SP

Sanjeev Prabhakar

Fri, Feb 24, 2023 4:19 PM

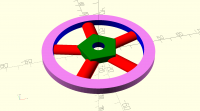

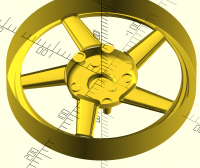

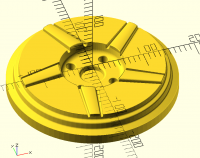

you can have various cases where the parting lines are very zigzag.

In die casting engineering products, I am aware of many such examples.

e.g. refer file attached

[image: download.png]

On Fri, 24 Feb 2023 at 21:17, Daniel Harvey dwaharvey@gmail.com wrote:

Hi Guenther,

In everything I have seen, an inprint is made in each of two halves, and

the halves are assembled together (with imprinting objects removed) and the

resulting mold is filled with a liquid that sets. But in all these cases

the two halves basically have a flat intersection face. In the example of

your Gollum bust, how are the two halves with the non-flat faces turned

into a mold? Also it seems like there would be many objects that could not

be handled at all - objects where there is no cutline that doesn't create a

situation with an upward pointing face that is shadowed by a downward

pointing one.

On Fri, Feb 24, 2023 at 8:22 AM Guenther Sohler guenther.sohler@gmail.com

wrote:

Hi Daniel,

In ideal case, a model like a wheel, is actually symmetrical around a

flat XY plane with 0 elevation at a certain z coordinate and fulfilling

sanjeevs task is just to

difference and to intersect with a big cube.

Unfortunately many models are not as easy as that. they have the point of

maximum lateral extent in differenz z heights.

If you still split such a model with a flat XY cut face, you could end up

in an upper mold which has faces which point downwards.

Did you browse youtube videos on green sand casting ? its very

interesting. if you do, you might get an idea why I came up with such a

complicated picture cut like in my first post.

On Fri, Feb 24, 2023 at 4:08 PM Daniel Harvey dwaharvey@gmail.com

wrote:

I haven't played with this problem myself, but is there a reason to not

have the algorithm decide a flat cut plane, and then find the triangles in

the stl that intersect this plane, and then cut these triangles into new

ones that are placed in the appropriate half? The intersection with a

triangular face in the model seems like it can only have three forms:

- coincident with a side, which is sort of like a non-intersection

(triangle goes in one half)

- coincident with a corner, which then creates two triangles (one to

each half)

- the else... will produce a triangle to go into one half, and a

trapezoid... the trapezoid can be broken into two (or more) co-planar

triangles.

Or just have the program suggest the best cut plane and let openscad

handle things using difference or intersection appropriately...?

In the case of the wheel, I'm not sure I understand why this is a

challenge (intersection with a cube where one face is the center line) -

can you explain?

On Fri, Feb 24, 2023 at 7:53 AM Sanjeev Prabhakar <

sprabhakar2006@gmail.com> wrote:

These are good tips to find way out.

I will try this in my free time.

Thanks for suggestions

On Fri, 24 Feb, 2023, 7:54 pm Guenther Sohler, <

guenther.sohler@gmail.com> wrote:

Hi Sanjeev,

stltool is coded in C and its a requirement to achieve the speed

stltool - moldsplit main task is to split a model around the biggest

lateral extent(this is where faces-up meet faces-down)

A) Find starting point

this is easy: find the lateral point, which has biggest lateral

distance from the center

B) find cutline around model

from the starting point build a tree, only valid directions are

edges where edge-up meet edge-down

finally hoping you can surround the model in CCW direction and

hopefully hit the start point again

C) find out which triangles are "above" and "below" the cutline. this

is not necessarily the triangles with the normvector show up and down

D) duplicate all points at the culine and use them for bottom and

upper half respectively

E) finally move the objects apart by simply raising z coordinate of

upper half

F) now fill the big hole which arises when pulling the halves apart

- simple polygon fill is not possible as the polygon might be concave

- polygon tesselation is not possible because the points are in 3d,

not 2d

- finally i came up which an algoithm which offsets the polygon with

negative values iteratively.

at some point two corners melt into one. this is exaclty the

required "helper point" to use to tesselate the polygon in a concave -

friendly way.

(actually i believe this algorithm is very similar to openscad

"roof" function.

Hope you got an idea, how the algorithm works, but i doubt you will

make it in python...

cheers

On Fri, Feb 24, 2023 at 3:07 PM Sanjeev Prabhakar <

sprabhakar2006@gmail.com> wrote:

Hi Guenther

Your picture of the split looks interesting.

