RW

Raymond West

Tue, Feb 21, 2023 10:42 AM

The patent drawings for Higbee thread are available on line.

https://patents.google.com/patent/US447775A Note that he is not bothered

about the termination profile of the thread. Over the years,

manufacturing/whatever has changed, and other forma are similar, and may

or may not be named the same. The name is not now used, at least on this

side of the pond, similar to Hoover (vacuum cleaner), Biro (ballpoint

pen) etc. As i mentioned, get the guy to send you a drawing of what he

thinks a Higbee is. (Even Chatgbt doesn't know what it is, therefore it

does not exist... 😁)

(This is the thread that keeps on giving)

The patent drawings for Higbee thread are available on line.

https://patents.google.com/patent/US447775A Note that he is not bothered

about the termination profile of the thread. Over the years,

manufacturing/whatever has changed, and other forma are similar, and may

or may not be named the same. The name is not now used, at least on this

side of the pond, similar to Hoover (vacuum cleaner), Biro (ballpoint

pen) etc. As i mentioned, get the guy to send you a drawing of what he

thinks a Higbee is. (Even Chatgbt doesn't know what it is, therefore it

does not exist... 😁)

(This is the thread that keeps on giving)

RD

Revar Desmera

Tue, Feb 21, 2023 10:51 AM

I pulled out my digital microscope and a beefy M5 screw to see if I can get a clearer view:

I pulled out my digital microscope and a beefy M5 screw to see if I can get a clearer view:

RW

Raymond West

Tue, Feb 21, 2023 11:02 AM

The Higbee thread and nut is the same principle as used in plastic

bottles and caps, having a short plain piece in each. For the screws for

the switch plate that I mentioned previously, they have a longer plain

end, since they do not fit a matching nut, just a tapped hole.

On 21/02/2023 10:42, Raymond West wrote:

The patent drawings for Higbee thread are available on line.

https://patents.google.com/patent/US447775A Note that he is not

bothered about the termination profile of the thread. Over the years,

manufacturing/whatever has changed, and other forma are similar, and

may or may not be named the same. The name is not now used, at least

on this side of the pond, similar to Hoover (vacuum cleaner), Biro

(ballpoint pen) etc. As i mentioned, get the guy to send you a drawing

of what he thinks a Higbee is. (Even Chatgbt doesn't know what it is,

therefore it does not exist... 😁)

(This is the thread that keeps on giving)

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

The Higbee thread and nut is the same principle as used in plastic

bottles and caps, having a short plain piece in each. For the screws for

the switch plate that I mentioned previously, they have a longer plain

end, since they do not fit a matching nut, just a tapped hole.

On 21/02/2023 10:42, Raymond West wrote:

> The patent drawings for Higbee thread are available on line.

> https://patents.google.com/patent/US447775A Note that he is not

> bothered about the termination profile of the thread. Over the years,

> manufacturing/whatever has changed, and other forma are similar, and

> may or may not be named the same. The name is not now used, at least

> on this side of the pond, similar to Hoover (vacuum cleaner), Biro

> (ballpoint pen) etc. As i mentioned, get the guy to send you a drawing

> of what he thinks a Higbee is. (Even Chatgbt doesn't know what it is,

> therefore it does not exist... 😁)

>

> (This is the thread that keeps on giving)

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

NH

nop head

Tue, Feb 21, 2023 12:24 PM

For nuts and female threads I taper the last half turn outwards until it

goes beyond the major diameter. That is what nuts I buy appear to do and

has worked fine for printed threads.

On Tue, 21 Feb 2023 at 11:03, Raymond West raywest@raywest.com wrote:

The Higbee thread and nut is the same principle as used in plastic

bottles and caps, having a short plain piece in each. For the screws for

the switch plate that I mentioned previously, they have a longer plain

end, since they do not fit a matching nut, just a tapped hole.

