Printing text flush to a flat surface

If you want flush text, then print it face down. do the lettering in

white then change to black for the rest of the lid. Probably two g-code

files, keep the heated bed on between filament change. one layer may be

enough.

On 26/11/2021 19:38, David Schooley wrote:

The solution might be to decide how flush is “flush enough.” One or

two millimeters might get it, but I don’t know the application that

Terry is working on.

Another option might be to print black on top of white. Use a white

base layer and then a millimeter or two of black on top. (However many

layers you need to get good coverage.) The letters would cut out of

the black to allow the white to show through. You could then either

leave it alone or use a clear filler if having it flush was a

requirement. I’m guessing a clear filler would be less troublesome

than white.

On Nov 26, 2021, at 1:11 PM, Leonard Martin Struttmann

lenstruttmann@gmail.com wrote:

David, No, my method would not. I guess I misread the original and

did not get that they needed to be flush. My mistake.

On Fri, Nov 26, 2021 at 12:45 PM David Schooley

dcschooley@gmail.com wrote:

He wants to make the text flush. Will your method work for that?

On Nov 26, 2021, at 12:42 PM, Leonard Martin Struttmann

<lenstruttmann@gmail.com> wrote:

This assumes that you extrude the text and place it just above

where you want it to be seen.

I use this method for making Plant ID signs for my garden.

On Fri, Nov 26, 2021 at 12:40 PM Leonard Martin Struttmann

<lenstruttmann@gmail.com> wrote:

Since you using Cura + Ender, you should be able to pause

the print using a Cura supplied script.

When you are slicing, add this script:

Extensions -> Post-processing -> Modify g-code

Select "Add a script" and select "Filament Change".

Change the "Layer" value to the layer where you want to

change the filament.

I have used this often and works well.

On Fri, Nov 26, 2021 at 12:06 PM Terry

<terrypingm@gmail.com> wrote:

This is largely a '3D printing' post, but hope I'm not

too far OT.

I've not yet made a print including text with my Ender 3

V2. But I'll soon need

to do so and would appreciate some advice on a few

practical points from more

experienced users please.

The 10 text labels will be on the top surface of a

rectangular box lid, which

has dimensions of 175 x 95 x 3 mm. Maybe a bit thicker

if necessary. The labels

(like On/Off, Up, Down, etc) will be near holes made for

various buttons and

switches. Each label will therefore be fairly small. I

want them to appear flush

with the surface, white on my black PLA filament.

One option might be to fill with something like 'Hard As

Nails' glue/filler,

wiping the surface clean before leaving the filler to set.

But ideally I'd like to do it by stopping the printer

just once, changing to

white filament, and resuming (something else I've not

yet tried). If I go that

route, what changes do I have to make in OpenSCAD and/or

Cura, so that the stop

occurs at exactly the right place?

Would another idea be to make each label say 1 or 2 mm

high and push them into

place? On reflection I suppose they could be printed as

one object joined by a

thin, easily removed line?

All suggestions/tips/advice will be much appreciated.

Terry

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

Yes! This video is an example: https://www.youtube.com/watch?v=KV2AjyowXX4

On Fri, Nov 26, 2021 at 2:07 PM Raymond West raywest@raywest.com wrote:

If you want flush text, then print it face down. do the lettering in white

then change to black for the rest of the lid. Probably two g-code files,

keep the heated bed on between filament change. one layer may be enough.

On 26/11/2021 19:38, David Schooley wrote:

The solution might be to decide how flush is “flush enough.” One or two

millimeters might get it, but I don’t know the application that Terry is

working on.

Another option might be to print black on top of white. Use a white base

layer and then a millimeter or two of black on top. (However many layers

you need to get good coverage.) The letters would cut out of the black to

allow the white to show through. You could then either leave it alone or

use a clear filler if having it flush was a requirement. I’m guessing a

clear filler would be less troublesome than white.

On Nov 26, 2021, at 1:11 PM, Leonard Martin Struttmann <

lenstruttmann@gmail.com> wrote:

David, No, my method would not. I guess I misread the original and did not

get that they needed to be flush. My mistake.

On Fri, Nov 26, 2021 at 12:45 PM David Schooley dcschooley@gmail.com

wrote:

He wants to make the text flush. Will your method work for that?

On Nov 26, 2021, at 12:42 PM, Leonard Martin Struttmann <

lenstruttmann@gmail.com> wrote:

This assumes that you extrude the text and place it just above where you

want it to be seen.

I use this method for making Plant ID signs for my garden.

On Fri, Nov 26, 2021 at 12:40 PM Leonard Martin Struttmann <

lenstruttmann@gmail.com> wrote:

Since you using Cura + Ender, you should be able to pause the print

using a Cura supplied script.

When you are slicing, add this script:

Extensions -> Post-processing -> Modify g-code

Select "Add a script" and select "Filament Change".

