painted myself into a corner

Greetings all;

I am in the process of replacing a hot end, along with all the junk

electronics of a bigger tronxu-400-pro printer.

Presently printing the adapter plate that bolts to the carriage via the

usual pair of bolts thru the top of the hot end.

One of crealities new Spider hot ends with 4 teeny 2.5mm tapped

boltholes surrounding the bowden tube entry will be mounted

to the bottom face of this "shelf" after unscrewing that fitting. An

orbiter v1.5 extruder will be screwed to the top so a short piece of

capricorn is trapped between them. Std so far...

The problem is that the fan houses on these BBLB printers don't control

the air from the fans at all well, depending on brute force and SWAG's

to get the needed cooling, so I want to put a short duct on the back of

the circular fan, perhaps 20mm long, that funnels the fans air down to a

22x27mm rectangle centered on the heat break, not exactly axially

aligned by 3 or so mm's.

We can taper a cylinder, but how the heck do we go from a 39mm circle

entrance to a 22x27mm rectangle exit? With walls about a mm thick since

this is flying weight?

I can envision writing a sine/cos to build a circle of polygon points

for the round end, and doing an equal number of ploygon points that

describe the rectangle but how do I connect them to get the needed

smooth funnel?

Many thanks for any hints.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

Gene:

Do examples 11 and 12 help at all?

https://github.com/revarbat/BOSL2/wiki/skin.scad

Jon

On 11/13/2022 5:41 PM, gene heskett wrote:

Greetings all;

I am in the process of replacing a hot end, along with all the junk

electronics of a bigger tronxu-400-pro printer.

Presently printing the adapter plate that bolts to the carriage via

the usual pair of bolts thru the top of the hot end.

One of crealities new Spider hot ends with 4 teeny 2.5mm tapped

boltholes surrounding the bowden tube entry will be mounted

to the bottom face of this "shelf" after unscrewing that fitting. An

orbiter v1.5 extruder will be screwed to the top so a short piece of

capricorn is trapped between them. Std so far...

The problem is that the fan houses on these BBLB printers don't control

the air from the fans at all well, depending on brute force and SWAG's

to get the needed cooling, so I want to put a short duct on the back

of the circular fan, perhaps 20mm long, that funnels the fans air down

to a 22x27mm rectangle centered on the heat break, not exactly axially

aligned by 3 or so mm's.

We can taper a cylinder, but how the heck do we go from a 39mm circle

entrance to a 22x27mm rectangle exit? With walls about a mm thick

since this is flying weight?

I can envision writing a sine/cos to build a circle of polygon points

for the round end, and doing an equal number of ploygon points that

describe the rectangle but how do I connect them to get the needed

smooth funnel?

Many thanks for any hints.

Cheers, Gene Heskett.

I'm not entirely clear what shape you're aiming for; is it something

like this? (once adjusted for your exact dimensions)

Steve

difference() {

hull(){

translate([0,0,20 - 1]) cylinder(h = 1, d = 39 + 2, center=true);

cube([22 + 1, 27 + 1, 1], center=true);

}

hull(){

translate([0,0, 20 - 1]) cylinder(h = 1, d = 39, center=true);

cube([22, 27, 1], center=true);

}

}

On 2022-11-13 2:41 p.m., gene heskett wrote:

We can taper a cylinder, but how the heck do we go from a 39mm circle

entrance to a 22x27mm rectangle exit?

On 11/13/22 17:47, jon wrote:

That looks like the general idea. I'll have to see if I can bend it to

do the job. I've not had occasion until now to look at BOSL2 so this

will hopefully be a learning experience. If I can get my ancient wet ram

to understand it.

Thank you very much, Jon.

Take care and stay well.

[...]

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

On 11/13/22 17:47, jon wrote:

I re-arranged example 11 into this, my style of coding:

module funnel()

{

include <BOSL2/std.scad>

xrot(90)down(1.5)

difference()

{

skin([square([2,.2],center=true),

circle($fn=64,r=0.5)], z=[0,3],

slices=40,sampling="length",method="reindex");

skin([square([1.9,.1],center=true),

circle($fn=64,r=0.45)], z=[-.01,3.01],

slices=40,sampling="length",method="reindex");

}

}

funnel();

But got this in the error window:

ERROR: Parser error: syntax error in file

.local/share/OpenSCAD/libraries/BOSL2/shapes3d.scad, line 15

Execution aborted

Line 15 of that file says use <builtins.scad>

And both files exist in the BOSL2 subdir of the library path.