On 21/02/2023 10:42, Raymond West wrote:

The patent drawings for Higbee thread are available on line.

https://patents.google.com/patent/US447775A Note that he is not

bothered about the termination profile of the thread. Over the years,

manufacturing/whatever has changed, and other forma are similar, and

may or may not be named the same. The name is not now used, at least

on this side of the pond, similar to Hoover (vacuum cleaner), Biro

(ballpoint pen) etc. As i mentioned, get the guy to send you a drawing

of what he thinks a Higbee is. (Even Chatgbt doesn't know what it is,

therefore it does not exist... 😁)

(This is the thread that keeps on giving)

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

For nuts and female threads I taper the last half turn outwards until it

goes beyond the major diameter. That is what nuts I buy appear to do and

has worked fine for printed threads.

On Tue, 21 Feb 2023 at 11:03, Raymond West <raywest@raywest.com> wrote:

> The Higbee thread and nut is the same principle as used in plastic

> bottles and caps, having a short plain piece in each. For the screws for

> the switch plate that I mentioned previously, they have a longer plain

> end, since they do not fit a matching nut, just a tapped hole.

>

> On 21/02/2023 10:42, Raymond West wrote:

> > The patent drawings for Higbee thread are available on line.

> > https://patents.google.com/patent/US447775A Note that he is not

> > bothered about the termination profile of the thread. Over the years,

> > manufacturing/whatever has changed, and other forma are similar, and

> > may or may not be named the same. The name is not now used, at least

> > on this side of the pond, similar to Hoover (vacuum cleaner), Biro

> > (ballpoint pen) etc. As i mentioned, get the guy to send you a drawing

> > of what he thinks a Higbee is. (Even Chatgbt doesn't know what it is,

> > therefore it does not exist... 😁)

> >

> > (This is the thread that keeps on giving)

> > _______________________________________________

> > OpenSCAD mailing list

> > To unsubscribe send an email to discuss-leave@lists.openscad.org

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

AM

Adrian Mariano

Tue, Feb 21, 2023 12:45 PM

Yes I quoted the patent in my earlier message. He focuses on the threads

being of full width, and doesn't say much about how you terminate, but he

does imply that the termination is abrupt, not some kind of long taper.

But the question isn't how to specifically do Higbee but how to do the best

possible threads given no classic manufacturing constraints.

On Tue, Feb 21, 2023 at 5:43 AM Raymond West raywest@raywest.com wrote:

The patent drawings for Higbee thread are available on line.

https://patents.google.com/patent/US447775A Note that he is not bothered

about the termination profile of the thread. Over the years,

manufacturing/whatever has changed, and other forma are similar, and may

or may not be named the same. The name is not now used, at least on this

side of the pond, similar to Hoover (vacuum cleaner), Biro (ballpoint

pen) etc. As i mentioned, get the guy to send you a drawing of what he

thinks a Higbee is. (Even Chatgbt doesn't know what it is, therefore it

does not exist... 😁)

(This is the thread that keeps on giving)

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Yes I quoted the patent in my earlier message. He focuses on the threads

being of full width, and doesn't say much about how you terminate, but he

does imply that the termination is abrupt, not some kind of long taper.

But the question isn't how to specifically do Higbee but how to do the best

possible threads given no classic manufacturing constraints.

On Tue, Feb 21, 2023 at 5:43 AM Raymond West <raywest@raywest.com> wrote:

> The patent drawings for Higbee thread are available on line.

> https://patents.google.com/patent/US447775A Note that he is not bothered

> about the termination profile of the thread. Over the years,

> manufacturing/whatever has changed, and other forma are similar, and may

> or may not be named the same. The name is not now used, at least on this

> side of the pond, similar to Hoover (vacuum cleaner), Biro (ballpoint

> pen) etc. As i mentioned, get the guy to send you a drawing of what he

> thinks a Higbee is. (Even Chatgbt doesn't know what it is, therefore it

> does not exist... 😁)

>

> (This is the thread that keeps on giving)

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

NH

nop head

Tue, Feb 21, 2023 12:53 PM

I don't think there is anything to be gained with an abrupt end, so a

tapered end and the ability to have the minor diameter cylinder extend past

the end of the thread seems fine to me. I fix the taper at 1/2 turn but if

it was specifiable 0 would be classic higbee, and a short one would be like

the bottle thread you showed.

