higbee ends for threads

Most of the machine screws depicted in McMaster Carr CAD files seem to

be like a threaded rod, chopped off arbitrarily then chamfered at 45

degrees. In designing optimal 3D-printed plastic threads, mass-produced

screws may be too simplistic to use for inspiration. And a general CAD

library may need to support two or three designs to cover the majority

of modeling applications.

-Curt

On 2/20/2023 3:23 PM, Adrian Mariano wrote:

The pic is a alas too rubbish for me to tell what' going on, but it

looks like it might be like my screws, which have a beveled end, not

the feature you're describing. Note that it's a small bevel, like the

size of one thread, so it has the effect of cutting off part of the

thread and could produce the illusion of an intentional taper like

you're describing. I inspected my screws under 10x magnification to

figure out what was going on.

On Mon, Feb 20, 2023 at 6:17 PM nop head nop.head@gmail.com wrote:

IMG_20230220_230829904.jpg

That is what it looks like to me. Excuse the rubbish photo, I only

have a phone with me.

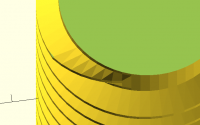

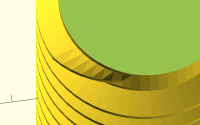

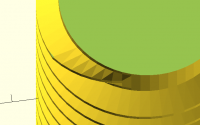

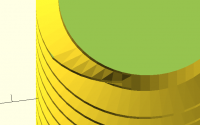

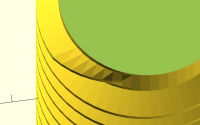

This is my attempt to model what I see.

image.png

On Mon, 20 Feb 2023 at 23:06, Adrian Mariano <avm4@cornell.edu> wrote:

I've never seen a higbee end either. But I've also never seen

a machine screw with a tapered thread like you are

describing. You have screws where there is a full thread that

gradually disappears by decreasing radius into the shaft, and

it's not because of a small bevel on the end? Mine all have

the shaft beveled.

On Mon, Feb 20, 2023 at 6:02 PM nop head <nop.head@gmail.com>

wrote:

Yes. The only things I have bevelled are leadscrews and

studding cut to length that I bevel myself on a grinder. I

have never seen a higbee end.

On Mon, 20 Feb 2023 at 22:37, Adrian Mariano

<avm4@cornell.edu> wrote:

You have machine screws where the threads taper at the

ends? Like I said...mine don't do that. The end is

just beveled.

On Mon, Feb 20, 2023 at 5:33 PM nop head

<nop.head@gmail.com> wrote:

I do it over half a turn because that is what my

machine screws look like they do and that is what

I am trying to realistically draw.

On Mon, 20 Feb 2023 at 22:28, Adrian Mariano

<avm4@cornell.edu> wrote:

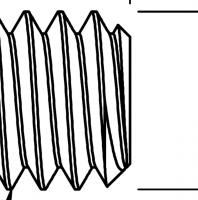

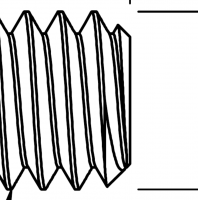

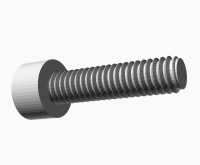

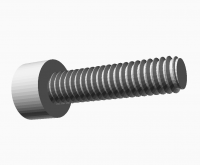

So lineiar decrease in diameter of the

thread? Something like this? I have two

views for clarity:

image.png

image.png

Why would you want to extend the taper for a

full half-turn. My correspondent was a little

self-inconsistent, but suggested a *much*

shorter length, and it seems like a shorter

length is better. In fact, I wonder if really

very short is best. Doesn't the section where

the diameter of the thread is reduced enable

you to hop over it to crossthread? It seems

like the abrupt end of the threads is the key

to success here: you can't hop into the next

thread because you have a full thread in the

way. That's why I wonder if tapering is even

a good idea as compared to a more abrupt

stop. On the other hand, maybe the bottle

makers know what they're doing? Their standard

doesn't specify this, but in their drawings it

looks like about a quarter of a right angle,

so ~20 degrees. My correspondent seemed to

think it should depend on the pitch size of

the threads, and nothing to do with angle,

though.

On Mon, Feb 20, 2023 at 5:00 PM nop head

<nop.head@gmail.com> wrote:

Tapered by making the thread diameter

decrease until it is below the minor

diameter and disappears. I do it linearly

over half a turn but your bottle

example was much less.

Higbee removes the crests instead because

the thread is already formed at the

nominal diameter. It can either ramp down

gradually or be completely removed with a

rotary milling tool leaving a short ramp

due to the tool radius. See

https://www.youtube.com/watch?v=MUojDLAaBiE

On Mon, 20 Feb 2023 at 21:49, Adrian

Mariano <avm4@cornell.edu> wrote:

So "simply tapered" is not

well-defined. Tapered how, and over

what length? In both directions or

just one? And why is that clearly

optimal.

On Mon, Feb 20, 2023 at 9:55 AM nop

head <nop.head@gmail.com> wrote:

Thinking some more about it, I

think higbee only makes sense when

you have a thread already made and

you want to clean up the end. The

optimal end shape is simply

tapered when you can mould it or

3D print it.

On Mon, 20 Feb 2023 at 14:45,

Rogier Wolff

<R.E.Wolff@bitwizard.nl> wrote:

On Mon, Feb 20, 2023 at

06:37:37AM -0500, Adrian

Mariano wrote:

I looked for info on how

screws are made and it sounds

like the

normal way is indeed to

press them between a pair of

flat dies.

This process could not make

a higbee end.

I checked out your link,

because I didn't think the

shape of a screw

could be pressed between two

dies.

Turns out the ROLL the

pre-screw between the two

dies. In hindsight

The hint was there with the

/flat/ dies, but for sure they

cannot be

FLAT because that'd make them

"cylindrical" instead of a screw.