Being green at BOSL2, I need a Translation.

Thanks, take care now.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

You can't include BOSL2 inside another module. That's likely to get you

in trouble with almost any included library. Move the include to the top

level of your program and it will work.

On Sun, Nov 13, 2022 at 7:59 PM gene heskett gheskett@shentel.net wrote:

On 11/13/22 17:47, jon wrote:

I re-arranged example 11 into this, my style of coding:

module funnel()

{

include <BOSL2/std.scad>

xrot(90)down(1.5)

difference()

{

skin([square([2,.2],center=true),

circle($fn=64,r=0.5)], z=[0,3],

slices=40,sampling="length",method="reindex");

skin([square([1.9,.1],center=true),

circle($fn=64,r=0.45)], z=[-.01,3.01],

slices=40,sampling="length",method="reindex");

}

}

funnel();

But got this in the error window:

ERROR: Parser error: syntax error in file

.local/share/OpenSCAD/libraries/BOSL2/shapes3d.scad, line 15

Execution aborted

Line 15 of that file says use <builtins.scad>

And both files exist in the BOSL2 subdir of the library path.

Being green at BOSL2, I need a Translation.

Thanks, take care now.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On 11/13/22 18:01, Steve Lelievre wrote:

I'm not entirely clear what shape you're aiming for; is it something

like this? (once adjusted for your exact dimensions)

Steve

That's quite close, I can put mounting ears on it easy enough, but how

do I put an offset into the rectangular end? 3, maybe 4mm up for

instance? To get the bottom of it away from the hot block. Another

possibility is to add about 4mm of wings on each side and let it

straddle the hot end frame to locate it. Maybe with a wing on top to fit

between the top fin and the frame too. Possibilities are many but all

depend on being able to warp the output end up a mm or 3.

Yup, a translate in front of the cube works. I think I've got it.

Thank you Steve. Take care and stay well.

difference() {

hull(){

translate([0,0,20 - 1]) cylinder(h = 1, d = 39 + 2, center=true);

cube([22 + 1, 27 + 1, 1], center=true);

}

hull(){

translate([0,0, 20 - 1]) cylinder(h = 1, d = 39, center=true);

cube([22, 27, 1], center=true);

}

}

On 2022-11-13 2:41 p.m., gene heskett wrote:

We can taper a cylinder, but how the heck do we go from a 39mm circle

entrance to a 22x27mm rectangle exit?

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

On 11/13/22 20:15, Adrian Mariano wrote:

You can't include BOSL2 inside another module. That's likely to get you

in trouble with almost any included library. Move the include to the top

level of your program and it will work.

Ahh, a limitation I hadn't learned yet. Thank you Jon.

Steves idea with the hull can be made to work, all I need now is some

location ears or wings. Play time tomorrow when the printer is free.

Right now its making the last mod to the first of 2 pieces.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

On 11/13/22 18:01, Steve Lelievre wrote:

I'm not entirely clear what shape you're aiming for; is it something

like this? (once adjusted for your exact dimensions)

Steve

difference() {

hull(){

translate([0,0,20 - 1]) cylinder(h = 1, d = 39 + 2, center=true);

cube([22 + 1, 27 + 1, 1], center=true);

}

hull(){

translate([0,0, 20 - 1]) cylinder(h = 1, d = 39, center=true);

cube([22, 27, 1], center=true);

}

}

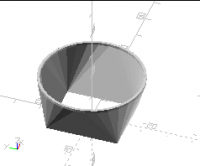

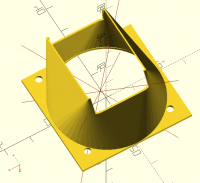

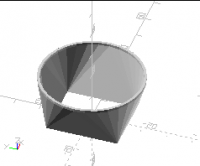

I bent, folded, stapled and otherwise mutilated this, got into a couple

days of it not rendering via F6, but I think I have it. test build on

the printer now. I added a more or less square flange to the input

circle, perforated that with some peg holes that match the holes in the

fan, and offset the output rectangle, and added another difference cube,

so it should now fit on the pegs sticking out of the front panel that

locate the fan, this sits on top of the fan and if the last difference

cube is correctly placed, it will be trapped until the heat from the hot

block a mm away, destroys it. Its the fans job to cool it enough that

doesn't happen.