Change the "Layer" value to the layer where you want to change the

filament.

I have used this often and works well.

On Fri, Nov 26, 2021 at 12:06 PM Terry terrypingm@gmail.com wrote:

This is largely a '3D printing' post, but hope I'm not too far OT.

I've not yet made a print including text with my Ender 3 V2. But I'll

soon need

to do so and would appreciate some advice on a few practical points

from more

experienced users please.

The 10 text labels will be on the top surface of a rectangular box lid,

which

has dimensions of 175 x 95 x 3 mm. Maybe a bit thicker if necessary.

The labels

(like On/Off, Up, Down, etc) will be near holes made for various

buttons and

switches. Each label will therefore be fairly small. I want them to

appear flush

with the surface, white on my black PLA filament.

One option might be to fill with something like 'Hard As Nails'

glue/filler,

wiping the surface clean before leaving the filler to set.

But ideally I'd like to do it by stopping the printer just once,

changing to

white filament, and resuming (something else I've not yet tried). If I

go that

route, what changes do I have to make in OpenSCAD and/or Cura, so that

the stop

occurs at exactly the right place?

Would another idea be to make each label say 1 or 2 mm high and push

them into

place? On reflection I suppose they could be printed as one object

joined by a

thin, easily removed line?

All suggestions/tips/advice will be much appreciated.

Terry

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Thanks Ray.

G-code files? As a novice I was hoping for a very simple way to:

- Code my Surface object in OpenSCAD

- Code my Text object

- Union or difference

- Add some clever code, so that after slicing in Cura the print would stop, I would change filament, taking care not to move the partial print, and resume to finish it.

Over naive I guess ;-)

But I’m surprised that what I’d have thought a commonplace requirement (printing text in a different colour to its background surface, with a single extruder) is not the no-brainer I’d expected.

Terry

On 26 Nov 2021, at 22:23, Raymond West raywest@raywest.com wrote:

If you want flush text, then print it face down. do the lettering in white then change to black for the rest of the lid. Probably two g-code files, keep the heated bed on between filament change. one layer may be enough.

On 26/11/2021 19:38, David Schooley wrote:

The solution might be to decide how flush is “flush enough.” One or two millimeters might get it, but I don’t know the application that Terry is working on.

Another option might be to print black on top of white. Use a white base layer and then a millimeter or two of black on top. (However many layers you need to get good coverage.) The letters would cut out of the black to allow the white to show through. You could then either leave it alone or use a clear filler if having it flush was a requirement. I’m guessing a clear filler would be less troublesome than white.

On Nov 26, 2021, at 1:11 PM, Leonard Martin Struttmann lenstruttmann@gmail.com wrote:

David, No, my method would not. I guess I misread the original and did not get that they needed to be flush. My mistake.

On Fri, Nov 26, 2021 at 12:45 PM David Schooley dcschooley@gmail.com wrote:

He wants to make the text flush. Will your method work for that?

On Nov 26, 2021, at 12:42 PM, Leonard Martin Struttmann lenstruttmann@gmail.com wrote:

This assumes that you extrude the text and place it just above where you want it to be seen.

I use this method for making Plant ID signs for my garden.

On Fri, Nov 26, 2021 at 12:40 PM Leonard Martin Struttmann lenstruttmann@gmail.com wrote:

Since you using Cura + Ender, you should be able to pause the print using a Cura supplied script.

When you are slicing, add this script:

Extensions -> Post-processing -> Modify g-code

Select "Add a script" and select "Filament Change".

Change the "Layer" value to the layer where you want to change the filament.

I have used this often and works well.

On Fri, Nov 26, 2021 at 12:06 PM Terry terrypingm@gmail.com wrote:

This is largely a '3D printing' post, but hope I'm not too far OT.

I've not yet made a print including text with my Ender 3 V2. But I'll soon need

to do so and would appreciate some advice on a few practical points from more

experienced users please.

The 10 text labels will be on the top surface of a rectangular box lid, which

has dimensions of 175 x 95 x 3 mm. Maybe a bit thicker if necessary. The labels

(like On/Off, Up, Down, etc) will be near holes made for various buttons and

switches. Each label will therefore be fairly small. I want them to appear flush

with the surface, white on my black PLA filament.

One option might be to fill with something like 'Hard As Nails' glue/filler,

wiping the surface clean before leaving the filler to set.

But ideally I'd like to do it by stopping the printer just once, changing to

white filament, and resuming (something else I've not yet tried). If I go that

route, what changes do I have to make in OpenSCAD and/or Cura, so that the stop

occurs at exactly the right place?

Would another idea be to make each label say 1 or 2 mm high and push them into

place? On reflection I suppose they could be printed as one object joined by a

thin, easily removed line?

All suggestions/tips/advice will be much appreciated.