(If I'm honest... I'd make the

dies round (on the outside of

a big

wheel (*)) so that you can

rotate them. rotate them in

opposite

directions so that the screws

remain stationary. Then turn one

slightly faster so that after

enough rotations it drops down

between

the two big dies after enough

of an impression has been

made. Feed a

new pre-screw in due time. I'd

think one machine can then

thread 36000

screws per hour easily.)

Roger.

(*) You can calculate the size

of the required wheel by knowing

howmany rotations of the screw

you want between the dies

(i.e. length

of the trajectory from

original cylinder to "finished

screw" )

--

** R.E.Wolff@BitWizard.nl **

https://www.BitWizard.nl/

<https://www.BitWizard.nl/> **

+31-15-2049110 **

** Delftechpark 11 2628 XJ

Delft, The Netherlands. KVK:

27239233 **

f equals m times a. When your

f is steady, and your m is

going down

your a is going up. -- Chris

Hadfield about flying up the

space shuttle.

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email

to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

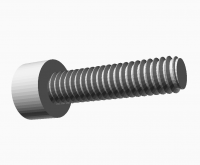

On 21/02/2023 10:51, Revar Desmera wrote:

I pulled out my digital microscope and a beefy M5 screw to see if I can get a clearer view:

I've just seen those images of a rolled thread. You can tell it is a

rolled thread, the crest of thread is rough, the valleys of thread is

smooth. The rolling has pushed the threads beyond the end, leaving the

end recessed (cupped) , and no sharp edges. At the end, there is no

resistance to the rolling pressures, so crests are not fully formed,

instead they get pushed over the end..

This link explains the faults in your 5mm example, (stock too small, and

possibly wrongly or no bevelled end )- typical of the stuff sold by 'big

box stores '(no manufacturer name). Not a problem for many applications.

https://www.iqsdirectory.com/articles/screw-machine-product/thread-rolling.html

I saw in Raymond's post the link to the rolled thread forming process,

which indicates that the end chamfer is an essential part of that process.

So that means all mass produced screws are going to have chamfered ends.

Someone wrote me directly saying "I've forgotten what the question was

about" so just to clarify my intention in starting this thread, the

situation is this.

BOSL2 has threading and that threading capability is very general. It can

bevel the ends or not, on both nuts and bolts. It can use any thread

profile, user supplied or from a list of standard profile, with any number

of starts. It can create thread ends that taper away or are cut

away---blunt start or higbee, perhaps. The length of that taper can be set

to anything, a short amount for a sharp cut, or a long taper, even the 180

deg favored by nophead. You can change where the threads end, to provide

flagpole section alignment for Jordan. When the threads taper they taper

in diameter (thread depth/height) and they taper in the axial direction

(thread width). I can specify functional forms for both directions of

taper. The problem is not "I can't do it". The problem is the reverse, "I

can do too much".

Making users choose values for all of these different options would

overwhelm most users. Now people do CAD for different reasons. One reason

is to model some existing object. In that case, there is such a thing as

the "right" result. It matches or it doesn't. I don't care about this

case. People who want to do that can handle a zillion parameters and can

figure out how to get their model to match up with the target.

The case I care about is people who want to model things to USE them. A

person who wants threads to USE doesn't have a model of what the threads

are supposed to look like. For that person, I want default behavior that

is as good as possible, and I want guidance about when and how to deviate

from the defaults. And I want an explanation that justifies the default

behavior. So the question I am trying to answer specifically with regards

to thread ends is how should the threads end ideally? Is the answer

different for metal or plastic? Is it different if you're mixing metal and

plastic in one model (e.g. you're making a threaded hole in plastic to

receive a metal bolt). If there is not a single best answer then what are

the handful of best answers for different cases. And what is the

explanation behind it all: why is answer X the best result for a specific

situation? That is, what is the intuition that explains how to choose the

parameters?

It seems like the function of thread ends treatment is to minimize the risk

of cross threading and perhaps to make the screw easier to start. So what

accomplishes that? It seems like threads that decrease in diameter are

bad, because they can more easily slip in too far and engage in

cross-thread. It seems also reasonably clear that a sharp cut is bad

because corners are always bad, so the end should be somehow rounded. I

would imagine that the exact way it's rounded probably doesn't matter. But

I think the length of the taper and whether the taper is in depth and/or

width might matter. If I want to draw a picture that shows cross threading

happening and another picture that shows how a particular thread end (or

other modification) prevents it, what would that picture look like?

Someone told me, "there will be many answers, which will be OK for those

that live in the practical engineering world, where it is all about

compromises". If it's all about compromises, what are the compromises?

What trade-offs exist in how the thread ends are designed?

Oh, and another question I was trying to get an answer to is what I should

call the library functionality that specifies the thread ends. My erratic

correspondent insisted that it should be called "higbee" and that everybody

who works with hardware knows what that means. I had question about that

because (1) it wasn't even clear that the tapered thread on the plastic

bottle met the definition of Higbee, since it wasn't maintaining the full

thread width and (2) it seems like actually nobody has heard of higbee.

(I hadn't before getting involved in this.)

On Wed, Feb 22, 2023 at 1:25 AM Curt McDowell maker@fishlet.com wrote:

Most of the machine screws depicted in McMaster Carr CAD files seem to be

like a threaded rod, chopped off arbitrarily then chamfered at 45 degrees.

In designing optimal 3D-printed plastic threads, mass-produced screws may

be too simplistic to use for inspiration. And a general CAD library may

need to support two or three designs to cover the majority of modeling

applications.

-Curt

On 2/20/2023 3:23 PM, Adrian Mariano wrote:

The pic is a alas too rubbish for me to tell what' going on, but it looks

like it might be like my screws, which have a beveled end, not the feature

you're describing. Note that it's a small bevel, like the size of one

thread, so it has the effect of cutting off part of the thread and could

produce the illusion of an intentional taper like you're describing. I

inspected my screws under 10x magnification to figure out what was going

on.

On Mon, Feb 20, 2023 at 6:17 PM nop head nop.head@gmail.com wrote:

[image: IMG_20230220_230829904.jpg]

That is what it looks like to me. Excuse the rubbish photo, I only have a

phone with me.

