Attributes on objects.

We can approach this from two perspectives:

1) As you say: "if we build it they will come". Start including

attributes in (say) 3MF files, and let slicers and other consumers

consume them if they like.

2) Some existing slicers (e.g. PrusaSlicer) already support attributes

in 3MF files. Have OpenSCAD provide mechanisms for programs to set

those attributes.

Or a mix of the two approaches.

Neither should be done in a vacuum. If OpenSCAD is going to start

playing with Prusa's attributes, we should have a conversation with the

Prusa folks. If we're going to start including our own attributes -

especially if we try to take over "generic" namespace, rather than using

names with "OpenSCAD" in them - then we should at least announce that

intention to the slicer groups and the other CAD groups.

On Mon, Sep 13, 2021 at 03:53:42PM +0000, Jordan Brown wrote:

We can approach this from two perspectives:

1) As you say: "if we build it they will come". Start including

attributes in (say) 3MF files, and let slicers and other consumers

consume them if they like.

2) Some existing slicers (e.g. PrusaSlicer) already support attributes

in 3MF files. Have OpenSCAD provide mechanisms for programs to set

those attributes.

Or a mix of the two approaches..lo9

Yeah, A mix would be most powerful: "See it, works, we're doing

it right, you're doing it right... But you don't support ... "

Neither should be done in a vacuum. If OpenSCAD is going to start

playing with Prusa's attributes, we should have a conversation with the

Prusa folks. If we're going to start including our own attributes -

especially if we try to take over "generic" namespace, rather than using

names with "OpenSCAD" in them - then we should at least announce that

intention to the slicer groups and the other CAD groups.

I was thinking that tagging the attributes on objects would be a

fundamental operation on openscad. But I just realized: Actually a

color is just such an attribute. It's just that the other attributes

can probably be ignored when rendering.

The thing is... the F5 render uses the color, but F6 loses them. That

might be a challenge to get the datastructures involved in the F6

render to keep the attributes.

Thinking about what namespace to use is useful, but could be postponed

until we're at the point that stuff is going to be put into files....

But preparations will never hurt.

IF we were to output openscad-infill: 30% then it will be difficult

for us to convince slicer teams to start interpreting them. They then

would also need to support fusion-infill freeCAD-infill

solidworks-infill autocad-infill etc etc. That's hopeless.

maybe a configurable prefix would allow for max flexibility (but

suggested default: None). That would allow users to get out of a

namespace collision on their own.

I think the most powerful way forward would be to just implement the

first and THEN say: "look we can propagate infill", do you agree

we should put it there?, what else would be useful?, etc.

Roger

--

** R.E.Wolff@BitWizard.nl ** https://www.BitWizard.nl/ ** +31-15-2049110 **

** Delftechpark 11 2628 XJ Delft, The Netherlands. KVK: 27239233 **

f equals m times a. When your f is steady, and your m is going down

your a is going up. -- Chris Hadfield about flying up the space shuttle.

I'm not sure what the 'ideal' solution would be, and one thing for sure,

whatever arises will not be ideal. Already dozens of 3d file formates

available. I would think that the best way forward would be to export

instead of stl, as perhaps 3mf or some other file standard which can

carry attributes, then hope that the slicer guys will implement that. If

Other 3d design programs use the same format, then we are in with a

chance. However, it could well be a case of backing the wrong horse, and

I expect that by the time that was working, there would be some other

preferred format.

Fundamentally, i wonder why, for many of us, we need to store the

information within the openscad file/3d file, if we have the control of

the slicing process. Perhaps we want to change colour part way up a tall

print, say. Not much of a problem, unless precision is wanted, but 3d

printing at the diy level, is not exactly precise.

here are three examples

/ example 1

color("blue")cube (20);

translate([0,0,15])color("red")cube(20);

// example 2

translate([30,0.0]){

color("blue")cube ([20,20,15]);

translate([0,0,15])color("red")cube(20);

}

// example 3

translate([60,0.0]){

cube ([20,20,35]);

//!! color("red")([0,0,15]);

}

you can often change colour, in any fdm printer, for example, by having

two stl files, and place them on top of each other. in the slicer.

However example 1, looks ok'ish in openscad, but once the blue is

printed, a bit of a problem will occur in printing the red We would

have to make sure that the translate terminated the height of the blue,

or the red cube was shorter..

example 2 is doable, but possibly not the way it would be naturally

drawn in openscad

example 3, is what I'm more inclined towards - parse the scad file,

pull out the //?? then parse the g-code, calculate the xyz location and

do whatever is necessary, provided it is just code insertion in the the

gcode.

