Strategies to accelerate rendering?

Hello,

Is there some tutorial to optimize code? The rendering stalls at 999/1000

for a long time as soon as my models are not strictly basic.

Thank you.

--

Sent from: http://forum.openscad.org/

Hard to say without seeing your model but I guess there are a lot of

objects that need to be unioned at the end.

Sometimes it can be done in 2D. For example if you make a grill in a panel

by subtracting hundreds of cylinders it will be very slow but if you

subtract circles from a square and then linear_extrude it to make a 3D

panel it will be instantaneous.

On Sat, 13 Jun 2020 at 11:05, amundsen roald.baudoux@brutele.be wrote:

Hello,

Is there some tutorial to optimize code? The rendering stalls at 999/1000

for a long time as soon as my models are not strictly basic.

Thank you.

--

Sent from: http://forum.openscad.org/

OpenSCAD mailing list

Discuss@lists.openscad.org

http://lists.openscad.org/mailman/listinfo/discuss_lists.openscad.org

I suspect you may be using high $fn values? Try 32 first, then selectively

increase in specific sections as needed, and/or use low values for

development and higher ones for final production.

Admin - email* me if you need anything, or if I've done something stupid...

- click on my MichaelAtOz label, there is a link to email me.

Unless specifically shown otherwise above, my contribution is in the Public Domain; to the extent possible under law, I have waived all copyright and related or neighbouring rights to this work. Obviously inclusion of works of previous authors is not included in the above.

--

Sent from: http://forum.openscad.org/

In addition to the other advice given, I've found that adding a render()

after creating a complex object that'll be re-used a lot will sometimes help

a lot. For example, if you do logical operations with text objects, a

render() can make a huge difference, as it simplifies the object by removing

stuff that is no longer needed.

--

Sent from: http://forum.openscad.org/

The difference operation seems to require a lot of computations sometimes so

I've created both parts involved as two different .stl files and made the

difference in a separate program.

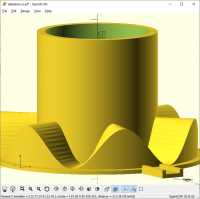

However here is a typical code which takes ages to be rendered. If you see

any possible improvement let me know. The shape to be rendered is displayed

below.

global_thickness = 20;

nombre_vagues = 6;

degres = 360;

base_thickness = 2;

wall_thickness = 4;

precision = 360;

union() {

for ( i = [0:1/3:degres * 9]) {

a = [sin(i/3) * (enclosure_radius-global_thickness), cos(i/3) *

(enclosure_radius-global_thickness)];

d = [sin((i+1)/3) * (enclosure_radius-global_thickness), cos((i+1)/3) *

(enclosure_radius-global_thickness)];

f = [sin(i/3) * enclosure_radius, cos(i/3) * enclosure_radius];

g = [sin((i+1)/3) * enclosure_radius, cos((i+1)/3) * enclosure_radius];

reference = [0,0];

translate([0,0,base_thickness]) {

translate([0,0,0]) {

linear_extrude(height = (sin(i/3 * nombre_vagues) * 10)+10, center =

false, convexity = 10, twist = 0, slices = 20, scale = 1.0, $fn = 16) {

polygon(points = [a,f,g,d], convexity = 100);

}

}

}

}

difference() {

union() {

cylinder(h = base_thickness, r = enclosure_radius + wall_thickness, $fn =

precision);

cylinder(h = 64, r = enclosure_radius -20, $fn = precision);

translate([0,0,1]) {

cube([wall_thickness * 2 + 4, enclosure_radius * 2 + 2 * wall_thickness

- 40, 2], center = true);

}

translate([5, enclosure_radius+14, 3]) {

cube([2,20,2], center = true);

}

translate([-5, enclosure_radius+14, 3]) {

cube([2,20,2], center = true);

}

translate([5, -enclosure_radius-14, 3]) {

cube([2,20,2], center = true);

}

translate([-5, -enclosure_radius-14, 3]) {

cube([2,20,2], center = true);

}

}

cylinder(h = 64, r = enclosure_radius - 24, $fn = precision);

}

}

http://forum.openscad.org/file/t2715/caption.jpg

--

Sent from: http://forum.openscad.org/

Use 2D as much as possible to avoid 3D difference(). E.g. don't subtract

cylinders, linear extrude a difference of two circles.

Similarly for the two channels, linear extrude the difference of two

squares.

Don't set $fn if you are 3D printing. Set $fa and $fs. I use $fa = 6 and

$fs = 0.25. Sometimes I lower $fa to 1 to when milling.

