AM

Adrian Mariano

Thu, Nov 7, 2024 11:09 AM

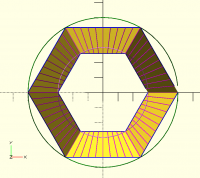

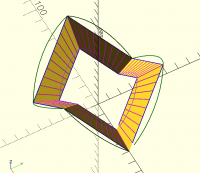

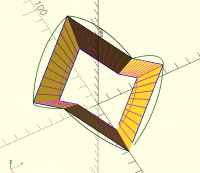

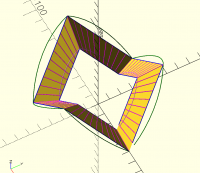

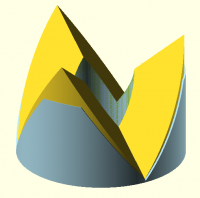

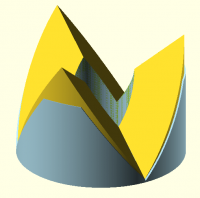

I do not understand the pictures. Or at least the top one is mystifying.

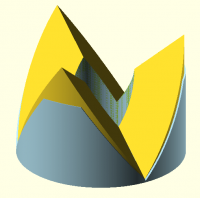

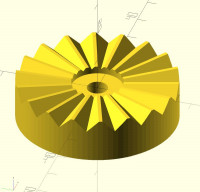

The bottom one looks like it could describe the process: the projection is

along vectors that originate at the origin and yes, you have a separate

projection onto the inner and outer cylinder.

On Wed, Nov 6, 2024 at 11:24 PM Sanjeev Prabhakar sprabhakar2006@gmail.com

wrote:

I don't think the straight projection on cylinder will work.

The only way I think this can work is if you project using vectors

considering outer race and inner race, projecting outwards and inwards

respectively on outer and inner cylinder.

picture below can make this clear.

magenta lines are the vectors

[image: Screenshot 2024-11-07 at 9.49.27 AM.png]

[image: Screenshot 2024-11-07 at 9.53.29 AM.png]

On Thu, 7 Nov, 2024, 8:12 am Adrian Mariano via Discuss, <

discuss@lists.openscad.org> wrote:

Bob, I did I think exactly the same thing in my code and didn't notice

anything, but now that you mention it, doing chamfers on an angular basis

is of course not going to match doing them on a linear basis. So that

means the geometry changes a bit if you change the chamfer size. This

isn't necessarily catastrophic, but is a little unexpected, I suppose.

Generally speaking you can't mate two parts produced with different chamfer

size anyway, so I'm not sure this is crucial to get right. But in order to

get it right, I think both thetaCA2 and phiCA are going to need to be

computed with trig---either that or there's some complicated way of

computing just one. The question is whether these two parameters can be

computed independently or are they related in some complicated way.

Treated as a 2d problem you are trying to get the angle that corresponds to

a fraction of a chord of the circle, which is a reasonably straight forward

triangle calculation. I got atan(chamfer*tan(angle)) where angle is

180/tooth_count for the ridge chamfer. But the chamfered one still doesn't

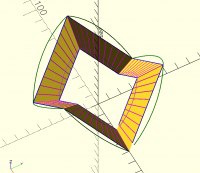

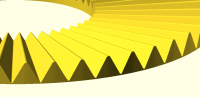

align with the unchamfered. For example:

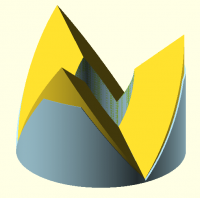

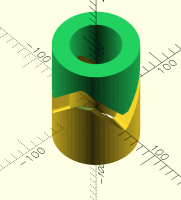

[image: image.png]

Yellow is unchamfered. Blue has huge chamfer applied only at ridge (and

slightly larger radius so we can see it clearly). And we see that the

angle has changed. I actually got less error with the original

calculation, but that might be because I didn't correct the phi angle only

the theta angle. (Or maybe I botched the trig.) So I tried computing a

correction for phi and got ridge_angle-atan(ridge_angle -

chamfer*(tan(ridge_angle)-tan(valley_angle))), but still things don't line

up correctly. (And the horizontal correction is still worse than not,

which makes me wonder if the horizontal correction needs to take into

account the vertical position of the chamfer somehow.) Doing the phi

correction alone actually is an improvement over no correction.

Here's my current code (without any chamfer corrections). It does

rounding and skew teeth.

module hirth(n, ir, or, id, od, tooth_angle=60, cone_angle=0, chamfer,

rounding, base=1, crop=false,skew=0, rot=false, orient,anchor,spin)

{

ir = get_radius(r=ir,d=id);

or = get_radius(r=or,d=od);

dummy = assert(all_positive([ir]), "ir/id must be a positive value")

assert(all_positive([or]), "or/od must be a positive value")

assert(is_int(n) && n>1, "n must be an integer larger than 1")

assert(is_finite(skew) && abs(skew)<=1, "skew must be a number

between -1 and 1")

assert(ir<or, "inside radius (ir/id) must be smaller than

outside radius (or/od)")

assert(all_positive([tooth_angle]) &&

tooth_angle<360*(n-1)/2/n, str("tooth angle must be between 0 and

",360*(n-1)/2/n," for spline with ",n," teeth."))

assert(num_defined([chamfer,rounding]) <=1, "Cannot define both

chamfer and rounding")

assert(is_undef(chamfer) || all_nonnegative([chamfer]) &&

chamfer<1/2, "chamfer must be a non-negative value smaller than 1/2")

assert(is_undef(rounding) || all_nonnegative([rounding]) &&

rounding<1/2, "rounding must be a non-negative value smaller than 1/2")

assert(all_positive([base]), "base must be a positive value") ;

tooth_height = sin(180/n) / tan(tooth_angle/2); // Normalized tooth

height

cone_height = -tan(cone_angle); // Normalized

height change corresponding to the cone angle

ridge_angle = atan(tooth_height/2 + cone_height);

valley_angle = atan(-tooth_height/2 + cone_height);

angle = 180/n; // Half the angle occupied by each tooth going around

the circle

factor = crop ? 3 : 1; // Make it oversized when crop is true

profile = is_undef(rounding) || rounding==0 ?

let(

chamfer=default(chamfer,0),

vchamf = chamfer*(ridge_angle-valley_angle),

pts = [

[-angle*(1-chamfer/2),

valley_angle+vchamf/2],

[-anglechamfer, ridge_angle-vchamf]

],

full = deduplicate(concat(pts, reverse(xflip(pts))))

)

back(valley_angle,

skew(sxy=skewangle/(ridge_angle-valley_angle),fwd(valley_angle,full)))

: let(

vround=rounding*(ridge_angle-valley_angle),

profpts = [

[ -angle, valley_angle+vround/2],

[ -angle*(1-rounding/2),

valley_angle+vround/2],

[ -anglerounding, ridge_angle-vround],

],

segs = max(16,segs(orrounding)),

full = concat(profpts, reverse(xflip(profpts))),

skewed = back(valley_angle,

skew(sxy=skew*angle/(ridge_angle-valley_angle),fwd(valley_angle,full))),

// Using computed values for the joints

lead to round-off error issues

joints = [(skewed[1]-skewed[0]).x,

(skewed[3]-skewed[2]).x/2,

(skewed[3]-skewed[2]).x/2,(skewed[5]-skewed[4]).x ],

roundpts = round_corners(skewed, joint=joints,

closed=false,$fn=segs)

)

roundpts;

// project spherical coordinate point onto cylinder of radius r

cyl_proj = function (r,theta_phi)

[for(pt=theta_phi)

let(xyz = spherical_to_xyz(1,pt[0], 90-pt[1]))

r * xyz / norm(point2d(xyz))];

bottom =

min([tan(valley_angle)ir,tan(valley_angle)or])-base-cone_heightir;

safebottom =

min([tan(valley_angle)ir/factor,tan(valley_angle)orfactor])-base-(crop?1:0)-cone_heightir;

ang_ofs = !rot ? -skewangle

: n%2==0 ? -(angle-skewangle) - skewangle

: -angle*(2-skew)-skewangle;

topinner = down(cone_heightir,[for(ang=lerpn(0,360,n,endpoint=false))

each

zrot(ang+ang_ofs,cyl_proj(ir/factor,profile))]);

topouter = down(cone_heightir,[for(ang=lerpn(0,360,n,endpoint=false))

each

zrot(ang+ang_ofs,cyl_proj(factoror,profile))]);

botinner = [for(val=topinner) [val.x,val.y,safebottom]];

botouter = [for(val=topouter) [val.x,val.y,safebottom]];

vert = [topouter, topinner, botinner, botouter];

anchors = [

named_anchor("teeth_bot", [0,0,bottom], DOWN)

];

attachable(anchor=anchor,spin=spin,orient=orient, r=or,

h=-2*bottom,anchors=anchors){

intersection(){

vnf_polyhedron(vnf_vertex_array(vert, reverse=true,

col_wrap=true, row_wrap=true),convexity=min(10,n));

if (crop)

zmove(bottom)tube(or=or,ir=ir,height=4*or,anchor=BOT,$fa=1,$fs=1);

}

children();

}

}

On Wed, Nov 6, 2024 at 7:55 PM Bob Carlson via Discuss <

discuss@lists.openscad.org> wrote:

I have established that there is an error in the code fragment. The line

thetaCA2 = _toothAngle(hs) * _chamfer(hs)/200;

Is where the error lies. What should it be? I was assuming that the

theta for the chamfer “shoulder” point would be proportional to the chamfer

but it produces a slight error. It is barely noticeable but gets more

blatant at low tooth counts and high conic.

Anyone see what it should be? I’m guessing there is some trig

functions involved,but ...

-Bob

On Nov 5, 2024, at 10:29, Bob Carlson via Discuss <

discuss@lists.openscad.org> wrote:

Here is just a code fragment but it gets the point across.

IR = _ir(hs);

OR = _or(hs) / cos(180/_n(hs)); // OR is the radius of the

circumscribing polygon of N

// Ridge Chamfer

thetaCA2 = _toothAngle(hs) * _chamfer(hs)/200;

phiCA = (_grooveAngle(hs) -_ridgeAngle(hs)) * _chamfer(hs)/100;

function profileToooth(r) =

[spherical2_to_xyz(r, thetaCA2, _ridgeAngle(hs) +

phiCA),

spherical2_to_xyz(r, _toothAngle(hs)/2, _grooveAngle(hs)),

spherical2_to_xyz(r, -_toothAngle(hs)/2, _grooveAngle(hs)),

spherical2_to_xyz(r, - thetaCA2, _ridgeAngle(hs) +

phiCA)

];

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

I do not understand the pictures. Or at least the top one is mystifying.