On Tue, 21 Feb 2023 at 12:46, Adrian Mariano avm4@cornell.edu wrote:

Yes I quoted the patent in my earlier message. He focuses on the threads

being of full width, and doesn't say much about how you terminate, but he

does imply that the termination is abrupt, not some kind of long taper.

But the question isn't how to specifically do Higbee but how to do the

best possible threads given no classic manufacturing constraints.

On Tue, Feb 21, 2023 at 5:43 AM Raymond West raywest@raywest.com wrote:

The patent drawings for Higbee thread are available on line.

https://patents.google.com/patent/US447775A Note that he is not bothered

about the termination profile of the thread. Over the years,

manufacturing/whatever has changed, and other forma are similar, and may

or may not be named the same. The name is not now used, at least on this

side of the pond, similar to Hoover (vacuum cleaner), Biro (ballpoint

pen) etc. As i mentioned, get the guy to send you a drawing of what he

thinks a Higbee is. (Even Chatgbt doesn't know what it is, therefore it

does not exist... 😁)

(This is the thread that keeps on giving)

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

I don't think there is anything to be gained with an abrupt end, so a

tapered end and the ability to have the minor diameter cylinder extend past

the end of the thread seems fine to me. I fix the taper at 1/2 turn but if

it was specifiable 0 would be classic higbee, and a short one would be like

the bottle thread you showed.

On Tue, 21 Feb 2023 at 12:46, Adrian Mariano <avm4@cornell.edu> wrote:

> Yes I quoted the patent in my earlier message. He focuses on the threads

> being of full width, and doesn't say much about how you terminate, but he

> does imply that the termination is abrupt, not some kind of long taper.

>

> But the question isn't how to specifically do Higbee but how to do the

> best possible threads given no classic manufacturing constraints.

>

> On Tue, Feb 21, 2023 at 5:43 AM Raymond West <raywest@raywest.com> wrote:

>

>> The patent drawings for Higbee thread are available on line.

>> https://patents.google.com/patent/US447775A Note that he is not bothered

>> about the termination profile of the thread. Over the years,

>> manufacturing/whatever has changed, and other forma are similar, and may

>> or may not be named the same. The name is not now used, at least on this

>> side of the pond, similar to Hoover (vacuum cleaner), Biro (ballpoint

>> pen) etc. As i mentioned, get the guy to send you a drawing of what he

>> thinks a Higbee is. (Even Chatgbt doesn't know what it is, therefore it

>> does not exist... 😁)

>>

>> (This is the thread that keeps on giving)

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

SP

Sanjeev Prabhakar

Tue, Feb 21, 2023 3:33 PM

oh

such a long discussion on threading/ bolts

I have never looked at it so seriously earlier.

I have never heard the word higbee earlier

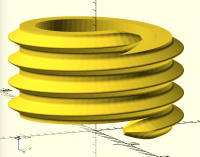

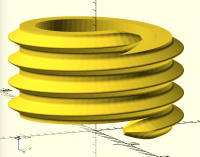

attempted a kind of path extrude, although it does not conform to any

standard and is only for concept drawing.

[image: Screenshot 2023-02-21 at 8.59.41 PM.png]

On Tue, 21 Feb 2023 at 18:24, nop head nop.head@gmail.com wrote:

I don't think there is anything to be gained with an abrupt end, so a

tapered end and the ability to have the minor diameter cylinder extend past

the end of the thread seems fine to me. I fix the taper at 1/2 turn but if

it was specifiable 0 would be classic higbee, and a short one would be like

the bottle thread you showed.

On Tue, 21 Feb 2023 at 12:46, Adrian Mariano avm4@cornell.edu wrote:

Yes I quoted the patent in my earlier message. He focuses on the threads

being of full width, and doesn't say much about how you terminate, but he

does imply that the termination is abrupt, not some kind of long taper.

But the question isn't how to specifically do Higbee but how to do the

best possible threads given no classic manufacturing constraints.

