as "nominal" and

not worry about these various deviations. As long as you pick the same

angle (and other parameters) for both sides of the joint, the parts will

mate. And if you don't like the angle you get---change it.

On Sun, Nov 17, 2024 at 12:15 AM Caddiy via Discuss <

discuss@lists.openscad.org> wrote:

I’ve had a look at some of the codes posted above and actually got one to

work. But the question remains:

In the image below, 60° triangles parallel to the z-axis linear_extruded

to the origin give an angle of 90° between the flanks of a spline, which

can be seen when one looks along a ridge towards the origin.

Are these then 60° splines or 90° splines?

OpenSCAD mailing list To unsubscribe send an email to

discuss-leave@lists.openscad.org

Immediately after posting, I thought I should have simply said that the

angle between the flanks of a spline viewed perpendicular to the axis of

the ring of splines is not the same as the angle around the ridge of the

spline = on the tooth. So your guess was right. I too would think that the

angle on the tooth would be what counts in practise. Unfortunately,

Wikipedia is not very clear on that. I wonder what our resident

engineer/machinist would say. Or maybe it’s actually the angle of the

cutting tool - that would be the angle between the flanks of adjacent

splines? Then only one tool would be needed.

Could be of interest for BOSL, as 60° and 90° seem to be the standard

angles, so it would be good to know how/where they are measured. With

increasing numbers of splines, the discrepancy between the two frames of

reference rapidly decreases.

I have a concept that seems promising, but doing the trigonometry is like

trying to swing from tree to tree in a dense jungle in a fog, so I have

given up for the time being.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

with 75 deg tooth angle 10 deg cone angle

[image: Screenshot 2024-11-17 at 7.03.48 PM.png]

with 80 deg tooth angle and 10 deg cone angle (lot of distortion)

[image: Screenshot 2024-11-17 at 7.11.04 PM.png]

On Sun, 17 Nov 2024 at 18:47, Adrian Mariano via Discuss <

discuss@lists.openscad.org> wrote:

> I did ponder the idea of trying to compute a correction factor to the

> tooth angle, but given the uncertainty about what the right angle actually

> is, and also uncertainty on my part about how to actually compute that

> correction factor, I didn't pursue this idea. Wouldn't angle between

> adjacent flanks be equivalent to angle on the tooth, which is basically the

> other angle between flanks? In the case of no cone angle these angles

> must be the same because the part mates with itself.

>

> Another thing is that my code supports skewing the teeth so you can make

> teeth with one face vertical, for example. This distorts the angle. I

> didn't see a compelling reason the angle needs to be "correct". Here an

> example of what you get if you ask for 60 degrees with maximal skew:

>

> [image: image.png]

> If I change the tooth angle to try to achieve actual 60 deg at the tops I

> get something like this

>

> [image: image.png]

> Note that the tooth height has radically changed. From a design

> perspective, I think it's maybe nicer for a user to be able to skew the

> teeth while keeping the tooth height fixed, rather than having these

> parameters coupled.

>

> In the case of very high cone angle (here 75 deg), weird stuff happens and

> I get shapes like this:

>

> [image: image.png]

> where the adjacent teeth flanks become coplanar, and then if I push cone

> angle higher (85 deg here) the "valley" between the teeth becomes a second

> ridge

>

> [image: image.png]

> It's not clear if forms like this are useful for anything. The

> construction still works, producing a mating shape that looks like this:

>

> [image: image.png]

> But clearly the tooth angle measured at the tooth ridge or the complement

> of the angle between the flanks is wildly different from the requested 60

> deg. I'll note also that the very high cone angles look less weird when

> the tooth count is high, though the tooth angle is still wildly different

> from what was requested. This is 75 deg angle with lots of teeth:

>

> [image: image.png]

> I'm not going to show another image, but if I line it up along a ridge by

> eye the tooth ridge angle looks like around 120 deg. But note how the

> triangles running around the baes actually look like 60 deg triangles.

