Re: Tangential join/infill two parallel vertical cylindrical tubes.

On Wednesday 21 April 2021 13:16:58 A. Craig West wrote:

Openscad is an amazingly flexible tool, but I do find that it is

overly limited by the assumption that 3d printers are the only

possible use case. I find that the language is great for expressing

geometry in 2d as well, but due to the assumption that all generated

objects must have thickness/volume, you can't actually use it for

things like laser cutting...

I didn't have laser cutting in mind, Craig, more like a suitable carbide

end mill whose dimensions would have to be known by the slicer. Or

assume sinker EDM, but that also has problems due to the erosion of the

sinker electrode as it works.

That too is a major problem when the hole being burnt is more than

electrode diameter deep. I have cut slots to make compressible petals

out of a socket to receive a ball screw, with tapered threads on the

outside. It does those slots an inch deep, .032" wide, putting a drive

shaft on the end of a ball screw for 2 lathes x drives now. No warpage,

no burrs, puts tons of grip on the end of a ball screw when its wet with

threadlocker and the nut drawn tight. Hasn't slipped a micron in many

years. That was the general idea.

So what to we have that can turn an openscad output into gcode?

Preferably metric based although linuxcnc accepts either measurement

system. Preferably something smart enough to make use of linuxcnc's

looping abilities. Something that turns 100 lines of source code into

100 gigabytes of gcode because it has to unroll all the loops, is not to

me, a workable solution. Success to me is a 90 line gcode program that

takes 3 days to run. I have done that by hand. It also made the sharpest

table saw carbide blade I've ever used.

So I am curious, if you are designing a part in openscad that will

eventually be made on a cnc controlled 3 or more axis milling machine,

what do you use to make that connection work?

Thank you all.

[...]

Cheers, Gene Heskett

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/gene

On Wednesday 21 April 2021 13:38:58 Alex Gibson wrote:

I’m confused to read that as I use it all the time for 2D!

Are you aware of the whole 2D subsystem? IE square([1,2]); instead of

cube([1,2,3]);?

And that you can both import and export DXF files which are good for

laser cutting and CNC routing?

(if you want to import DXF files – you need to make sure they don’t

contain curves as these come in many incompatible dialects – instead

decimate them to many straight sections – there’s an excellent plugin

for Inkscape called ‘DXF output for OpenSCAD’ or similar which does

this for you)

I got many and confusing hits on that, exact URL please?

You can take a 2D shape and linear or rotate extrude to 3D, or you can

cut a cross section from a 3D model in 2D with projection()…

Or… what is it you’re struggling to do?

Cheers,

Alex Gibson

admg consulting

edumaker limited

· Project management

· Operations & Process improvement

· 3D Printing

From: A. Craig West [mailto:acraigwest@gmail.com]

Sent: 21 April 2021 18:17

To: OpenSCAD general discussion

Subject: [OpenSCAD] Re: Linear_extrude

Openscad is an amazingly flexible tool, but I do find that it is

overly limited by the assumption that 3d printers are the only

possible use case. I find that the language is great for expressing

geometry in 2d as well, but due to the assumption that all generated

objects must have thickness/volume, you can't actually use it for

things like laser cutting...

On Wed, 21 Apr 2021, 12:50 Gene Heskett, gheskett@shentel.net wrote:

On Wednesday 21 April 2021 11:03:52 A. Craig West wrote:

I would just use:

mirror([0, 0, 1]) linear_extrude...

Now, why didn't I think of that? Go ahead, answer that, I deserve it.

That would be an ideal first step in making gcode for a milliing

machine. The next would be a "slicer" like translator to break that

depth into something the machine is capable of. Just think, from an

idea done in openscad, sliced into gcode to drive the machine. The

capabilities of that, and the time saved in making the finished part

are mind boggling.

On Wed, 21 Apr 2021, 10:55 Ray West, raywest@raywest.com wrote:

Is there a method of doing a linear-extrude or equivalent in the

opposite direction, (-ve z instead of +ve)? In simple 3 axis

machining, it is usual to have z0 at the top of the work piece,

and it would make things easier, I think, if an extrude in the -ve

z direction was possible.

For example, instead of a number of lines like

'translate([0,0,-5])linear_extrude(5)notch();' could simply write

'linear_extrude(-5)notch;' It would allow a very quick way of

getting the 2d drawing into a 3d model of the object.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Cheers, Gene Heskett

Cheers, Gene Heskett

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/gene

I use PyCam to convert OpenSCAD to gcode that I then run on LinuxCNC to

drive my router.