This is my attempt to model what I see.

[image: image.png]

On Mon, 20 Feb 2023 at 23:06, Adrian Mariano avm4@cornell.edu wrote:

I've never seen a higbee end either. But I've also never seen a machine

screw with a tapered thread like you are describing. You have screws where

there is a full thread that gradually disappears by decreasing radius into

the shaft, and it's not because of a small bevel on the end? Mine all have

the shaft beveled.

On Mon, Feb 20, 2023 at 6:02 PM nop head nop.head@gmail.com wrote:

Yes. The only things I have bevelled are leadscrews and studding cut to

length that I bevel myself on a grinder. I have never seen a higbee end.

On Mon, 20 Feb 2023 at 22:37, Adrian Mariano avm4@cornell.edu wrote:

You have machine screws where the threads taper at the ends? Like I

said...mine don't do that. The end is just beveled.

On Mon, Feb 20, 2023 at 5:33 PM nop head nop.head@gmail.com wrote:

I do it over half a turn because that is what my machine screws look

like they do and that is what I am trying to realistically draw.

On Mon, 20 Feb 2023 at 22:28, Adrian Mariano avm4@cornell.edu

wrote:

So lineiar decrease in diameter of the thread? Something like

this? I have two views for clarity:

[image: image.png]

[image: image.png]

Why would you want to extend the taper for a full half-turn. My

correspondent was a little self-inconsistent, but suggested a much

shorter length, and it seems like a shorter length is better. In fact, I

wonder if really very short is best. Doesn't the section where the

diameter of the thread is reduced enable you to hop over it to

crossthread? It seems like the abrupt end of the threads is the key to

success here: you can't hop into the next thread because you have a full

thread in the way. That's why I wonder if tapering is even a good idea as

compared to a more abrupt stop. On the other hand, maybe the bottle makers

know what they're doing? Their standard doesn't specify this, but in

their drawings it looks like about a quarter of a right angle, so ~20

degrees. My correspondent seemed to think it should depend on the pitch

size of the threads, and nothing to do with angle, though.

On Mon, Feb 20, 2023 at 5:00 PM nop head nop.head@gmail.com wrote:

Tapered by making the thread diameter decrease until it is below

the minor diameter and disappears. I do it linearly over half a turn but

your bottle example was much less.

Higbee removes the crests instead because the thread is already

formed at the nominal diameter. It can either ramp down gradually or be

completely removed with a rotary milling tool leaving a short ramp due to

the tool radius. See https://www.youtube.com/watch?v=MUojDLAaBiE

On Mon, 20 Feb 2023 at 21:49, Adrian Mariano avm4@cornell.edu

wrote:

So "simply tapered" is not well-defined. Tapered how, and over

what length? In both directions or just one? And why is that clearly

optimal.

On Mon, Feb 20, 2023 at 9:55 AM nop head nop.head@gmail.com

wrote:

Thinking some more about it, I think higbee only makes sense when

you have a thread already made and you want to clean up the end. The

optimal end shape is simply tapered when you can mould it or 3D print it.

On Mon, 20 Feb 2023 at 14:45, Rogier Wolff <

R.E.Wolff@bitwizard.nl> wrote:

On Mon, Feb 20, 2023 at 06:37:37AM -0500, Adrian Mariano wrote:

I looked for info on how screws are made and it sounds like the

normal way is indeed to press them between a pair of flat dies.

This process could not make a higbee end.

I checked out your link, because I didn't think the shape of a

screw

could be pressed between two dies.

Turns out the ROLL the pre-screw between the two dies. In

hindsight

The hint was there with the /flat/ dies, but for sure they

cannot be

FLAT because that'd make them "cylindrical" instead of a screw.

(If I'm honest... I'd make the dies round (on the outside of a

big

wheel (*)) so that you can rotate them. rotate them in opposite

directions so that the screws remain stationary. Then turn one

slightly faster so that after enough rotations it drops down

between

the two big dies after enough of an impression has been made.

Feed a

new pre-screw in due time. I'd think one machine can then thread

36000

screws per hour easily.)

Roger.

(*) You can calculate the size of the required wheel by knowing

howmany rotations of the screw you want between the dies (i.e.

length

of the trajectory from original cylinder to "finished screw" )

--

** R.E.Wolff@BitWizard.nl ** https://www.BitWizard.nl/ **

+31-15-2049110 **

** Delftechpark 11 2628 XJ Delft, The Netherlands. KVK:

27239233 **

f equals m times a. When your f is steady, and your m is going

down

your a is going up. -- Chris Hadfield about flying up the space

shuttle.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On 2/22/2023 8:13 AM, Adrian Mariano wrote:

Making users choose values for all of these different options would

overwhelm most users. Now people do CAD for different reasons. One

reason is to model some existing object. In that case, there is such

a thing as the "right" result. It matches or it doesn't. I don't

care about this case. People who want to do that can handle a zillion

parameters and can figure out how to get their model to match up with

the target.

Functions for machine screws, bottle caps, jar caps, flag poles, etc.

would allow most users to avoid dealing with the zillion parameters.

BOSL2 is an amazing library, and perhaps as it becomes the de facto

go-to for OpenSCAD, few here would have to worry about re-inventing

threads for the millionth time.

The case I care about is people who want to model things to USE them.

A person who wants threads to USE doesn't have a model of what the

threads are supposed to look like. For that person, I want default

behavior that is as good as possible, and I want guidance about when

and how to deviate from the defaults. And I want an explanation that

justifies the default behavior.

As a user, the above functions are what I want, but I'd also want them

to conform to industry standards. For example, something that screws

onto the top of a 2-liter bottle, or a vessel that can be sealed with a

Mason jar lid or screwed onto a Mason jar, or a plastic hole that

tightly accepts an M6 bolt, or a flagpole mount, or something that

screws onto a painter's extension pole, or just a container and lid

where the threads are indeed compatible with off-the-shelf containers

and lids.