The bottom one looks like it could describe the process: the projection is

along vectors that originate at the origin and yes, you have a separate

projection onto the inner and outer cylinder.

On Wed, Nov 6, 2024 at 11:24 PM Sanjeev Prabhakar <sprabhakar2006@gmail.com>

wrote:

> I don't think the straight projection on cylinder will work.

> The only way I think this can work is if you project using vectors

> considering outer race and inner race, projecting outwards and inwards

> respectively on outer and inner cylinder.

> picture below can make this clear.

> magenta lines are the vectors

> [image: Screenshot 2024-11-07 at 9.49.27 AM.png]

> [image: Screenshot 2024-11-07 at 9.53.29 AM.png]

>

> On Thu, 7 Nov, 2024, 8:12 am Adrian Mariano via Discuss, <

> discuss@lists.openscad.org> wrote:

>

>> Bob, I did I think exactly the same thing in my code and didn't notice

>> anything, but now that you mention it, doing chamfers on an angular basis

>> is of course not going to match doing them on a linear basis. So that

>> means the geometry changes a bit if you change the chamfer size. This

>> isn't necessarily catastrophic, but is a little unexpected, I suppose.

>> Generally speaking you can't mate two parts produced with different chamfer

>> size anyway, so I'm not sure this is crucial to get right. But in order to

>> get it right, I think both thetaCA2 and phiCA are going to need to be

>> computed with trig---either that or there's some complicated way of

>> computing just one. The question is whether these two parameters can be

>> computed independently or are they related in some complicated way.

>> Treated as a 2d problem you are trying to get the angle that corresponds to

>> a fraction of a chord of the circle, which is a reasonably straight forward

>> triangle calculation. I got atan(chamfer*tan(angle)) where angle is

>> 180/tooth_count for the ridge chamfer. But the chamfered one still doesn't

>> align with the unchamfered. For example:

>>

>> [image: image.png]

>>

>> Yellow is unchamfered. Blue has huge chamfer applied only at ridge (and

>> slightly larger radius so we can see it clearly). And we see that the

>> angle has changed. I actually got less error with the original

>> calculation, but that might be because I didn't correct the phi angle only

>> the theta angle. (Or maybe I botched the trig.) So I tried computing a

>> correction for phi and got ridge_angle-atan(ridge_angle -

>> chamfer*(tan(ridge_angle)-tan(valley_angle))), but still things don't line

>> up correctly. (And the horizontal correction is still worse than not,

>> which makes me wonder if the horizontal correction needs to take into

>> account the vertical position of the chamfer somehow.) Doing the phi

>> correction alone actually is an improvement over no correction.

>>

>> Here's my current code (without any chamfer corrections). It does

>> rounding and skew teeth.

>>

>> module hirth(n, ir, or, id, od, tooth_angle=60, cone_angle=0, chamfer,

>> rounding, base=1, crop=false,skew=0, rot=false, orient,anchor,spin)

>> {

>> ir = get_radius(r=ir,d=id);

>> or = get_radius(r=or,d=od);

>> dummy = assert(all_positive([ir]), "ir/id must be a positive value")

>> assert(all_positive([or]), "or/od must be a positive value")

>> assert(is_int(n) && n>1, "n must be an integer larger than 1")

>> assert(is_finite(skew) && abs(skew)<=1, "skew must be a number

>> between -1 and 1")

>> assert(ir<or, "inside radius (ir/id) must be smaller than

>> outside radius (or/od)")

>> assert(all_positive([tooth_angle]) &&

>> tooth_angle<360*(n-1)/2/n, str("tooth angle must be between 0 and

>> ",360*(n-1)/2/n," for spline with ",n," teeth."))

>> assert(num_defined([chamfer,rounding]) <=1, "Cannot define both

>> chamfer and rounding")

>> assert(is_undef(chamfer) || all_nonnegative([chamfer]) &&

>> chamfer<1/2, "chamfer must be a non-negative value smaller than 1/2")

>> assert(is_undef(rounding) || all_nonnegative([rounding]) &&

>> rounding<1/2, "rounding must be a non-negative value smaller than 1/2")

>> assert(all_positive([base]), "base must be a positive value") ;

>> tooth_height = sin(180/n) / tan(tooth_angle/2); // Normalized tooth

>> height

>> cone_height = -tan(cone_angle); // Normalized

>> height change corresponding to the cone angle

>> ridge_angle = atan(tooth_height/2 + cone_height);

>> valley_angle = atan(-tooth_height/2 + cone_height);

>> angle = 180/n; // Half the angle occupied by each tooth going around

>> the circle

>>

>> factor = crop ? 3 : 1; // Make it oversized when crop is true

>>

>> profile = is_undef(rounding) || rounding==0 ?

>> let(

>> chamfer=default(chamfer,0),

>> vchamf = chamfer*(ridge_angle-valley_angle),

>> pts = [

>> [-angle*(1-chamfer/2),

>> valley_angle+vchamf/2],

>> [-angle*chamfer, ridge_angle-vchamf]

>> ],

>> full = deduplicate(concat(pts, reverse(xflip(pts))))

>> )

>> back(valley_angle,

>> skew(sxy=skew*angle/(ridge_angle-valley_angle),fwd(valley_angle,full)))

>> : let(

>> vround=rounding*(ridge_angle-valley_angle),

>> profpts = [

>> [ -angle, valley_angle+vround/2],

>> [ -angle*(1-rounding/2),

>> valley_angle+vround/2],

>> [ -angle*rounding, ridge_angle-vround],

>> ],

>> segs = max(16,segs(or*rounding)),

>> full = concat(profpts, reverse(xflip(profpts))),

>> skewed = back(valley_angle,

>> skew(sxy=skew*angle/(ridge_angle-valley_angle),fwd(valley_angle,full))),

>> // Using computed values for the joints

>> lead to round-off error issues

>> joints = [(skewed[1]-skewed[0]).x,

>> (skewed[3]-skewed[2]).x/2,

>> (skewed[3]-skewed[2]).x/2,(skewed[5]-skewed[4]).x ],

>> roundpts = round_corners(skewed, joint=joints,

>> closed=false,$fn=segs)

>> )

>> roundpts;

>>

>> // project spherical coordinate point onto cylinder of radius r

>> cyl_proj = function (r,theta_phi)

>> [for(pt=theta_phi)

>> let(xyz = spherical_to_xyz(1,pt[0], 90-pt[1]))

>> r * xyz / norm(point2d(xyz))];

>>

>> bottom =

>> min([tan(valley_angle)*ir,tan(valley_angle)*or])-base-cone_height*ir;

>> safebottom =

>> min([tan(valley_angle)*ir/factor,tan(valley_angle)*or*factor])-base-(crop?1:0)-cone_height*ir;

>> ang_ofs = !rot ? -skew*angle

>> : n%2==0 ? -(angle-skew*angle) - skew*angle

>> : -angle*(2-skew)-skew*angle;

>> topinner = down(cone_height*ir,[for(ang=lerpn(0,360,n,endpoint=false))

>> each

>> zrot(ang+ang_ofs,cyl_proj(ir/factor,profile))]);

>> topouter = down(cone_height*ir,[for(ang=lerpn(0,360,n,endpoint=false))

>> each

>> zrot(ang+ang_ofs,cyl_proj(factor*or,profile))]);

>> botinner = [for(val=topinner) [val.x,val.y,safebottom]];

>> botouter = [for(val=topouter) [val.x,val.y,safebottom]];

>> vert = [topouter, topinner, botinner, botouter];

>>

>> anchors = [

>> named_anchor("teeth_bot", [0,0,bottom], DOWN)

>> ];

>> attachable(anchor=anchor,spin=spin,orient=orient, r=or,

>> h=-2*bottom,anchors=anchors){

>> intersection(){

>> vnf_polyhedron(vnf_vertex_array(vert, reverse=true,

>> col_wrap=true, row_wrap=true),convexity=min(10,n));

>> if (crop)

>>

>> zmove(bottom)tube(or=or,ir=ir,height=4*or,anchor=BOT,$fa=1,$fs=1);

>> }

>> children();

>> }

>> }

>>

>>

>>

>> On Wed, Nov 6, 2024 at 7:55 PM Bob Carlson via Discuss <

>> discuss@lists.openscad.org> wrote:

>>

>>> I have established that there is an error in the code fragment. The line

>>>

>>> thetaCA2 = _toothAngle(hs) * _chamfer(hs)/200;

>>>

>>> Is where the error lies. What should it be? I was assuming that the

>>> theta for the chamfer “shoulder” point would be proportional to the chamfer

>>> but it produces a slight error. It is barely noticeable but gets more

>>> blatant at low tooth counts and high conic.

>>>

>>> Anyone see what it should be? I’m guessing there is some trig

>>> functions involved,but ...

>>>

>>> -Bob

>>>

>>> On Nov 5, 2024, at 10:29, Bob Carlson via Discuss <

>>> discuss@lists.openscad.org> wrote:

>>>

>>> Here is just a code fragment but it gets the point across.

>>>

>>> IR = _ir(hs);

>>> OR = _or(hs) / cos(180/_n(hs)); // OR is the radius of the

>>> circumscribing polygon of N

>>>

>>> // Ridge Chamfer

>>> thetaCA2 = _toothAngle(hs) * _chamfer(hs)/200;

>>> phiCA = (_grooveAngle(hs) -_ridgeAngle(hs)) * _chamfer(hs)/100;

>>>

>>> function profileToooth(r) =

>>> [spherical2_to_xyz(r, thetaCA2, _ridgeAngle(hs) +

>>> phiCA),

>>> spherical2_to_xyz(r, _toothAngle(hs)/2, _grooveAngle(hs)),

>>> spherical2_to_xyz(r, -_toothAngle(hs)/2, _grooveAngle(hs)),

>>> spherical2_to_xyz(r, - thetaCA2, _ridgeAngle(hs) +

>>> phiCA)

>>> ];

>>>

>>>

>>> _______________________________________________

>>> OpenSCAD mailing list

>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

>

SP

Sanjeev Prabhakar

Thu, Nov 7, 2024 11:23 AM

All the magenta lines are vectors, you can think of them originating from

any side of the line.