That will work, relatively easy for basic stuff, colour changes, insert

magnets/whatever. However it would be too much for me to think about if

the orientation/scale was changed in the slicer.

These examples are trivial, for a few changes it is easy enough to do it

manually, (tedious scrolling through thousands of lines of g-code) but I

think they show the sort of fun that can be had with what we have

available now.

Best wishes,

Ray

On 14/09/2021 07:01, Rogier Wolff wrote:

On Mon, Sep 13, 2021 at 03:53:42PM +0000, Jordan Brown wrote:

We can approach this from two perspectives:

1) As you say: "if we build it they will come". Start including

attributes in (say) 3MF files, and let slicers and other consumers

consume them if they like.

2) Some existing slicers (e.g. PrusaSlicer) already support attributes

in 3MF files. Have OpenSCAD provide mechanisms for programs to set

those attributes.Or a mix of the two approaches..lo9

Yeah, A mix would be most powerful: "See it, works, we're doing

it right, you're doing it right... But you don't support ... "

Neither should be done in a vacuum. If OpenSCAD is going to start

playing with Prusa's attributes, we should have a conversation with the

Prusa folks. If we're going to start including our own attributes -

especially if we try to take over "generic" namespace, rather than using

names with "OpenSCAD" in them - then we should at least announce that

intention to the slicer groups and the other CAD groups.

I was thinking that tagging the attributes on objects would be a

fundamental operation on openscad. But I just realized: Actually a

color is just such an attribute. It's just that the other attributes

can probably be ignored when rendering.

The thing is... the F5 render uses the color, but F6 loses them. That

might be a challenge to get the datastructures involved in the F6

render to keep the attributes.

Thinking about what namespace to use is useful, but could be postponed

until we're at the point that stuff is going to be put into files....

But preparations will never hurt.

IF we were to output openscad-infill: 30% then it will be difficult

for us to convince slicer teams to start interpreting them. They then

would also need to support fusion-infill freeCAD-infill

solidworks-infill autocad-infill etc etc. That's hopeless.

maybe a configurable prefix would allow for max flexibility (but

suggested default: None). That would allow users to get out of a

namespace collision on their own.

I think the most powerful way forward would be to just implement the

first and THEN say: "look we can propagate infill", do you agree

we should put it there?, what else would be useful?, etc.

Roger

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

There is more than just colour (though it is a simple example). But

the first come or last come solution is obvious.

Just a "top of my head" list of other attributes:

- Infill

- Infill-pattern

- Layer height (needed where vertical detail is critical, but skippable

where not - Slic3r tries to do this automagically) - Support (meaning this module is manual support structure - for a

multihead with soluble plastic) - notSupport (hint to the slicer, don't do support beneath this - also

implied for modules maked Support) - Extra "quality" (basically asking a FDM slicer to go slower)

- ... and colour.

Colour or Support only makes sense for a multi head 3D printer. I have a

hard time thinking how/where/when a "pause" attribute would propage from

the OpenSCAD through the slicer and to the Gcode, but it might be a good

search string for manual fiddling. Which leaves the most famous catch all

- the Comment (which invariably gets misused for things not in the

standard).

If all parameters are keyword=text style, then only these few keywords need

"standardizing". Slicer variations become the headache of the OpenSCAD

owner (one slicer expects a 1-100% for infill, another expects a 0.1 - 1.0)

This is the wrong forum to ask - we're all OpenSCAD users and happy, but

how much of 3D print originates from OpenSCAD? 360Fusion, Blender, and so

on also generate files for printing - what have they tried to implement?

(NB:

https://all3dp.com/1/best-free-3d-printing-software-3d-printer-program/#section-3d-modeling-software

does not mention OpenSCAD) Easier to hitch onto someone else format (Open,

not proprietary! of course)

Hmmm... maybe I should do some reading/googling... more informed

suggestions might be better (and a new mail thread). We should rather

discuss the user requirements : what are we trying to solve? (The

OriginalPost had a point ... lost my copy) Then we can worry about how that

might be represented, and lastly one can discuss if it is OpenSCAD or the

slicer that should handle conflicting volumes and how that might be.

I really want sections of my models to have seperate infill values, I

really want some parts marked "non-critical", I have a two head; I want

easy colour (head1/head2) or manual support that the slicer knows is

support. Ah, well, I manage.