Can you give some more information on the workflow and the logic.

In case it is possible to share the stltool developed by you, would

be great, although i have very limited understanding of softwares.

I started working on openscad as it initially looked simpler to work

on.

Then learnt a little bit of python to circumvent the limitations of

openscad language.

Now it seems I need to learn another one. Not sure if I will do that

as it is taking a lot of my time.

Anyway, I am not using it for any professional purposes and is a

hobby.

On Fri, 24 Feb, 2023, 7:15 pm Guenther Sohler, <

guenther.sohler@gmail.com> wrote:

hi Sanjeev,

I know exactly what you mean, I also do green-sand-casting and

demolding it the key for successful metal casting.

I spent over 6 month on writing software to find the best split of a

given bust stl file programmatically. the tool is called "stltool"

Right now developing the tool is on hold as I need some time for

more inspiration.

Examples of successful splits are here:

https://twitter.com/gadget_3d/status/1581385519308890112/photo/1

was also able to split "batman" mold successfully, but by far not

all bust are splittable for molding.

when splitting your weel, which is very symmetrical, isn't it

possible to split the face at the symmetry line using "difference" or

"intersection" ?

when you very easily split your triangles into two bins when

watching if the z coordinate of the normal vector is pointing up or down.

For my tool i spent

25% of the time on finding the best cut line around the model

75% of the time to filling the big hole in the model which arises

when splitting the model into 2 halves ....

On Fri, Feb 24, 2023 at 2:29 PM Sanjeev Prabhakar <

sprabhakar2006@gmail.com> wrote:

I have a requirement to develop a casting mould for a part e.g.

wheel.

All the surfaces which are visible from top needs to be extracted

to get one half of the mould.

Similarly surfaces which are visible from bottom needs to be

extracted to develop other side of the mould.

Parting lines can be zigzag depending on the part geometry.

Any ideas to do such a thing in openscad will be really helpful

Regards

Sanjeev

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

you can have various cases where the parting lines are very zigzag.

In die casting engineering products, I am aware of many such examples.

e.g. refer file attached

[image: download.png]

On Fri, 24 Feb 2023 at 21:17, Daniel Harvey <dwaharvey@gmail.com> wrote:

> Hi Guenther,

> In everything I have seen, an inprint is made in each of two halves, and

> the halves are assembled together (with imprinting objects removed) and the

> resulting mold is filled with a liquid that sets. But in all these cases

> the two halves basically have a flat intersection face. In the example of

> your Gollum bust, how are the two halves with the non-flat faces turned

> into a mold? Also it seems like there would be many objects that could not

> be handled at all - objects where there is no cutline that doesn't create a

> situation with an upward pointing face that is shadowed by a downward

> pointing one.

>

> On Fri, Feb 24, 2023 at 8:22 AM Guenther Sohler <guenther.sohler@gmail.com>

> wrote:

>

>> Hi Daniel,

>>

>> In ideal case, a model like a wheel, is actually symmetrical around a

>> flat XY plane with 0 elevation at a certain z coordinate and fulfilling

>> sanjeevs task is just to

>> difference and to intersect with a big cube.

>>

>> Unfortunately many models are not as easy as that. they have the point of

>> maximum lateral extent in differenz z heights.

>> If you still split such a model with a flat XY cut face, you could end up

>> in an upper mold which has faces which point downwards.

>>

>> Did you browse youtube videos on green sand casting ? its very

>> interesting. if you do, you might get an idea why I came up with such a

>> complicated picture cut like in my first post.

>>

>>

>>

>> On Fri, Feb 24, 2023 at 4:08 PM Daniel Harvey <dwaharvey@gmail.com>

>> wrote:

>>

>>> I haven't played with this problem myself, but is there a reason to not

>>> have the algorithm decide a flat cut plane, and then find the triangles in

>>> the stl that intersect this plane, and then cut these triangles into new

>>> ones that are placed in the appropriate half? The intersection with a

>>> triangular face in the model seems like it can only have three forms:

>>> 1) coincident with a side, which is sort of like a non-intersection

>>> (triangle goes in one half)

>>> 2) coincident with a corner, which then creates two triangles (one to

>>> each half)

>>> 3) the else... will produce a triangle to go into one half, and a

>>> trapezoid... the trapezoid can be broken into two (or more) co-planar

>>> triangles.

>>>

>>> Or just have the program suggest the best cut plane and let openscad

>>> handle things using difference or intersection appropriately...?