Each line intersects a circumscribing cylinder outer or inner and that

forms the circular hirth coupling.

On Thu, 7 Nov, 2024, 4:40 pm Adrian Mariano, avm4@cornell.edu wrote:

I do not understand the pictures. Or at least the top one is mystifying.

The bottom one looks like it could describe the process: the projection is

along vectors that originate at the origin and yes, you have a separate

projection onto the inner and outer cylinder.

On Wed, Nov 6, 2024 at 11:24 PM Sanjeev Prabhakar <

sprabhakar2006@gmail.com> wrote:

I don't think the straight projection on cylinder will work.

The only way I think this can work is if you project using vectors

considering outer race and inner race, projecting outwards and inwards

respectively on outer and inner cylinder.

picture below can make this clear.

magenta lines are the vectors

[image: Screenshot 2024-11-07 at 9.49.27 AM.png]

[image: Screenshot 2024-11-07 at 9.53.29 AM.png]

On Thu, 7 Nov, 2024, 8:12 am Adrian Mariano via Discuss, <

discuss@lists.openscad.org> wrote:

Bob, I did I think exactly the same thing in my code and didn't notice

anything, but now that you mention it, doing chamfers on an angular basis

is of course not going to match doing them on a linear basis. So that

means the geometry changes a bit if you change the chamfer size. This

isn't necessarily catastrophic, but is a little unexpected, I suppose.

Generally speaking you can't mate two parts produced with different chamfer

size anyway, so I'm not sure this is crucial to get right. But in order to

get it right, I think both thetaCA2 and phiCA are going to need to be

computed with trig---either that or there's some complicated way of

computing just one. The question is whether these two parameters can be

computed independently or are they related in some complicated way.

Treated as a 2d problem you are trying to get the angle that corresponds to

a fraction of a chord of the circle, which is a reasonably straight forward

triangle calculation. I got atan(chamfer*tan(angle)) where angle is

180/tooth_count for the ridge chamfer. But the chamfered one still doesn't

align with the unchamfered. For example:

[image: image.png]

Yellow is unchamfered. Blue has huge chamfer applied only at ridge (and

slightly larger radius so we can see it clearly). And we see that the

angle has changed. I actually got less error with the original

calculation, but that might be because I didn't correct the phi angle only

the theta angle. (Or maybe I botched the trig.) So I tried computing a

correction for phi and got ridge_angle-atan(ridge_angle -

chamfer*(tan(ridge_angle)-tan(valley_angle))), but still things don't line

up correctly. (And the horizontal correction is still worse than not,

which makes me wonder if the horizontal correction needs to take into

account the vertical position of the chamfer somehow.) Doing the phi

correction alone actually is an improvement over no correction.

Here's my current code (without any chamfer corrections). It does

rounding and skew teeth.

module hirth(n, ir, or, id, od, tooth_angle=60, cone_angle=0, chamfer,

rounding, base=1, crop=false,skew=0, rot=false, orient,anchor,spin)

{

ir = get_radius(r=ir,d=id);

or = get_radius(r=or,d=od);

dummy = assert(all_positive([ir]), "ir/id must be a positive value")

assert(all_positive([or]), "or/od must be a positive value")

assert(is_int(n) && n>1, "n must be an integer larger than 1")

assert(is_finite(skew) && abs(skew)<=1, "skew must be a number

between -1 and 1")

assert(ir<or, "inside radius (ir/id) must be smaller than

outside radius (or/od)")

assert(all_positive([tooth_angle]) &&

tooth_angle<360*(n-1)/2/n, str("tooth angle must be between 0 and

",360*(n-1)/2/n," for spline with ",n," teeth."))

assert(num_defined([chamfer,rounding]) <=1, "Cannot define

both chamfer and rounding")

assert(is_undef(chamfer) || all_nonnegative([chamfer]) &&

chamfer<1/2, "chamfer must be a non-negative value smaller than 1/2")

assert(is_undef(rounding) || all_nonnegative([rounding]) &&

rounding<1/2, "rounding must be a non-negative value smaller than 1/2")

assert(all_positive([base]), "base must be a positive value") ;

tooth_height = sin(180/n) / tan(tooth_angle/2); // Normalized

tooth height

cone_height = -tan(cone_angle); // Normalized

height change corresponding to the cone angle

ridge_angle = atan(tooth_height/2 + cone_height);

valley_angle = atan(-tooth_height/2 + cone_height);

angle = 180/n; // Half the angle occupied by each tooth going

around the circle

factor = crop ? 3 : 1; // Make it oversized when crop is true

profile = is_undef(rounding) || rounding==0 ?

let(

chamfer=default(chamfer,0),

vchamf = chamfer*(ridge_angle-valley_angle),

pts = [

[-angle*(1-chamfer/2),

valley_angle+vchamf/2],

[-anglechamfer, ridge_angle-vchamf]

],

full = deduplicate(concat(pts, reverse(xflip(pts))))

)

back(valley_angle,

skew(sxy=skewangle/(ridge_angle-valley_angle),fwd(valley_angle,full)))

: let(

vround=rounding*(ridge_angle-valley_angle),

profpts = [

[ -angle, valley_angle+vround/2],

[ -angle*(1-rounding/2),

valley_angle+vround/2],

[ -anglerounding, ridge_angle-vround],

],

segs = max(16,segs(orrounding)),

full = concat(profpts, reverse(xflip(profpts))),

skewed = back(valley_angle,

skew(sxy=skew*angle/(ridge_angle-valley_angle),fwd(valley_angle,full))),

// Using computed values for the joints

lead to round-off error issues

joints = [(skewed[1]-skewed[0]).x,

(skewed[3]-skewed[2]).x/2,

(skewed[3]-skewed[2]).x/2,(skewed[5]-skewed[4]).x ],

roundpts = round_corners(skewed, joint=joints,

closed=false,$fn=segs)

)

roundpts;

// project spherical coordinate point onto cylinder of radius r

cyl_proj = function (r,theta_phi)

[for(pt=theta_phi)

let(xyz = spherical_to_xyz(1,pt[0], 90-pt[1]))

r * xyz / norm(point2d(xyz))];

bottom =

min([tan(valley_angle)ir,tan(valley_angle)or])-base-cone_heightir;

safebottom =

min([tan(valley_angle)ir/factor,tan(valley_angle)orfactor])-base-(crop?1:0)-cone_heightir;

ang_ofs = !rot ? -skewangle

: n%2==0 ? -(angle-skewangle) - skewangle

: -angle*(2-skew)-skewangle;

topinner = down(cone_heightir,[for(ang=lerpn(0,360,n,endpoint=false))

each

zrot(ang+ang_ofs,cyl_proj(ir/factor,profile))]);

topouter = down(cone_heightir,[for(ang=lerpn(0,360,n,endpoint=false))

each

zrot(ang+ang_ofs,cyl_proj(factoror,profile))]);

botinner = [for(val=topinner) [val.x,val.y,safebottom]];

botouter = [for(val=topouter) [val.x,val.y,safebottom]];

vert = [topouter, topinner, botinner, botouter];

anchors = [

named_anchor("teeth_bot", [0,0,bottom], DOWN)

];

attachable(anchor=anchor,spin=spin,orient=orient, r=or,

h=-2*bottom,anchors=anchors){

intersection(){

vnf_polyhedron(vnf_vertex_array(vert, reverse=true,

col_wrap=true, row_wrap=true),convexity=min(10,n));

if (crop)

zmove(bottom)tube(or=or,ir=ir,height=4*or,anchor=BOT,$fa=1,$fs=1);

}

children();

}

}

On Wed, Nov 6, 2024 at 7:55 PM Bob Carlson via Discuss <

discuss@lists.openscad.org> wrote:

I have established that there is an error in the code fragment. The line

thetaCA2 = _toothAngle(hs) * _chamfer(hs)/200;

Is where the error lies. What should it be? I was assuming that the

theta for the chamfer “shoulder” point would be proportional to the chamfer

but it produces a slight error. It is barely noticeable but gets more

blatant at low tooth counts and high conic.

Anyone see what it should be? I’m guessing there is some trig

functions involved,but ...

-Bob

On Nov 5, 2024, at 10:29, Bob Carlson via Discuss <

discuss@lists.openscad.org> wrote:

Here is just a code fragment but it gets the point across.

IR = _ir(hs);

OR = _or(hs) / cos(180/_n(hs)); // OR is the radius of the

circumscribing polygon of N

// Ridge Chamfer

thetaCA2 = _toothAngle(hs) * _chamfer(hs)/200;

phiCA = (_grooveAngle(hs) -_ridgeAngle(hs)) * _chamfer(hs)/100;

function profileToooth(r) =

[spherical2_to_xyz(r, thetaCA2, _ridgeAngle(hs) +

phiCA),

spherical2_to_xyz(r, _toothAngle(hs)/2, _grooveAngle(hs)),

spherical2_to_xyz(r, -_toothAngle(hs)/2, _grooveAngle(hs)),

spherical2_to_xyz(r, - thetaCA2, _ridgeAngle(hs) +

phiCA)

];

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

All the magenta lines are vectors, you can think of them originating from

any side of the line.

Each line intersects a circumscribing cylinder outer or inner and that

forms the circular hirth coupling.

On Thu, 7 Nov, 2024, 4:40 pm Adrian Mariano, <avm4@cornell.edu> wrote:

> I do not understand the pictures. Or at least the top one is mystifying.

> The bottom one looks like it could describe the process: the projection is

> along vectors that originate at the origin and yes, you have a separate

> projection onto the inner and outer cylinder.

>

> On Wed, Nov 6, 2024 at 11:24 PM Sanjeev Prabhakar <

> sprabhakar2006@gmail.com> wrote:

>

>> I don't think the straight projection on cylinder will work.

>> The only way I think this can work is if you project using vectors

>> considering outer race and inner race, projecting outwards and inwards

>> respectively on outer and inner cylinder.

>> picture below can make this clear.

>> magenta lines are the vectors

>> [image: Screenshot 2024-11-07 at 9.49.27 AM.png]

>> [image: Screenshot 2024-11-07 at 9.53.29 AM.png]

>>

>> On Thu, 7 Nov, 2024, 8:12 am Adrian Mariano via Discuss, <

>> discuss@lists.openscad.org> wrote:

>>

>>> Bob, I did I think exactly the same thing in my code and didn't notice

>>> anything, but now that you mention it, doing chamfers on an angular basis

>>> is of course not going to match doing them on a linear basis. So that

>>> means the geometry changes a bit if you change the chamfer size. This

>>> isn't necessarily catastrophic, but is a little unexpected, I suppose.