So the question I am trying to answer specifically with regards to

thread ends is how should the threads end ideally? Is the answer

different for metal or plastic? Is it different if you're mixing

metal and plastic in one model (e.g. you're making a threaded hole in

plastic to receive a metal bolt). If there is not a single best answer

then what are the handful of best answers for different cases. And

what is the explanation behind it all: why is answer X the best result

for a specific situation? That is, what is the intuition that

explains how to choose the parameters?

The ideal shapes for those will certainly vary for metal, ceramic, wood,

plastic, rubber, etc. But even within a category, industries will have

spent years or decades perfecting the shapes, according to constraints

on ease of use, effectiveness, durability, manufacturability, cost,

safety (Higbee), etc. Is it even possible to list the situations, let

alone fully explain them and try to out-design the master engineers?

It seems like the function of thread ends treatment is to minimize the

risk of cross threading and perhaps to make the screw easier to

start. So what accomplishes that? It seems like threads that

decrease in diameter are bad, because they can more easily slip in too

far and engage in cross-thread. It seems also reasonably clear that a

sharp cut is bad because corners are always bad, so the end should be

somehow rounded. I would imagine that the exact way it's rounded

probably doesn't matter. But I think the length of the taper and

whether the taper is in depth and/or width might matter. If I want to

draw a picture that shows cross threading happening and another

picture that shows how a particular thread end (or other modification)

prevents it, what would that picture look like?

If you're like me, you're probably imagining 3D printed interior and

exterior threads. If in fact industry standards aren't sufficient due to

tolerances or 3D constraints/advantages, there could be an opportunity

to come up with a new standard. But it wouldn't be just a mathematical

experiment, would it? A great solution (or several) would require

extensive testing on a lot of prototypes of different ideas in different

methods and materials.

Oh, and another question I was trying to get an answer to is what I

should call the library functionality that specifies the thread ends.

My erratic correspondent insisted that it should be called "higbee"

and that everybody who works with hardware knows what that means. I

had question about that because (1) it wasn't even clear that the

tapered thread on the plastic bottle met the definition of Higbee,

since it wasn't maintaining the full thread width and (2) it seems

like actually nobody has heard of higbee. (I hadn't before getting

involved in this.)

I had never heard of it either. The Wikipedia page is short with few

references. There are three equivalent names: "Higbee cut", "convoluted

thread" and "blunt start thread" (ASME B1.7-2006).

Regards,

Curt

On Wed, Feb 22, 2023 at 1:25 AM Curt McDowell maker@fishlet.com wrote:

Most of the machine screws depicted in McMaster Carr CAD files

seem to be like a threaded rod, chopped off arbitrarily then

chamfered at 45 degrees. In designing optimal 3D-printed plastic

threads, mass-produced screws may be too simplistic to use for

inspiration. And a general CAD library may need to support two or

three designs to cover the majority of modeling applications.

-Curt

On 2/20/2023 3:23 PM, Adrian Mariano wrote:

The pic is a alas too rubbish for me to tell what' going on, but

it looks like it might be like my screws, which have a beveled

end, not the feature you're describing. Note that it's a small

bevel, like the size of one thread, so it has the effect of

cutting off part of the thread and could produce the illusion of

an intentional taper like you're describing. I inspected my

screws under 10x magnification to figure out what was going on.

On Mon, Feb 20, 2023 at 6:17 PM nop head <nop.head@gmail.com> wrote:

IMG_20230220_230829904.jpg

That is what it looks like to me. Excuse the rubbish photo, I

only have a phone with me.

This is my attempt to model what I see.

image.png

On Mon, 20 Feb 2023 at 23:06, Adrian Mariano

<avm4@cornell.edu> wrote:

I've never seen a higbee end either. But I've also never

seen a machine screw with a tapered thread like you are

describing. You have screws where there is a full thread

that gradually disappears by decreasing radius into the

shaft, and it's not because of a small bevel on the end?

Mine all have the shaft beveled.

On Mon, Feb 20, 2023 at 6:02 PM nop head

<nop.head@gmail.com> wrote:

Yes. The only things I have bevelled are leadscrews

and studding cut to length that I bevel myself on a

grinder. I have never seen a higbee end.

On Mon, 20 Feb 2023 at 22:37, Adrian Mariano

<avm4@cornell.edu> wrote:

You have machine screws where the threads taper

at the ends? Like I said...mine don't do that.

The end is just beveled.

On Mon, Feb 20, 2023 at 5:33 PM nop head

<nop.head@gmail.com> wrote:

I do it over half a turn because that is what

my machine screws look like they do and that

is what I am trying to realistically draw.

On Mon, 20 Feb 2023 at 22:28, Adrian Mariano

<avm4@cornell.edu> wrote:

So lineiar decrease in diameter of the

thread? Something like this? I have two

views for clarity:

image.png

image.png

Why would you want to extend the taper

for a full half-turn. My correspondent

was a little self-inconsistent, but

suggested a *much* shorter length, and it

seems like a shorter length is better.

In fact, I wonder if really very short is

best. Doesn't the section where the

diameter of the thread is reduced enable

you to hop over it to crossthread? It

seems like the abrupt end of the threads

is the key to success here: you can't hop

into the next thread because you have a

full thread in the way. That's why I

wonder if tapering is even a good idea as

compared to a more abrupt stop. On the

other hand, maybe the bottle makers know

what they're doing? Their standard

doesn't specify this, but in their

drawings it looks like about a quarter of

a right angle, so ~20 degrees. My

correspondent seemed to think it should

depend on the pitch size of the threads,

and nothing to do with angle, though.

On Mon, Feb 20, 2023 at 5:00 PM nop head

<nop.head@gmail.com> wrote:

Tapered by making the thread diameter

decrease until it is below the minor

diameter and disappears. I do it

linearly over half a turn but your

bottle example was much less.