>>> In the case of the wheel, I'm not sure I understand why this is a

>>> challenge (intersection with a cube where one face is the center line) -

>>> can you explain?

>>>

>>> On Fri, Feb 24, 2023 at 7:53 AM Sanjeev Prabhakar <

>>> sprabhakar2006@gmail.com> wrote:

>>>

>>>> These are good tips to find way out.

>>>>

>>>> I will try this in my free time.

>>>>

>>>> Thanks for suggestions

>>>>

>>>>

>>>> On Fri, 24 Feb, 2023, 7:54 pm Guenther Sohler, <

>>>> guenther.sohler@gmail.com> wrote:

>>>>

>>>>> Hi Sanjeev,

>>>>>

>>>>> stltool is coded in C and its a requirement to achieve the speed

>>>>>

>>>>> stltool - moldsplit main task is to split a model around the biggest

>>>>> lateral extent(this is where faces-up meet faces-down)

>>>>>

>>>>> A) Find starting point

>>>>> this is easy: find the lateral point, which has biggest lateral

>>>>> distance from the center

>>>>> B) find cutline around model

>>>>> from the starting point build a tree, only valid directions are

>>>>> edges where edge-up meet edge-down

>>>>> finally hoping you can surround the model in CCW direction and

>>>>> hopefully hit the start point again

>>>>> C) find out which triangles are "above" and "below" the cutline. this

>>>>> is not necessarily the triangles with the normvector show up and down

>>>>>

>>>>> D) duplicate all points at the culine and use them for bottom and

>>>>> upper half respectively

>>>>> E) finally move the objects apart by simply raising z coordinate of

>>>>> upper half

>>>>> F) now fill the big hole which arises when pulling the halves apart

>>>>> * simple polygon fill is not possible as the polygon might be concave

>>>>> * polygon tesselation is not possible because the points are in 3d,

>>>>> not 2d

>>>>> * finally i came up which an algoithm which offsets the polygon with

>>>>> negative values iteratively.

>>>>> at some point two corners melt into one. this is exaclty the

>>>>> required "helper point" to use to tesselate the polygon in a concave -

>>>>> friendly way.

>>>>> (actually i believe this algorithm is very similar to openscad

>>>>> "roof" function.

>>>>>

>>>>> Hope you got an idea, how the algorithm works, but i doubt you will

>>>>> make it in python...

>>>>>

>>>>> cheers

>>>>>

>>>>>

>>>>>

>>>>> On Fri, Feb 24, 2023 at 3:07 PM Sanjeev Prabhakar <

>>>>> sprabhakar2006@gmail.com> wrote:

>>>>>

>>>>>> Hi Guenther

>>>>>>

>>>>>> Your picture of the split looks interesting.

>>>>>>

>>>>>> Can you give some more information on the workflow and the logic.

>>>>>>

>>>>>> In case it is possible to share the stltool developed by you, would

>>>>>> be great, although i have very limited understanding of softwares.

>>>>>>

>>>>>> I started working on openscad as it initially looked simpler to work

>>>>>> on.

>>>>>>

>>>>>> Then learnt a little bit of python to circumvent the limitations of

>>>>>> openscad language.

>>>>>>

>>>>>> Now it seems I need to learn another one. Not sure if I will do that

>>>>>> as it is taking a lot of my time.

>>>>>>

>>>>>> Anyway, I am not using it for any professional purposes and is a

>>>>>> hobby.

>>>>>>

>>>>>>

>>>>>>

>>>>>>

>>>>>>

>>>>>>

>>>>>>

>>>>>>

>>>>>>

>>>>>> On Fri, 24 Feb, 2023, 7:15 pm Guenther Sohler, <

>>>>>> guenther.sohler@gmail.com> wrote:

>>>>>>

>>>>>>> hi Sanjeev,

>>>>>>>

>>>>>>> I know exactly what you mean, I also do green-sand-casting and

>>>>>>> demolding it *the* key for successful metal casting.

>>>>>>>

>>>>>>> I spent over 6 month on writing software to find the best split of a

>>>>>>> given bust stl file programmatically. the tool is called "stltool"

>>>>>>>

>>>>>>> Right now developing the tool is on hold as I need some time for

>>>>>>> more inspiration.

>>>>>>>

>>>>>>> Examples of successful splits are here:

>>>>>>>

>>>>>>> https://twitter.com/gadget_3d/status/1581385519308890112/photo/1

>>>>>>>

>>>>>>> was also able to split "batman" mold successfully, but by far not

>>>>>>> all bust are splittable for molding.