>>> Generally speaking you can't mate two parts produced with different chamfer

>>> size anyway, so I'm not sure this is crucial to get right. But in order to

>>> get it right, I think both thetaCA2 and phiCA are going to need to be

>>> computed with trig---either that or there's some complicated way of

>>> computing just one. The question is whether these two parameters can be

>>> computed independently or are they related in some complicated way.

>>> Treated as a 2d problem you are trying to get the angle that corresponds to

>>> a fraction of a chord of the circle, which is a reasonably straight forward

>>> triangle calculation. I got atan(chamfer*tan(angle)) where angle is

>>> 180/tooth_count for the ridge chamfer. But the chamfered one still doesn't

>>> align with the unchamfered. For example:

>>>

>>> [image: image.png]

>>>

>>> Yellow is unchamfered. Blue has huge chamfer applied only at ridge (and

>>> slightly larger radius so we can see it clearly). And we see that the

>>> angle has changed. I actually got less error with the original

>>> calculation, but that might be because I didn't correct the phi angle only

>>> the theta angle. (Or maybe I botched the trig.) So I tried computing a

>>> correction for phi and got ridge_angle-atan(ridge_angle -

>>> chamfer*(tan(ridge_angle)-tan(valley_angle))), but still things don't line

>>> up correctly. (And the horizontal correction is still worse than not,

>>> which makes me wonder if the horizontal correction needs to take into

>>> account the vertical position of the chamfer somehow.) Doing the phi

>>> correction alone actually is an improvement over no correction.

>>>

>>> Here's my current code (without any chamfer corrections). It does

>>> rounding and skew teeth.

>>>

>>> module hirth(n, ir, or, id, od, tooth_angle=60, cone_angle=0, chamfer,

>>> rounding, base=1, crop=false,skew=0, rot=false, orient,anchor,spin)

>>> {

>>> ir = get_radius(r=ir,d=id);

>>> or = get_radius(r=or,d=od);

>>> dummy = assert(all_positive([ir]), "ir/id must be a positive value")

>>> assert(all_positive([or]), "or/od must be a positive value")

>>> assert(is_int(n) && n>1, "n must be an integer larger than 1")

>>> assert(is_finite(skew) && abs(skew)<=1, "skew must be a number

>>> between -1 and 1")

>>> assert(ir<or, "inside radius (ir/id) must be smaller than

>>> outside radius (or/od)")

>>> assert(all_positive([tooth_angle]) &&

>>> tooth_angle<360*(n-1)/2/n, str("tooth angle must be between 0 and

>>> ",360*(n-1)/2/n," for spline with ",n," teeth."))

>>> assert(num_defined([chamfer,rounding]) <=1, "Cannot define

>>> both chamfer and rounding")

>>> assert(is_undef(chamfer) || all_nonnegative([chamfer]) &&

>>> chamfer<1/2, "chamfer must be a non-negative value smaller than 1/2")

>>> assert(is_undef(rounding) || all_nonnegative([rounding]) &&

>>> rounding<1/2, "rounding must be a non-negative value smaller than 1/2")

>>> assert(all_positive([base]), "base must be a positive value") ;

>>> tooth_height = sin(180/n) / tan(tooth_angle/2); // Normalized

>>> tooth height

>>> cone_height = -tan(cone_angle); // Normalized

>>> height change corresponding to the cone angle

>>> ridge_angle = atan(tooth_height/2 + cone_height);

>>> valley_angle = atan(-tooth_height/2 + cone_height);

>>> angle = 180/n; // Half the angle occupied by each tooth going

>>> around the circle

>>>

>>> factor = crop ? 3 : 1; // Make it oversized when crop is true

>>>

>>> profile = is_undef(rounding) || rounding==0 ?

>>> let(

>>> chamfer=default(chamfer,0),

>>> vchamf = chamfer*(ridge_angle-valley_angle),

>>> pts = [

>>> [-angle*(1-chamfer/2),

>>> valley_angle+vchamf/2],

>>> [-angle*chamfer, ridge_angle-vchamf]

>>> ],

>>> full = deduplicate(concat(pts, reverse(xflip(pts))))

>>> )

>>> back(valley_angle,

>>> skew(sxy=skew*angle/(ridge_angle-valley_angle),fwd(valley_angle,full)))

>>> : let(

>>> vround=rounding*(ridge_angle-valley_angle),

>>> profpts = [

>>> [ -angle, valley_angle+vround/2],

>>> [ -angle*(1-rounding/2),

>>> valley_angle+vround/2],

>>> [ -angle*rounding, ridge_angle-vround],

>>> ],

>>> segs = max(16,segs(or*rounding)),

>>> full = concat(profpts, reverse(xflip(profpts))),

>>> skewed = back(valley_angle,

>>> skew(sxy=skew*angle/(ridge_angle-valley_angle),fwd(valley_angle,full))),

>>> // Using computed values for the joints

>>> lead to round-off error issues

>>> joints = [(skewed[1]-skewed[0]).x,

>>> (skewed[3]-skewed[2]).x/2,

>>> (skewed[3]-skewed[2]).x/2,(skewed[5]-skewed[4]).x ],

>>> roundpts = round_corners(skewed, joint=joints,

>>> closed=false,$fn=segs)

>>> )

>>> roundpts;

>>>

>>> // project spherical coordinate point onto cylinder of radius r

>>> cyl_proj = function (r,theta_phi)

>>> [for(pt=theta_phi)

>>> let(xyz = spherical_to_xyz(1,pt[0], 90-pt[1]))

>>> r * xyz / norm(point2d(xyz))];

>>>

>>> bottom =

>>> min([tan(valley_angle)*ir,tan(valley_angle)*or])-base-cone_height*ir;

>>> safebottom =

>>> min([tan(valley_angle)*ir/factor,tan(valley_angle)*or*factor])-base-(crop?1:0)-cone_height*ir;

>>> ang_ofs = !rot ? -skew*angle

>>> : n%2==0 ? -(angle-skew*angle) - skew*angle

>>> : -angle*(2-skew)-skew*angle;

>>> topinner = down(cone_height*ir,[for(ang=lerpn(0,360,n,endpoint=false))

>>> each

>>> zrot(ang+ang_ofs,cyl_proj(ir/factor,profile))]);

>>> topouter = down(cone_height*ir,[for(ang=lerpn(0,360,n,endpoint=false))

>>> each

>>> zrot(ang+ang_ofs,cyl_proj(factor*or,profile))]);

>>> botinner = [for(val=topinner) [val.x,val.y,safebottom]];

>>> botouter = [for(val=topouter) [val.x,val.y,safebottom]];

>>> vert = [topouter, topinner, botinner, botouter];

>>>

>>> anchors = [

>>> named_anchor("teeth_bot", [0,0,bottom], DOWN)

>>> ];

>>> attachable(anchor=anchor,spin=spin,orient=orient, r=or,

>>> h=-2*bottom,anchors=anchors){

>>> intersection(){

>>> vnf_polyhedron(vnf_vertex_array(vert, reverse=true,

>>> col_wrap=true, row_wrap=true),convexity=min(10,n));

>>> if (crop)

>>>

>>> zmove(bottom)tube(or=or,ir=ir,height=4*or,anchor=BOT,$fa=1,$fs=1);

>>> }

>>> children();

>>> }

>>> }

>>>

>>>

>>>

>>> On Wed, Nov 6, 2024 at 7:55 PM Bob Carlson via Discuss <

>>> discuss@lists.openscad.org> wrote:

>>>

>>>> I have established that there is an error in the code fragment. The line

>>>>

>>>> thetaCA2 = _toothAngle(hs) * _chamfer(hs)/200;

>>>>

>>>> Is where the error lies. What should it be? I was assuming that the

>>>> theta for the chamfer “shoulder” point would be proportional to the chamfer

>>>> but it produces a slight error. It is barely noticeable but gets more

>>>> blatant at low tooth counts and high conic.

>>>>

>>>> Anyone see what it should be? I’m guessing there is some trig

>>>> functions involved,but ...

>>>>

>>>> -Bob

>>>>

>>>> On Nov 5, 2024, at 10:29, Bob Carlson via Discuss <

>>>> discuss@lists.openscad.org> wrote:

>>>>

>>>> Here is just a code fragment but it gets the point across.

>>>>

>>>> IR = _ir(hs);

>>>> OR = _or(hs) / cos(180/_n(hs)); // OR is the radius of the

>>>> circumscribing polygon of N

>>>>

>>>> // Ridge Chamfer

>>>> thetaCA2 = _toothAngle(hs) * _chamfer(hs)/200;

>>>> phiCA = (_grooveAngle(hs) -_ridgeAngle(hs)) * _chamfer(hs)/100;

>>>>

>>>> function profileToooth(r) =

>>>> [spherical2_to_xyz(r, thetaCA2, _ridgeAngle(hs) +

>>>> phiCA),

>>>> spherical2_to_xyz(r, _toothAngle(hs)/2, _grooveAngle(hs)),

>>>> spherical2_to_xyz(r, -_toothAngle(hs)/2, _grooveAngle(hs)),

>>>> spherical2_to_xyz(r, - thetaCA2, _ridgeAngle(hs) +

>>>> phiCA)

>>>> ];

>>>>

>>>>

>>>> _______________________________________________

>>>> OpenSCAD mailing list

>>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>

>>> _______________________________________________

>>> OpenSCAD mailing list

>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>

>>

SP

Sanjeev Prabhakar

Thu, Nov 7, 2024 11:24 AM

Thanks David

That book you share is good, but it is taking some time to absorb

On Thu, 7 Nov, 2024, 11:53 am John David, ebo.2112@gmail.com wrote:

very nice! Thank you for sharing ;-)

On Wed, Nov 6, 2024 at 11:59 PM Sanjeev Prabhakar via Discuss <

discuss@lists.openscad.org> wrote:

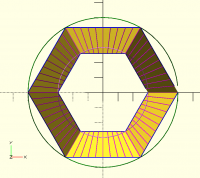

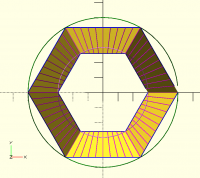

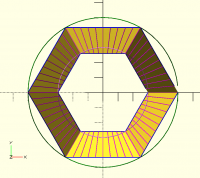

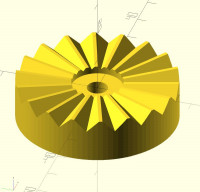

this is the final version (attached is the scad file)

[image: Screenshot 2024-11-07 at 10.26.12 AM.png]

On Thu, 7 Nov 2024 at 09:54, Sanjeev Prabhakar sprabhakar2006@gmail.com

wrote:

I don't think the straight projection on cylinder will work.