On Wed, 21 Apr 2021 at 19:37, Gene Heskett gheskett@shentel.net wrote:

On Wednesday 21 April 2021 13:38:58 Alex Gibson wrote:

I’m confused to read that as I use it all the time for 2D!

Are you aware of the whole 2D subsystem? IE square([1,2]); instead of

cube([1,2,3]);?

And that you can both import and export DXF files which are good for

laser cutting and CNC routing?

(if you want to import DXF files – you need to make sure they don’t

contain curves as these come in many incompatible dialects – instead

decimate them to many straight sections – there’s an excellent plugin

for Inkscape called ‘DXF output for OpenSCAD’ or similar which does

this for you)

I got many and confusing hits on that, exact URL please?

You can take a 2D shape and linear or rotate extrude to 3D, or you can

cut a cross section from a 3D model in 2D with projection()…

Or… what is it you’re struggling to do?

Cheers,

Alex Gibson

admg consulting

edumaker limited

· Project management

· Operations & Process improvement

· 3D Printing

From: A. Craig West [mailto:acraigwest@gmail.com]

Sent: 21 April 2021 18:17

To: OpenSCAD general discussion

Subject: [OpenSCAD] Re: Linear_extrude

Openscad is an amazingly flexible tool, but I do find that it is

overly limited by the assumption that 3d printers are the only

possible use case. I find that the language is great for expressing

geometry in 2d as well, but due to the assumption that all generated

objects must have thickness/volume, you can't actually use it for

things like laser cutting...

On Wed, 21 Apr 2021, 12:50 Gene Heskett, gheskett@shentel.net wrote:

On Wednesday 21 April 2021 11:03:52 A. Craig West wrote:

I would just use:

mirror([0, 0, 1]) linear_extrude...

Now, why didn't I think of that? Go ahead, answer that, I deserve it.

That would be an ideal first step in making gcode for a milliing

machine. The next would be a "slicer" like translator to break that

depth into something the machine is capable of. Just think, from an

idea done in openscad, sliced into gcode to drive the machine. The

capabilities of that, and the time saved in making the finished part

are mind boggling.

On Wed, 21 Apr 2021, 10:55 Ray West, raywest@raywest.com wrote:

Is there a method of doing a linear-extrude or equivalent in the

opposite direction, (-ve z instead of +ve)? In simple 3 axis

machining, it is usual to have z0 at the top of the work piece,

and it would make things easier, I think, if an extrude in the -ve

z direction was possible.

For example, instead of a number of lines like

'translate([0,0,-5])linear_extrude(5)notch();' could simply write

'linear_extrude(-5)notch;' It would allow a very quick way of

getting the 2d drawing into a 3d model of the object.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Cheers, Gene Heskett

Cheers, Gene Heskett

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/gene

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Thanks for all the replies,

My method is basically import a 2d dxf into the cam software, select the

boundaries, and profile or pocket as required, either remembering the

depths of cut or otherwise. A 2d dxf from openscad does the job, but to

get the boundaries, it is sometimes necessary to difference shapes

purely to get boundaries. It came to mind, that it would be simple to

quickly check the shape of the object by extruding downwards, in the

similar way as I think of the machining action, and the depths could be

extracted for use in the cam program. Mirroring would work, but then I'd

have to be thinking 'upside-down' so to speak. I'm not sure of the logic

behind not being able to extrude downwards, I would have thought it

would be not difficult to allow that. A bit more fiddling, and could

probably use offset to generate the tool path for cylindrical cutters,

but the cam does that fine, if I get the outlines.

On 21/04/2021 18:16, A. Craig West wrote:

Openscad is an amazingly flexible tool, but I do find that it is

overly limited by the assumption that 3d printers are the only

possible use case. I find that the language is great for expressing

geometry in 2d as well, but due to the assumption that all generated

objects must have thickness/volume, you can't actually use it for

things like laser cutting...

On Wed, 21 Apr 2021, 12:50 Gene Heskett, <gheskett@shentel.net

mailto:gheskett@shentel.net> wrote:

On Wednesday 21 April 2021 11:03:52 A. Craig West wrote:

I would just use:

mirror([0, 0, 1]) linear_extrude...

Now, why didn't I think of that? Go ahead, answer that, I deserve it.

That would be an ideal first step in making gcode for a milliing

machine.

The next would be a "slicer" like translator to break that depth into

something the machine is capable of. Just think, from an idea done in

openscad, sliced into gcode to drive the machine. The capabilities of

that, and the time saved in making the finished part are mind

boggling.

On Wed, 21 Apr 2021, 10:55 Ray West, <raywest@raywest.com

<mailto:raywest@raywest.com>> wrote:

Is there a method of doing a linear-extrude or equivalent in the

opposite direction, (-ve z instead of +ve)? In simple 3 axis

machining, it is usual to have z0 at the top of the work

piece, and

it would make things easier, I think, if an extrude in the -ve z

direction was possible.

For example, instead of a number of lines like

'translate([0,0,-5])linear_extrude(5)notch();' could simply write

'linear_extrude(-5)notch;' It would allow a very quick way of

getting the 2d drawing into a 3d model of the object.

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

<mailto:discuss-leave@lists.openscad.org>

Cheers, Gene Heskett

--

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author)

If we desire respect for the law, we must first make the law

respectable.

- Louis D. Brandeis

Genes Web page <http://geneslinuxbox.net:6309/gene

<http://geneslinuxbox.net:6309/gene>>

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

<mailto:discuss-leave@lists.openscad.org>

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Hi Gene

I'm not surprised, there were several plugins with similar names that evolved from one another.

This is to my knowledge the best version, definitely works, and takes the best bits from the others - so is the one I'd recommend.

https://github.com/brad/Inkscape-OpenSCAD-DXF-Export

I've validated the install instructions on Windows and Linux - basically just copying files into Inkscape's extensions folder.

With it installed you can open Inkscape, draw or import something, then just need to make sure you've done a 'convert object to path' and then 'save as' and choose the option OpenSCAD DXF.

Good luck!

Alex Gibson

admg consulting

edumaker limited

• Project management

• Operations & Process improvement

• 3D Printing

-----Original Message-----

From: Gene Heskett [mailto:gheskett@shentel.net]

Sent: 21 April 2021 19:37

To: discuss@lists.openscad.org

Subject: [OpenSCAD] Re: Linear_extrude

On Wednesday 21 April 2021 13:38:58 Alex Gibson wrote:

I’m confused to read that as I use it all the time for 2D!

Are you aware of the whole 2D subsystem? IE square([1,2]); instead of

cube([1,2,3]);?

And that you can both import and export DXF files which are good for

laser cutting and CNC routing?

(if you want to import DXF files – you need to make sure they don’t

contain curves as these come in many incompatible dialects – instead

decimate them to many straight sections – there’s an excellent plugin

for Inkscape called ‘DXF output for OpenSCAD’ or similar which does

this for you)

I got many and confusing hits on that, exact URL please?

You can take a 2D shape and linear or rotate extrude to 3D, or you can

cut a cross section from a 3D model in 2D with projection()…

Or… what is it you’re struggling to do?

Cheers,

Alex Gibson

admg consulting

edumaker limited

· Project management

· Operations & Process improvement

· 3D Printing

From: A. Craig West [mailto:acraigwest@gmail.com]

Sent: 21 April 2021 18:17

To: OpenSCAD general discussion

Subject: [OpenSCAD] Re: Linear_extrude

Openscad is an amazingly flexible tool, but I do find that it is

overly limited by the assumption that 3d printers are the only

possible use case. I find that the language is great for expressing

geometry in 2d as well, but due to the assumption that all generated

objects must have thickness/volume, you can't actually use it for

things like laser cutting...

On Wed, 21 Apr 2021, 12:50 Gene Heskett, gheskett@shentel.net wrote:

On Wednesday 21 April 2021 11:03:52 A. Craig West wrote:

I would just use:

mirror([0, 0, 1]) linear_extrude...

Now, why didn't I think of that? Go ahead, answer that, I deserve it.

That would be an ideal first step in making gcode for a milliing

machine. The next would be a "slicer" like translator to break that

depth into something the machine is capable of. Just think, from an

idea done in openscad, sliced into gcode to drive the machine. The

capabilities of that, and the time saved in making the finished part

are mind boggling.

On Wed, 21 Apr 2021, 10:55 Ray West, raywest@raywest.com wrote:

Is there a method of doing a linear-extrude or equivalent in the

opposite direction, (-ve z instead of +ve)? In simple 3 axis

machining, it is usual to have z0 at the top of the work piece,

and it would make things easier, I think, if an extrude in the -ve

z direction was possible.