Msquare

On Tue, 14 Sept 2021 at 13:57, Ray West raywest@raywest.com wrote:

I'm not sure what the 'ideal' solution would be, and one thing for sure,

whatever arises will not be ideal. Already dozens of 3d file formates

available. I would think that the best way forward would be to export

instead of stl, as perhaps 3mf or some other file standard which can

carry attributes, then hope that the slicer guys will implement that. If

Other 3d design programs use the same format, then we are in with a

chance. However, it could well be a case of backing the wrong horse, and

I expect that by the time that was working, there would be some other

preferred format.

Fundamentally, i wonder why, for many of us, we need to store the

information within the openscad file/3d file, if we have the control of

the slicing process. Perhaps we want to change colour part way up a tall

print, say. Not much of a problem, unless precision is wanted, but 3d

printing at the diy level, is not exactly precise.

here are three examples

/ example 1

color("blue")cube (20);

translate([0,0,15])color("red")cube(20);

// example 2

translate([30,0.0]){

color("blue")cube ([20,20,15]);

translate([0,0,15])color("red")cube(20);

}

// example 3

translate([60,0.0]){

cube ([20,20,35]);

//!! color("red")([0,0,15]);

}

you can often change colour, in any fdm printer, for example, by having

two stl files, and place them on top of each other. in the slicer.

However example 1, looks ok'ish in openscad, but once the blue is

printed, a bit of a problem will occur in printing the red We would

have to make sure that the translate terminated the height of the blue,

or the red cube was shorter..

example 2 is doable, but possibly not the way it would be naturally

drawn in openscad

example 3, is what I'm more inclined towards - parse the scad file,

pull out the //?? then parse the g-code, calculate the xyz location and

do whatever is necessary, provided it is just code insertion in the the

gcode.

That will work, relatively easy for basic stuff, colour changes, insert

magnets/whatever. However it would be too much for me to think about if

the orientation/scale was changed in the slicer.

These examples are trivial, for a few changes it is easy enough to do it

manually, (tedious scrolling through thousands of lines of g-code) but I

think they show the sort of fun that can be had with what we have

available now.

Best wishes,

Ray

On 14/09/2021 07:01, Rogier Wolff wrote:

On Mon, Sep 13, 2021 at 03:53:42PM +0000, Jordan Brown wrote:

We can approach this from two perspectives:

- As you say: "if we build it they will come". Start including

attributes in (say) 3MF files, and let slicers and other consumers

consume them if they like. - Some existing slicers (e.g. PrusaSlicer) already support attributes

in 3MF files. Have OpenSCAD provide mechanisms for programs to set

those attributes.

Or a mix of the two approaches..lo9

Yeah, A mix would be most powerful: "See it, works, we're doing

it right, you're doing it right... But you don't support ... "

Neither should be done in a vacuum. If OpenSCAD is going to start

playing with Prusa's attributes, we should have a conversation with the

Prusa folks. If we're going to start including our own attributes -

especially if we try to take over "generic" namespace, rather than using

names with "OpenSCAD" in them - then we should at least announce that

intention to the slicer groups and the other CAD groups.

I was thinking that tagging the attributes on objects would be a

fundamental operation on openscad. But I just realized: Actually a

color is just such an attribute. It's just that the other attributes

can probably be ignored when rendering.

The thing is... the F5 render uses the color, but F6 loses them. That

might be a challenge to get the datastructures involved in the F6

render to keep the attributes.

Thinking about what namespace to use is useful, but could be postponed

until we're at the point that stuff is going to be put into files....

But preparations will never hurt.

IF we were to output openscad-infill: 30% then it will be difficult

for us to convince slicer teams to start interpreting them. They then

would also need to support fusion-infill freeCAD-infill

solidworks-infill autocad-infill etc etc. That's hopeless.

maybe a configurable prefix would allow for max flexibility (but

suggested default: None). That would allow users to get out of a

namespace collision on their own.

I think the most powerful way forward would be to just implement the

first and THEN say: "look we can propagate infill", do you agree

we should put it there?, what else would be useful?, etc.

Roger

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On 9/13/2021 11:01 PM, Rogier Wolff wrote:

The thing is... the F5 render uses the color, but F6 loses them. That

might be a challenge to get the datastructures involved in the F6

render to keep the attributes.

Absolutely. Today, F6 of this program

union() {

color("red") cube(5);

color("blue") sphere(5);

}

produces a single object. With full color support, it would need to

produce, in some sense, two objects, a red one and a blue one. Probably

it would be sort of equivalent to

color("red") difference() {

cube(5);

sphere(5);

}

color("blue") sphere(5);

except that from an OpenSCAD perspective it would still be a single child.