The only way I think this can work is if you project using vectors

considering outer race and inner race, projecting outwards and inwards

respectively on outer and inner cylinder.

picture below can make this clear.

magenta lines are the vectors

[image: Screenshot 2024-11-07 at 9.49.27 AM.png]

[image: Screenshot 2024-11-07 at 9.53.29 AM.png]

On Thu, 7 Nov, 2024, 8:12 am Adrian Mariano via Discuss, <

discuss@lists.openscad.org> wrote:

Bob, I did I think exactly the same thing in my code and didn't notice

anything, but now that you mention it, doing chamfers on an angular basis

is of course not going to match doing them on a linear basis. So that

means the geometry changes a bit if you change the chamfer size. This

isn't necessarily catastrophic, but is a little unexpected, I suppose.

Generally speaking you can't mate two parts produced with different chamfer

size anyway, so I'm not sure this is crucial to get right. But in order to

get it right, I think both thetaCA2 and phiCA are going to need to be

computed with trig---either that or there's some complicated way of

computing just one. The question is whether these two parameters can be

computed independently or are they related in some complicated way.

Treated as a 2d problem you are trying to get the angle that corresponds to

a fraction of a chord of the circle, which is a reasonably straight forward

triangle calculation. I got atan(chamfer*tan(angle)) where angle is

180/tooth_count for the ridge chamfer. But the chamfered one still doesn't

align with the unchamfered. For example:

[image: image.png]

Yellow is unchamfered. Blue has huge chamfer applied only at ridge

(and slightly larger radius so we can see it clearly). And we see that the

angle has changed. I actually got less error with the original

calculation, but that might be because I didn't correct the phi angle only

the theta angle. (Or maybe I botched the trig.) So I tried computing a

correction for phi and got ridge_angle-atan(ridge_angle -

chamfer*(tan(ridge_angle)-tan(valley_angle))), but still things don't line

up correctly. (And the horizontal correction is still worse than not,

which makes me wonder if the horizontal correction needs to take into

account the vertical position of the chamfer somehow.) Doing the phi

correction alone actually is an improvement over no correction.

Here's my current code (without any chamfer corrections). It does

rounding and skew teeth.

module hirth(n, ir, or, id, od, tooth_angle=60, cone_angle=0, chamfer,

rounding, base=1, crop=false,skew=0, rot=false, orient,anchor,spin)

{

ir = get_radius(r=ir,d=id);

or = get_radius(r=or,d=od);

dummy = assert(all_positive([ir]), "ir/id must be a positive value")

assert(all_positive([or]), "or/od must be a positive value")

assert(is_int(n) && n>1, "n must be an integer larger than 1")

assert(is_finite(skew) && abs(skew)<=1, "skew must be a

number between -1 and 1")

assert(ir<or, "inside radius (ir/id) must be smaller than

outside radius (or/od)")

assert(all_positive([tooth_angle]) &&

tooth_angle<360*(n-1)/2/n, str("tooth angle must be between 0 and

",360*(n-1)/2/n," for spline with ",n," teeth."))

assert(num_defined([chamfer,rounding]) <=1, "Cannot define

both chamfer and rounding")

assert(is_undef(chamfer) || all_nonnegative([chamfer]) &&

chamfer<1/2, "chamfer must be a non-negative value smaller than 1/2")

assert(is_undef(rounding) || all_nonnegative([rounding]) &&

rounding<1/2, "rounding must be a non-negative value smaller than 1/2")

assert(all_positive([base]), "base must be a positive value")

;

tooth_height = sin(180/n) / tan(tooth_angle/2); // Normalized

tooth height

cone_height = -tan(cone_angle); // Normalized

height change corresponding to the cone angle

ridge_angle = atan(tooth_height/2 + cone_height);

valley_angle = atan(-tooth_height/2 + cone_height);

angle = 180/n; // Half the angle occupied by each tooth going

around the circle

factor = crop ? 3 : 1; // Make it oversized when crop is true

profile = is_undef(rounding) || rounding==0 ?

let(

chamfer=default(chamfer,0),

vchamf = chamfer*(ridge_angle-valley_angle),

pts = [

[-angle*(1-chamfer/2),

valley_angle+vchamf/2],

[-anglechamfer, ridge_angle-vchamf]

],

full = deduplicate(concat(pts,

reverse(xflip(pts))))

)

back(valley_angle,

skew(sxy=skewangle/(ridge_angle-valley_angle),fwd(valley_angle,full)))

: let(

vround=rounding*(ridge_angle-valley_angle),

profpts = [

[ -angle, valley_angle+vround/2],

[ -angle*(1-rounding/2),

valley_angle+vround/2],

[ -anglerounding, ridge_angle-vround],

],

segs = max(16,segs(orrounding)),

full = concat(profpts, reverse(xflip(profpts))),

skewed = back(valley_angle,

skew(sxy=skew*angle/(ridge_angle-valley_angle),fwd(valley_angle,full))),

// Using computed values for the joints

lead to round-off error issues

joints = [(skewed[1]-skewed[0]).x,

(skewed[3]-skewed[2]).x/2,

(skewed[3]-skewed[2]).x/2,(skewed[5]-skewed[4]).x ],

roundpts = round_corners(skewed, joint=joints,

closed=false,$fn=segs)

)

roundpts;

// project spherical coordinate point onto cylinder of radius r

cyl_proj = function (r,theta_phi)

[for(pt=theta_phi)

let(xyz = spherical_to_xyz(1,pt[0], 90-pt[1]))

r * xyz / norm(point2d(xyz))];

bottom =

min([tan(valley_angle)ir,tan(valley_angle)or])-base-cone_heightir;

safebottom =

min([tan(valley_angle)ir/factor,tan(valley_angle)orfactor])-base-(crop?1:0)-cone_heightir;

ang_ofs = !rot ? -skewangle

: n%2==0 ? -(angle-skewangle) - skewangle

: -angle*(2-skew)-skewangle;

topinner = down(cone_heightir,[for(ang=lerpn(0,360,n,endpoint=false))

each

zrot(ang+ang_ofs,cyl_proj(ir/factor,profile))]);

topouter = down(cone_heightir,[for(ang=lerpn(0,360,n,endpoint=false))

each

zrot(ang+ang_ofs,cyl_proj(factoror,profile))]);

botinner = [for(val=topinner) [val.x,val.y,safebottom]];

botouter = [for(val=topouter) [val.x,val.y,safebottom]];

vert = [topouter, topinner, botinner, botouter];

anchors = [

named_anchor("teeth_bot", [0,0,bottom], DOWN)

];

attachable(anchor=anchor,spin=spin,orient=orient, r=or,

h=-2*bottom,anchors=anchors){

intersection(){

vnf_polyhedron(vnf_vertex_array(vert, reverse=true,

col_wrap=true, row_wrap=true),convexity=min(10,n));

if (crop)

zmove(bottom)tube(or=or,ir=ir,height=4*or,anchor=BOT,$fa=1,$fs=1);

}

children();

}

}

On Wed, Nov 6, 2024 at 7:55 PM Bob Carlson via Discuss <

discuss@lists.openscad.org> wrote:

I have established that there is an error in the code fragment. The

line

thetaCA2 = _toothAngle(hs) * _chamfer(hs)/200;

Is where the error lies. What should it be? I was assuming that the

theta for the chamfer “shoulder” point would be proportional to the chamfer

but it produces a slight error. It is barely noticeable but gets more

blatant at low tooth counts and high conic.

Anyone see what it should be? I’m guessing there is some trig

functions involved,but ...

-Bob

On Nov 5, 2024, at 10:29, Bob Carlson via Discuss <

discuss@lists.openscad.org> wrote:

Here is just a code fragment but it gets the point across.

IR = _ir(hs);

OR = _or(hs) / cos(180/_n(hs)); // OR is the radius of the

circumscribing polygon of N

// Ridge Chamfer

thetaCA2 = _toothAngle(hs) * _chamfer(hs)/200;

phiCA = (_grooveAngle(hs) -_ridgeAngle(hs)) * _chamfer(hs)/100;

function profileToooth(r) =

[spherical2_to_xyz(r, thetaCA2, _ridgeAngle(hs) +

phiCA),

spherical2_to_xyz(r, _toothAngle(hs)/2, _grooveAngle(hs)),

spherical2_to_xyz(r, -_toothAngle(hs)/2, _grooveAngle(hs)),

spherical2_to_xyz(r, - thetaCA2, _ridgeAngle(hs) +

phiCA)

];

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Thanks David

That book you share is good, but it is taking some time to absorb

On Thu, 7 Nov, 2024, 11:53 am John David, <ebo.2112@gmail.com> wrote:

> very nice! Thank you for sharing ;-)

>

> On Wed, Nov 6, 2024 at 11:59 PM Sanjeev Prabhakar via Discuss <

> discuss@lists.openscad.org> wrote:

>

>> this is the final version (attached is the scad file)

>> [image: Screenshot 2024-11-07 at 10.26.12 AM.png]

>>

>> On Thu, 7 Nov 2024 at 09:54, Sanjeev Prabhakar <sprabhakar2006@gmail.com>

>> wrote:

>>

>>> I don't think the straight projection on cylinder will work.

>>> The only way I think this can work is if you project using vectors

>>> considering outer race and inner race, projecting outwards and inwards

>>> respectively on outer and inner cylinder.

>>> picture below can make this clear.

>>> magenta lines are the vectors

>>> [image: Screenshot 2024-11-07 at 9.49.27 AM.png]

>>> [image: Screenshot 2024-11-07 at 9.53.29 AM.png]

>>>

>>> On Thu, 7 Nov, 2024, 8:12 am Adrian Mariano via Discuss, <

>>> discuss@lists.openscad.org> wrote:

>>>

>>>> Bob, I did I think exactly the same thing in my code and didn't notice

>>>> anything, but now that you mention it, doing chamfers on an angular basis

>>>> is of course not going to match doing them on a linear basis. So that

>>>> means the geometry changes a bit if you change the chamfer size. This

>>>> isn't necessarily catastrophic, but is a little unexpected, I suppose.