>

> On Sun, Nov 17, 2024 at 2:38 AM Caddiy via Discuss <

> discuss@lists.openscad.org> wrote:

>

>> Adrian Mariano wrote:

>>

>> I think it's tough to tell what the angles are in the fixed view like

>> that due to the distortion from perspective. In my code the triangles that

>> form the teeth are constructed with the specified angle, but then they end

>> up getting projected at a different angle depending on the cone angle you

>> pick. Furthermore, there's the question of where the angle is measured. I

>> think the wikipedia page suggested it is measured relative to the cylinder

>> axis, but I'd normally expect tooth angle to be measured on the tooth,

>> which means the slope of the tooth will also lead to a change in the

>> effective angle. (Maybe this factor is what you're talking about?) I

>> decided for my implementation to treat the requested angle as "nominal" and

>> not worry about these various deviations. As long as you pick the same

>> angle (and other parameters) for both sides of the joint, the parts will

>> mate. And if you don't like the angle you get---change it.

>>

>> On Sun, Nov 17, 2024 at 12:15 AM Caddiy via Discuss <

>> discuss@lists.openscad.org> wrote:

>>

>> I’ve had a look at some of the codes posted above and actually got one to

>> work. But the question remains:

>>

>> In the image below, 60° triangles parallel to the z-axis linear_extruded

>> to the origin give an angle of 90° between the flanks of a spline, which

>> can be seen when one looks along a ridge towards the origin.

>>

>> Are these then 60° splines or 90° splines?

>> ------------------------------

>>

>> OpenSCAD mailing list To unsubscribe send an email to

>> discuss-leave@lists.openscad.org

>>

>> Immediately after posting, I thought I should have simply said that the

>> angle between the flanks of a spline viewed perpendicular to the axis of

>> the ring of splines is not the same as the angle around the ridge of the

>> spline = on the tooth. So your guess was right. I too would think that the

>> angle on the tooth would be what counts in practise. Unfortunately,

>> Wikipedia is not very clear on that. I wonder what our resident

>> engineer/machinist would say. Or maybe it’s actually the angle of the

>> cutting tool - that would be the angle between the flanks of adjacent

>> splines? Then only one tool would be needed.

>>

>> Could be of interest for BOSL, as 60° and 90° seem to be the standard

>> angles, so it would be good to know how/where they are measured. With

>> increasing numbers of splines, the discrepancy between the two frames of

>> reference rapidly decreases.

>>

>> I have a concept that seems promising, but doing the trigonometry is like

>> trying to swing from tree to tree in a dense jungle in a fog, so I have

>> given up for the time being.

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

SP

Sanjeev Prabhakar

Sun, Nov 17, 2024 2:01 PM

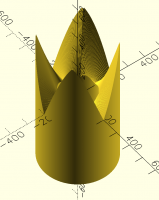

50 teeth cone angle 40 deg tooth angle 75 deg

[image: Screenshot 2024-11-17 at 7.29.01 PM.png]

50 teeth cone angle 40 deg tooth angle 75 deg

[image: Screenshot 2024-11-17 at 7.29.01 PM.png]

SP

Sanjeev Prabhakar

Sun, Nov 17, 2024 2:05 PM

50 teeth cone angle 40 deg tooth angle 80 deg

[image: Screenshot 2024-11-17 at 7.34.19 PM.png]

50 teeth cone angle 40 deg tooth angle 80 deg

[image: Screenshot 2024-11-17 at 7.34.19 PM.png]

AM

Adrian Mariano

Sun, Nov 17, 2024 2:21 PM

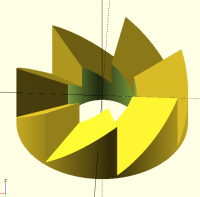

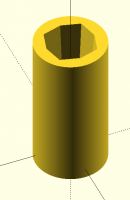

Sanjeev, your definition of cone angle is not the same as mine, it would

appear. I measure cone angle by the line through the center of the

triangle so a zero cone angle is when the mating parts are identical, which

I consider to be the standard joint configuration. Two parts will mate if

their cone angles are the opposite sign with my approach.

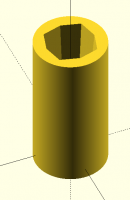

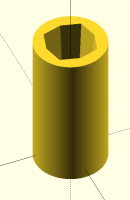

So 60 deg tooth angle, 0 deg cone angle:

[image: image.png]

And the case of 50 teeth, 40 deg cone angle, 75 deg tooth angle for me is

this:

[image: image.png]

Are you constructing your model so that the 75 deg angle is achieved as

measured on the tooth ridge?