For example, instead of a number of lines like

'translate([0,0,-5])linear_extrude(5)notch();' could simply write

'linear_extrude(-5)notch;' It would allow a very quick way of

getting the 2d drawing into a 3d model of the object.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Cheers, Gene Heskett

Cheers, Gene Heskett

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/gene

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

--

This email has been checked for viruses by AVG.

https://www.avg.com

What would linear-extruding down do that's different from mirroring?

The only thing I can think of offhand is that maybe the direction of the

twist would be reversed - and of course a relatively simple wrapper

could do that.

On Wednesday 21 April 2021 17:16:32 Alex Gibson wrote:

Hi Gene

I'm not surprised, there were several plugins with similar names that

evolved from one another.

This is to my knowledge the best version, definitely works, and takes

the best bits from the others - so is the one I'd recommend.

https://github.com/brad/Inkscape-OpenSCAD-DXF-Export

I've validated the install instructions on Windows and Linux -

basically just copying files into Inkscape's extensions folder.

With it installed you can open Inkscape, draw or import something,

then just need to make sure you've done a 'convert object to path' and

then 'save as' and choose the option OpenSCAD DXF.

That machine, since its a new buster install needed another 6 gigabytes

of stuff installed to get rid of all but one dependency error in the

extensions-error.log. From that log:

Extension "Win32 Vector Print" failed to load because the extension is

designed for Windows only. This is caused by an improper .inx file for

this extension. An improper .inx file could have been caused by a

faulty installation of Inkscape.

Extension "Sketch Input" failed to load because a dependency was not met.

Dependency:

type: executable

location: path

string: skconvert

LaTex was also missing, but roughly 5GB of texlive stuff seems to have

satisfied that. LaTex support seems to be on its way to the dustbin of

history anyway.

skconvert is still missing and despite the error msgs above claim that it

indicates a faulty windows install, everything on that machine is either

an AppImage or came from the buster repo's. skconvert is apparently a

windows utility to convert sketchup files to something inkscape can use.

I promise I won't miss it. :) Sketchup if you recall history was a free

google offering, but was converted to a windows only app for seat fees

by google. Obvously I've not a copy of it on any of my farm today.

Now, for my 86 yo wet ram to see what it can do for openscad.

However, in my messing around I did crash inkscape as it stopped

responding and I had to do another login from a different workspace and

issue a killall inkscape.

Good luck!

Alex Gibson

Thank you Alex Gibson for that link. Its been an interesting 3.5 hours

of installing stuff. The net seems a bit slower tonight. But I am

getting the bandwidth I'm paying for.

admg consulting

edumaker limited

• Project management

• Operations & Process improvement

• 3D Printing

Take care and stay well folks.

Cheers, Gene Heskett

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/gene

On 21/04/2021 23:29, Jordan Brown wrote:

What would linear-extruding down do that's different from mirroring?

The only thing I can think of offhand is that maybe the direction of

the twist would be reversed - and of course a relatively simple

wrapper could do that.

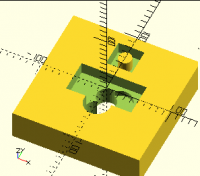

The following code may explain the overall awkwardness of my efforts

translate([400,0]){

difference(){

linear_extrude(30)square(250,true);

linear_extrude(20)circle (100);

linear_extrude(50)circle(50);

linear_extrude(50)translate ([0,80]) square(25,true);

linear_extrude(50)translate ([80,0]) circle(20);

}

}

// 2d conversion.

difference(){

square(250,true); //block 250square by 30

circle (100); // bore 20 deep

}

circle(50); // bore right through

translate ([0,80]) square(25,true); //bore right through

translate ([80,0]) circle(20); //bore right through

The first block of code shows the shape of the object (It is not too

difficult to draw it upside down). the linear_extrude values are the

depths of the pockets/profiles (-z values). To convert it back to 2d for

exporting as dxf, requires differencing some items. On this simple made

up example, it is not much of a problem, but it certainly would be for a

more complex item. (move the small square to [0,90], say. I would like

to be able to produce the 2d drawing (my initial starting point) without

fussing with differences, etc, and simply add some linear-extrudes with

depths, to get a quick look at the solid object.

The starting point would be from the 2d dimensions, a hand drawn sketch,

say.