Terry

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

I have done this in the past simply by noting at what layer I need to

pause the print and manually pausing the printer, swapping filament

colors, and then resuming. It is a little time consuming, but it works

fine.

If you use PrusaSlicer, the ability to insert a Pause is built into the

slicer:

https://help.prusa3d.com/en/article/insert-pause-or-custom-g-code-at-layer_120490

On 11/26/2021 6:02 PM, terrypingm@gmail.com wrote:

Thanks Ray.

G-code files? As a novice I was hoping for a very simple way to:

- Code my Surface object in OpenSCAD

- Code my Text object

- Union or difference

- Add some clever code, so that after slicing in Cura the print would

stop, I would change filament, taking care not to move the partial

print, and resume to finish it.

Over naive I guess ;-)

But I’m surprised that what I’d have thought a commonplace requirement

(printing text in a different colour to its background surface, with a

single extruder) is not the no-brainer I’d expected.

Terry

On 26 Nov 2021, at 22:23, Raymond West raywest@raywest.com wrote:

If you want flush text, then print it face down. do the lettering in

white then change to black for the rest of the lid. Probably two

g-code files, keep the heated bed on between filament change. one

layer may be enough.

On 26/11/2021 19:38, David Schooley wrote:

The solution might be to decide how flush is “flush enough.” One or

two millimeters might get it, but I don’t know the application that

Terry is working on.

Another option might be to print black on top of white. Use a white

base layer and then a millimeter or two of black on top. (However

many layers you need to get good coverage.) The letters would cut

out of the black to allow the white to show through. You could then

either leave it alone or use a clear filler if having it flush was a

requirement. I’m guessing a clear filler would be less troublesome

than white.

On Nov 26, 2021, at 1:11 PM, Leonard Martin Struttmann

lenstruttmann@gmail.com wrote:

David, No, my method would not. I guess I misread the original and

did not get that they needed to be flush. My mistake.

On Fri, Nov 26, 2021 at 12:45 PM David Schooley

dcschooley@gmail.com wrote:

He wants to make the text flush. Will your method work for that?

On Nov 26, 2021, at 12:42 PM, Leonard Martin Struttmann

<lenstruttmann@gmail.com> wrote:

This assumes that you extrude the text and place it just above

where you want it to be seen.

I use this method for making Plant ID signs for my garden.

On Fri, Nov 26, 2021 at 12:40 PM Leonard Martin Struttmann

<lenstruttmann@gmail.com> wrote:

Since you using Cura + Ender, you should be able to pause

the print using a Cura supplied script.

When you are slicing, add this script:

Extensions -> Post-processing -> Modify g-code

Select "Add a script" and select "Filament Change".

Change the "Layer" value to the layer where you want to

change the filament.

I have used this often and works well.

On Fri, Nov 26, 2021 at 12:06 PM Terry

<terrypingm@gmail.com> wrote:

This is largely a '3D printing' post, but hope I'm not

too far OT.

I've not yet made a print including text with my Ender

3 V2. But I'll soon need

to do so and would appreciate some advice on a few

practical points from more

experienced users please.

The 10 text labels will be on the top surface of a

rectangular box lid, which

has dimensions of 175 x 95 x 3 mm. Maybe a bit thicker

if necessary. The labels

(like On/Off, Up, Down, etc) will be near holes made

for various buttons and

switches. Each label will therefore be fairly small. I

want them to appear flush

with the surface, white on my black PLA filament.

One option might be to fill with something like 'Hard

As Nails' glue/filler,

wiping the surface clean before leaving the filler to set.

But ideally I'd like to do it by stopping the printer

just once, changing to

white filament, and resuming (something else I've not

yet tried). If I go that

route, what changes do I have to make in OpenSCAD

and/or Cura, so that the stop

occurs at exactly the right place?

Would another idea be to make each label say 1 or 2 mm

high and push them into

place? On reflection I suppose they could be printed

as one object joined by a

thin, easily removed line?

All suggestions/tips/advice will be much appreciated.

Terry

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

Terry, It is even more simple than you say

- code surface object in openscad

2)code the text object

-

difference text from object

-

comment out the text object, render and save main object as stl

5)comment out main object - uncomment text, render and save text as stl

-

load each stl into your slicer to produce two g-code files.

-

print the text g-code file

-

keep the bed and nozzle temperature on

-

change filament and purge old filament, print the second g-code file.

-

No clever code required.

On 26/11/2021 23:02, terrypingm@gmail.com wrote:

Thanks Ray.

G-code files? As a novice I was hoping for a very simple way to:

- Code my Surface object in OpenSCAD

- Code my Text object

- Union or difference

- Add some clever code, so that after slicing in Cura the print would

stop, I would change filament, taking care not to move the partial

print, and resume to finish it.