On Tue, Feb 21, 2023 at 5:43 AM Raymond West raywest@raywest.com wrote:

The patent drawings for Higbee thread are available on line.

https://patents.google.com/patent/US447775A Note that he is not

bothered

about the termination profile of the thread. Over the years,

manufacturing/whatever has changed, and other forma are similar, and may

or may not be named the same. The name is not now used, at least on this

side of the pond, similar to Hoover (vacuum cleaner), Biro (ballpoint

pen) etc. As i mentioned, get the guy to send you a drawing of what he

thinks a Higbee is. (Even Chatgbt doesn't know what it is, therefore it

does not exist... 😁)

(This is the thread that keeps on giving)

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

oh

such a long discussion on threading/ bolts

I have never looked at it so seriously earlier.

I have never heard the word higbee earlier

attempted a kind of path extrude, although it does not conform to any

standard and is only for concept drawing.

[image: Screenshot 2023-02-21 at 8.59.41 PM.png]

On Tue, 21 Feb 2023 at 18:24, nop head <nop.head@gmail.com> wrote:

> I don't think there is anything to be gained with an abrupt end, so a

> tapered end and the ability to have the minor diameter cylinder extend past

> the end of the thread seems fine to me. I fix the taper at 1/2 turn but if

> it was specifiable 0 would be classic higbee, and a short one would be like

> the bottle thread you showed.

>

> On Tue, 21 Feb 2023 at 12:46, Adrian Mariano <avm4@cornell.edu> wrote:

>

>> Yes I quoted the patent in my earlier message. He focuses on the threads

>> being of full width, and doesn't say much about how you terminate, but he

>> does imply that the termination is abrupt, not some kind of long taper.

>>

>> But the question isn't how to specifically do Higbee but how to do the

>> best possible threads given no classic manufacturing constraints.

>>

>> On Tue, Feb 21, 2023 at 5:43 AM Raymond West <raywest@raywest.com> wrote:

>>

>>> The patent drawings for Higbee thread are available on line.

>>> https://patents.google.com/patent/US447775A Note that he is not

>>> bothered

>>> about the termination profile of the thread. Over the years,

>>> manufacturing/whatever has changed, and other forma are similar, and may

>>> or may not be named the same. The name is not now used, at least on this

>>> side of the pond, similar to Hoover (vacuum cleaner), Biro (ballpoint

>>> pen) etc. As i mentioned, get the guy to send you a drawing of what he

>>> thinks a Higbee is. (Even Chatgbt doesn't know what it is, therefore it

>>> does not exist... 😁)

>>>

>>> (This is the thread that keeps on giving)

>>> _______________________________________________

>>> OpenSCAD mailing list

>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

AM

Adrian Mariano

Tue, Feb 21, 2023 9:11 PM

I think you may be mistaken, that in fact a very short thread termination

is important for reducing cross threading, and that a 180 degree taper is

actually bad. if there is a large amount of partial height or narrower

thread then that is just the thing that can start a crossthread.

On Tue, Feb 21, 2023, 07:54 nop head nop.head@gmail.com wrote:

I don't think there is anything to be gained with an abrupt end, so a

tapered end and the ability to have the minor diameter cylinder extend past

the end of the thread seems fine to me. I fix the taper at 1/2 turn but if

it was specifiable 0 would be classic higbee, and a short one would be like

the bottle thread you showed.

On Tue, 21 Feb 2023 at 12:46, Adrian Mariano avm4@cornell.edu wrote:

Yes I quoted the patent in my earlier message. He focuses on the threads

being of full width, and doesn't say much about how you terminate, but he

does imply that the termination is abrupt, not some kind of long taper.

But the question isn't how to specifically do Higbee but how to do the

best possible threads given no classic manufacturing constraints.