>>>> Generally speaking you can't mate two parts produced with different chamfer

>>>> size anyway, so I'm not sure this is crucial to get right. But in order to

>>>> get it right, I think both thetaCA2 and phiCA are going to need to be

>>>> computed with trig---either that or there's some complicated way of

>>>> computing just one. The question is whether these two parameters can be

>>>> computed independently or are they related in some complicated way.

>>>> Treated as a 2d problem you are trying to get the angle that corresponds to

>>>> a fraction of a chord of the circle, which is a reasonably straight forward

>>>> triangle calculation. I got atan(chamfer*tan(angle)) where angle is

>>>> 180/tooth_count for the ridge chamfer. But the chamfered one still doesn't

>>>> align with the unchamfered. For example:

>>>>

>>>> [image: image.png]

>>>>

>>>> Yellow is unchamfered. Blue has huge chamfer applied only at ridge

>>>> (and slightly larger radius so we can see it clearly). And we see that the

>>>> angle has changed. I actually got less error with the original

>>>> calculation, but that might be because I didn't correct the phi angle only

>>>> the theta angle. (Or maybe I botched the trig.) So I tried computing a

>>>> correction for phi and got ridge_angle-atan(ridge_angle -

>>>> chamfer*(tan(ridge_angle)-tan(valley_angle))), but still things don't line

>>>> up correctly. (And the horizontal correction is still worse than not,

>>>> which makes me wonder if the horizontal correction needs to take into

>>>> account the vertical position of the chamfer somehow.) Doing the phi

>>>> correction alone actually is an improvement over no correction.

>>>>

>>>> Here's my current code (without any chamfer corrections). It does

>>>> rounding and skew teeth.

>>>>

>>>> module hirth(n, ir, or, id, od, tooth_angle=60, cone_angle=0, chamfer,

>>>> rounding, base=1, crop=false,skew=0, rot=false, orient,anchor,spin)

>>>> {

>>>> ir = get_radius(r=ir,d=id);

>>>> or = get_radius(r=or,d=od);

>>>> dummy = assert(all_positive([ir]), "ir/id must be a positive value")

>>>> assert(all_positive([or]), "or/od must be a positive value")

>>>> assert(is_int(n) && n>1, "n must be an integer larger than 1")

>>>> assert(is_finite(skew) && abs(skew)<=1, "skew must be a

>>>> number between -1 and 1")

>>>> assert(ir<or, "inside radius (ir/id) must be smaller than

>>>> outside radius (or/od)")

>>>> assert(all_positive([tooth_angle]) &&

>>>> tooth_angle<360*(n-1)/2/n, str("tooth angle must be between 0 and

>>>> ",360*(n-1)/2/n," for spline with ",n," teeth."))

>>>> assert(num_defined([chamfer,rounding]) <=1, "Cannot define

>>>> both chamfer and rounding")

>>>> assert(is_undef(chamfer) || all_nonnegative([chamfer]) &&

>>>> chamfer<1/2, "chamfer must be a non-negative value smaller than 1/2")

>>>> assert(is_undef(rounding) || all_nonnegative([rounding]) &&

>>>> rounding<1/2, "rounding must be a non-negative value smaller than 1/2")

>>>> assert(all_positive([base]), "base must be a positive value")

>>>> ;

>>>> tooth_height = sin(180/n) / tan(tooth_angle/2); // Normalized

>>>> tooth height

>>>> cone_height = -tan(cone_angle); // Normalized

>>>> height change corresponding to the cone angle

>>>> ridge_angle = atan(tooth_height/2 + cone_height);

>>>> valley_angle = atan(-tooth_height/2 + cone_height);

>>>> angle = 180/n; // Half the angle occupied by each tooth going

>>>> around the circle

>>>>

>>>> factor = crop ? 3 : 1; // Make it oversized when crop is true

>>>>

>>>> profile = is_undef(rounding) || rounding==0 ?

>>>> let(

>>>> chamfer=default(chamfer,0),

>>>> vchamf = chamfer*(ridge_angle-valley_angle),

>>>> pts = [

>>>> [-angle*(1-chamfer/2),

>>>> valley_angle+vchamf/2],

>>>> [-angle*chamfer, ridge_angle-vchamf]

>>>> ],

>>>> full = deduplicate(concat(pts,

>>>> reverse(xflip(pts))))

>>>> )

>>>> back(valley_angle,

>>>> skew(sxy=skew*angle/(ridge_angle-valley_angle),fwd(valley_angle,full)))

>>>> : let(

>>>> vround=rounding*(ridge_angle-valley_angle),

>>>> profpts = [

>>>> [ -angle, valley_angle+vround/2],

>>>> [ -angle*(1-rounding/2),

>>>> valley_angle+vround/2],

>>>> [ -angle*rounding, ridge_angle-vround],

>>>> ],

>>>> segs = max(16,segs(or*rounding)),

>>>> full = concat(profpts, reverse(xflip(profpts))),

>>>> skewed = back(valley_angle,

>>>> skew(sxy=skew*angle/(ridge_angle-valley_angle),fwd(valley_angle,full))),

>>>> // Using computed values for the joints

>>>> lead to round-off error issues

>>>> joints = [(skewed[1]-skewed[0]).x,

>>>> (skewed[3]-skewed[2]).x/2,

>>>> (skewed[3]-skewed[2]).x/2,(skewed[5]-skewed[4]).x ],

>>>> roundpts = round_corners(skewed, joint=joints,

>>>> closed=false,$fn=segs)

>>>> )

>>>> roundpts;

>>>>

>>>> // project spherical coordinate point onto cylinder of radius r

>>>> cyl_proj = function (r,theta_phi)

>>>> [for(pt=theta_phi)

>>>> let(xyz = spherical_to_xyz(1,pt[0], 90-pt[1]))

>>>> r * xyz / norm(point2d(xyz))];

>>>>

>>>> bottom =

>>>> min([tan(valley_angle)*ir,tan(valley_angle)*or])-base-cone_height*ir;

>>>> safebottom =

>>>> min([tan(valley_angle)*ir/factor,tan(valley_angle)*or*factor])-base-(crop?1:0)-cone_height*ir;

>>>> ang_ofs = !rot ? -skew*angle

>>>> : n%2==0 ? -(angle-skew*angle) - skew*angle

>>>> : -angle*(2-skew)-skew*angle;

>>>> topinner = down(cone_height*ir,[for(ang=lerpn(0,360,n,endpoint=false))

>>>> each

>>>> zrot(ang+ang_ofs,cyl_proj(ir/factor,profile))]);

>>>> topouter = down(cone_height*ir,[for(ang=lerpn(0,360,n,endpoint=false))

>>>> each

>>>> zrot(ang+ang_ofs,cyl_proj(factor*or,profile))]);

>>>> botinner = [for(val=topinner) [val.x,val.y,safebottom]];

>>>> botouter = [for(val=topouter) [val.x,val.y,safebottom]];

>>>> vert = [topouter, topinner, botinner, botouter];

>>>>

>>>> anchors = [

>>>> named_anchor("teeth_bot", [0,0,bottom], DOWN)

>>>> ];

>>>> attachable(anchor=anchor,spin=spin,orient=orient, r=or,

>>>> h=-2*bottom,anchors=anchors){

>>>> intersection(){

>>>> vnf_polyhedron(vnf_vertex_array(vert, reverse=true,

>>>> col_wrap=true, row_wrap=true),convexity=min(10,n));

>>>> if (crop)

>>>>

>>>> zmove(bottom)tube(or=or,ir=ir,height=4*or,anchor=BOT,$fa=1,$fs=1);

>>>> }

>>>> children();

>>>> }

>>>> }

>>>>

>>>>

>>>>

>>>> On Wed, Nov 6, 2024 at 7:55 PM Bob Carlson via Discuss <

>>>> discuss@lists.openscad.org> wrote:

>>>>

>>>>> I have established that there is an error in the code fragment. The

>>>>> line

>>>>>

>>>>> thetaCA2 = _toothAngle(hs) * _chamfer(hs)/200;

>>>>>

>>>>> Is where the error lies. What should it be? I was assuming that the

>>>>> theta for the chamfer “shoulder” point would be proportional to the chamfer

>>>>> but it produces a slight error. It is barely noticeable but gets more

>>>>> blatant at low tooth counts and high conic.

>>>>>

>>>>> Anyone see what it should be? I’m guessing there is some trig

>>>>> functions involved,but ...

>>>>>

>>>>> -Bob

>>>>>

>>>>> On Nov 5, 2024, at 10:29, Bob Carlson via Discuss <

>>>>> discuss@lists.openscad.org> wrote:

>>>>>

>>>>> Here is just a code fragment but it gets the point across.

>>>>>

>>>>> IR = _ir(hs);

>>>>> OR = _or(hs) / cos(180/_n(hs)); // OR is the radius of the

>>>>> circumscribing polygon of N

>>>>>

>>>>> // Ridge Chamfer

>>>>> thetaCA2 = _toothAngle(hs) * _chamfer(hs)/200;

>>>>> phiCA = (_grooveAngle(hs) -_ridgeAngle(hs)) * _chamfer(hs)/100;

>>>>>

>>>>> function profileToooth(r) =

>>>>> [spherical2_to_xyz(r, thetaCA2, _ridgeAngle(hs) +

>>>>> phiCA),

>>>>> spherical2_to_xyz(r, _toothAngle(hs)/2, _grooveAngle(hs)),

>>>>> spherical2_to_xyz(r, -_toothAngle(hs)/2, _grooveAngle(hs)),

>>>>> spherical2_to_xyz(r, - thetaCA2, _ridgeAngle(hs) +

>>>>> phiCA)

>>>>> ];

>>>>>

>>>>>

>>>>> _______________________________________________

>>>>> OpenSCAD mailing list

>>>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>>

>>>> _______________________________________________

>>>> OpenSCAD mailing list

>>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>

>>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

>

AM

Adrian Mariano

Thu, Nov 7, 2024 11:29 AM

In the to picture, there is no cylinder pictured, but some complicated

shape with multiple curves, some of which are not even circular arcs. So I

don't understand that picture. You can try the code I posted earlier,

which uses the cylinder projection approach.