On Mon, 15 Jun 2020 at 12:10, amundsen roald.baudoux@brutele.be wrote:

The difference operation seems to require a lot of computations sometimes

so

I've created both parts involved as two different .stl files and made the

difference in a separate program.

However here is a typical code which takes ages to be rendered. If you see

any possible improvement let me know. The shape to be rendered is displayed

below.

global_thickness = 20;

nombre_vagues = 6;

degres = 360;

base_thickness = 2;

wall_thickness = 4;

precision = 360;

union() {

for ( i = [0:1/3:degres * 9]) {

a = [sin(i/3) * (enclosure_radius-global_thickness),

cos(i/3) *

(enclosure_radius-global_thickness)];

d = [sin((i+1)/3) * (enclosure_radius-global_thickness),

cos((i+1)/3) *

(enclosure_radius-global_thickness)];

f = [sin(i/3) * enclosure_radius, cos(i/3) *

enclosure_radius];

g = [sin((i+1)/3) * enclosure_radius, cos((i+1)/3) *

enclosure_radius];

reference = [0,0];

translate([0,0,base_thickness]) {

translate([0,0,0]) {

linear_extrude(height = (sin(i/3 *

nombre_vagues) * 10)+10, center =

false, convexity = 10, twist = 0, slices = 20, scale = 1.0, $fn = 16) {

polygon(points = [a,f,g,d],

convexity = 100);

}

}

}

}

difference() {

union() {

cylinder(h = base_thickness, r = enclosure_radius

- wall_thickness, $fn =

precision);

cylinder(h = 64, r = enclosure_radius -20, $fn =

precision);

translate([0,0,1]) {

cube([wall_thickness * 2 + 4,

enclosure_radius * 2 + 2 * wall_thickness - 40, 2], center = true);

}

translate([5, enclosure_radius+14, 3]) {

cube([2,20,2], center = true);

}

translate([-5, enclosure_radius+14, 3]) {

cube([2,20,2], center = true);

}

translate([5, -enclosure_radius-14, 3]) {

cube([2,20,2], center = true);

}

translate([-5, -enclosure_radius-14, 3]) {

cube([2,20,2], center = true);

}

}

cylinder(h = 64, r = enclosure_radius - 24, $fn =

precision);

}

}

http://forum.openscad.org/file/t2715/caption.jpg

--

Sent from: http://forum.openscad.org/

OpenSCAD mailing list

Discuss@lists.openscad.org

http://lists.openscad.org/mailman/listinfo/discuss_lists.openscad.org

I'll give a try to set $fa and $fs instead of $fn. Thank you.

--

Sent from: http://forum.openscad.org/

Setting $fn to 360 is an obvious culprit, but it's not the real problem.

There's another segment that seems to be doing too much work. (And is

also harder to understand than it needs to be.)

On 6/15/2020 4:09 AM, amundsen wrote:

degres = 360;

[...]

for ( i = [0:1/3:degres * 9]) {

a = [sin(i/3) * (enclosure_radius-global_thickness), cos(i/3) *

(enclosure_radius-global_thickness)];

d = [sin((i+1)/3) * (enclosure_radius-global_thickness), cos((i+1)/3) *

(enclosure_radius-global_thickness)];

This steps around the circle three times. The second and third times

are identical to the first and can be eliminated.

It would then be stepping from 0 to 3*360 by 1/3. The multiply-by-3 is

cancelled by the divide-by-3s in the body, making the whole thing

unnecessarily complex. The effect is to step around the circle by 1/9

degree increments; it could do that directly, eliminating all of the

divides.

Net, this is building 9720 linear-extruded blocks 2/3 of which are

redundant.

After eliminating the redundant blocks, you'll still have 3240 of them.

That's a lot.

I'd have to figure out how big the stair steps involved really are to

know if you need that much resolution. But assuming for the moment that

you do, you still probably don't need it all the time. You could do

much of your work at much lower resolution, and only render at full

resolution when you're ready to print.

Something like:

step = 1/9;

[...]

for ( i = [0:step:degres]) {

a = [sin(i) * (enclosure_radius-global_thickness), cos(i) * (enclosure_radius-global_thickness)];

d = [sin(i+step) * (enclosure_radius-global_thickness), cos(i+step) * (enclosure_radius-global_thickness)];

f = [sin(i) * enclosure_radius, cos(i) * enclosure_radius];

g = [sin(i+step) * enclosure_radius, cos(i+step) * enclosure_radius];

reference = [0,0];

translate([0,0,base_thickness]) {

translate([0,0,0]) {

linear_extrude(height = (sin(i * nombre_vagues) * 10)+10, center = false, convexity = 10) {

polygon(points = [a,f,g,d], convexity = 100);

}

}

}

}

and then set "step" to different values depending on what you're doing.