And that would have to propagate through all of the geometry processing,

so that

union() {

union() {

color("red") cube(5);

color("blue") sphere(5);

}

color("green") cylinder(h=5,d=7);

}

would produce:

- A green cylinder.

- A blue sphere, less the cylinder.

- A red cube, less the cylinder and the sphere.

IF we were to output openscad-infill: 30% then it will be difficult

for us to convince slicer teams to start interpreting them. They then

would also need to support fusion-infill freeCAD-infill

solidworks-infill autocad-infill etc etc. That's hopeless.

Not totally hopeless, but certainly suboptimal. For something

relatively generic like this, those slicers could have a simple list of

aliases. What would be hard would be if each CAD program had a subtly

different interpretation of the value.

And of course the flip side, where the slicer teams each have their own

attributes, would be poor for the CAD teams; every CAD program would

have to support prusa-infill, cura-infill, simplify-infill, et cetera.

Ideal would be if the 3MF Consortium managed a shared attribute

definition list.

Is anybody here already a member of the 3MF Consortium?

I think the most powerful way forward would be to just implement the

first and THEN say: "look we can propagate infill", do you agree we

should put it there?, what else would be useful?, etc.

My transitional idea (before any real standardization) would be to have

a mechanism that can supply any name and any value, so that OpenSCAD per

se doesn't have to know about the attributes available.

On 9/14/2021 4:56 AM, Ray West wrote:

However, it could well be a case of backing the wrong horse, and I

expect that by the time that was working, there would be some other

preferred format.

One might hope that we could come up with language and

geometry-processing features that are generic enough that their results

can be exported into any reasonable format.

Fundamentally, i wonder why, for many of us, we need to store the

information within the openscad file/3d file, if we have the control

of the slicing process.

Because then there are two distinct parts of the project that have to be

kept in sync.

Perhaps we want to change colour part way up a tall print, say.

Sure. Or change the color of the text atop a card - and be able to

change the thickness of the card with the customizer and have the color

change track it.

Or any number of other variations, if you have a multi-extruder printer.

example 3, is what I'm more inclined towards - parse the scad file,

pull out the //?? then parse the g-code, calculate the xyz location

and do whatever is necessary, provided it is just code insertion in

the the gcode.

I don't know about anybody else's work, but only the most trivial of my

projects are amenable to external processing. Figuring out where a

particular subcomponent is in the final object, or even what shape it

is, would require executing the OpenSCAD program.

You could do better by having an alternate mode for the OpenSCAD program

that would echo() slicing information. You'd still need to figure out

how to post-process that output into configuration input for the

slicer. Also, OpenSCAD modules don't naturally know the transformation

they are embedded in, so may not be able to easily emit the information

needed.

On Tue, Sep 14, 2021 at 04:37:36PM +0000, Jordan Brown wrote:

And of course the flip side, where the slicer teams each have their own

attributes, would be poor for the CAD teams; every CAD program would

have to support prusa-infill, cura-infill, simplify-infill, et cetera.

Ideal would be if the 3MF Consortium managed a shared attribute

definition list.

I think we should desing this from a language-point-of-view. Consider

3MF as a language, and what would be useful and "neat" (*) to have in

that language.

I think discussions with "authorities" would go easier and quicker

once there is a proof-of-concept demo available.

In my example of setting the infill for a specific project,

infill (5) mainobject ();

would suffice. No subobjects having such attributes and complex mixing

of said attributes....

The problem that triggered this for me was a case where I need to set

printing order. Again:

printing_priority (1) translate ([ 0, 0]) mainojbect ();

printing_priority (2) translate ([60, 20]) mainojbect ();

printing_priority (3) translate ([ 0, 100]) mainojbect ();

printing_priority (4) translate ([60, 110]) mainojbect ();

No mixing trouble.

Some simple inheritance rules "for now" with clear documentation

stating that this is temporary could be a workaround. So when you

union a red cube and a blue sphere, the resulting union would be red.

First attribute of a type is used, later ones ignored. (union a red

cube and a 10% infill sphere, you get a red 10% infill union).

Roger.

(*) Neat, not as in "cool! I like that" but neat, as in regular with

the rest.

--

** R.E.Wolff@BitWizard.nl ** https://www.BitWizard.nl/ ** +31-15-2049110 **

** Delftechpark 11 2628 XJ Delft, The Netherlands. KVK: 27239233 **

f equals m times a. When your f is steady, and your m is going down

your a is going up. -- Chris Hadfield about flying up the space shuttle.