>>>>>>>

>>>>>>> when splitting your weel, which is very symmetrical, isn't it

>>>>>>> possible to split the face at the symmetry line using "difference" or

>>>>>>> "intersection" ?

>>>>>>>

>>>>>>> --------

>>>>>>> when you very easily split your triangles into two bins when

>>>>>>> watching if the z coordinate of the normal vector is pointing up or down.

>>>>>>>

>>>>>>> For my tool i spent

>>>>>>>

>>>>>>> 25% of the time on finding the best cut line around the model

>>>>>>> 75% of the time to filling the big hole in the model which arises

>>>>>>> when splitting the model into 2 halves ....

>>>>>>>

>>>>>>>

>>>>>>>

>>>>>>>

>>>>>>>

>>>>>>>

>>>>>>>

>>>>>>> On Fri, Feb 24, 2023 at 2:29 PM Sanjeev Prabhakar <

>>>>>>> sprabhakar2006@gmail.com> wrote:

>>>>>>>

>>>>>>>> I have a requirement to develop a casting mould for a part e.g.

>>>>>>>> wheel.

>>>>>>>>

>>>>>>>> All the surfaces which are visible from top needs to be extracted

>>>>>>>> to get one half of the mould.

>>>>>>>>

>>>>>>>> Similarly surfaces which are visible from bottom needs to be

>>>>>>>> extracted to develop other side of the mould.

>>>>>>>>

>>>>>>>> Parting lines can be zigzag depending on the part geometry.

>>>>>>>>

>>>>>>>> Any ideas to do such a thing in openscad will be really helpful

>>>>>>>>

>>>>>>>> Regards

>>>>>>>> Sanjeev

>>>>>>>>

>>>>>>>> _______________________________________________

>>>>>>>> OpenSCAD mailing list

>>>>>>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>>>>>

>>>>>>> _______________________________________________

>>>>>>> OpenSCAD mailing list

>>>>>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>>>>

>>>>>> _______________________________________________

>>>>>> OpenSCAD mailing list

>>>>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>>>

>>>>> _______________________________________________

>>>>> OpenSCAD mailing list

>>>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>>

>>>> _______________________________________________

>>>> OpenSCAD mailing list

>>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>

>>> _______________________________________________

>>> OpenSCAD mailing list

>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

K

Ken

Fri, Feb 24, 2023 7:53 PM

Not sure if this is what you want Sanjeev, it's pretty simplistic code-

I wrote it to create patterns for casting flywheels for small stationary

engines. It has draft so you can get it out of the sand, and you can set

oval or round spokes, any (reasonable) number of spokes, plus either a

circular hub or one with sides equal to the number of spokes. I just use

difference to get the half, and there are two holes in the flat back for

registration pins.

$fn = 128;

include <BOSL2/std.scad>

//Set up the dimensions

hubdiameter = 31;

shaftdiameter = 12;

wheeldiameter = 100;

hubthickness = 10;

rimthickness = 20;

spokethickness = 8;

numberofspokes = 5;

//Set draught so mold can be

//removed from sand. Be aware

//that too much draught will break

//the fillet at the base of the spoke.

draught = 1;//[.5:.1:10]

//Don't change the next 5 lines

wheelrimthickness = (wheeldiameter - rimthickness);

spokelength = 1+(((wheeldiameter-rimthickness)/2)- (hubdiameter/2.4));

rotation = 360/(numberofspokes);

spoke_rotation = rotation*0.5;

hubradius = hubdiameter/2;

circumradius = hubradius/cos(180/numberofspokes);

//Set the ovalness of the spokes (1=round,

// less than one is oval in one plane,

// more than one is oval in the other plane

ovality = 1.5;

//Make the wheel

difference(){

//Wheel rim

difference(){

difference(){

color ("violet")

cylinder(h=12,d1=wheeldiameter,d2=wheeldiameter-draught,center=true);

//Two 3mm holes so the wheel halves

//can be correctly registered in the mold

translate([0, wheeldiameter/2-5, -5])

cylinder(h=10,d=3);

translate([0, -(wheeldiameter/2-5), -5])

cylinder(h=10,d=3);

}

//Cut out the annulus and make the spokes

difference(){

color ("blue")

cyl(h=13,d1=wheelrimthickness-draught,d2=wheelrimthickness,center=true);

for (i=[0:numberofspokes]){

rotate([90, 0, rotation * i + spoke_rotation])

translate([0,0,12])

scale([ovality,1,1])

color ("red")