Higbee removes the crests instead

because the thread is already formed

at the nominal diameter. It can

either ramp down gradually or be

completely removed with a rotary

milling tool leaving a short ramp due

to the tool radius. See

https://www.youtube.com/watch?v=MUojDLAaBiE

On Mon, 20 Feb 2023 at 21:49, Adrian

Mariano <avm4@cornell.edu> wrote:

So "simply tapered" is not

well-defined. Tapered how, and

over what length? In both

directions or just one? And why

is that clearly optimal.

On Mon, Feb 20, 2023 at 9:55 AM

nop head <nop.head@gmail.com> wrote:

Thinking some more about it,

I think higbee only makes

sense when you have a thread

already made and you want to

clean up the end. The optimal

end shape is simply tapered

when you can mould it or 3D

print it.

On Mon, 20 Feb 2023 at 14:45,

Rogier Wolff

<R.E.Wolff@bitwizard.nl> wrote:

On Mon, Feb 20, 2023 at

06:37:37AM -0500, Adrian

Mariano wrote:

I looked for info on

how screws are made and

it sounds like the

normal way is indeed to

press them between a pair

of flat dies.

This process could not

make a higbee end.

I checked out your link,

because I didn't think

the shape of a screw

could be pressed between

two dies.

Turns out the ROLL the

pre-screw between the two

dies. In hindsight

The hint was there with

the /flat/ dies, but for

sure they cannot be

FLAT because that'd make

them "cylindrical"

instead of a screw.

(If I'm honest... I'd

make the dies round (on

the outside of a big

wheel (*)) so that you

can rotate them. rotate

them in opposite

directions so that the

screws remain

stationary. Then turn one

slightly faster so that

after enough rotations it

drops down between

the two big dies after

enough of an impression

has been made. Feed a

new pre-screw in due

time. I'd think one

machine can then thread 36000

screws per hour easily.)

Roger.

(*) You can calculate the

size of the required

wheel by knowing

howmany rotations of the

screw you want between

the dies (i.e. length

of the trajectory from

original cylinder to

"finished screw" )

--

** R.E.Wolff@BitWizard.nl

**

https://www.BitWizard.nl/

<https://www.BitWizard.nl/>

** +31-15-2049110 **

** Delftechpark 11

2628 XJ Delft, The

Netherlands. KVK: 27239233 **

f equals m times a. When

your f is steady, and

your m is going down

your a is going up. --

Chris Hadfield about

flying up the space shuttle.

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an

email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email

to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

Thanks, those alternative names get a lot more hits than Higbee and "blunt"

is the best description as a blunt start is unlikely to cut a new thread,

so stops cross threading. Chamfering creates a sharp edge where it

intersects the thread crest. The Higbee cut removes that.

On Thu, 23 Feb 2023 at 05:58, Curt McDowell maker@fishlet.com wrote:

On 2/22/2023 8:13 AM, Adrian Mariano wrote:

Making users choose values for all of these different options would

overwhelm most users. Now people do CAD for different reasons. One reason

is to model some existing object. In that case, there is such a thing as

the "right" result. It matches or it doesn't. I don't care about this

case. People who want to do that can handle a zillion parameters and can

figure out how to get their model to match up with the target.

Functions for machine screws, bottle caps, jar caps, flag poles, etc.

would allow most users to avoid dealing with the zillion parameters. BOSL2

is an amazing library, and perhaps as it becomes the de facto go-to for

OpenSCAD, few here would have to worry about re-inventing threads for the

millionth time.

The case I care about is people who want to model things to USE them. A

person who wants threads to USE doesn't have a model of what the threads

are supposed to look like. For that person, I want default behavior that

is as good as possible, and I want guidance about when and how to deviate

from the defaults. And I want an explanation that justifies the default

behavior.

As a user, the above functions are what I want, but I'd also want them to

conform to industry standards. For example, something that screws onto the

top of a 2-liter bottle, or a vessel that can be sealed with a Mason jar

lid or screwed onto a Mason jar, or a plastic hole that tightly accepts an

M6 bolt, or a flagpole mount, or something that screws onto a painter's

extension pole, or just a container and lid where the threads are indeed

compatible with off-the-shelf containers and lids.

So the question I am trying to answer specifically with regards to thread

ends is how should the threads end ideally? Is the answer different for

metal or plastic? Is it different if you're mixing metal and plastic in

one model (e.g. you're making a threaded hole in plastic to receive a metal

bolt). If there is not a single best answer then what are the handful of

best answers for different cases. And what is the explanation behind it

all: why is answer X the best result for a specific situation? That is,

what is the intuition that explains how to choose the parameters?

The ideal shapes for those will certainly vary for metal, ceramic, wood,

plastic, rubber, etc. But even within a category, industries will have

spent years or decades perfecting the shapes, according to constraints on

ease of use, effectiveness, durability, manufacturability, cost, safety

(Higbee), etc. Is it even possible to list the situations, let alone fully

explain them and try to out-design the master engineers?

It seems like the function of thread ends treatment is to minimize the

risk of cross threading and perhaps to make the screw easier to start. So

what accomplishes that? It seems like threads that decrease in diameter

are bad, because they can more easily slip in too far and engage in

cross-thread. It seems also reasonably clear that a sharp cut is bad

because corners are always bad, so the end should be somehow rounded. I

would imagine that the exact way it's rounded probably doesn't matter. But

I think the length of the taper and whether the taper is in depth and/or

width might matter. If I want to draw a picture that shows cross threading

happening and another picture that shows how a particular thread end (or

other modification) prevents it, what would that picture look like?

If you're like me, you're probably imagining 3D printed interior and

exterior threads. If in fact industry standards aren't sufficient due to

tolerances or 3D constraints/advantages, there could be an opportunity to

come up with a new standard. But it wouldn't be just a mathematical

experiment, would it? A great solution (or several) would require extensive

testing on a lot of prototypes of different ideas in different methods and

materials.

Oh, and another question I was trying to get an answer to is what I should

call the library functionality that specifies the thread ends. My erratic

correspondent insisted that it should be called "higbee" and that everybody

who works with hardware knows what that means. I had question about that

because (1) it wasn't even clear that the tapered thread on the plastic

bottle met the definition of Higbee, since it wasn't maintaining the full

thread width and (2) it seems like actually nobody has heard of higbee.