Over naive I guess ;-)

But I’m surprised that what I’d have thought a commonplace requirement

(printing text in a different colour to its background surface, with a

single extruder) is not the no-brainer I’d expected.

Terry

On 26 Nov 2021, at 22:23, Raymond West raywest@raywest.com wrote:

If you want flush text, then print it face down. do the lettering in

white then change to black for the rest of the lid. Probably two

g-code files, keep the heated bed on between filament change. one

layer may be enough.

On 26/11/2021 19:38, David Schooley wrote:

The solution might be to decide how flush is “flush enough.” One or

two millimeters might get it, but I don’t know the application that

Terry is working on.

Another option might be to print black on top of white. Use a white

base layer and then a millimeter or two of black on top. (However

many layers you need to get good coverage.) The letters would cut

out of the black to allow the white to show through. You could then

either leave it alone or use a clear filler if having it flush was a

requirement. I’m guessing a clear filler would be less troublesome

than white.

On Nov 26, 2021, at 1:11 PM, Leonard Martin Struttmann

lenstruttmann@gmail.com wrote:

David, No, my method would not. I guess I misread the original and

did not get that they needed to be flush. My mistake.

On Fri, Nov 26, 2021 at 12:45 PM David Schooley

dcschooley@gmail.com wrote:

He wants to make the text flush. Will your method work for that?

On Nov 26, 2021, at 12:42 PM, Leonard Martin Struttmann

<lenstruttmann@gmail.com> wrote:

This assumes that you extrude the text and place it just above

where you want it to be seen.

I use this method for making Plant ID signs for my garden.

On Fri, Nov 26, 2021 at 12:40 PM Leonard Martin Struttmann

<lenstruttmann@gmail.com> wrote:

Since you using Cura + Ender, you should be able to pause

the print using a Cura supplied script.

When you are slicing, add this script:

Extensions -> Post-processing -> Modify g-code

Select "Add a script" and select "Filament Change".

Change the "Layer" value to the layer where you want to

change the filament.

I have used this often and works well.

On Fri, Nov 26, 2021 at 12:06 PM Terry

<terrypingm@gmail.com> wrote:

This is largely a '3D printing' post, but hope I'm not

too far OT.

I've not yet made a print including text with my Ender

3 V2. But I'll soon need

to do so and would appreciate some advice on a few

practical points from more

experienced users please.

The 10 text labels will be on the top surface of a

rectangular box lid, which

has dimensions of 175 x 95 x 3 mm. Maybe a bit thicker

if necessary. The labels

(like On/Off, Up, Down, etc) will be near holes made

for various buttons and

switches. Each label will therefore be fairly small. I

want them to appear flush

with the surface, white on my black PLA filament.

One option might be to fill with something like 'Hard

As Nails' glue/filler,

wiping the surface clean before leaving the filler to set.

But ideally I'd like to do it by stopping the printer

just once, changing to

white filament, and resuming (something else I've not

yet tried). If I go that

route, what changes do I have to make in OpenSCAD

and/or Cura, so that the stop

occurs at exactly the right place?

Would another idea be to make each label say 1 or 2 mm

high and push them into

place? On reflection I suppose they could be printed

as one object joined by a

thin, easily removed line?

All suggestions/tips/advice will be much appreciated.

Terry

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

Here is an example where I did almost the exact thing you are talking about except that I didn’t make the text flush, but I could have. (I think I have other examples where I kept the interior color flush with the surface.) It follows your first three steps below. Letting the text protrude a bit actually makes life a bit easier for OoenSCAD. Step 4 is to bring the two stl or 3mf files into Cura, select the proper extruder for each object, and merge the objects. Given that the text isn’t exactly flush with the background this could be done with a single extruder using the techniques described earlier. I would probably be unwilling to do it that way more than once. Dual extruders are in that category of things that seem unnecessary until you have a need for them.

Sent from my iPhone

On Nov 26, 2021, at 5:03 PM, terrypingm@gmail.com wrote:

Thanks Ray.

G-code files? As a novice I was hoping for a very simple way to:

- Code my Surface object in OpenSCAD

- Code my Text object

- Union or difference

- Add some clever code, so that after slicing in Cura the print would stop, I would change filament, taking care not to move the partial print, and resume to finish it.

Over naive I guess ;-)

But I’m surprised that what I’d have thought a commonplace requirement (printing text in a different colour to its background surface, with a single extruder) is not the no-brainer I’d expected.

Terry

On 26 Nov 2021, at 22:23, Raymond West raywest@raywest.com wrote:

If you want flush text, then print it face down. do the lettering in white then change to black for the rest of the lid. Probably two g-code files, keep the heated bed on between filament change. one layer may be enough.

On 26/11/2021 19:38, David Schooley wrote:

The solution might be to decide how flush is “flush enough.” One or two millimeters might get it, but I don’t know the application that Terry is working on.