//comment out cylinder line and uncomment

//cube line for rectangular spokes

cyl(h=spokelength, d=spokethickness, rounding1=-draught,

rounding2=-draught, center=false);}

// cuboid([65,spokethickness, 5], rounding= 1);}

}

color ("lightblue");

cylinder(h=12,d=15,center=true);

}

//This cube differences out half the wheel

//to make a mold for casting

translate ([0, 0, -10])

cube ([wheeldiameter+10, wheeldiameter+10, 20],center = true);

}

//Draw half a hub center

difference(){

color ("green")

translate ([0, 0, 3])

rotate ([0,0,90])

cyl(h=6,d1=circumradius2,d2=(circumradius2)-draught,center=true,

rounding2 =.5, $fn = numberofspokes);

color ("navy")

cylinder(h=13,d1=shaftdiameter,d2=shaftdiameter-draught, center=true);

}

On 2023-02-25 00:28, Sanjeev Prabhakar wrote:

I have a requirement to develop a casting mould for a part e.g. wheel.

All the surfaces which are visible from top needs to be extracted to

get one half of the mould.

Similarly surfaces which are visible from bottom needs to be extracted

to develop other side of the mould.

Parting lines can be zigzag depending on the part geometry.

Any ideas to do such a thing in openscad will be really helpful

Regards

Sanjeev

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

A baby can be defined as an ego with a noise at one end and a smell at the other.

Your job as parents is to teach them to control all three.

My job as a retiree is to tell you how you are doing it all wrong!

Not sure if this is what you want Sanjeev, it's pretty simplistic code-

I wrote it to create patterns for casting flywheels for small stationary

engines. It has draft so you can get it out of the sand, and you can set

oval or round spokes, any (reasonable) number of spokes, plus either a

circular hub or one with sides equal to the number of spokes. I just use

difference to get the half, and there are two holes in the flat back for

registration pins.

$fn = 128;

include <BOSL2/std.scad>

//Set up the dimensions

hubdiameter = 31;

shaftdiameter = 12;

wheeldiameter = 100;

hubthickness = 10;

rimthickness = 20;

spokethickness = 8;

numberofspokes = 5;

//Set draught so mold can be

//removed from sand. Be aware

//that too much draught will break

//the fillet at the base of the spoke.

draught = 1;//[.5:.1:10]

//Don't change the next 5 lines

wheelrimthickness = (wheeldiameter - rimthickness);

spokelength = 1+(((wheeldiameter-rimthickness)/2)- (hubdiameter/2.4));

rotation = 360/(numberofspokes);

spoke_rotation = rotation*0.5;

hubradius = hubdiameter/2;

circumradius = hubradius/cos(180/numberofspokes);

//Set the ovalness of the spokes (1=round,

// less than one is oval in one plane,

// more than one is oval in the other plane

ovality = 1.5;

//Make the wheel

difference(){

//Wheel rim

difference(){

difference(){

color ("violet")

cylinder(h=12,d1=wheeldiameter,d2=wheeldiameter-draught,center=true);

//Two 3mm holes so the wheel halves

//can be correctly registered in the mold

translate([0, wheeldiameter/2-5, -5])

cylinder(h=10,d=3);

translate([0, -(wheeldiameter/2-5), -5])

cylinder(h=10,d=3);

}

//Cut out the annulus and make the spokes

difference(){

color ("blue")

cyl(h=13,d1=wheelrimthickness-draught,d2=wheelrimthickness,center=true);

for (i=[0:numberofspokes]){

rotate([90, 0, rotation * i + spoke_rotation])

translate([0,0,12])

scale([ovality,1,1])

color ("red")

//comment out cylinder line and uncomment

//cube line for rectangular spokes

cyl(h=spokelength, d=spokethickness, rounding1=-draught,

rounding2=-draught, center=false);}

// cuboid([65,spokethickness, 5], rounding= 1);}

}

color ("lightblue");

cylinder(h=12,d=15,center=true);

}

//This cube differences out half the wheel

//to make a mold for casting

translate ([0, 0, -10])

cube ([wheeldiameter+10, wheeldiameter+10, 20],center = true);

}

//Draw half a hub center

difference(){

color ("green")

translate ([0, 0, 3])

rotate ([0,0,90])

cyl(h=6,d1=circumradius*2,d2=(circumradius*2)-draught,center=true,

rounding2 =.5, $fn = numberofspokes);

color ("navy")

cylinder(h=13,d1=shaftdiameter,d2=shaftdiameter-draught, center=true);

}

On 2023-02-25 00:28, Sanjeev Prabhakar wrote:

> I have a requirement to develop a casting mould for a part e.g. wheel.

>

> All the surfaces which are visible from top needs to be extracted to

> get one half of the mould.

>

> Similarly surfaces which are visible from bottom needs to be extracted

> to develop other side of the mould.

>

> Parting lines can be zigzag depending on the part geometry.

>

> Any ideas to do such a thing in openscad will be really helpful

>

> Regards

> Sanjeev

>

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email todiscuss-leave@lists.openscad.org

--

Cheers, Ken

bats059@gmail.com

https://vk7krj.com/running.html

https://sstv.vk7krj.com/all_bands.html

----------------------------------------

A baby can be defined as an ego with a noise at one end and a smell at the other.

Your job as parents is to teach them to control all three.

My job as a retiree is to tell you how you are doing it all wrong!

SP

Sanjeev Prabhakar

Fri, Feb 24, 2023 10:50 PM

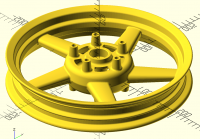

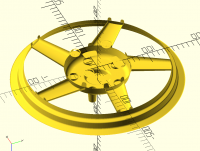

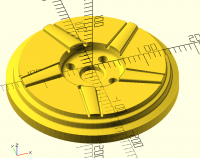

Hi Ken

my model is a little complicated and difference will not work, I have tried

it

[image: wheel.png]

Hi Ken

my model is a little complicated and difference will not work, I have tried

it

[image: wheel.png]

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

K

Ken

Sat, Feb 25, 2023 7:03 AM

Ah yes, I see.

Looking at it, that would be a rather tricky moulding job,

at least 4 parts that I can see, and rather tricky to assemble.

Sooner you than me Sanjeev!

On 2023-02-25 09:50, Sanjeev Prabhakar wrote:

Hi Ken

my model is a little complicated and difference will not work, I have

tried it

wheel.png

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

A baby can be defined as an ego with a noise at one end and a smell at the other.

Your job as parents is to teach them to control all three.

My job as a retiree is to tell you how you are doing it all wrong!

Ah yes, I see.

Looking at it, that would be a rather tricky moulding job,

at least 4 parts that I can see, and rather tricky to assemble.

Sooner you than me Sanjeev!

On 2023-02-25 09:50, Sanjeev Prabhakar wrote:

> Hi Ken

> my model is a little complicated and difference will not work, I have

> tried it

> wheel.png

>

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email todiscuss-leave@lists.openscad.org

--

Cheers, Ken

bats059@gmail.com

https://vk7krj.com/running.html

https://sstv.vk7krj.com/all_bands.html

----------------------------------------

A baby can be defined as an ego with a noise at one end and a smell at the other.

Your job as parents is to teach them to control all three.

My job as a retiree is to tell you how you are doing it all wrong!

SP

Sanjeev Prabhakar

Sat, Feb 25, 2023 7:20 AM

I think I have found a generic solution which doesn't need any difference

or intersection.

This will also show in case there are any undercuts.

It was simpler than I anticipated.

Will share it once I get some time

Thanks everyone

On Sat, 25 Feb, 2023, 12:35 pm Ken, bats059@gmail.com wrote:

Ah yes, I see.

Looking at it, that would be a rather tricky moulding job,

at least 4 parts that I can see, and rather tricky to assemble.

Sooner you than me Sanjeev!

On 2023-02-25 09:50, Sanjeev Prabhakar wrote:

Hi Ken

my model is a little complicated and difference will not work, I have

tried it

[image: wheel.png]

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

--

Cheers, Kenbats059@gmail.comhttps://vk7krj.com/running.htmlhttps://sstv.vk7krj.com/all_bands.html

A baby can be defined as an ego with a noise at one end and a smell at the other.

Your job as parents is to teach them to control all three.

My job as a retiree is to tell you how you are doing it all wrong!

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

I think I have found a generic solution which doesn't need any difference

or intersection.

This will also show in case there are any undercuts.

It was simpler than I anticipated.

Will share it once I get some time

Thanks everyone

On Sat, 25 Feb, 2023, 12:35 pm Ken, <bats059@gmail.com> wrote:

> Ah yes, I see.

> Looking at it, that would be a rather tricky moulding job,

> at least 4 parts that I can see, and rather tricky to assemble.

>

> Sooner you than me Sanjeev!