(I hadn't before getting involved in this.)

I had never heard of it either. The Wikipedia page is short with few

references. There are three equivalent names: "Higbee cut", "convoluted

thread" and "blunt start thread" (ASME B1.7-2006).

Regards,

Curt

On Wed, Feb 22, 2023 at 1:25 AM Curt McDowell maker@fishlet.com wrote:

Most of the machine screws depicted in McMaster Carr CAD files seem to be

like a threaded rod, chopped off arbitrarily then chamfered at 45 degrees.

In designing optimal 3D-printed plastic threads, mass-produced screws may

be too simplistic to use for inspiration. And a general CAD library may

need to support two or three designs to cover the majority of modeling

applications.

-Curt

On 2/20/2023 3:23 PM, Adrian Mariano wrote:

The pic is a alas too rubbish for me to tell what' going on, but it looks

like it might be like my screws, which have a beveled end, not the feature

you're describing. Note that it's a small bevel, like the size of one

thread, so it has the effect of cutting off part of the thread and could

produce the illusion of an intentional taper like you're describing. I

inspected my screws under 10x magnification to figure out what was going

on.

On Mon, Feb 20, 2023 at 6:17 PM nop head nop.head@gmail.com wrote:

[image: IMG_20230220_230829904.jpg]

That is what it looks like to me. Excuse the rubbish photo, I only have

a phone with me.

This is my attempt to model what I see.

[image: image.png]

On Mon, 20 Feb 2023 at 23:06, Adrian Mariano avm4@cornell.edu wrote:

I've never seen a higbee end either. But I've also never seen a

machine screw with a tapered thread like you are describing. You have

screws where there is a full thread that gradually disappears by decreasing

radius into the shaft, and it's not because of a small bevel on the end?

Mine all have the shaft beveled.

On Mon, Feb 20, 2023 at 6:02 PM nop head nop.head@gmail.com wrote:

Yes. The only things I have bevelled are leadscrews and studding cut

to length that I bevel myself on a grinder. I have never seen a higbee end.

On Mon, 20 Feb 2023 at 22:37, Adrian Mariano avm4@cornell.edu wrote:

You have machine screws where the threads taper at the ends? Like I

said...mine don't do that. The end is just beveled.

On Mon, Feb 20, 2023 at 5:33 PM nop head nop.head@gmail.com wrote:

I do it over half a turn because that is what my machine screws look

like they do and that is what I am trying to realistically draw.

On Mon, 20 Feb 2023 at 22:28, Adrian Mariano avm4@cornell.edu

wrote:

So lineiar decrease in diameter of the thread? Something like

this? I have two views for clarity:

[image: image.png]

[image: image.png]

Why would you want to extend the taper for a full half-turn. My

correspondent was a little self-inconsistent, but suggested a much

shorter length, and it seems like a shorter length is better. In fact, I

wonder if really very short is best. Doesn't the section where the

diameter of the thread is reduced enable you to hop over it to

crossthread? It seems like the abrupt end of the threads is the key to

success here: you can't hop into the next thread because you have a full

thread in the way. That's why I wonder if tapering is even a good idea as

compared to a more abrupt stop. On the other hand, maybe the bottle makers

know what they're doing? Their standard doesn't specify this, but in

their drawings it looks like about a quarter of a right angle, so ~20

degrees. My correspondent seemed to think it should depend on the pitch

size of the threads, and nothing to do with angle, though.

On Mon, Feb 20, 2023 at 5:00 PM nop head nop.head@gmail.com

wrote:

Tapered by making the thread diameter decrease until it is below

the minor diameter and disappears. I do it linearly over half a turn but

your bottle example was much less.

Higbee removes the crests instead because the thread is already

formed at the nominal diameter. It can either ramp down gradually or be

completely removed with a rotary milling tool leaving a short ramp due to

the tool radius. See https://www.youtube.com/watch?v=MUojDLAaBiE

On Mon, 20 Feb 2023 at 21:49, Adrian Mariano avm4@cornell.edu

wrote:

So "simply tapered" is not well-defined. Tapered how, and over

what length? In both directions or just one? And why is that clearly

optimal.

On Mon, Feb 20, 2023 at 9:55 AM nop head nop.head@gmail.com

wrote:

Thinking some more about it, I think higbee only makes sense

when you have a thread already made and you want to clean up the end. The

optimal end shape is simply tapered when you can mould it or 3D print it.

On Mon, 20 Feb 2023 at 14:45, Rogier Wolff <

R.E.Wolff@bitwizard.nl> wrote:

On Mon, Feb 20, 2023 at 06:37:37AM -0500, Adrian Mariano wrote:

I looked for info on how screws are made and it sounds like

the

normal way is indeed to press them between a pair of flat

dies.

This process could not make a higbee end.

I checked out your link, because I didn't think the shape of a

screw

could be pressed between two dies.

Turns out the ROLL the pre-screw between the two dies. In

hindsight

The hint was there with the /flat/ dies, but for sure they

cannot be

FLAT because that'd make them "cylindrical" instead of a screw.

(If I'm honest... I'd make the dies round (on the outside of a

big

wheel (*)) so that you can rotate them. rotate them in opposite

directions so that the screws remain stationary. Then turn one

slightly faster so that after enough rotations it drops down

between

the two big dies after enough of an impression has been made.

Feed a

new pre-screw in due time. I'd think one machine can then

thread 36000

screws per hour easily.)

Roger.

(*) You can calculate the size of the required wheel by knowing

howmany rotations of the screw you want between the dies (i.e.

length

of the trajectory from original cylinder to "finished screw" )

--

** R.E.Wolff@BitWizard.nl ** https://www.BitWizard.nl/ **

+31-15-2049110 **

** Delftechpark 11 2628 XJ Delft, The Netherlands. KVK:

27239233 **

f equals m times a. When your f is steady, and your m is going

down

your a is going up. -- Chris Hadfield about flying up the

space shuttle.