On Tue, Feb 21, 2023 at 5:43 AM Raymond West raywest@raywest.com wrote:

The patent drawings for Higbee thread are available on line.

https://patents.google.com/patent/US447775A Note that he is not

bothered

about the termination profile of the thread. Over the years,

manufacturing/whatever has changed, and other forma are similar, and may

or may not be named the same. The name is not now used, at least on this

side of the pond, similar to Hoover (vacuum cleaner), Biro (ballpoint

pen) etc. As i mentioned, get the guy to send you a drawing of what he

thinks a Higbee is. (Even Chatgbt doesn't know what it is, therefore it

does not exist... 😁)

(This is the thread that keeps on giving)

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

I think you may be mistaken, that in fact a very short thread termination

is important for reducing cross threading, and that a 180 degree taper is

actually bad. if there is a large amount of partial height or narrower

thread then that is just the thing that can start a crossthread.

On Tue, Feb 21, 2023, 07:54 nop head <nop.head@gmail.com> wrote:

> I don't think there is anything to be gained with an abrupt end, so a

> tapered end and the ability to have the minor diameter cylinder extend past

> the end of the thread seems fine to me. I fix the taper at 1/2 turn but if

> it was specifiable 0 would be classic higbee, and a short one would be like

> the bottle thread you showed.

>

> On Tue, 21 Feb 2023 at 12:46, Adrian Mariano <avm4@cornell.edu> wrote:

>

>> Yes I quoted the patent in my earlier message. He focuses on the threads

>> being of full width, and doesn't say much about how you terminate, but he

>> does imply that the termination is abrupt, not some kind of long taper.

>>

>> But the question isn't how to specifically do Higbee but how to do the

>> best possible threads given no classic manufacturing constraints.

>>

>> On Tue, Feb 21, 2023 at 5:43 AM Raymond West <raywest@raywest.com> wrote:

>>

>>> The patent drawings for Higbee thread are available on line.

>>> https://patents.google.com/patent/US447775A Note that he is not

>>> bothered

>>> about the termination profile of the thread. Over the years,

>>> manufacturing/whatever has changed, and other forma are similar, and may

>>> or may not be named the same. The name is not now used, at least on this

>>> side of the pond, similar to Hoover (vacuum cleaner), Biro (ballpoint

>>> pen) etc. As i mentioned, get the guy to send you a drawing of what he

>>> thinks a Higbee is. (Even Chatgbt doesn't know what it is, therefore it

>>> does not exist... 😁)

>>>

>>> (This is the thread that keeps on giving)

>>> _______________________________________________

>>> OpenSCAD mailing list

>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

NH

nop head

Tue, Feb 21, 2023 10:40 PM

Well if that is true you can simply set the taper length to zero, or close

to zero for printed threads but to represent screws I can buy I use 180

degrees and never had a problem with cross threading large 3D printed

threads.

On Tue, 21 Feb 2023 at 21:12, Adrian Mariano avm4@cornell.edu wrote:

I think you may be mistaken, that in fact a very short thread termination

is important for reducing cross threading, and that a 180 degree taper is

actually bad. if there is a large amount of partial height or narrower

thread then that is just the thing that can start a crossthread.

On Tue, Feb 21, 2023, 07:54 nop head nop.head@gmail.com wrote:

I don't think there is anything to be gained with an abrupt end, so a

tapered end and the ability to have the minor diameter cylinder extend past

the end of the thread seems fine to me. I fix the taper at 1/2 turn but if

it was specifiable 0 would be classic higbee, and a short one would be like

the bottle thread you showed.

On Tue, 21 Feb 2023 at 12:46, Adrian Mariano avm4@cornell.edu wrote:

Yes I quoted the patent in my earlier message. He focuses on the

threads being of full width, and doesn't say much about how you terminate,

but he does imply that the termination is abrupt, not some kind of long

taper.

But the question isn't how to specifically do Higbee but how to do the

best possible threads given no classic manufacturing constraints.