>

> On 2023-02-25 09:50, Sanjeev Prabhakar wrote:

>

> Hi Ken

> my model is a little complicated and difference will not work, I have

> tried it

> [image: wheel.png]

>

>

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

>

> --

> Cheers, Kenbats059@gmail.comhttps://vk7krj.com/running.htmlhttps://sstv.vk7krj.com/all_bands.html

> ----------------------------------------

> A baby can be defined as an ego with a noise at one end and a smell at the other.

> Your job as parents is to teach them to control all three.

> My job as a retiree is to tell you how you are doing it all wrong!

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

SP

Sanjeev Prabhakar

Sun, Feb 26, 2023 1:18 AM

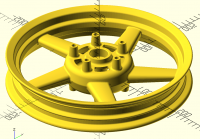

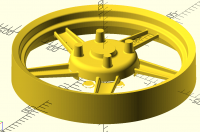

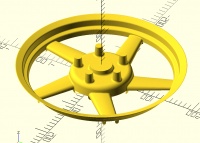

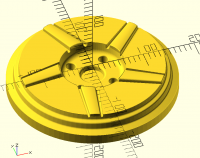

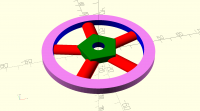

results of the top and bottom surface extraction

there is some more work that needs to be done, to remove some unnecessary

things but i think it's quite workable now.

[image: Screenshot 2023-02-26 at 6.26.52 AM.png]

[image: Screenshot 2023-02-26 at 6.28.00 AM.png]

[image: Screenshot 2023-02-26 at 6.44.18 AM.png]

[image: Screenshot 2023-02-26 at 6.45.00 AM.png]

On Sat, 25 Feb 2023 at 12:50, Sanjeev Prabhakar sprabhakar2006@gmail.com

wrote:

I think I have found a generic solution which doesn't need any difference

or intersection.

This will also show in case there are any undercuts.

It was simpler than I anticipated.

Will share it once I get some time

Thanks everyone

On Sat, 25 Feb, 2023, 12:35 pm Ken, bats059@gmail.com wrote:

Ah yes, I see.

Looking at it, that would be a rather tricky moulding job,

at least 4 parts that I can see, and rather tricky to assemble.

Sooner you than me Sanjeev!

On 2023-02-25 09:50, Sanjeev Prabhakar wrote:

Hi Ken

my model is a little complicated and difference will not work, I have

tried it

[image: wheel.png]

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

--

Cheers, Kenbats059@gmail.comhttps://vk7krj.com/running.htmlhttps://sstv.vk7krj.com/all_bands.html

A baby can be defined as an ego with a noise at one end and a smell at the other.

Your job as parents is to teach them to control all three.

My job as a retiree is to tell you how you are doing it all wrong!

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

results of the top and bottom surface extraction

there is some more work that needs to be done, to remove some unnecessary

things but i think it's quite workable now.

[image: Screenshot 2023-02-26 at 6.26.52 AM.png]

[image: Screenshot 2023-02-26 at 6.28.00 AM.png]

[image: Screenshot 2023-02-26 at 6.44.18 AM.png]

[image: Screenshot 2023-02-26 at 6.45.00 AM.png]

On Sat, 25 Feb 2023 at 12:50, Sanjeev Prabhakar <sprabhakar2006@gmail.com>

wrote:

> I think I have found a generic solution which doesn't need any difference

> or intersection.

>

> This will also show in case there are any undercuts.

>

> It was simpler than I anticipated.

>

> Will share it once I get some time

>

> Thanks everyone

>

> On Sat, 25 Feb, 2023, 12:35 pm Ken, <bats059@gmail.com> wrote:

>

>> Ah yes, I see.

>> Looking at it, that would be a rather tricky moulding job,

>> at least 4 parts that I can see, and rather tricky to assemble.

>>

>> Sooner you than me Sanjeev!

>>

>> On 2023-02-25 09:50, Sanjeev Prabhakar wrote:

>>

>> Hi Ken

>> my model is a little complicated and difference will not work, I have

>> tried it

>> [image: wheel.png]

>>

>>

>>> _______________________________________________

>>> OpenSCAD mailing list

>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>

>>

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

>>

>> --

>> Cheers, Kenbats059@gmail.comhttps://vk7krj.com/running.htmlhttps://sstv.vk7krj.com/all_bands.html

>> ----------------------------------------

>> A baby can be defined as an ego with a noise at one end and a smell at the other.

>> Your job as parents is to teach them to control all three.

>> My job as a retiree is to tell you how you are doing it all wrong!

>>

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

>

SP

Sanjeev Prabhakar

Thu, Mar 2, 2023 5:43 PM

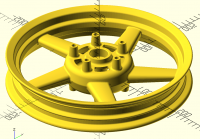

bottom mould completely done in openscad.