On Thu, Nov 7, 2024 at 6:23 AM Sanjeev Prabhakar sprabhakar2006@gmail.com

wrote:

All the magenta lines are vectors, you can think of them originating from

any side of the line.

Each line intersects a circumscribing cylinder outer or inner and that

forms the circular hirth coupling.

On Thu, 7 Nov, 2024, 4:40 pm Adrian Mariano, avm4@cornell.edu wrote:

I do not understand the pictures. Or at least the top one is

mystifying. The bottom one looks like it could describe the process: the

projection is along vectors that originate at the origin and yes, you have

a separate projection onto the inner and outer cylinder.

On Wed, Nov 6, 2024 at 11:24 PM Sanjeev Prabhakar <

sprabhakar2006@gmail.com> wrote:

I don't think the straight projection on cylinder will work.

The only way I think this can work is if you project using vectors

considering outer race and inner race, projecting outwards and inwards

respectively on outer and inner cylinder.

picture below can make this clear.

magenta lines are the vectors

[image: Screenshot 2024-11-07 at 9.49.27 AM.png]

[image: Screenshot 2024-11-07 at 9.53.29 AM.png]

On Thu, 7 Nov, 2024, 8:12 am Adrian Mariano via Discuss, <

discuss@lists.openscad.org> wrote:

Bob, I did I think exactly the same thing in my code and didn't notice

anything, but now that you mention it, doing chamfers on an angular basis

is of course not going to match doing them on a linear basis. So that

means the geometry changes a bit if you change the chamfer size. This

isn't necessarily catastrophic, but is a little unexpected, I suppose.

Generally speaking you can't mate two parts produced with different chamfer

size anyway, so I'm not sure this is crucial to get right. But in order to

get it right, I think both thetaCA2 and phiCA are going to need to be

computed with trig---either that or there's some complicated way of

computing just one. The question is whether these two parameters can be

computed independently or are they related in some complicated way.

Treated as a 2d problem you are trying to get the angle that corresponds to

a fraction of a chord of the circle, which is a reasonably straight forward

triangle calculation. I got atan(chamfer*tan(angle)) where angle is

180/tooth_count for the ridge chamfer. But the chamfered one still doesn't

align with the unchamfered. For example:

[image: image.png]

Yellow is unchamfered. Blue has huge chamfer applied only at ridge

(and slightly larger radius so we can see it clearly). And we see that the

angle has changed. I actually got less error with the original

calculation, but that might be because I didn't correct the phi angle only

the theta angle. (Or maybe I botched the trig.) So I tried computing a

correction for phi and got ridge_angle-atan(ridge_angle -

chamfer*(tan(ridge_angle)-tan(valley_angle))), but still things don't line

up correctly. (And the horizontal correction is still worse than not,

which makes me wonder if the horizontal correction needs to take into

account the vertical position of the chamfer somehow.) Doing the phi

correction alone actually is an improvement over no correction.

Here's my current code (without any chamfer corrections). It does

rounding and skew teeth.

module hirth(n, ir, or, id, od, tooth_angle=60, cone_angle=0, chamfer,

rounding, base=1, crop=false,skew=0, rot=false, orient,anchor,spin)

{

ir = get_radius(r=ir,d=id);

or = get_radius(r=or,d=od);

dummy = assert(all_positive([ir]), "ir/id must be a positive value")

assert(all_positive([or]), "or/od must be a positive value")

assert(is_int(n) && n>1, "n must be an integer larger than 1")

assert(is_finite(skew) && abs(skew)<=1, "skew must be a

number between -1 and 1")

assert(ir<or, "inside radius (ir/id) must be smaller than

outside radius (or/od)")

assert(all_positive([tooth_angle]) &&

tooth_angle<360*(n-1)/2/n, str("tooth angle must be between 0 and

",360*(n-1)/2/n," for spline with ",n," teeth."))

assert(num_defined([chamfer,rounding]) <=1, "Cannot define

both chamfer and rounding")

assert(is_undef(chamfer) || all_nonnegative([chamfer]) &&

chamfer<1/2, "chamfer must be a non-negative value smaller than 1/2")

assert(is_undef(rounding) || all_nonnegative([rounding]) &&

rounding<1/2, "rounding must be a non-negative value smaller than 1/2")

assert(all_positive([base]), "base must be a positive value")

;

tooth_height = sin(180/n) / tan(tooth_angle/2); // Normalized

tooth height

cone_height = -tan(cone_angle); // Normalized

height change corresponding to the cone angle

ridge_angle = atan(tooth_height/2 + cone_height);

valley_angle = atan(-tooth_height/2 + cone_height);

angle = 180/n; // Half the angle occupied by each tooth going

around the circle

factor = crop ? 3 : 1; // Make it oversized when crop is true

profile = is_undef(rounding) || rounding==0 ?

let(

chamfer=default(chamfer,0),

vchamf = chamfer*(ridge_angle-valley_angle),

pts = [

[-angle*(1-chamfer/2),

valley_angle+vchamf/2],

[-anglechamfer, ridge_angle-vchamf]

],

full = deduplicate(concat(pts,

reverse(xflip(pts))))

)

back(valley_angle,

skew(sxy=skewangle/(ridge_angle-valley_angle),fwd(valley_angle,full)))

: let(

vround=rounding*(ridge_angle-valley_angle),

profpts = [

[ -angle, valley_angle+vround/2],

[ -angle*(1-rounding/2),

valley_angle+vround/2],

[ -anglerounding, ridge_angle-vround],

],

segs = max(16,segs(orrounding)),

full = concat(profpts, reverse(xflip(profpts))),

skewed = back(valley_angle,

skew(sxy=skew*angle/(ridge_angle-valley_angle),fwd(valley_angle,full))),

// Using computed values for the joints

lead to round-off error issues

joints = [(skewed[1]-skewed[0]).x,

(skewed[3]-skewed[2]).x/2,

(skewed[3]-skewed[2]).x/2,(skewed[5]-skewed[4]).x ],

roundpts = round_corners(skewed, joint=joints,

closed=false,$fn=segs)

)

roundpts;

// project spherical coordinate point onto cylinder of radius r

cyl_proj = function (r,theta_phi)

[for(pt=theta_phi)

let(xyz = spherical_to_xyz(1,pt[0], 90-pt[1]))

r * xyz / norm(point2d(xyz))];

bottom =

min([tan(valley_angle)ir,tan(valley_angle)or])-base-cone_heightir;

safebottom =

min([tan(valley_angle)ir/factor,tan(valley_angle)orfactor])-base-(crop?1:0)-cone_heightir;

ang_ofs = !rot ? -skewangle

: n%2==0 ? -(angle-skewangle) - skewangle

: -angle*(2-skew)-skewangle;

topinner = down(cone_heightir,[for(ang=lerpn(0,360,n,endpoint=false))

each

zrot(ang+ang_ofs,cyl_proj(ir/factor,profile))]);

topouter = down(cone_heightir,[for(ang=lerpn(0,360,n,endpoint=false))

each

zrot(ang+ang_ofs,cyl_proj(factoror,profile))]);

botinner = [for(val=topinner) [val.x,val.y,safebottom]];

botouter = [for(val=topouter) [val.x,val.y,safebottom]];

vert = [topouter, topinner, botinner, botouter];

anchors = [

named_anchor("teeth_bot", [0,0,bottom], DOWN)

];

attachable(anchor=anchor,spin=spin,orient=orient, r=or,

h=-2*bottom,anchors=anchors){

intersection(){

vnf_polyhedron(vnf_vertex_array(vert, reverse=true,

col_wrap=true, row_wrap=true),convexity=min(10,n));

if (crop)

zmove(bottom)tube(or=or,ir=ir,height=4*or,anchor=BOT,$fa=1,$fs=1);

}

children();

}

}

On Wed, Nov 6, 2024 at 7:55 PM Bob Carlson via Discuss <

discuss@lists.openscad.org> wrote:

I have established that there is an error in the code fragment. The

line

thetaCA2 = _toothAngle(hs) * _chamfer(hs)/200;

Is where the error lies. What should it be? I was assuming that the

theta for the chamfer “shoulder” point would be proportional to the chamfer

but it produces a slight error. It is barely noticeable but gets more

blatant at low tooth counts and high conic.

Anyone see what it should be? I’m guessing there is some trig

functions involved,but ...

-Bob

On Nov 5, 2024, at 10:29, Bob Carlson via Discuss <

discuss@lists.openscad.org> wrote:

Here is just a code fragment but it gets the point across.

IR = _ir(hs);

OR = _or(hs) / cos(180/_n(hs)); // OR is the radius of the

circumscribing polygon of N

// Ridge Chamfer

thetaCA2 = _toothAngle(hs) * _chamfer(hs)/200;

phiCA = (_grooveAngle(hs) -_ridgeAngle(hs)) * _chamfer(hs)/100;

function profileToooth(r) =

[spherical2_to_xyz(r, thetaCA2, _ridgeAngle(hs) +

phiCA),

spherical2_to_xyz(r, _toothAngle(hs)/2, _grooveAngle(hs)),

spherical2_to_xyz(r, -_toothAngle(hs)/2, _grooveAngle(hs)),

spherical2_to_xyz(r, - thetaCA2, _ridgeAngle(hs) +

phiCA)

];

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

In the to picture, there is no cylinder pictured, but some complicated

shape with multiple curves, some of which are not even circular arcs. So I

don't understand that picture. You can try the code I posted earlier,

which uses the cylinder projection approach.

On Thu, Nov 7, 2024 at 6:23 AM Sanjeev Prabhakar <sprabhakar2006@gmail.com>

wrote:

> All the magenta lines are vectors, you can think of them originating from

> any side of the line.

>

> Each line intersects a circumscribing cylinder outer or inner and that

> forms the circular hirth coupling.

>

>

>

> On Thu, 7 Nov, 2024, 4:40 pm Adrian Mariano, <avm4@cornell.edu> wrote:

>

>> I do not understand the pictures. Or at least the top one is

>> mystifying. The bottom one looks like it could describe the process: the

>> projection is along vectors that originate at the origin and yes, you have

>> a separate projection onto the inner and outer cylinder.

>>

>> On Wed, Nov 6, 2024 at 11:24 PM Sanjeev Prabhakar <

>> sprabhakar2006@gmail.com> wrote:

>>

>>> I don't think the straight projection on cylinder will work.

>>> The only way I think this can work is if you project using vectors

>>> considering outer race and inner race, projecting outwards and inwards

>>> respectively on outer and inner cylinder.