On Tue, Feb 21, 2023 at 5:43 AM Raymond West raywest@raywest.com

wrote:

The patent drawings for Higbee thread are available on line.

https://patents.google.com/patent/US447775A Note that he is not

bothered

about the termination profile of the thread. Over the years,

manufacturing/whatever has changed, and other forma are similar, and

may

or may not be named the same. The name is not now used, at least on

this

side of the pond, similar to Hoover (vacuum cleaner), Biro (ballpoint

pen) etc. As i mentioned, get the guy to send you a drawing of what he

thinks a Higbee is. (Even Chatgbt doesn't know what it is, therefore it

does not exist... 😁)

(This is the thread that keeps on giving)

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Well if that is true you can simply set the taper length to zero, or close

to zero for printed threads but to represent screws I can buy I use 180

degrees and never had a problem with cross threading large 3D printed

threads.

On Tue, 21 Feb 2023 at 21:12, Adrian Mariano <avm4@cornell.edu> wrote:

> I think you may be mistaken, that in fact a very short thread termination

> is important for reducing cross threading, and that a 180 degree taper is

> actually bad. if there is a large amount of partial height or narrower

> thread then that is just the thing that can start a crossthread.

>

> On Tue, Feb 21, 2023, 07:54 nop head <nop.head@gmail.com> wrote:

>

>> I don't think there is anything to be gained with an abrupt end, so a

>> tapered end and the ability to have the minor diameter cylinder extend past

>> the end of the thread seems fine to me. I fix the taper at 1/2 turn but if

>> it was specifiable 0 would be classic higbee, and a short one would be like

>> the bottle thread you showed.

>>

>> On Tue, 21 Feb 2023 at 12:46, Adrian Mariano <avm4@cornell.edu> wrote:

>>

>>> Yes I quoted the patent in my earlier message. He focuses on the

>>> threads being of full width, and doesn't say much about how you terminate,

>>> but he does imply that the termination is abrupt, not some kind of long

>>> taper.

>>>

>>> But the question isn't how to specifically do Higbee but how to do the

>>> best possible threads given no classic manufacturing constraints.

>>>

>>> On Tue, Feb 21, 2023 at 5:43 AM Raymond West <raywest@raywest.com>

>>> wrote:

>>>

>>>> The patent drawings for Higbee thread are available on line.

>>>> https://patents.google.com/patent/US447775A Note that he is not

>>>> bothered

>>>> about the termination profile of the thread. Over the years,

>>>> manufacturing/whatever has changed, and other forma are similar, and

>>>> may

>>>> or may not be named the same. The name is not now used, at least on

>>>> this

>>>> side of the pond, similar to Hoover (vacuum cleaner), Biro (ballpoint

>>>> pen) etc. As i mentioned, get the guy to send you a drawing of what he

>>>> thinks a Higbee is. (Even Chatgbt doesn't know what it is, therefore it

>>>> does not exist... 😁)

>>>>

>>>> (This is the thread that keeps on giving)

>>>> _______________________________________________

>>>> OpenSCAD mailing list

>>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>

>>> _______________________________________________

>>> OpenSCAD mailing list

>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

AM

Adrian Mariano

Tue, Feb 21, 2023 11:18 PM

Yes, no taper at all is what I originally did, in fact. But perhaps a

small taper helps with engaging the threads, so things don't have to be

perfectly aligned to get started?

On Tue, Feb 21, 2023 at 5:41 PM nop head nop.head@gmail.com wrote:

Well if that is true you can simply set the taper length to zero, or close

to zero for printed threads but to represent screws I can buy I use 180

degrees and never had a problem with cross threading large 3D printed

threads.

On Tue, 21 Feb 2023 at 21:12, Adrian Mariano avm4@cornell.edu wrote:

I think you may be mistaken, that in fact a very short thread

termination is important for reducing cross threading, and that a 180

degree taper is actually bad. if there is a large amount of partial height

or narrower thread then that is just the thing that can start a

crossthread.

On Tue, Feb 21, 2023, 07:54 nop head nop.head@gmail.com wrote:

I don't think there is anything to be gained with an abrupt end, so a

tapered end and the ability to have the minor diameter cylinder extend past

the end of the thread seems fine to me. I fix the taper at 1/2 turn but if

it was specifiable 0 would be classic higbee, and a short one would be like

the bottle thread you showed.