On Sun, Nov 17, 2024 at 9:06 AM Sanjeev Prabhakar sprabhakar2006@gmail.com

wrote:

50 teeth cone angle 40 deg tooth angle 80 deg

[image: Screenshot 2024-11-17 at 7.34.19 PM.png]

Sanjeev, your definition of cone angle is not the same as mine, it would

appear. I measure cone angle by the line through the center of the

triangle so a zero cone angle is when the mating parts are identical, which

I consider to be the standard joint configuration. Two parts will mate if

their cone angles are the opposite sign with my approach.

So 60 deg tooth angle, 0 deg cone angle:

[image: image.png]

And the case of 50 teeth, 40 deg cone angle, 75 deg tooth angle for me is

this:

[image: image.png]

Are you constructing your model so that the 75 deg angle is achieved as

measured on the tooth ridge?

On Sun, Nov 17, 2024 at 9:06 AM Sanjeev Prabhakar <sprabhakar2006@gmail.com>

wrote:

> 50 teeth cone angle 40 deg tooth angle 80 deg

>

> [image: Screenshot 2024-11-17 at 7.34.19 PM.png]

>

SP

Sanjeev Prabhakar

Sun, Nov 17, 2024 2:34 PM

I think the tooth angle is the angle which one side of the tooth makes with

x-y plane

I will check that once again

On Sun, 17 Nov, 2024, 7:52 pm Adrian Mariano, avm4@cornell.edu wrote:

Sanjeev, your definition of cone angle is not the same as mine, it would

appear. I measure cone angle by the line through the center of the

triangle so a zero cone angle is when the mating parts are identical, which

I consider to be the standard joint configuration. Two parts will mate if

their cone angles are the opposite sign with my approach.

So 60 deg tooth angle, 0 deg cone angle:

[image: image.png]

And the case of 50 teeth, 40 deg cone angle, 75 deg tooth angle for me is

this:

[image: image.png]

Are you constructing your model so that the 75 deg angle is achieved as

measured on the tooth ridge?

On Sun, Nov 17, 2024 at 9:06 AM Sanjeev Prabhakar <

sprabhakar2006@gmail.com> wrote:

50 teeth cone angle 40 deg tooth angle 80 deg

[image: Screenshot 2024-11-17 at 7.34.19 PM.png]

I think the tooth angle is the angle which one side of the tooth makes with

x-y plane

I will check that once again

On Sun, 17 Nov, 2024, 7:52 pm Adrian Mariano, <avm4@cornell.edu> wrote:

> Sanjeev, your definition of cone angle is not the same as mine, it would

> appear. I measure cone angle by the line through the center of the

> triangle so a zero cone angle is when the mating parts are identical, which

> I consider to be the standard joint configuration. Two parts will mate if

> their cone angles are the opposite sign with my approach.

>

> So 60 deg tooth angle, 0 deg cone angle:

>

> [image: image.png]

>

> And the case of 50 teeth, 40 deg cone angle, 75 deg tooth angle for me is

> this:

>

> [image: image.png]

> Are you constructing your model so that the 75 deg angle is achieved as

> measured on the tooth ridge?

>

> On Sun, Nov 17, 2024 at 9:06 AM Sanjeev Prabhakar <

> sprabhakar2006@gmail.com> wrote:

>

>> 50 teeth cone angle 40 deg tooth angle 80 deg

>>

>> [image: Screenshot 2024-11-17 at 7.34.19 PM.png]

>>

>

SP

Sanjeev Prabhakar

Sun, Nov 17, 2024 3:23 PM

I have checked the tooth angles and the measured values are 80.65 on the

inner side, 80.59 on the outer side and cone angle is perfect 40 deg.

Maybe this distortion in angle is due to projection on the cylinder

[image: Screenshot 2024-11-17 at 8.39.03 PM.png]

[image: Screenshot 2024-11-17 at 8.42.14 PM.png]

[image: Screenshot 2024-11-17 at 8.46.45 PM.png]

I have checked the tooth angles and the measured values are 80.65 on the

inner side, 80.59 on the outer side and cone angle is perfect 40 deg.

Maybe this distortion in angle is due to projection on the cylinder

[image: Screenshot 2024-11-17 at 8.39.03 PM.png]

[image: Screenshot 2024-11-17 at 8.42.14 PM.png]

[image: Screenshot 2024-11-17 at 8.46.45 PM.png]