Another option might be to print black on top of white. Use a white base layer and then a millimeter or two of black on top. (However many layers you need to get good coverage.) The letters would cut out of the black to allow the white to show through. You could then either leave it alone or use a clear filler if having it flush was a requirement. I’m guessing a clear filler would be less troublesome than white.

On Nov 26, 2021, at 1:11 PM, Leonard Martin Struttmann lenstruttmann@gmail.com wrote:

David, No, my method would not. I guess I misread the original and did not get that they needed to be flush. My mistake.

On Fri, Nov 26, 2021 at 12:45 PM David Schooley dcschooley@gmail.com wrote:

He wants to make the text flush. Will your method work for that?

On Nov 26, 2021, at 12:42 PM, Leonard Martin Struttmann lenstruttmann@gmail.com wrote:

This assumes that you extrude the text and place it just above where you want it to be seen.

I use this method for making Plant ID signs for my garden.

On Fri, Nov 26, 2021 at 12:40 PM Leonard Martin Struttmann lenstruttmann@gmail.com wrote:

Since you using Cura + Ender, you should be able to pause the print using a Cura supplied script.

When you are slicing, add this script:

Extensions -> Post-processing -> Modify g-code

Select "Add a script" and select "Filament Change".

Change the "Layer" value to the layer where you want to change the filament.

I have used this often and works well.

On Fri, Nov 26, 2021 at 12:06 PM Terry terrypingm@gmail.com wrote:

This is largely a '3D printing' post, but hope I'm not too far OT.

I've not yet made a print including text with my Ender 3 V2. But I'll soon need

to do so and would appreciate some advice on a few practical points from more

experienced users please.

The 10 text labels will be on the top surface of a rectangular box lid, which

has dimensions of 175 x 95 x 3 mm. Maybe a bit thicker if necessary. The labels

(like On/Off, Up, Down, etc) will be near holes made for various buttons and

switches. Each label will therefore be fairly small. I want them to appear flush

with the surface, white on my black PLA filament.

One option might be to fill with something like 'Hard As Nails' glue/filler,

wiping the surface clean before leaving the filler to set.

But ideally I'd like to do it by stopping the printer just once, changing to

white filament, and resuming (something else I've not yet tried). If I go that

route, what changes do I have to make in OpenSCAD and/or Cura, so that the stop

occurs at exactly the right place?

Would another idea be to make each label say 1 or 2 mm high and push them into

place? On reflection I suppose they could be printed as one object joined by a

thin, easily removed line?

All suggestions/tips/advice will be much appreciated.

Terry

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On Friday 26 November 2021 18:02:53 terrypingm@gmail.com wrote:

Thanks Ray.

G-code files? As a novice I was hoping for a very simple way to:

A complex way to say two files, one for each color. g-code is in fact

what runs the printer, everything else winds up being translated to

g-code, but because its progressive, one layer at a time, it doesn't

resemble that which runs the other 4 metal carving machines in my

garage. No loops, its all unwound so its 50+ megs of code for some 3d

prints, the interpreter in the printer is dumbed down and wouldn't have

the foggiest what to do with a 90 line program I wrote to sharpen a 10"

table saw blade as it takes 3 days to run that 90 line program. It also

made the sharpest, longest lasting blade I've ever had on it.

- Code my Surface object in OpenSCAD

- Code my Text object

- Union or difference

- Add some clever code, so that after slicing in Cura the print would

stop, I would change filament, taking care not to move the partial

print, and resume to finish it.

Over naive I guess ;-)

But I’m surprised that what I’d have thought a commonplace requirement

(printing text in a different colour to its background surface, with a

single extruder) is not the no-brainer I’d expected. --

Terry

On 26 Nov 2021, at 22:23, Raymond West raywest@raywest.com wrote:

If you want flush text, then print it face down. do the lettering in

white then change to black for the rest of the lid. Probably two

g-code files, keep the heated bed on between filament change. one

layer may be enough.

On 26/11/2021 19:38, David Schooley wrote:

The solution might be to decide how flush is “flush enough.” One or

two millimeters might get it, but I don’t know the application that

Terry is working on.

Another option might be to print black on top of white. Use a white

base layer and then a millimeter or two of black on top. (However

many layers you need to get good coverage.) The letters would cut

out of the black to allow the white to show through. You could then

either leave it alone or use a clear filler if having it flush was

a requirement. I’m guessing a clear filler would be less

troublesome than white.

On Nov 26, 2021, at 1:11 PM, Leonard Martin Struttmann

lenstruttmann@gmail.com wrote:

David, No, my method would not. I guess I misread the original and

did not get that they needed to be flush. My mistake.

On Fri, Nov 26, 2021 at 12:45 PM David Schooley

dcschooley@gmail.com wrote:

He wants to make the text flush. Will your method work for that?