Note: Your blocks were 1/3 degree wide and stepped in 1/9 degree

intervals; mine are "step" wide, with "step" intervals.

A more advanced answer might be to stop using linear_extruded blocks -

which have flat tops - and instead use polyhedra. With a polyhedron you

could have a top that slopes, which will more naturally fit the sine

wave that you're trying to generate. You could probably get away with

many fewer steps that way. It looks like 1-degree or 2-degree steps

might well be fine

Here's a variation that renders in ~90 seconds for me, versus >10

minutes for even a simplified version of the original. And the fidelity

is pretty good, maybe even better than the original. I had to guess at

a value for enclosure_radius; the original didn't provide one. Dropping

precision to 60 takes it down to 42. Setting step to 5 and precision to

60 makes it render in 25 seconds. The fidelity there is probably not

good enough for production, but is probably good enough for

pre-production work.

Somebody should check my polyhedra. My 3D geometry isn't quite good

enough for me to be sure that the "top" isn't really a quadrilateral,

that it really does need to be split into two triangles.

enclosure_radius=50;

global_thickness = 20;

nombre_vagues = 6;

degres = 360;

base_thickness = 2;

wall_thickness = 4;

precision = 360;

step = 2;

union() {

for ( i = [0:step:degres]) {

abot = [sin(i) * (enclosure_radius-global_thickness), cos(i) *

(enclosure_radius-global_thickness), 0];

dbot = [sin(i+step) * (enclosure_radius-global_thickness), cos(i+step) *

(enclosure_radius-global_thickness), 0];

fbot = [sin(i) * enclosure_radius, cos(i) * enclosure_radius, 0];

gbot = [sin(i+step) * enclosure_radius, cos(i+step) * enclosure_radius, 0];

h1 = (sin(i * nombre_vagues) * 10)+10;

h2 = (sin((i+step) * nombre_vagues) * 10)+10;

atop = abot + [0,0,h1];

dtop = dbot + [0,0,h2];

ftop = fbot + [0,0,h1];

gtop = gbot + [0,0,h2];

reference = [0,0];

translate([0,0,base_thickness]) {

polyhedron(points=[abot, dbot, fbot, gbot, atop, dtop, ftop, gtop], faces=[

[0,1,3,2],

[4,5,1,0],

[0,2,6,4],

[5,7,3,1],

[2,3,7,6],

[7,5,4],

[4,6,7]

], convexity=10);

}

}

difference() {

union() {

cylinder(h = base_thickness, r = enclosure_radius + wall_thickness, $fn =

precision);

cylinder(h = 64, r = enclosure_radius -20, $fn = precision);

translate([0,0,1]) {

cube([wall_thickness * 2 + 4, enclosure_radius * 2 + 2 * wall_thickness

- 40, 2], center = true);

}

translate([5, enclosure_radius+14, 3]) {

cube([2,20,2], center = true);

}

translate([-5, enclosure_radius+14, 3]) {

cube([2,20,2], center = true);

}

translate([5, -enclosure_radius-14, 3]) {

cube([2,20,2], center = true);

}

translate([-5, -enclosure_radius-14, 3]) {

cube([2,20,2], center = true);

}

}

cylinder(h = 64, r = enclosure_radius - 24, $fn = precision);

}

}

A still more advanced answer would construct the entire outer ring as a

single polyhedron, but that exceeds what I want to do today. (But it

would probably be faster still.)

Thanks a lot @JordanBrown!

The first version without polyhedron is still quite slow but it might be in

part because I have an integrated GPU only.

The second version is indeed much faster. I need to analyze the code!

--

Sent from: http://forum.openscad.org/

hello,

I am not sure if this has anything to do with the topic but i see you all

look at the programming code for optimizing.

I wonder if there is something in openscad/cgal eating up rendering time.

Rendering the code for my project takes a staggering 5mins 50 secs but the

CPU load stay's at 9% and the GPU load stay's at 5%.

so the computer is almost doing nothing!

(AMD Ryzen 7 3700X 8core 3.59 and GTX 1650S)

it is as if the computer power is not important at all and there is some

other reason why the calculations are so slow.

I did expect a higer GPU/CPU load when the calculations increase

rgrds

Henk

--

Sent from: http://forum.openscad.org/