The following is much easier to write, it complies with 2.5 d thinking,

and the the concept would work on polygons, or other 2d shapes. It is

all constructed from 2d and extruding, but There is no straightforward

way to convert it to a dxf file within openscad, afaik.

module xyz(x,y,z){

linear_extrude(-z)

translate([x,y])children();

}

intersection(){

difference(){

xyz(0,0,-50)square(200,true); // work piece

// pockets

xyz(0,-30,-50)circle(20);

xyz(0,0,-50)circle(15);

xyz(20,0,-30)circle(20);

xyz(0,0,-20)square([100,50],true);

//island

difference(){

xyz(0,60,-20)square(40,true);

xyz(0,60,-20)circle(10);

}

}

// profile (intersection with object)

xyz(0,0,-49)square(195,true);

}

On 22/04/2021 13:14, Ray West wrote:

On 21/04/2021 23:29, Jordan Brown wrote:

What would linear-extruding down do that's different from mirroring?

The only thing I can think of offhand is that maybe the direction of

the twist would be reversed - and of course a relatively simple

wrapper could do that.

The following code may explain the overall awkwardness of my efforts

translate([400,0]){

difference(){

linear_extrude(30)square(250,true);

linear_extrude(20)circle (100);

linear_extrude(50)circle(50);

linear_extrude(50)translate ([0,80]) square(25,true);

linear_extrude(50)translate ([80,0]) circle(20);

}

}

// 2d conversion.

difference(){

square(250,true); //block 250square by 30

circle (100); // bore 20 deep

}

circle(50); // bore right through

translate ([0,80]) square(25,true); //bore right through

translate ([80,0]) circle(20); //bore right through

The first block of code shows the shape of the object (It is not too

difficult to draw it upside down). the linear_extrude values are the

depths of the pockets/profiles (-z values). To convert it back to 2d

for exporting as dxf, requires differencing some items. On this simple

made up example, it is not much of a problem, but it certainly would

be for a more complex item. (move the small square to [0,90], say. I

would like to be able to produce the 2d drawing (my initial starting

point) without fussing with differences, etc, and simply add some

linear-extrudes with depths, to get a quick look at the solid object.

The starting point would be from the 2d dimensions, a hand drawn

sketch, say.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On 4/22/2021 11:42 AM, Ray West wrote:

The following is much easier to write, it complies with 2.5 d

thinking, and the the concept would work on polygons, or other 2d

shapes. It is all constructed from 2d and extruding, but There is no

straightforward way to convert it to a dxf file within openscad, afaik.

module xyz(x,y,z){

linear_extrude(-z)

translate([x,y])children();

}

I think you have the signs wrong; you negate Z here but then you supply

negative values below so the result is positive.

I'm going to assume that you only intended one negation; you want to

drill holes down from the Z=0 plane.

So why doesn't this do what you want?

module xyz(x,y,z){

mirror([0,0,1]) linear_extrude(-z)

translate([x,y])children();

}

intersection(){

difference(){

xyz(0,0,-50)square(200,true); // work piece

// pockets

xyz(0,-30,-50)circle(20);

xyz(0,0,-50)circle(15);

xyz(20,0,-30)circle(20);

xyz(0,0,-20)square([100,50],true);

//island

difference(){

xyz(0,60,-20)square(40,true);

xyz(0,60,-20)circle(10);

}

}

// profile (intersection with object)

xyz(0,0,-49)square(195,true);

}

On 22/04/2021 13:14, Ray West wrote:

On 21/04/2021 23:29, Jordan Brown wrote:

What would linear-extruding down do that's different from mirroring?

The only thing I can think of offhand is that maybe the direction of

the twist would be reversed - and of course a relatively simple

wrapper could do that.

The following code may explain the overall awkwardness of my efforts

translate([400,0]){

difference(){

linear_extrude(30)square(250,true);

linear_extrude(20)circle (100);

linear_extrude(50)circle(50);

linear_extrude(50)translate ([0,80]) square(25,true);

linear_extrude(50)translate ([80,0]) circle(20);

}

}

// 2d conversion.

difference(){

square(250,true); //block 250square by 30

circle (100); // bore 20 deep

}

circle(50); // bore right through

translate ([0,80]) square(25,true); //bore right through

translate ([80,0]) circle(20); //bore right through

The first block of code shows the shape of the object (It is not too

difficult to draw it upside down). the linear_extrude values are the

depths of the pockets/profiles (-z values). To convert it back to 2d

for exporting as dxf, requires differencing some items. On this

simple made up example, it is not much of a problem, but it certainly

would be for a more complex item. (move the small square to [0,90],

say. I would like to be able to produce the 2d drawing (my initial

starting point) without fussing with differences, etc, and simply add

some linear-extrudes with depths, to get a quick look at the solid

object.

The starting point would be from the 2d dimensions, a hand drawn

sketch, say.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org