>>> picture below can make this clear.

>>> magenta lines are the vectors

>>> [image: Screenshot 2024-11-07 at 9.49.27 AM.png]

>>> [image: Screenshot 2024-11-07 at 9.53.29 AM.png]

>>>

>>> On Thu, 7 Nov, 2024, 8:12 am Adrian Mariano via Discuss, <

>>> discuss@lists.openscad.org> wrote:

>>>

>>>> Bob, I did I think exactly the same thing in my code and didn't notice

>>>> anything, but now that you mention it, doing chamfers on an angular basis

>>>> is of course not going to match doing them on a linear basis. So that

>>>> means the geometry changes a bit if you change the chamfer size. This

>>>> isn't necessarily catastrophic, but is a little unexpected, I suppose.

>>>> Generally speaking you can't mate two parts produced with different chamfer

>>>> size anyway, so I'm not sure this is crucial to get right. But in order to

>>>> get it right, I think both thetaCA2 and phiCA are going to need to be

>>>> computed with trig---either that or there's some complicated way of

>>>> computing just one. The question is whether these two parameters can be

>>>> computed independently or are they related in some complicated way.

>>>> Treated as a 2d problem you are trying to get the angle that corresponds to

>>>> a fraction of a chord of the circle, which is a reasonably straight forward

>>>> triangle calculation. I got atan(chamfer*tan(angle)) where angle is

>>>> 180/tooth_count for the ridge chamfer. But the chamfered one still doesn't

>>>> align with the unchamfered. For example:

>>>>

>>>> [image: image.png]

>>>>

>>>> Yellow is unchamfered. Blue has huge chamfer applied only at ridge

>>>> (and slightly larger radius so we can see it clearly). And we see that the

>>>> angle has changed. I actually got less error with the original

>>>> calculation, but that might be because I didn't correct the phi angle only

>>>> the theta angle. (Or maybe I botched the trig.) So I tried computing a

>>>> correction for phi and got ridge_angle-atan(ridge_angle -

>>>> chamfer*(tan(ridge_angle)-tan(valley_angle))), but still things don't line

>>>> up correctly. (And the horizontal correction is still worse than not,

>>>> which makes me wonder if the horizontal correction needs to take into

>>>> account the vertical position of the chamfer somehow.) Doing the phi

>>>> correction alone actually is an improvement over no correction.

>>>>

>>>> Here's my current code (without any chamfer corrections). It does

>>>> rounding and skew teeth.

>>>>

>>>> module hirth(n, ir, or, id, od, tooth_angle=60, cone_angle=0, chamfer,

>>>> rounding, base=1, crop=false,skew=0, rot=false, orient,anchor,spin)

>>>> {

>>>> ir = get_radius(r=ir,d=id);

>>>> or = get_radius(r=or,d=od);

>>>> dummy = assert(all_positive([ir]), "ir/id must be a positive value")

>>>> assert(all_positive([or]), "or/od must be a positive value")

>>>> assert(is_int(n) && n>1, "n must be an integer larger than 1")

>>>> assert(is_finite(skew) && abs(skew)<=1, "skew must be a

>>>> number between -1 and 1")

>>>> assert(ir<or, "inside radius (ir/id) must be smaller than

>>>> outside radius (or/od)")

>>>> assert(all_positive([tooth_angle]) &&

>>>> tooth_angle<360*(n-1)/2/n, str("tooth angle must be between 0 and

>>>> ",360*(n-1)/2/n," for spline with ",n," teeth."))

>>>> assert(num_defined([chamfer,rounding]) <=1, "Cannot define

>>>> both chamfer and rounding")

>>>> assert(is_undef(chamfer) || all_nonnegative([chamfer]) &&

>>>> chamfer<1/2, "chamfer must be a non-negative value smaller than 1/2")

>>>> assert(is_undef(rounding) || all_nonnegative([rounding]) &&

>>>> rounding<1/2, "rounding must be a non-negative value smaller than 1/2")

>>>> assert(all_positive([base]), "base must be a positive value")

>>>> ;

>>>> tooth_height = sin(180/n) / tan(tooth_angle/2); // Normalized

>>>> tooth height

>>>> cone_height = -tan(cone_angle); // Normalized

>>>> height change corresponding to the cone angle

>>>> ridge_angle = atan(tooth_height/2 + cone_height);

>>>> valley_angle = atan(-tooth_height/2 + cone_height);

>>>> angle = 180/n; // Half the angle occupied by each tooth going

>>>> around the circle

>>>>

>>>> factor = crop ? 3 : 1; // Make it oversized when crop is true

>>>>

>>>> profile = is_undef(rounding) || rounding==0 ?

>>>> let(

>>>> chamfer=default(chamfer,0),

>>>> vchamf = chamfer*(ridge_angle-valley_angle),

>>>> pts = [

>>>> [-angle*(1-chamfer/2),

>>>> valley_angle+vchamf/2],

>>>> [-angle*chamfer, ridge_angle-vchamf]

>>>> ],

>>>> full = deduplicate(concat(pts,

>>>> reverse(xflip(pts))))

>>>> )

>>>> back(valley_angle,

>>>> skew(sxy=skew*angle/(ridge_angle-valley_angle),fwd(valley_angle,full)))

>>>> : let(

>>>> vround=rounding*(ridge_angle-valley_angle),

>>>> profpts = [

>>>> [ -angle, valley_angle+vround/2],

>>>> [ -angle*(1-rounding/2),

>>>> valley_angle+vround/2],

>>>> [ -angle*rounding, ridge_angle-vround],

>>>> ],

>>>> segs = max(16,segs(or*rounding)),

>>>> full = concat(profpts, reverse(xflip(profpts))),

>>>> skewed = back(valley_angle,

>>>> skew(sxy=skew*angle/(ridge_angle-valley_angle),fwd(valley_angle,full))),

>>>> // Using computed values for the joints

>>>> lead to round-off error issues

>>>> joints = [(skewed[1]-skewed[0]).x,

>>>> (skewed[3]-skewed[2]).x/2,

>>>> (skewed[3]-skewed[2]).x/2,(skewed[5]-skewed[4]).x ],

>>>> roundpts = round_corners(skewed, joint=joints,

>>>> closed=false,$fn=segs)

>>>> )

>>>> roundpts;

>>>>

>>>> // project spherical coordinate point onto cylinder of radius r

>>>> cyl_proj = function (r,theta_phi)

>>>> [for(pt=theta_phi)

>>>> let(xyz = spherical_to_xyz(1,pt[0], 90-pt[1]))

>>>> r * xyz / norm(point2d(xyz))];

>>>>

>>>> bottom =

>>>> min([tan(valley_angle)*ir,tan(valley_angle)*or])-base-cone_height*ir;

>>>> safebottom =

>>>> min([tan(valley_angle)*ir/factor,tan(valley_angle)*or*factor])-base-(crop?1:0)-cone_height*ir;

>>>> ang_ofs = !rot ? -skew*angle

>>>> : n%2==0 ? -(angle-skew*angle) - skew*angle

>>>> : -angle*(2-skew)-skew*angle;

>>>> topinner = down(cone_height*ir,[for(ang=lerpn(0,360,n,endpoint=false))

>>>> each

>>>> zrot(ang+ang_ofs,cyl_proj(ir/factor,profile))]);

>>>> topouter = down(cone_height*ir,[for(ang=lerpn(0,360,n,endpoint=false))

>>>> each

>>>> zrot(ang+ang_ofs,cyl_proj(factor*or,profile))]);

>>>> botinner = [for(val=topinner) [val.x,val.y,safebottom]];

>>>> botouter = [for(val=topouter) [val.x,val.y,safebottom]];

>>>> vert = [topouter, topinner, botinner, botouter];

>>>>

>>>> anchors = [

>>>> named_anchor("teeth_bot", [0,0,bottom], DOWN)

>>>> ];

>>>> attachable(anchor=anchor,spin=spin,orient=orient, r=or,

>>>> h=-2*bottom,anchors=anchors){

>>>> intersection(){

>>>> vnf_polyhedron(vnf_vertex_array(vert, reverse=true,

>>>> col_wrap=true, row_wrap=true),convexity=min(10,n));

>>>> if (crop)

>>>>

>>>> zmove(bottom)tube(or=or,ir=ir,height=4*or,anchor=BOT,$fa=1,$fs=1);

>>>> }

>>>> children();

>>>> }

>>>> }

>>>>

>>>>

>>>>

>>>> On Wed, Nov 6, 2024 at 7:55 PM Bob Carlson via Discuss <

>>>> discuss@lists.openscad.org> wrote:

>>>>

>>>>> I have established that there is an error in the code fragment. The

>>>>> line

>>>>>

>>>>> thetaCA2 = _toothAngle(hs) * _chamfer(hs)/200;

>>>>>

>>>>> Is where the error lies. What should it be? I was assuming that the

>>>>> theta for the chamfer “shoulder” point would be proportional to the chamfer

>>>>> but it produces a slight error. It is barely noticeable but gets more

>>>>> blatant at low tooth counts and high conic.

>>>>>

>>>>> Anyone see what it should be? I’m guessing there is some trig

>>>>> functions involved,but ...

>>>>>

>>>>> -Bob

>>>>>

>>>>> On Nov 5, 2024, at 10:29, Bob Carlson via Discuss <

>>>>> discuss@lists.openscad.org> wrote:

>>>>>

>>>>> Here is just a code fragment but it gets the point across.

>>>>>

>>>>> IR = _ir(hs);

>>>>> OR = _or(hs) / cos(180/_n(hs)); // OR is the radius of the

>>>>> circumscribing polygon of N

>>>>>

>>>>> // Ridge Chamfer

>>>>> thetaCA2 = _toothAngle(hs) * _chamfer(hs)/200;

>>>>> phiCA = (_grooveAngle(hs) -_ridgeAngle(hs)) * _chamfer(hs)/100;

>>>>>

>>>>> function profileToooth(r) =

>>>>> [spherical2_to_xyz(r, thetaCA2, _ridgeAngle(hs) +

>>>>> phiCA),

>>>>> spherical2_to_xyz(r, _toothAngle(hs)/2, _grooveAngle(hs)),

>>>>> spherical2_to_xyz(r, -_toothAngle(hs)/2, _grooveAngle(hs)),

>>>>> spherical2_to_xyz(r, - thetaCA2, _ridgeAngle(hs) +

>>>>> phiCA)

>>>>> ];

>>>>>

>>>>>