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Curt, the industry standards for threading specify the thread form and

pitch. At least when such standards exist. (There is for example, a

standard for plastic bottle threads but no standard for the threads of the

mating caps.) Conforming to those standard dimensions ensures that

modeled parts are compatible with standard parts.

The question of blunt start is different, because it's a tweak on the

threads that has no effect on compatibility. And in the context of metal

threads, it's too expensive to use so there's no standard for it, at least

not there. The plastic standards do specify thread ends, but they are

vague about it. It is not obvious to me that the ideal shape of the ends

of the threads must necessarily vary significantly across materials in the

manner that you suggest. My goal here was not to launch a new research

project, but to find somebody with existing knowledge on the topic.

There may be a larger question out there which is: given that I want to

design a mated pair of threads at a particular diameter and 3d print in

material X, what should the thread geometry be? I would guess that using

the plastic thread standard form would be better than using the standard

metal screw form. But maybe 3d printing has its own optimal thread form

that nobody has identified. That's an interesting question, but not

something I'm trying to figure out.

On Thu, Feb 23, 2023 at 12:57 AM Curt McDowell maker@fishlet.com wrote:

On 2/22/2023 8:13 AM, Adrian Mariano wrote:

Making users choose values for all of these different options would

overwhelm most users. Now people do CAD for different reasons. One reason

is to model some existing object. In that case, there is such a thing as

the "right" result. It matches or it doesn't. I don't care about this

case. People who want to do that can handle a zillion parameters and can

figure out how to get their model to match up with the target.

Functions for machine screws, bottle caps, jar caps, flag poles, etc.

would allow most users to avoid dealing with the zillion parameters. BOSL2

is an amazing library, and perhaps as it becomes the de facto go-to for

OpenSCAD, few here would have to worry about re-inventing threads for the

millionth time.

The case I care about is people who want to model things to USE them. A

person who wants threads to USE doesn't have a model of what the threads

are supposed to look like. For that person, I want default behavior that

is as good as possible, and I want guidance about when and how to deviate

from the defaults. And I want an explanation that justifies the default

behavior.

As a user, the above functions are what I want, but I'd also want them to

conform to industry standards. For example, something that screws onto the

top of a 2-liter bottle, or a vessel that can be sealed with a Mason jar

lid or screwed onto a Mason jar, or a plastic hole that tightly accepts an

M6 bolt, or a flagpole mount, or something that screws onto a painter's

extension pole, or just a container and lid where the threads are indeed

compatible with off-the-shelf containers and lids.

So the question I am trying to answer specifically with regards to thread

ends is how should the threads end ideally? Is the answer different for

metal or plastic? Is it different if you're mixing metal and plastic in

one model (e.g. you're making a threaded hole in plastic to receive a metal

bolt). If there is not a single best answer then what are the handful of

best answers for different cases. And what is the explanation behind it

all: why is answer X the best result for a specific situation? That is,

what is the intuition that explains how to choose the parameters?

The ideal shapes for those will certainly vary for metal, ceramic, wood,

plastic, rubber, etc. But even within a category, industries will have

spent years or decades perfecting the shapes, according to constraints on

ease of use, effectiveness, durability, manufacturability, cost, safety

(Higbee), etc. Is it even possible to list the situations, let alone fully

explain them and try to out-design the master engineers?

It seems like the function of thread ends treatment is to minimize the

risk of cross threading and perhaps to make the screw easier to start. So

what accomplishes that? It seems like threads that decrease in diameter

are bad, because they can more easily slip in too far and engage in

cross-thread. It seems also reasonably clear that a sharp cut is bad

because corners are always bad, so the end should be somehow rounded. I

would imagine that the exact way it's rounded probably doesn't matter. But

I think the length of the taper and whether the taper is in depth and/or

width might matter. If I want to draw a picture that shows cross threading

happening and another picture that shows how a particular thread end (or

other modification) prevents it, what would that picture look like?

If you're like me, you're probably imagining 3D printed interior and

exterior threads. If in fact industry standards aren't sufficient due to

tolerances or 3D constraints/advantages, there could be an opportunity to

come up with a new standard. But it wouldn't be just a mathematical

experiment, would it? A great solution (or several) would require extensive

testing on a lot of prototypes of different ideas in different methods and

materials.

Oh, and another question I was trying to get an answer to is what I should

call the library functionality that specifies the thread ends. My erratic

correspondent insisted that it should be called "higbee" and that everybody

who works with hardware knows what that means. I had question about that

because (1) it wasn't even clear that the tapered thread on the plastic

bottle met the definition of Higbee, since it wasn't maintaining the full

thread width and (2) it seems like actually nobody has heard of higbee.

(I hadn't before getting involved in this.)

I had never heard of it either. The Wikipedia page is short with few

references. There are three equivalent names: "Higbee cut", "convoluted

thread" and "blunt start thread" (ASME B1.7-2006).

Regards,

Curt

On Wed, Feb 22, 2023 at 1:25 AM Curt McDowell maker@fishlet.com wrote:

Most of the machine screws depicted in McMaster Carr CAD files seem to be

like a threaded rod, chopped off arbitrarily then chamfered at 45 degrees.

In designing optimal 3D-printed plastic threads, mass-produced screws may

be too simplistic to use for inspiration. And a general CAD library may

need to support two or three designs to cover the majority of modeling

applications.

-Curt

On 2/20/2023 3:23 PM, Adrian Mariano wrote:

The pic is a alas too rubbish for me to tell what' going on, but it looks

like it might be like my screws, which have a beveled end, not the feature

you're describing. Note that it's a small bevel, like the size of one

thread, so it has the effect of cutting off part of the thread and could

produce the illusion of an intentional taper like you're describing. I

inspected my screws under 10x magnification to figure out what was going

on.

On Mon, Feb 20, 2023 at 6:17 PM nop head nop.head@gmail.com wrote:

[image: IMG_20230220_230829904.jpg]

That is what it looks like to me. Excuse the rubbish photo, I only have

a phone with me.