On Tue, 21 Feb 2023 at 12:46, Adrian Mariano avm4@cornell.edu wrote:

Yes I quoted the patent in my earlier message. He focuses on the

threads being of full width, and doesn't say much about how you terminate,

but he does imply that the termination is abrupt, not some kind of long

taper.

But the question isn't how to specifically do Higbee but how to do the

best possible threads given no classic manufacturing constraints.

On Tue, Feb 21, 2023 at 5:43 AM Raymond West raywest@raywest.com

wrote:

The patent drawings for Higbee thread are available on line.

https://patents.google.com/patent/US447775A Note that he is not

bothered

about the termination profile of the thread. Over the years,

manufacturing/whatever has changed, and other forma are similar, and

may

or may not be named the same. The name is not now used, at least on

this

side of the pond, similar to Hoover (vacuum cleaner), Biro (ballpoint

pen) etc. As i mentioned, get the guy to send you a drawing of what he

thinks a Higbee is. (Even Chatgbt doesn't know what it is, therefore

it

does not exist... 😁)

(This is the thread that keeps on giving)

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Yes, no taper at all is what I originally did, in fact. But perhaps a

small taper helps with engaging the threads, so things don't have to be

perfectly aligned to get started?

On Tue, Feb 21, 2023 at 5:41 PM nop head <nop.head@gmail.com> wrote:

> Well if that is true you can simply set the taper length to zero, or close

> to zero for printed threads but to represent screws I can buy I use 180

> degrees and never had a problem with cross threading large 3D printed

> threads.

>

> On Tue, 21 Feb 2023 at 21:12, Adrian Mariano <avm4@cornell.edu> wrote:

>

>> I think you may be mistaken, that in fact a very short thread

>> termination is important for reducing cross threading, and that a 180

>> degree taper is actually bad. if there is a large amount of partial height

>> or narrower thread then that is just the thing that can start a

>> crossthread.

>>

>> On Tue, Feb 21, 2023, 07:54 nop head <nop.head@gmail.com> wrote:

>>

>>> I don't think there is anything to be gained with an abrupt end, so a

>>> tapered end and the ability to have the minor diameter cylinder extend past

>>> the end of the thread seems fine to me. I fix the taper at 1/2 turn but if

>>> it was specifiable 0 would be classic higbee, and a short one would be like

>>> the bottle thread you showed.

>>>

>>> On Tue, 21 Feb 2023 at 12:46, Adrian Mariano <avm4@cornell.edu> wrote:

>>>

>>>> Yes I quoted the patent in my earlier message. He focuses on the

>>>> threads being of full width, and doesn't say much about how you terminate,

>>>> but he does imply that the termination is abrupt, not some kind of long

>>>> taper.

>>>>

>>>> But the question isn't how to specifically do Higbee but how to do the

>>>> best possible threads given no classic manufacturing constraints.

>>>>

>>>> On Tue, Feb 21, 2023 at 5:43 AM Raymond West <raywest@raywest.com>

>>>> wrote:

>>>>

>>>>> The patent drawings for Higbee thread are available on line.

>>>>> https://patents.google.com/patent/US447775A Note that he is not

>>>>> bothered

>>>>> about the termination profile of the thread. Over the years,

>>>>> manufacturing/whatever has changed, and other forma are similar, and

>>>>> may

>>>>> or may not be named the same. The name is not now used, at least on

>>>>> this

>>>>> side of the pond, similar to Hoover (vacuum cleaner), Biro (ballpoint

>>>>> pen) etc. As i mentioned, get the guy to send you a drawing of what he

>>>>> thinks a Higbee is. (Even Chatgbt doesn't know what it is, therefore

>>>>> it

>>>>> does not exist... 😁)

>>>>>

>>>>> (This is the thread that keeps on giving)

>>>>> _______________________________________________

>>>>> OpenSCAD mailing list

>>>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>>

>>>> _______________________________________________

>>>> OpenSCAD mailing list

>>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>

>>> _______________________________________________

>>> OpenSCAD mailing list

>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>