On Nov 26, 2021, at 12:42 PM, Leonard Martin Struttmann

lenstruttmann@gmail.com wrote:

This assumes that you extrude the text and place it just above

where you want it to be seen.

I use this method for making Plant ID signs for my garden.

On Fri, Nov 26, 2021 at 12:40 PM Leonard Martin Struttmann

lenstruttmann@gmail.com wrote:

Since you using Cura + Ender, you should be able to pause the

print using a Cura supplied script.

When you are slicing, add this script:

Extensions -> Post-processing -> Modify g-code

Select "Add a script" and select "Filament Change".

Change the "Layer" value to the layer where you want to change

the filament.

I have used this often and works well.

On Fri, Nov 26, 2021 at 12:06 PM Terry terrypingm@gmail.com

wrote:

This is largely a '3D printing' post, but hope I'm not too far

OT.

I've not yet made a print including text with my Ender 3 V2.

But I'll soon need to do so and would appreciate some advice

on a few practical points from more experienced users please.

The 10 text labels will be on the top surface of a rectangular

box lid, which has dimensions of 175 x 95 x 3 mm. Maybe a bit

thicker if necessary. The labels (like On/Off, Up, Down, etc)

will be near holes made for various buttons and switches. Each

label will therefore be fairly small. I want them to appear

flush with the surface, white on my black PLA filament.

One option might be to fill with something like 'Hard As

Nails' glue/filler, wiping the surface clean before leaving

the filler to set.

But ideally I'd like to do it by stopping the printer just

once, changing to white filament, and resuming (something else

I've not yet tried). If I go that route, what changes do I

have to make in OpenSCAD and/or Cura, so that the stop occurs

at exactly the right place?

Would another idea be to make each label say 1 or 2 mm high

and push them into place? On reflection I suppose they could

be printed as one object joined by a thin, easily removed

line?

All suggestions/tips/advice will be much appreciated.

Terry

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/gene

This is how I have been doing it recently -- BUT, the "text" object will

need to be reversed. And when printing the 2nd gcode file (the "body

around the text"), don't you have to set the "z-hop" so that the nozzle

jumps over the lettering and doesn't knock it from the bed? See this video

for an explanation -- "Smooth Two Color Inlay 3D Print Using Cura Z Hop on

Creality Ender 3" https://youtu.be/0Sla-vIsvh4

The other problem I had with this method was that when I bring the 2

separate STL files into the slicer, it always centers them on the bed, and

most of the time this ends up in the lettering not being aligned with the

"body" object. My "fix" was to put a VERY thin "border/bounding box"

around the object that is rendered in both stl files -- this way the

objects get centered based on this "bounding box" and will be aligned

properly. If someone else knows a better way to make sure both objects are

aligned, please share.

... Billy ...

On Fri, Nov 26, 2021 at 6:53 PM Raymond West raywest@raywest.com wrote:

Terry, It is even more simple than you say

- code surface object in openscad

2)code the text object

-

difference text from object

-

comment out the text object, render and save main object as stl

5)comment out main object - uncomment text, render and save text as stl

-

load each stl into your slicer to produce two g-code files.

-

print the text g-code file

-

keep the bed and nozzle temperature on

-

change filament and purge old filament, print the second g-code file.

-

No clever code required.

On 26/11/2021 23:02, terrypingm@gmail.com wrote:

Thanks Ray.

G-code files? As a novice I was hoping for a very simple way to:

- Code my Surface object in OpenSCAD

- Code my Text object

- Union or difference

- Add some clever code, so that after slicing in Cura the print would

stop, I would change filament, taking care not to move the partial print,

and resume to finish it.

Over naive I guess ;-)

But I’m surprised that what I’d have thought a commonplace requirement

(printing text in a different colour to its background surface, with a

single extruder) is not the no-brainer I’d expected.

Terry

On 26 Nov 2021, at 22:23, Raymond West raywest@raywest.com

raywest@raywest.com wrote:

If you want flush text, then print it face down. do the lettering in white

then change to black for the rest of the lid. Probably two g-code files,

keep the heated bed on between filament change. one layer may be enough.

On 26/11/2021 19:38, David Schooley wrote:

The solution might be to decide how flush is “flush enough.” One or two

millimeters might get it, but I don’t know the application that Terry is

working on.

Another option might be to print black on top of white. Use a white base

layer and then a millimeter or two of black on top. (However many layers

you need to get good coverage.) The letters would cut out of the black to

allow the white to show through. You could then either leave it alone or

use a clear filler if having it flush was a requirement. I’m guessing a

clear filler would be less troublesome than white.

On Nov 26, 2021, at 1:11 PM, Leonard Martin Struttmann <

lenstruttmann@gmail.com> wrote:

David, No, my method would not. I guess I misread the original and did not

get that they needed to be flush. My mistake.

On Fri, Nov 26, 2021 at 12:45 PM David Schooley dcschooley@gmail.com

wrote:

He wants to make the text flush. Will your method work for that?

On Nov 26, 2021, at 12:42 PM, Leonard Martin Struttmann <

lenstruttmann@gmail.com> wrote:

This assumes that you extrude the text and place it just above where you

want it to be seen.

I use this method for making Plant ID signs for my garden.

On Fri, Nov 26, 2021 at 12:40 PM Leonard Martin Struttmann <

lenstruttmann@gmail.com> wrote:

Since you using Cura + Ender, you should be able to pause the print

using a Cura supplied script.

When you are slicing, add this script:

Extensions -> Post-processing -> Modify g-code

Select "Add a script" and select "Filament Change".

Change the "Layer" value to the layer where you want to change the

filament.

I have used this often and works well.

On Fri, Nov 26, 2021 at 12:06 PM Terry terrypingm@gmail.com wrote:

This is largely a '3D printing' post, but hope I'm not too far OT.

I've not yet made a print including text with my Ender 3 V2. But I'll

soon need

to do so and would appreciate some advice on a few practical points

from more

experienced users please.

The 10 text labels will be on the top surface of a rectangular box lid,

which

has dimensions of 175 x 95 x 3 mm. Maybe a bit thicker if necessary.

The labels

(like On/Off, Up, Down, etc) will be near holes made for various

buttons and

switches. Each label will therefore be fairly small. I want them to

appear flush

with the surface, white on my black PLA filament.

One option might be to fill with something like 'Hard As Nails'

glue/filler,

wiping the surface clean before leaving the filler to set.

But ideally I'd like to do it by stopping the printer just once,

changing to

white filament, and resuming (something else I've not yet tried). If I

go that

route, what changes do I have to make in OpenSCAD and/or Cura, so that

the stop

occurs at exactly the right place?

Would another idea be to make each label say 1 or 2 mm high and push

them into

place? On reflection I suppose they could be printed as one object

joined by a

thin, easily removed line?

All suggestions/tips/advice will be much appreciated.

Terry

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Note that you have to manually edit the .gcode files with a text editor to

remove the post-amble of the first, and the preamble of the second and

following so the printer doesn't try to re-measure the bed or whatever you

are used to at the start of every print.

On Fri, Nov 26, 2021 at 5:08 PM Billy playmeforafool@gmail.com wrote:

This is how I have been doing it recently -- BUT, the "text" object will

need to be reversed. And when printing the 2nd gcode file (the "body

around the text"), don't you have to set the "z-hop" so that the nozzle

jumps over the lettering and doesn't knock it from the bed? See this video

for an explanation -- "Smooth Two Color Inlay 3D Print Using Cura Z Hop on

Creality Ender 3" https://youtu.be/0Sla-vIsvh4

The other problem I had with this method was that when I bring the 2

separate STL files into the slicer, it always centers them on the bed, and

most of the time this ends up in the lettering not being aligned with the

"body" object. My "fix" was to put a VERY thin "border/bounding box"

around the object that is rendered in both stl files -- this way the

objects get centered based on this "bounding box" and will be aligned

properly. If someone else knows a better way to make sure both objects are

aligned, please share.

... Billy ...

On Fri, Nov 26, 2021 at 6:53 PM Raymond West raywest@raywest.com wrote:

Terry, It is even more simple than you say

- code surface object in openscad

2)code the text object

-

difference text from object

-

comment out the text object, render and save main object as stl

5)comment out main object - uncomment text, render and save text as stl

-

load each stl into your slicer to produce two g-code files.

-

print the text g-code file

-

keep the bed and nozzle temperature on

-

change filament and purge old filament, print the second g-code file.

-

No clever code required.

On 26/11/2021 23:02, terrypingm@gmail.com wrote:

Thanks Ray.

G-code files? As a novice I was hoping for a very simple way to:

- Code my Surface object in OpenSCAD

- Code my Text object

- Union or difference

- Add some clever code, so that after slicing in Cura the print would

stop, I would change filament, taking care not to move the partial print,

and resume to finish it.

Over naive I guess ;-)

But I’m surprised that what I’d have thought a commonplace requirement

(printing text in a different colour to its background surface, with a

single extruder) is not the no-brainer I’d expected.

Terry

On 26 Nov 2021, at 22:23, Raymond West raywest@raywest.com

raywest@raywest.com wrote:

If you want flush text, then print it face down. do the lettering in

white then change to black for the rest of the lid. Probably two g-code

files, keep the heated bed on between filament change. one layer may be

enough.

On 26/11/2021 19:38, David Schooley wrote:

The solution might be to decide how flush is “flush enough.” One or two

millimeters might get it, but I don’t know the application that Terry is

working on.