This is my attempt to model what I see.

[image: image.png]

On Mon, 20 Feb 2023 at 23:06, Adrian Mariano avm4@cornell.edu wrote:

I've never seen a higbee end either. But I've also never seen a

machine screw with a tapered thread like you are describing. You have

screws where there is a full thread that gradually disappears by decreasing

radius into the shaft, and it's not because of a small bevel on the end?

Mine all have the shaft beveled.

On Mon, Feb 20, 2023 at 6:02 PM nop head nop.head@gmail.com wrote:

Yes. The only things I have bevelled are leadscrews and studding cut

to length that I bevel myself on a grinder. I have never seen a higbee end.

On Mon, 20 Feb 2023 at 22:37, Adrian Mariano avm4@cornell.edu wrote:

You have machine screws where the threads taper at the ends? Like I

said...mine don't do that. The end is just beveled.

On Mon, Feb 20, 2023 at 5:33 PM nop head nop.head@gmail.com wrote:

I do it over half a turn because that is what my machine screws look

like they do and that is what I am trying to realistically draw.

On Mon, 20 Feb 2023 at 22:28, Adrian Mariano avm4@cornell.edu

wrote:

So lineiar decrease in diameter of the thread? Something like

this? I have two views for clarity:

[image: image.png]

[image: image.png]

Why would you want to extend the taper for a full half-turn. My

correspondent was a little self-inconsistent, but suggested a much

shorter length, and it seems like a shorter length is better. In fact, I

wonder if really very short is best. Doesn't the section where the

diameter of the thread is reduced enable you to hop over it to

crossthread? It seems like the abrupt end of the threads is the key to

success here: you can't hop into the next thread because you have a full

thread in the way. That's why I wonder if tapering is even a good idea as

compared to a more abrupt stop. On the other hand, maybe the bottle makers

know what they're doing? Their standard doesn't specify this, but in

their drawings it looks like about a quarter of a right angle, so ~20

degrees. My correspondent seemed to think it should depend on the pitch

size of the threads, and nothing to do with angle, though.

On Mon, Feb 20, 2023 at 5:00 PM nop head nop.head@gmail.com

wrote:

Tapered by making the thread diameter decrease until it is below

the minor diameter and disappears. I do it linearly over half a turn but

your bottle example was much less.

Higbee removes the crests instead because the thread is already

formed at the nominal diameter. It can either ramp down gradually or be

completely removed with a rotary milling tool leaving a short ramp due to

the tool radius. See https://www.youtube.com/watch?v=MUojDLAaBiE

On Mon, 20 Feb 2023 at 21:49, Adrian Mariano avm4@cornell.edu

wrote:

So "simply tapered" is not well-defined. Tapered how, and over

what length? In both directions or just one? And why is that clearly

optimal.

On Mon, Feb 20, 2023 at 9:55 AM nop head nop.head@gmail.com

wrote:

Thinking some more about it, I think higbee only makes sense

when you have a thread already made and you want to clean up the end. The

optimal end shape is simply tapered when you can mould it or 3D print it.

On Mon, 20 Feb 2023 at 14:45, Rogier Wolff <

R.E.Wolff@bitwizard.nl> wrote:

On Mon, Feb 20, 2023 at 06:37:37AM -0500, Adrian Mariano wrote:

I looked for info on how screws are made and it sounds like

the

normal way is indeed to press them between a pair of flat

dies.

This process could not make a higbee end.

I checked out your link, because I didn't think the shape of a

screw

could be pressed between two dies.

Turns out the ROLL the pre-screw between the two dies. In

hindsight

The hint was there with the /flat/ dies, but for sure they

cannot be

FLAT because that'd make them "cylindrical" instead of a screw.

(If I'm honest... I'd make the dies round (on the outside of a

big

wheel (*)) so that you can rotate them. rotate them in opposite

directions so that the screws remain stationary. Then turn one

slightly faster so that after enough rotations it drops down

between

the two big dies after enough of an impression has been made.

Feed a

new pre-screw in due time. I'd think one machine can then

thread 36000

screws per hour easily.)

Roger.

(*) You can calculate the size of the required wheel by knowing

howmany rotations of the screw you want between the dies (i.e.

length

of the trajectory from original cylinder to "finished screw" )

--

** R.E.Wolff@BitWizard.nl ** https://www.BitWizard.nl/ **

+31-15-2049110 **

** Delftechpark 11 2628 XJ Delft, The Netherlands. KVK:

27239233 **

f equals m times a. When your f is steady, and your m is going

down

your a is going up. -- Chris Hadfield about flying up the

space shuttle.

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On 23/02/2023 11:34, Adrian Mariano wrote:

But maybe 3d printing has its own optimal thread form that nobody has

identified.

I guess you've got some testing ahead.

I'm not sure of the practical use, but then 50 years ago, I said

computer games would never catch on...

I just made up my own thread profile for 3D printed parts that has 45

degree slopes and a wide crest that are easier to print than 30 degree

pointy ones. It doesn't conform to any standards but it works for me. And

tapered lead-ins, which also work for me. Not quite the same as higbee

because mine start narrow when only the peak is above the minor diameter

and get wider as they get higher. Higbee starts wide and narrows as it gets

higher. Not sure if that works better, or is just more practical to make

when not 3D printing. Because it starts as a wide ramp I could imagine it

jamming on the crest when mis-aligned with the female thread whereas mine

would more likely engage.

When I wanted to print a bottle cap I couldn't find any proper data to feed

into my thread generator but I found a part on Thingiverse that fitted

perfectly when sliced with Cura. A rare thing.

[image: IMG_20220705_091939414.jpg]

On Thu, 23 Feb 2023 at 11:44, Raymond West raywest@raywest.com wrote:

On 23/02/2023 11:34, Adrian Mariano wrote:

But maybe 3d printing has its own optimal thread form that nobody has

identified.

I guess you've got some testing ahead.

I'm not sure of the practical use, but then 50 years ago, I said

computer games would never catch on...

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org