Morphing irregular shape while extruding?

Haven't done any printing for ages, and more than a bit rusty, so...

I have a garden 'blower' that I want to improvise for an unusual

purpose. I need to print a PLA add-on I can temporarily push inside its

open end. That end of the part must obviously roughly match the blower

tube's shape. Although not an OpenSCAD issue, any tips on the best way

to capture that closed curve would be welcome. The best two

I've come up with so far:

-

Wrap some stiff wire tightly around the blower near its end. Or

perhaps better, a long but thin strip of aluminium; slide that off and

make an SVG.in Inkscape (when I've relearnt how to do that). -

Use the rough pencil trace I've made as the SVG basis. Then in

OpenSCAD reduce its 'x' coordinates appropriately. Presumably the factor

would be b/h estimated from the photo.

Precision won't be an issue as I'll glue some thin but flexible stuff to

the outside.

The more difficult aspect is that the other end of the print must be a

cylinder of about 2 inches (50 mm) in height and 5/8 inch (15 mm) inner

diameter. (I'll be attaching a hose or similar.) This would obviously be

trivial if the starting shape was circular, but what is the general

approach for extruding from an irregular shape to a circle?

While preparing this a simpler idea dawned, and it would take a fraction

of the time to prepare. A rectangular piece of plywood or similar

covering the entire end of the blower, secured by screws or velcro to

the adjacent plastic area. The 3d print (if an existing piece of tubing

cannot be found) would be a simple cylinder, friction fitted inside a

hole in the wood's centre.

But I'd still like to learn how to 'morph' from one 2D shape to another

please.

Image attached, or here:

https://www.dropbox.com/s/tcj3g1f0zd4n1j7/Two-plus.jpg?raw=1

Terry, UK

I'm not going to say this is THE answer, but it might still work as desired. Your SVG tracing can be imported and extruded to a minimal height. A circle of the appropriate dimensions also created to a minimal height, then translated to the desired distance.

Hull() the pair twice, rescale the x/y for the second hull(), then difference them.

This idea stems from a web search for "OpenSCAD loft" which presented an Instructable that didn't really help, but twisted the alleged mind in this direction.

On Thursday, January 19, 2023 at 10:55:30 AM EST, Terry <terrypingm@gmail.com> wrote:

Haven't done any printing for ages, and more than a bit rusty, so...

I have a garden 'blower' that I want to improvise for an unusual

purpose. I need to print a PLA add-on I can temporarily push inside its

open end. That end of the part must obviously roughly match the blower

tube's shape. Although not an OpenSCAD issue, any tips on the best way

to capture that closed curve would be welcome. The best two

I've come up with so far:

-

Wrap some stiff wire tightly around the blower near its end. Or

perhaps better, a long but thin strip of aluminium; slide that off and

make an SVG.in Inkscape (when I've relearnt how to do that). -

Use the rough pencil trace I've made as the SVG basis. Then in

OpenSCAD reduce its 'x' coordinates appropriately. Presumably the factor

would be b/h estimated from the photo.

Precision won't be an issue as I'll glue some thin but flexible stuff to

the outside.

The more difficult aspect is that the other end of the print must be a

cylinder of about 2 inches (50 mm) in height and 5/8 inch (15 mm) inner

diameter. (I'll be attaching a hose or similar.) This would obviously be

trivial if the starting shape was circular, but what is the general

approach for extruding from an irregular shape to a circle?

While preparing this a simpler idea dawned, and it would take a fraction

of the time to prepare. A rectangular piece of plywood or similar

covering the entire end of the blower, secured by screws or velcro to

the adjacent plastic area. The 3d print (if an existing piece of tubing

cannot be found) would be a simple cylinder, friction fitted inside a

hole in the wood's centre.

But I'd still like to learn how to 'morph' from one 2D shape to another

please.

Image attached, or here:

https://www.dropbox.com/s/tcj3g1f0zd4n1j7/Two-plus.jpg?raw=1

Terry, UK

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Hi,

I think we should generalize the "linear_extrude" module. Split it

into two parts.