Another option might be to print black on top of white. Use a white base

layer and then a millimeter or two of black on top. (However many layers

you need to get good coverage.) The letters would cut out of the black to

allow the white to show through. You could then either leave it alone or

use a clear filler if having it flush was a requirement. I’m guessing a

clear filler would be less troublesome than white.

On Nov 26, 2021, at 1:11 PM, Leonard Martin Struttmann <

lenstruttmann@gmail.com> wrote:

David, No, my method would not. I guess I misread the original and did

not get that they needed to be flush. My mistake.

On Fri, Nov 26, 2021 at 12:45 PM David Schooley dcschooley@gmail.com

wrote:

He wants to make the text flush. Will your method work for that?

On Nov 26, 2021, at 12:42 PM, Leonard Martin Struttmann <

lenstruttmann@gmail.com> wrote:

This assumes that you extrude the text and place it just above where you

want it to be seen.

I use this method for making Plant ID signs for my garden.

On Fri, Nov 26, 2021 at 12:40 PM Leonard Martin Struttmann <

lenstruttmann@gmail.com> wrote:

Since you using Cura + Ender, you should be able to pause the print

using a Cura supplied script.

When you are slicing, add this script:

Extensions -> Post-processing -> Modify g-code

Select "Add a script" and select "Filament Change".

Change the "Layer" value to the layer where you want to change the

filament.

I have used this often and works well.

On Fri, Nov 26, 2021 at 12:06 PM Terry terrypingm@gmail.com wrote:

This is largely a '3D printing' post, but hope I'm not too far OT.

I've not yet made a print including text with my Ender 3 V2. But I'll

soon need

to do so and would appreciate some advice on a few practical points

from more

experienced users please.

The 10 text labels will be on the top surface of a rectangular box

lid, which

has dimensions of 175 x 95 x 3 mm. Maybe a bit thicker if necessary.

The labels

(like On/Off, Up, Down, etc) will be near holes made for various

buttons and

switches. Each label will therefore be fairly small. I want them to

appear flush

with the surface, white on my black PLA filament.

One option might be to fill with something like 'Hard As Nails'

glue/filler,

wiping the surface clean before leaving the filler to set.

But ideally I'd like to do it by stopping the printer just once,

changing to

white filament, and resuming (something else I've not yet tried). If I

go that

route, what changes do I have to make in OpenSCAD and/or Cura, so that

the stop

occurs at exactly the right place?

Would another idea be to make each label say 1 or 2 mm high and push

them into

place? On reflection I suppose they could be printed as one object

joined by a

thin, easily removed line?

All suggestions/tips/advice will be much appreciated.

Terry

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

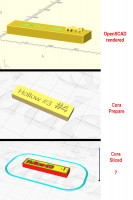

Thanks for all the help so far, much appreciated and will keep my busy for

some time.

Meanwhile, where am I going wrong with this first very simple (!) test

please. I just wanted to print a small rectangle containing two pieces of

text to:

- Give me a feel for font size

- Let me try filling some taped hollow text

- See what 1 mm high embossed text looks & feels like, prior to trying

that with white PLA..

But Cura shows that it will at best fail to print the latter, and I can't

spot why?

difference()

{

[image: MissingText.jpg]

translate([0, 8, 0])

cube([30, 7, 3]);

translate([2, 10, -0.5])

color("navy")

linear_extrude(5)

text("Hollow #3 ", 3);

}

translate([22, 10, 1])

color("lime")

linear_extrude(3)

text("#4", 4);

On Fri, 26 Nov 2021 at 18:06, Terry terrypingm@gmail.com wrote:

This is largely a '3D printing' post, but hope I'm not too far OT.

I've not yet made a print including text with my Ender 3 V2. But I'll soon

need

to do so and would appreciate some advice on a few practical points from

more

experienced users please.

The 10 text labels will be on the top surface of a rectangular box lid,

which

has dimensions of 175 x 95 x 3 mm. Maybe a bit thicker if necessary. The

labels

(like On/Off, Up, Down, etc) will be near holes made for various buttons

and

switches. Each label will therefore be fairly small. I want them to appear

flush

with the surface, white on my black PLA filament.

One option might be to fill with something like 'Hard As Nails'

glue/filler,

wiping the surface clean before leaving the filler to set.

But ideally I'd like to do it by stopping the printer just once, changing

to

white filament, and resuming (something else I've not yet tried). If I go

that

route, what changes do I have to make in OpenSCAD and/or Cura, so that the

stop

occurs at exactly the right place?

Would another idea be to make each label say 1 or 2 mm high and push them

into

place? On reflection I suppose they could be printed as one object joined

by a

thin, easily removed line?

All suggestions/tips/advice will be much appreciated.

Terry

--

LargePrefPlaceholder-XKUz1MEJBwkOM