[image: Screenshot 2023-03-02 at 11.10.21 PM.png]

bottom mould completely done in openscad.

[image: Screenshot 2023-03-02 at 11.10.21 PM.png]

GS

Guenther Sohler

Fri, Mar 3, 2023 10:05 AM

it looks very nice!

Whats your workflow like?

apparently you cannot pour molten metal onto the plastic

On Thu, Mar 2, 2023 at 6:45 PM Sanjeev Prabhakar sprabhakar2006@gmail.com

wrote:

bottom mould completely done in openscad.

[image: Screenshot 2023-03-02 at 11.10.21 PM.png]

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

it looks very nice!

Whats your workflow like?

apparently you cannot pour molten metal onto the plastic

On Thu, Mar 2, 2023 at 6:45 PM Sanjeev Prabhakar <sprabhakar2006@gmail.com>

wrote:

> bottom mould completely done in openscad.

>

> [image: Screenshot 2023-03-02 at 11.10.21 PM.png]

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

SP

Sanjeev Prabhakar

Fri, Mar 3, 2023 12:06 PM

Guenther

I am not planning to do anything with this.

I was just checking if dies can be modelled with this approach.

In the process I found it is very complex right now to do something like

this. But lot of learning from this challenging work.

On Fri, 3 Mar, 2023, 3:38 pm Guenther Sohler, guenther.sohler@gmail.com

wrote:

it looks very nice!

Whats your workflow like?

apparently you cannot pour molten metal onto the plastic

On Thu, Mar 2, 2023 at 6:45 PM Sanjeev Prabhakar sprabhakar2006@gmail.com

wrote:

bottom mould completely done in openscad.

[image: Screenshot 2023-03-02 at 11.10.21 PM.png]

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Guenther

I am not planning to do anything with this.

I was just checking if dies can be modelled with this approach.

In the process I found it is very complex right now to do something like

this. But lot of learning from this challenging work.

On Fri, 3 Mar, 2023, 3:38 pm Guenther Sohler, <guenther.sohler@gmail.com>

wrote:

> it looks very nice!

> Whats your workflow like?

> apparently you cannot pour molten metal onto the plastic

>

>

> On Thu, Mar 2, 2023 at 6:45 PM Sanjeev Prabhakar <sprabhakar2006@gmail.com>

> wrote:

>

>> bottom mould completely done in openscad.

>>

>> [image: Screenshot 2023-03-02 at 11.10.21 PM.png]

>>

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

SS

Steve Schlaifer

Sat, Mar 4, 2023 7:23 PM

You could use this as the start of a lost wax process.

Steve Schlaifer

On Mar 3, 2023 at 4:07 AM -0800, Sanjeev Prabhakar sprabhakar2006@gmail.com, wrote:

Guenther

I am not planning to do anything with this.

I was just checking if dies can be modelled with this approach.

In the process I found it is very complex right now to do something like this. But lot of learning from this challenging work.

it looks very nice!

Whats your workflow like?

apparently you cannot pour molten metal onto the plastic

bottom mould completely done in openscad.

<Screenshot 2023-03-02 at 11.10.21 PM.png>

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

You could use this as the start of a lost wax process.

Steve Schlaifer

On Mar 3, 2023 at 4:07 AM -0800, Sanjeev Prabhakar <sprabhakar2006@gmail.com>, wrote:

> Guenther

>

> I am not planning to do anything with this.

>

> I was just checking if dies can be modelled with this approach.

>

> In the process I found it is very complex right now to do something like this. But lot of learning from this challenging work.

>

>

> > On Fri, 3 Mar, 2023, 3:38 pm Guenther Sohler, <guenther.sohler@gmail.com> wrote:

> > > it looks very nice!

> > > Whats your workflow like?

> > > apparently you cannot pour molten metal onto the plastic

> > >

> > >

> > > > On Thu, Mar 2, 2023 at 6:45 PM Sanjeev Prabhakar <sprabhakar2006@gmail.com> wrote:

> > > > > bottom mould completely done in openscad.

> > > > >

> > > > > <Screenshot 2023-03-02 at 11.10.21 PM.png>

> > > > >

> > > > > _______________________________________________

> > > > > OpenSCAD mailing list

> > > > > To unsubscribe send an email to discuss-leave@lists.openscad.org

> > > _______________________________________________

> > > OpenSCAD mailing list

> > > To unsubscribe send an email to discuss-leave@lists.openscad.org

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org