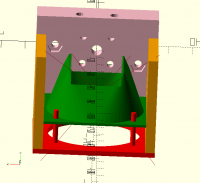

Looks like the attached .png now.

Also a sorta bottom view, where each color is a different part on the

printer.

Thank you very much, Steve, it was, and is now, exactly what I had in mind.

Take care & stay well.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

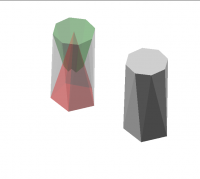

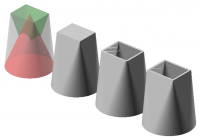

FYI,

I know that this thread is old now so interest will have waned and the

OP's requirement has been solved ... but I just realized that there is a

better way than I suggested in my original post from weeks ago, for

morphing a tube from having a rectangular end to a circular end (which

is what the OP wanted to do for a fan housing.)

The transition can be achieved, both exactly and code-efficiently, by

hulling a cone and an inverted pyramid. I implemented this solution as

the very small module called morph contained in the code pasted after my

signature (feel free to copy/adapt). To convert the morphed shape to a

hollow tube you either use Minkowski or make slightly oversize version

of the same shape, then subtract the original shape to leave only walls

(see the notes in my code.)

More generally, if you want to morph any polygon to any other polygon,

such as a pentagon to octagon as shown here, you just hull together a

cone and an inverted cone, setting the number of sides required for each

cone by supplying $fn parameters.

Cheers,

Steve

$fn = 60;

module morph(h, d, x, y) {

// Morphs a rectangle to a circle. By Steve Lelievre, 2022.

// h: transition height.

// d: diameter of circular lower end.

// x: x dimension (length) of rectangular upper end.

// y: y dimension (width) of rectangular upper end.

hull() {

resize([d, d, h]) cylinder(h = 1, r1 = 0, r2 = 1); // cone

resize([x, y, h]) rotate(45) cylinder(h = 1, r1 = 1, r2 = 0, $fn

= 4); // inverted pyramid

}

}

// Example usage

translate([-15, 0, 0]) morph(30, 25, 15, 12);

// Code snippet to demonstrate how the morph works

translate([-45, 0, 0]) union() {

color("red", 0.3) resize([25, 25, 30]) cylinder(h = 1, r1 = 0, r2 =

1); // cone

color("green", 0.3) resize([15, 12, 30]) rotate(45) cylinder(h = 1,

r1 = 1, r2 = 0, $fn = 4); // inverted pyramid

color("silver", 0.3) morph(30, 25, 15, 12);

}

// Extending the idea to make a tubular connector:

// Option A. Using Minkowski ensures wall thickness is exactly as

specified when measured in cross section.

// Corners of the rectangular end are rounded accordingly. THe corner

radius is the wall thickness.

module tubeA(h, d, x, y, w) {

// Creates an open tube by Minkowski addition of a sphere to an

internal shape,

// followed by trimming back to height and then subtraction of the

internal shape to hollow out the tube.

// w: wall thickness. This is the thickness in cross section (what

would usually be considered the 'true' value).

// The other parameters are those used in the morph module.

sizeLimit = max(d / 2 + w, sqrt((x + w)^2 + (y + d)^2)); // maximum

radius needed for trimming cylinder

difference() {

intersection() {

minkowski() {

morph(h, d, x, y);

sphere(r = w);

}

cylinder(h = h, r = sizeLimit);

}

morph(h, d, x, y);

}

}

translate([15, 0, 0]) tubeA(30, 25, 15, 12, 1);

// Option B. Subtract inner shape from geometrically similar but

slightly larger outer shape.

// Gives square corners to rectangular end.

// !!! However, in some cases, the wall's cross section will be thinner

than this value !!!

module tubeB(h, d, x, y, w) {

// w: wall thickness in horizontal section.

// The other parameters are those used in the morph module.

difference() {

morph(h, d + 2 * w, x + 2 * w, y + 2 * w);

morph(h, d, x, y);

}

}

translate([45, 0, 0]) tubeB(30, 25, 15, 12, 1);

<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

On 2022-11-13 3:00 p.m., Steve Lelievre wrote:

I'm not entirely clear what shape you're aiming for; is it something

like this? (once adjusted for your exact dimensions)

Steve