For now it creates a surface between a bunch of 2D objects placed at

different heights. Currently it can do two (or more?) transformations

to the given 2D object at each height.

the first is

rotate (cur_height/total_height * rotation_angle)

and the second is a scale. Maybe there are more.

But somewhere down there there is now a "children ()".

If instead we'd pass a extrude_position=... parameter to the to be

instantiated children, those modules can do other (more generic)

morphing than just rotate and scale.

That'd make say extruding a pipe with a spline function as the

diameter way more elegant than calculating the points by hand and

calling polyhedron at the end.

Roger.

On Thu, Jan 19, 2023 at 03:53:59PM +0000, Terry wrote:

Haven't done any printing for ages, and more than a bit rusty, so...

I have a garden 'blower' that I want to improvise for an unusual

purpose. I need to print a PLA add-on I can temporarily push inside its

open end. That end of the part must obviously roughly match the blower

tube's shape. Although not an OpenSCAD issue, any tips on the best way

to capture that closed curve would be welcome. The best two

I've come up with so far:

-

Wrap some stiff wire tightly around the blower near its end. Or

perhaps better, a long but thin strip of aluminium; slide that off and

make an SVG.in Inkscape (when I've relearnt how to do that). -

Use the rough pencil trace I've made as the SVG basis. Then in

OpenSCAD reduce its 'x' coordinates appropriately. Presumably the factor

would be b/h estimated from the photo.

Precision won't be an issue as I'll glue some thin but flexible stuff to

the outside.

The more difficult aspect is that the other end of the print must be a

cylinder of about 2 inches (50 mm) in height and 5/8 inch (15 mm) inner

diameter. (I'll be attaching a hose or similar.) This would obviously be

trivial if the starting shape was circular, but what is the general

approach for extruding from an irregular shape to a circle?

While preparing this a simpler idea dawned, and it would take a fraction

of the time to prepare. A rectangular piece of plywood or similar

covering the entire end of the blower, secured by screws or velcro to

the adjacent plastic area. The 3d print (if an existing piece of tubing

cannot be found) would be a simple cylinder, friction fitted inside a

hole in the wood's centre.

But I'd still like to learn how to 'morph' from one 2D shape to another

please.

Image attached, or here:

https://www.dropbox.com/s/tcj3g1f0zd4n1j7/Two-plus.jpg?raw=1

Terry, UK

--

** R.E.Wolff@BitWizard.nl ** https://www.BitWizard.nl/ ** +31-15-2049110 **

** Delftechpark 11 2628 XJ Delft, The Netherlands. KVK: 27239233 **

f equals m times a. When your f is steady, and your m is going down

your a is going up. -- Chris Hadfield about flying up the space shuttle.

Terry,

I had another thought - simplistic but I think it should be enough for

your needs:

Make a solid object by importing your SVG and using linear_extrude to

convert it into a cone (by setting the scale parameter to 0). Add a

cylinder to match the required inside radius of your hose end and tall

enough to protrude by the distance you need. Add a straight-sided

linear_extruded section at the bottom to make a connector for your

blower end.

Repeat to make a second object, but this time offset the SVG to make it

a bit bigger and also widen the cylinder to the required outer radius.

Take the difference of the two objects, second minus first, to produce a

hollow funnel.

The following sample code does the job. You might have to alter the

bottom outline depending on whether you want your blower to fit inside

or outside the funnel, and for the specific dimensions and connector

lengths you need (and of course, if the exact wall thickness is

important you would have to use minkowski to form the outer shape.)

file = "footprint.svg";

$fn = 60;

difference() {

union() {

linear_extrude(100, scale = 0) offset(2) import(file);

cylinder(100, r = 15 + 2);

translate([0, 0, -10]) linear_extrude(10) offset(2) import(file);

}

union() {

linear_extrude(100, scale = 0) import(file);

cylinder(100, r = 15);

translate([0, 0, -10])linear_extrude(10) import(file);

}

}

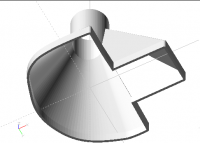

And here's a screenshot using an arbitrary footprint.

Cheers,

Steve

On 2023-01-19 7:53 a.m., Terry wrote:

Haven't done any printing for ages, and more than a bit rusty, so...

I have a garden 'blower' that I want to improvise for an unusual

purpose. I need to print a PLA add-on I can temporarily push inside its

open end. That end of the part must obviously roughly match the blower

tube's shape. Although not an OpenSCAD issue, any tips on the best way

to capture that closed curve would be welcome. The best two

I've come up with so far:

-

Wrap some stiff wire tightly around the blower near its end. Or

perhaps better, a long but thin strip of aluminium; slide that off and

make an SVG.in Inkscape (when I've relearnt how to do that). -

Use the rough pencil trace I've made as the SVG basis. Then in

OpenSCAD reduce its 'x' coordinates appropriately. Presumably the factor

would be b/h estimated from the photo.

Precision won't be an issue as I'll glue some thin but flexible stuff to

the outside.

The more difficult aspect is that the other end of the print must be a

cylinder of about 2 inches (50 mm) in height and 5/8 inch (15 mm) inner

diameter. (I'll be attaching a hose or similar.) This would obviously be

trivial if the starting shape was circular, but what is the general

approach for extruding from an irregular shape to a circle?

While preparing this a simpler idea dawned, and it would take a fraction

of the time to prepare. A rectangular piece of plywood or similar

covering the entire end of the blower, secured by screws or velcro to

the adjacent plastic area. The 3d print (if an existing piece of tubing

cannot be found) would be a simple cylinder, friction fitted inside a

hole in the wood's centre.

But I'd still like to learn how to 'morph' from one 2D shape to another

please.

Image attached, or here:

https://www.dropbox.com/s/tcj3g1f0zd4n1j7/Two-plus.jpg?raw=1

Terry, UK

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

Thanks Steve. But why the hollow ‘wedge’ extension? Without that, it looks like my original intention. Which was already somewhat OTT on reflection.

Anyway, learning exercise apart, for a task that will be rarely used I’m pretty sure I’ll go with the previously discussed crude approach!

--

Terry

On 20 Jan 2023, at 16:42, Steve Lelievre <steve.lelievre.canada@gmail.com> wrote:

Terry,

I had another thought - simplistic but I think it should be enough for your needs:

Make a solid object by importing your SVG and using linear_extrude to convert it into a cone (by setting the scale parameter to 0). Add a cylinder to match the required inside radius of your hose end and tall enough to protrude by the distance you need. Add a straight-sided linear_extruded section at the bottom to make a connector for your blower end.

Repeat to make a second object, but this time offset the SVG to make it a bit bigger and also widen the cylinder to the required outer radius.

Take the difference of the two objects, second minus first, to produce a hollow funnel.

The following sample code does the job. You might have to alter the bottom outline depending on whether you want your blower to fit inside or outside the funnel, and for the specific dimensions and connector lengths you need (and of course, if the exact wall thickness is important you would have to use minkowski to form the outer shape.)

file = "footprint.svg";

$fn = 60;

difference() {

union() {

linear_extrude(100, scale = 0) offset(2) import(file);

cylinder(100, r = 15 + 2);

translate([0, 0, -10]) linear_extrude(10) offset(2) import(file);

}

union() {

linear_extrude(100, scale = 0) import(file);

cylinder(100, r = 15);

translate([0, 0, -10])linear_extrude(10) import(file);

}

}

And here's a screenshot using an arbitrary footprint.

<00AwiOdUczn1Et7F.png>

Cheers,

Steve

On 2023-01-19 7:53 a.m., Terry wrote:

<pre class="moz-quote-pre" wrap="">Haven't done any printing for ages, and more than a bit rusty, so... I have a garden 'blower' that I want to improvise for an unusual purpose. I need to print a PLA add-on I can temporarily push inside its open end. That end of the part must obviously roughly match the blower tube's shape. Although not an OpenSCAD issue, any tips on the best way to capture that closed curve would be welcome. The best two I've come up with so far: 1. Wrap some stiff wire tightly around the blower near its end. Or perhaps better, a long but thin strip of aluminium; slide that off and make an SVG.in Inkscape (when I've relearnt how to do that). 2. Use the rough pencil trace I've made as the SVG basis. Then in OpenSCAD reduce its 'x' coordinates appropriately. Presumably the factor would be b/h estimated from the photo. Precision won't be an issue as I'll glue some thin but flexible stuff to the outside. The more difficult aspect is that the other end of the print must be a cylinder of about 2 inches (50 mm) in height and 5/8 inch (15 mm) inner diameter. (I'll be attaching a hose or similar.) This would obviously be trivial if the starting shape was circular, but what is the general approach for extruding from an irregular shape to a circle? -------------------- While preparing this a simpler idea dawned, and it would take a fraction of the time to prepare. A rectangular piece of plywood or similar covering the entire end of the blower, secured by screws or velcro to the adjacent plastic area. The 3d print (if an existing piece of tubing cannot be found) would be a simple cylinder, friction fitted inside a hole in the wood's centre. But I'd still like to learn how to 'morph' from one 2D shape to another please. Image attached, or here: <a class="moz-txt-link-freetext" href="https://www.dropbox.com/s/tcj3g1f0zd4n1j7/Two-plus.jpg?raw=1">https://www.dropbox.com/s/tcj3g1f0zd4n1j7/Two-plus.jpg?raw=1</a> Terry, UK<pre class="moz-quote-pre" wrap="">_______________________________________________ OpenSCAD mailing list To unsubscribe send an email to <a class="moz-txt-link-abbreviated" href="mailto:discuss-leave@lists.openscad.org">discuss-leave@lists.openscad.org</a>

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On 2023-01-20 10:28 a.m., terrypingm@gmail.com wrote:

Thanks Steve. But why the hollow ‘wedge’ extension? Without that, it

looks like my original intention.

It just means l wasn't quite clear about the shape you wanted.

Steve

On 1/20/2023 4:02 AM, Rogier Wolff wrote:

If instead we'd pass a extrude_position=... parameter to the to be

instantiated children, those modules can do other (more generic)

morphing than just rotate and scale.

I believe the current linear extrude takes advantage of the fact that

each successive layer has the same vertices, and connects them.

Connecting two arbitrary 2D shapes is a much harder problem.

I believe some of the libraries (like BOSL2) have more general sweep

functions that can tolerate changes in the shape, but I don't know what

the limitations are.

Rogier, it sounds like you're asking for something like the sweep() module

that has been implemented in various libraries, going back to the original

list-comprehension-demos library. But still not available directly in

OpenSCAD.

On Fri, Jan 20, 2023 at 7:03 AM Rogier Wolff R.E.Wolff@bitwizard.nl wrote:

Hi,

I think we should generalize the "linear_extrude" module. Split it

into two parts.

For now it creates a surface between a bunch of 2D objects placed at

different heights. Currently it can do two (or more?) transformations

to the given 2D object at each height.

the first is

rotate (cur_height/total_height * rotation_angle)

and the second is a scale. Maybe there are more.

But somewhere down there there is now a "children ()".

If instead we'd pass a extrude_position=... parameter to the to be

instantiated children, those modules can do other (more generic)

morphing than just rotate and scale.

That'd make say extruding a pipe with a spline function as the

diameter way more elegant than calculating the points by hand and

calling polyhedron at the end.

Roger.

On Thu, Jan 19, 2023 at 03:53:59PM +0000, Terry wrote:

Haven't done any printing for ages, and more than a bit rusty, so...

I have a garden 'blower' that I want to improvise for an unusual

purpose. I need to print a PLA add-on I can temporarily push inside its

open end. That end of the part must obviously roughly match the blower

tube's shape. Although not an OpenSCAD issue, any tips on the best way

to capture that closed curve would be welcome. The best two

I've come up with so far:

-

Wrap some stiff wire tightly around the blower near its end. Or

perhaps better, a long but thin strip of aluminium; slide that off and

make an SVG.in Inkscape (when I've relearnt how to do that). -

Use the rough pencil trace I've made as the SVG basis. Then in

OpenSCAD reduce its 'x' coordinates appropriately. Presumably the factor

would be b/h estimated from the photo.

Precision won't be an issue as I'll glue some thin but flexible stuff to

the outside.

The more difficult aspect is that the other end of the print must be a

cylinder of about 2 inches (50 mm) in height and 5/8 inch (15 mm) inner

diameter. (I'll be attaching a hose or similar.) This would obviously be

trivial if the starting shape was circular, but what is the general

approach for extruding from an irregular shape to a circle?

While preparing this a simpler idea dawned, and it would take a fraction

of the time to prepare. A rectangular piece of plywood or similar

covering the entire end of the blower, secured by screws or velcro to

the adjacent plastic area. The 3d print (if an existing piece of tubing

cannot be found) would be a simple cylinder, friction fitted inside a

hole in the wood's centre.

But I'd still like to learn how to 'morph' from one 2D shape to another

please.

Image attached, or here:

https://www.dropbox.com/s/tcj3g1f0zd4n1j7/Two-plus.jpg?raw=1

Terry, UK

--

** R.E.Wolff@BitWizard.nl ** https://www.BitWizard.nl/ ** +31-15-2049110

**

** Delftechpark 11 2628 XJ Delft, The Netherlands. KVK: 27239233 **

f equals m times a. When your f is steady, and your m is going down

your a is going up. -- Chris Hadfield about flying up the space shuttle.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

It sounded like Rogier was talking about applying a transformation to the

children, so that means you have a vertex mapping from cross section to

cross section.

Connecting two arbitrary 2d shapes is hard. I have written code to do it

in BOSL2.

https://github.com/revarbat/BOSL2/wiki/skin.scad#functionmodule-skin

There are several methods provided that may work for different situations.

It's hard to say what exactly the limitations are. You should be able to

connect any two convex shapes and get a valid and generally reasonable

result if you pick the right options. If you go to concave shapes, it may

be difficult to get a good result in some cases unless you manually

establish the vertex mapping by adding extra points (possibly coincident).

On Fri, Jan 20, 2023 at 4:07 PM Jordan Brown openscad@jordan.maileater.net

wrote:

On 1/20/2023 4:02 AM, Rogier Wolff wrote:

If instead we'd pass a extrude_position=... parameter to the to be

instantiated children, those modules can do other (more generic)

morphing than just rotate and scale.

I believe the current linear extrude takes advantage of the fact that each

successive layer has the same vertices, and connects them. Connecting two

arbitrary 2D shapes is a much harder problem.

I believe some of the libraries (like BOSL2) have more general sweep

functions that can tolerate changes in the shape, but I don't know what the

limitations are.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On Fri, Jan 20, 2023 at 01:07:12PM -0800, Jordan Brown wrote:

On 1/20/2023 4:02 AM, Rogier Wolff wrote:

If instead we'd pass a extrude_position=... parameter to the to be

instantiated children, those modules can do other (more generic)

morphing than just rotate and scale.

I believe the current linear extrude takes advantage of the fact that

each successive layer has the same vertices, and connects them.

Connecting two arbitrary 2D shapes is a much harder problem.

In the meanwhile, I thought of that too, and devised a test.

linear_extrude (height=40, twist=10) circle (50);

When you increase the twist at some point the sides flip back.... So no

it is not using the corresponding points....

And then I tried this:

module obj ()

{

translate ([0,0,0]) circle (50);

translate ([50,0,0]) circle (5);

}

linear_extrude (height=40, twist=1800, slices = 10 ) obj ();

which clearly shows that it IS using corresponding points.

So I'm afraid you're right after all: it is assuming something about

corresponding points.

While I agree that it IS much harder, I think it is "doable" and it

would be beneficial to move in that direction. But of course I don't

have the time to put in the legwork. So I'm not "demanding" that this

be implemented. If someone finds it useful to generalize the linear

extrusion: I think it is a good idea and you have my support.

Roger.

--

** R.E.Wolff@BitWizard.nl ** https://www.BitWizard.nl/ ** +31-15-2049110 **

** Delftechpark 11 2628 XJ Delft, The Netherlands. KVK: 27239233 **

f equals m times a. When your f is steady, and your m is going down

your a is going up. -- Chris Hadfield about flying up the space shuttle.