On 9/14/2021 10:24 AM, Rogier Wolff wrote:

In my example of setting the infill for a specific project,

infill (5) mainobject ();

would suffice. No subobjects having such attributes and complex mixing

of said attributes....

https://docs.microsoft.com/en-us/windows-hardware/drivers/3dprint/output-keywords#42-job3ddensity

One has to wonder why they only allowed five levels (0, 10, 25, 50, 100)

rather than just letting you specify a fraction.

I don't understand the schema well enough to know whether you can apply

this attribute separately to different objects in the file.

Hi,

Cura slicer can import and export 3MF format files, i guess to the same

standard as some software handles dxf files. I expect slic3r and it's

forks do the same, or will do. Already you can vary the density of

infill in a slicer, by using support blockers, afaik. It is merely a

question of communicating the descriptions from openscad to the slicer,

the mechanics are almost there.

All this would be avoided if resin printing, no infill, no colour, no

size worth speaking of. It is easy to calculate one level of infill, and

one pattern, at least to start with, and in the real world five levels

are probably good enough, but what fill pattern, what skin thickness, etc?

Openscad, gcode and klipper commands are all plain text, so very easy to

check what is going on, and where. If you want all the information in

one file, it is possible to write a shell to combine them as one file,

and split them up as needed, but the danger of too much in one file, all

in one place, is in a year's time, when the filament is no longer made,

you have to start over. - granularity is important. All I would need to

keep, is the scad file, with its comments. Not sure if it is worth it

for me to change my cnc gcode editing software to automate the editing

of these 3d printing files.

I've tested the idea of using comments in openscad, and can get good

enough positions in the g-code file, for what I need, (but I've never

needed it, so far) so testing on a couple of encapsulated 5mm nuts in a

20 mm cube, I can pull out the following comments from my openscad file

//?? insert(5mm nut flat)([10,10,6.5])

//?? insert(5mm nut vertical){[6,6, 14.8])

and in the g code, somewhere after z 6.5 I put 'rw_insert 5mm nut flat'

and after z 14.5 put 'rw_insert 5mm nut vertical' (or I could put the

text exactly as after the //??)

When the g-code is read into the printer, then my Klipper gcode macro,

picks out the 'rw_insert' and displays the message 'insert 5mm nut

vertical' on my pc (with a confirmation of the actual coordinates wrt

the bed), or phone and on the printer lcd display, sounds a beeper,

pauses the print, moves the head away. When I've put in the 5mm nut, I

send 'resume' and it carries on. Or, it could drive a pick and place

robot arm. Not sure if placing magnets, and using a steel printer nozzle

would work, so well, however.

It would be very similar for colour change e.g. //??

color("red")([25,35,10]) say, generating g-code rw_color "red" being

caught by a macro in the printer and doing whatever.

For changing infill, then if the region was specified in openscad, by

xyz's, then the gcode could be pulled apart in that area, not so easy,

but certainly doable (not sure I'd want to do it, tho'.).

I really do not need openscad to get more complex than it is. I am

concerned about the set up of 3MF, it is likely to be worse than dxf,

after all, autodesk is involved.

Best wishes,

Ray

On 14/09/2021 19:33, Jordan Brown wrote:

On 9/14/2021 10:24 AM, Rogier Wolff wrote:

In my example of setting the infill for a specific project,

infill (5) mainobject ();

would suffice. No subobjects having such attributes and complex

mixing of said attributes....

https://docs.microsoft.com/en-us/windows-hardware/drivers/3dprint/output-keywords#42-job3ddensity

One has to wonder why they only allowed five levels (0, 10, 25, 50,

100) rather than just letting you specify a fraction.

I don't understand the schema well enough to know whether you can

apply this attribute separately to different objects in the file.

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

On Tue, Sep 14, 2021, at 9:40 AM, Michael Möller wrote:

Colour or Support only makes sense for a multi head 3D printer.

I think you are talking about consumer grade FDM printers, which do multi-colour prints by switching between different coloured filaments. But if you use a service provider like ShapeWays for printing, then there are multiple technologies for full colour printing, where you have full CMYK control over the colour at each print position.

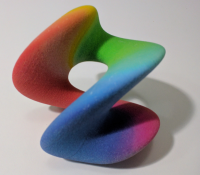

I dunno, maybe this is considered out of scope for OpenSCAD. One of the reasons I created my own OpenSCAD-like language was to do full colour printing like this. For output, I use file formats that support vertex colouring (where you specify a separate colour for each vertex in the model). 3MF is one of the file formats that supports vertex colouring.

Here's an example of a print that I created using Curv, exported as coloured vertexes, and printed using Shapeways: