higbee ends for threads

Is there anybody out there who is an expert in threading with a deep

understanding of how thread ends should be formed? I'm trying to figure

out how the higbee ends in BOSL2 should work, and I got some feedback from

an erratic individual who writes once a month that I was doing it all

wrong. And I think that he was at least partly correct, but without better

communication, I'm having trouble nailing down how to fix the

implementation.

So I'm left with a variety of questions about this topic and haven't had

much luck researching this on line.

-

What is the ideal way to terminate threads, given that in 3d modeling

we aren't constrained by machining limitations. How abruptly should the

thread end? Should it taper in width? In short, what exactly should

BOSL2 do when producing threads? -

What kind of thread ends should a threading library support more

broadly? Is one type of end enough? It seems like thread ends for plastic

bottles taper in a different way than the patented higbee. -

What type of thread endings does the term "higbee" apply to? The

original patent refers to "blunt ends" and the modern nomenclature seems to

be to move away from "higbee" to "blunt start", but my erratic

correspondent insisted that any thread end where the thread wasn't clipped

off by the end of the bold was a "higbee" and that the term "higbee" was

best. -

How exactly does the higbee thread prevent cross threading. How does

cross threading happen? I guess this relates back to #1. When I was

thinking about it I got a feeling it had to do with a lack of a

fractionally wide thread, which can more easily engage at a funny angle.

That would suggest that a thread that tapers in width would be bad, since

it could suffer the same problem. Am I right about that?

I am not an expert but I think normal machine screws that you can buy the

thread at the end tapers in diameter, so it sort of follows a chamfer. My

thread library supports that and a simple chamfered end, which is what you

get when you cut a threaded rod and then chamfer the end.

Higbee seems to be cutting off the crests of the leading treads, making

them flat topped. It seems to be a second pass on a CNC lathe that uses a

flat ended grooving tool to remove the sharp crests left by the threading

tool when it meets the chamfer.

On Sun, 19 Feb 2023 at 22:11, Adrian Mariano avm4@cornell.edu wrote:

Is there anybody out there who is an expert in threading with a deep

understanding of how thread ends should be formed? I'm trying to figure

out how the higbee ends in BOSL2 should work, and I got some feedback from

an erratic individual who writes once a month that I was doing it all

wrong. And I think that he was at least partly correct, but without better

communication, I'm having trouble nailing down how to fix the

implementation.

So I'm left with a variety of questions about this topic and haven't had

much luck researching this on line.

-

What is the ideal way to terminate threads, given that in 3d modeling

we aren't constrained by machining limitations. How abruptly should the

thread end? Should it taper in width? In short, what exactly should

BOSL2 do when producing threads? -

What kind of thread ends should a threading library support more

broadly? Is one type of end enough? It seems like thread ends for plastic

bottles taper in a different way than the patented higbee. -

What type of thread endings does the term "higbee" apply to? The

original patent refers to "blunt ends" and the modern nomenclature seems to

be to move away from "higbee" to "blunt start", but my erratic

correspondent insisted that any thread end where the thread wasn't clipped

off by the end of the bold was a "higbee" and that the term "higbee" was

best. -

How exactly does the higbee thread prevent cross threading. How does

cross threading happen? I guess this relates back to #1. When I was

thinking about it I got a feeling it had to do with a lack of a

fractionally wide thread, which can more easily engage at a funny angle.

That would suggest that a thread that tapers in width would be bad, since

it could suffer the same problem. Am I right about that?

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

I think a normal thread is created by tapping the thread onto a rod or into

a hole. Possibly a chamfer is applied afterwards. I think this is done

for normal machine screws because it's cheap and fast, not because it is

good. In the context of 3d printed parts, there is no reason not to choose

the best option, because we aren't paying a machinist. Furthermore, the

knife-thin edge that arises when you carry threading out to the end of a

rod is probably not the best shape for 3d printing anyway, so why do that?

Maybe the chamfer helps reduce it, but it's not the best solution. And it

sounds like the chamfer isn't ideal for preventing cross threading. My

erratic correspondent seemed to think that threads made the "standard" way

were worthless in 3d printed plastic if the parts were going to be

disassembled and reassembled multiple times, though I admit that I don't

understand why. He seemed to think---possibly based on experience with

failed parts?--- that such threads just wouldn't last, and that the higbee

end is essential.

On Sun, Feb 19, 2023 at 5:39 PM nop head nop.head@gmail.com wrote:

I am not an expert but I think normal machine screws that you can buy the

thread at the end tapers in diameter, so it sort of follows a chamfer. My

thread library supports that and a simple chamfered end, which is what you

get when you cut a threaded rod and then chamfer the end.

Higbee seems to be cutting off the crests of the leading treads, making

them flat topped. It seems to be a second pass on a CNC lathe that uses a

flat ended grooving tool to remove the sharp crests left by the threading

tool when it meets the chamfer.

On Sun, 19 Feb 2023 at 22:11, Adrian Mariano avm4@cornell.edu wrote:

Is there anybody out there who is an expert in threading with a deep

understanding of how thread ends should be formed? I'm trying to figure

out how the higbee ends in BOSL2 should work, and I got some feedback from

an erratic individual who writes once a month that I was doing it all

wrong. And I think that he was at least partly correct, but without better

communication, I'm having trouble nailing down how to fix the

implementation.

So I'm left with a variety of questions about this topic and haven't had

much luck researching this on line.

-

What is the ideal way to terminate threads, given that in 3d modeling

we aren't constrained by machining limitations. How abruptly should the

thread end? Should it taper in width? In short, what exactly should

BOSL2 do when producing threads? -

What kind of thread ends should a threading library support more

broadly? Is one type of end enough? It seems like thread ends for plastic

bottles taper in a different way than the patented higbee. -

What type of thread endings does the term "higbee" apply to? The

original patent refers to "blunt ends" and the modern nomenclature seems to

be to move away from "higbee" to "blunt start", but my erratic

correspondent insisted that any thread end where the thread wasn't clipped

off by the end of the bold was a "higbee" and that the term "higbee" was

best. -

How exactly does the higbee thread prevent cross threading. How does

cross threading happen? I guess this relates back to #1. When I was

thinking about it I got a feeling it had to do with a lack of a

fractionally wide thread, which can more easily engage at a funny angle.

That would suggest that a thread that tapers in width would be bad, since

it could suffer the same problem. Am I right about that?

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

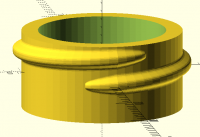

I mainly model threads I can buy or make myself, rather than 3D print. I

don't think machine screws are tapped rods. I think they are stamped out.

They don't have higbee ends. They have tapered ends and I find that also

works fine for large 3D printed threads like screw tops for jars.

[image: image.png]

I don't remember seeing anything with a higbee thread but instead of

tapering inwards it gets truncated inwards instead. Perhaps it cross

threads less because the lack of sharp crest stops it tappings its own

thread but it isn't how normal screws are made.

On Sun, 19 Feb 2023 at 23:07, Adrian Mariano avm4@cornell.edu wrote:

I think a normal thread is created by tapping the thread onto a rod or

into a hole. Possibly a chamfer is applied afterwards. I think this is

done for normal machine screws because it's cheap and fast, not because it

is good. In the context of 3d printed parts, there is no reason not to

choose the best option, because we aren't paying a machinist. Furthermore,

the knife-thin edge that arises when you carry threading out to the end of

a rod is probably not the best shape for 3d printing anyway, so why do

that? Maybe the chamfer helps reduce it, but it's not the best solution.

And it sounds like the chamfer isn't ideal for preventing cross threading.

My erratic correspondent seemed to think that threads made the "standard"

way were worthless in 3d printed plastic if the parts were going to be

disassembled and reassembled multiple times, though I admit that I don't

understand why. He seemed to think---possibly based on experience with

failed parts?--- that such threads just wouldn't last, and that the higbee

end is essential.

On Sun, Feb 19, 2023 at 5:39 PM nop head nop.head@gmail.com wrote:

I am not an expert but I think normal machine screws that you can buy the

thread at the end tapers in diameter, so it sort of follows a chamfer. My

thread library supports that and a simple chamfered end, which is what you

get when you cut a threaded rod and then chamfer the end.

Higbee seems to be cutting off the crests of the leading treads, making

them flat topped. It seems to be a second pass on a CNC lathe that uses a

flat ended grooving tool to remove the sharp crests left by the threading

tool when it meets the chamfer.

On Sun, 19 Feb 2023 at 22:11, Adrian Mariano avm4@cornell.edu wrote:

Is there anybody out there who is an expert in threading with a deep

understanding of how thread ends should be formed? I'm trying to figure

out how the higbee ends in BOSL2 should work, and I got some feedback from

an erratic individual who writes once a month that I was doing it all

wrong. And I think that he was at least partly correct, but without better

communication, I'm having trouble nailing down how to fix the

implementation.

So I'm left with a variety of questions about this topic and haven't had

much luck researching this on line.

-

What is the ideal way to terminate threads, given that in 3d

modeling we aren't constrained by machining limitations. How abruptly

should the thread end? Should it taper in width? In short, what exactly

should BOSL2 do when producing threads? -

What kind of thread ends should a threading library support more

broadly? Is one type of end enough? It seems like thread ends for plastic

bottles taper in a different way than the patented higbee. -

What type of thread endings does the term "higbee" apply to? The

original patent refers to "blunt ends" and the modern nomenclature seems to

be to move away from "higbee" to "blunt start", but my erratic

correspondent insisted that any thread end where the thread wasn't clipped

off by the end of the bold was a "higbee" and that the term "higbee" was

best. -

How exactly does the higbee thread prevent cross threading. How

does cross threading happen? I guess this relates back to #1. When I was

thinking about it I got a feeling it had to do with a lack of a

fractionally wide thread, which can more easily engage at a funny angle.

That would suggest that a thread that tapers in width would be bad, since

it could suffer the same problem. Am I right about that?

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

I looked for info on how screws are made and it sounds like the normal way

is indeed to press them between a pair of flat dies. This process could

not make a higbee end.

https://www.wuerth-industrie.com/web/media/en/pictures/wuerthindustrie/technikportal/dinokapitel/Kapitel_04_DINO_techn_Teil.pdf

https://www.accu.co.uk/p/105-how-is-a-machine-screw-made

Second link has a video of a factory. I guess the chamfer on the end is

included in the die?

But still the question of optimal thread ends remains. Look at a jar or

plastic bottle and you will see smooth tapering thread ends, not ends that

run off the end like the picture above. For example, SP400 threads:

[image: image.png]

So this seems like a better model for how 3d printed threads should look

than die pressed threads in metal. We are not constrained---we can make

the thread end in 3d printed models. And it sounds like that's better

design, so that's what should be done.

On Mon, Feb 20, 2023 at 2:13 AM nop head nop.head@gmail.com wrote:

I mainly model threads I can buy or make myself, rather than 3D print. I

don't think machine screws are tapped rods. I think they are stamped out.

They don't have higbee ends. They have tapered ends and I find that also

works fine for large 3D printed threads like screw tops for jars.

[image: image.png]

I don't remember seeing anything with a higbee thread but instead of

tapering inwards it gets truncated inwards instead. Perhaps it cross

threads less because the lack of sharp crest stops it tappings its own

thread but it isn't how normal screws are made.

On Sun, 19 Feb 2023 at 23:07, Adrian Mariano avm4@cornell.edu wrote:

I think a normal thread is created by tapping the thread onto a rod or

into a hole. Possibly a chamfer is applied afterwards. I think this is

done for normal machine screws because it's cheap and fast, not because it

is good. In the context of 3d printed parts, there is no reason not to

choose the best option, because we aren't paying a machinist. Furthermore,

the knife-thin edge that arises when you carry threading out to the end of

a rod is probably not the best shape for 3d printing anyway, so why do

that? Maybe the chamfer helps reduce it, but it's not the best solution.

And it sounds like the chamfer isn't ideal for preventing cross threading.

My erratic correspondent seemed to think that threads made the "standard"

way were worthless in 3d printed plastic if the parts were going to be

disassembled and reassembled multiple times, though I admit that I don't

understand why. He seemed to think---possibly based on experience with

failed parts?--- that such threads just wouldn't last, and that the higbee

end is essential.

On Sun, Feb 19, 2023 at 5:39 PM nop head nop.head@gmail.com wrote:

I am not an expert but I think normal machine screws that you can buy

the thread at the end tapers in diameter, so it sort of follows a chamfer.

My thread library supports that and a simple chamfered end, which is what

you get when you cut a threaded rod and then chamfer the end.

Higbee seems to be cutting off the crests of the leading treads, making

them flat topped. It seems to be a second pass on a CNC lathe that uses a

flat ended grooving tool to remove the sharp crests left by the threading

tool when it meets the chamfer.

On Sun, 19 Feb 2023 at 22:11, Adrian Mariano avm4@cornell.edu wrote:

Is there anybody out there who is an expert in threading with a deep

understanding of how thread ends should be formed? I'm trying to figure

out how the higbee ends in BOSL2 should work, and I got some feedback from

an erratic individual who writes once a month that I was doing it all

wrong. And I think that he was at least partly correct, but without better

communication, I'm having trouble nailing down how to fix the

implementation.

So I'm left with a variety of questions about this topic and haven't

had much luck researching this on line.

-

What is the ideal way to terminate threads, given that in 3d

modeling we aren't constrained by machining limitations. How abruptly

should the thread end? Should it taper in width? In short, what exactly

should BOSL2 do when producing threads? -

What kind of thread ends should a threading library support more

broadly? Is one type of end enough? It seems like thread ends for plastic

bottles taper in a different way than the patented higbee. -

What type of thread endings does the term "higbee" apply to? The

original patent refers to "blunt ends" and the modern nomenclature seems to

be to move away from "higbee" to "blunt start", but my erratic

correspondent insisted that any thread end where the thread wasn't clipped

off by the end of the bold was a "higbee" and that the term "higbee" was

best. -

How exactly does the higbee thread prevent cross threading. How

does cross threading happen? I guess this relates back to #1. When I was

thinking about it I got a feeling it had to do with a lack of a

fractionally wide thread, which can more easily engage at a funny angle.

That would suggest that a thread that tapers in width would be bad, since

it could suffer the same problem. Am I right about that?

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

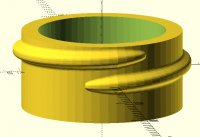

That bottle thread is just tapered off much faster and then doesn't go

right to the end of the tube. I think my library does it over half a turn.

Here is a drill case I printed and it never cross threads.

[image: image.png]

It is different with fine thread in metal though as it is much easier to

cross thread if say you put a steel screw into brass.

On Mon, 20 Feb 2023 at 11:38, Adrian Mariano avm4@cornell.edu wrote:

I looked for info on how screws are made and it sounds like the normal way

is indeed to press them between a pair of flat dies. This process could

not make a higbee end.

https://www.wuerth-industrie.com/web/media/en/pictures/wuerthindustrie/technikportal/dinokapitel/Kapitel_04_DINO_techn_Teil.pdf

https://www.accu.co.uk/p/105-how-is-a-machine-screw-made

Second link has a video of a factory. I guess the chamfer on the end is

included in the die?

But still the question of optimal thread ends remains. Look at a jar or

plastic bottle and you will see smooth tapering thread ends, not ends that

run off the end like the picture above. For example, SP400 threads:

[image: image.png]

So this seems like a better model for how 3d printed threads should look

than die pressed threads in metal. We are not constrained---we can make

the thread end in 3d printed models. And it sounds like that's better

design, so that's what should be done.

On Mon, Feb 20, 2023 at 2:13 AM nop head nop.head@gmail.com wrote:

I mainly model threads I can buy or make myself, rather than 3D print. I

don't think machine screws are tapped rods. I think they are stamped out.

They don't have higbee ends. They have tapered ends and I find that also

works fine for large 3D printed threads like screw tops for jars.

[image: image.png]

I don't remember seeing anything with a higbee thread but instead of

tapering inwards it gets truncated inwards instead. Perhaps it cross

threads less because the lack of sharp crest stops it tappings its own

thread but it isn't how normal screws are made.

On Sun, 19 Feb 2023 at 23:07, Adrian Mariano avm4@cornell.edu wrote:

I think a normal thread is created by tapping the thread onto a rod or

into a hole. Possibly a chamfer is applied afterwards. I think this is

done for normal machine screws because it's cheap and fast, not because it

is good. In the context of 3d printed parts, there is no reason not to

choose the best option, because we aren't paying a machinist. Furthermore,

the knife-thin edge that arises when you carry threading out to the end of

a rod is probably not the best shape for 3d printing anyway, so why do

that? Maybe the chamfer helps reduce it, but it's not the best solution.

And it sounds like the chamfer isn't ideal for preventing cross threading.

My erratic correspondent seemed to think that threads made the "standard"

way were worthless in 3d printed plastic if the parts were going to be

disassembled and reassembled multiple times, though I admit that I don't

understand why. He seemed to think---possibly based on experience with

failed parts?--- that such threads just wouldn't last, and that the higbee

end is essential.

On Sun, Feb 19, 2023 at 5:39 PM nop head nop.head@gmail.com wrote:

I am not an expert but I think normal machine screws that you can buy

the thread at the end tapers in diameter, so it sort of follows a chamfer.

My thread library supports that and a simple chamfered end, which is what

you get when you cut a threaded rod and then chamfer the end.

Higbee seems to be cutting off the crests of the leading treads, making

them flat topped. It seems to be a second pass on a CNC lathe that uses a

flat ended grooving tool to remove the sharp crests left by the threading

tool when it meets the chamfer.

On Sun, 19 Feb 2023 at 22:11, Adrian Mariano avm4@cornell.edu wrote:

Is there anybody out there who is an expert in threading with a deep

understanding of how thread ends should be formed? I'm trying to figure

out how the higbee ends in BOSL2 should work, and I got some feedback from

an erratic individual who writes once a month that I was doing it all

wrong. And I think that he was at least partly correct, but without better

communication, I'm having trouble nailing down how to fix the

implementation.

So I'm left with a variety of questions about this topic and haven't

had much luck researching this on line.

-

What is the ideal way to terminate threads, given that in 3d

modeling we aren't constrained by machining limitations. How abruptly

should the thread end? Should it taper in width? In short, what exactly

should BOSL2 do when producing threads? -

What kind of thread ends should a threading library support more

broadly? Is one type of end enough? It seems like thread ends for plastic

bottles taper in a different way than the patented higbee. -

What type of thread endings does the term "higbee" apply to? The

original patent refers to "blunt ends" and the modern nomenclature seems to

be to move away from "higbee" to "blunt start", but my erratic

correspondent insisted that any thread end where the thread wasn't clipped

off by the end of the bold was a "higbee" and that the term "higbee" was

best. -

How exactly does the higbee thread prevent cross threading. How

does cross threading happen? I guess this relates back to #1. When I was

thinking about it I got a feeling it had to do with a lack of a

fractionally wide thread, which can more easily engage at a funny angle.

That would suggest that a thread that tapers in width would be bad, since

it could suffer the same problem. Am I right about that?

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On 2/20/23 06:39, Adrian Mariano wrote:

I looked for info on how screws are made and it sounds like the normal

way is indeed to press them between a pair of flat dies. This process

could not make a higbee end.

https://www.wuerth-industrie.com/web/media/en/pictures/wuerthindustrie/technikportal/dinokapitel/Kapitel_04_DINO_techn_Teil.pdf https://www.wuerth-industrie.com/web/media/en/pictures/wuerthindustrie/technikportal/dinokapitel/Kapitel_04_DINO_techn_Teil.pdf

https://www.accu.co.uk/p/105-how-is-a-machine-screw-made

https://www.accu.co.uk/p/105-how-is-a-machine-screw-made

Second link has a video of a factory. I guess the chamfer on the end is

included in the die?

But still the question of optimal thread ends remains. Look at a jar or

plastic bottle and you will see smooth tapering thread ends, not ends

that run off the end like the picture above. For example, SP400 threads:

image.png

So this seems like a better model for how 3d printed threads should look

than die pressed threads in metal. We are not constrained---we can make

the thread end in 3d printed models. And it sounds like that's better

design, so that's what should be done.

On Mon, Feb 20, 2023 at 2:13 AM nop head <nop.head@gmail.com

mailto:nop.head@gmail.com> wrote:

I mainly model threads I can buy or make myself, rather than 3D

print. I don't think machine screws are tapped rods. I think they

are stamped out. They don't have higbee ends. They have tapered ends

and I find that also works fine for large 3D printed threads like

screw tops for jars.

image.png

I don't remember seeing anything with a higbee thread but instead of

tapering inwards it gets truncated inwards instead. Perhaps it cross

threads less because the lack of sharp crest stops it tappings its

own thread but it isn't how normal screws are made.

On Sun, 19 Feb 2023 at 23:07, Adrian Mariano <avm4@cornell.edu

<mailto:avm4@cornell.edu>> wrote:

I think a normal thread is created by tapping the thread onto a

rod or into a hole. Possibly a chamfer is applied afterwards.

I think this is done for normal machine screws because it's

cheap and fast, not because it is good. In the context of 3d

printed parts, there is no reason not to choose the best option,

because we aren't paying a machinist. Furthermore, the

knife-thin edge that arises when you carry threading out to the

end of a rod is probably not the best shape for 3d printing

anyway, so why do that? Maybe the chamfer helps reduce it, but

it's not the best solution. And it sounds like the chamfer

isn't ideal for preventing cross threading. My erratic

correspondent seemed to think that threads made the "standard"

way were worthless in 3d printed plastic if the parts were going

to be disassembled and reassembled multiple times, though I

admit that I don't understand why. He seemed to

think---possibly based on experience with failed parts?--- that

such threads just wouldn't last, and that the higbee end is

essential.

On Sun, Feb 19, 2023 at 5:39 PM nop head <nop.head@gmail.com

<mailto:nop.head@gmail.com>> wrote:

I am not an expert but I think normal machine screws that

you can buy the thread at the end tapers in diameter, so it

sort of follows a chamfer. My thread library supports that

and a simple chamfered end, which is what you get when you

cut a threaded rod and then chamfer the end.

Higbee seems to be cutting off the crests of the leading

treads, making them flat topped. It seems to be a second

pass on a CNC lathe that uses a flat ended grooving tool to

remove the sharp crests left by the threading tool when it

meets the chamfer.

On Sun, 19 Feb 2023 at 22:11, Adrian Mariano

<avm4@cornell.edu <mailto:avm4@cornell.edu>> wrote:

Is there anybody out there who is an expert in threading

with a deep understanding of how thread ends should be

formed? I'm trying to figure out how the higbee ends

in BOSL2 should work, and I got some feedback from an

erratic individual who writes once a month that I was

doing it all wrong. And I think that he was at least

partly correct, but without better communication, I'm

having trouble nailing down how to fix the implementation.

So I'm left with a variety of questions about this topic

and haven't had much luck researching this on line.

1. What is the ideal way to terminate threads, given

that in 3d modeling we aren't constrained by machining

limitations. How abruptly should the thread end?

Should it taper in width? In short, what exactly

should BOSL2 do when producing threads?

2. What kind of thread ends should a threading library

support more broadly? Is one type of end enough? It

seems like thread ends for plastic bottles taper in a

different way than the patented higbee.

3. What type of thread endings does the term "higbee"

apply to? The original patent refers to "blunt ends"

and the modern nomenclature seems to be to move away

from "higbee" to "blunt start", but my erratic

correspondent insisted that any thread end where the

thread wasn't clipped off by the end of the bold was a

"higbee" and that the term "higbee" was best.

4. How exactly does the higbee thread prevent cross

threading. How does cross threading happen? I guess

this relates back to #1. When I was thinking about it I

got a feeling it had to do with a lack of a fractionally

wide thread, which can more easily engage at a funny

angle. That would suggest that a thread that tapers in

width would be bad, since it could suffer the same

problem. Am I right about that?

The only comment I can make is not expert, I'm not a pro machinist, just

a retired broadcast engineer. But I have used it many times, I have 4

cnc'ed machines I rebuilt from manual stuff and converted to cnc.

The ability to control the entry and withdraw profiles that LinuxCNC's

G76 canned threading can do, normally used where threading the middle of

a rod to make a bolt or nut, where the single tooth cutter is ramped

from its baseline to the depth of the thread being cut on this pass,

internal thread or external being auto selected by the base line being

inside or or outside of the thread G76 has a length for that, normally

used to give a fraction of a turn profile for the ends of the thread.

Normally used for the entry, aka the right hand end of the thread, the

other end, visualize that as at the underside of a bolts head, is either

subject to a precut groove to give the tool room to withdraw at an

achievable speed. Or you can just let the withdraw ramp out to a bolt

shank diameter withdraw as long as the tool doesn't actually touch the

underside of the head.

But this old Iowa farm kid thinks outside of the box now and then, and

needing a compression method of attaching the drive from the motor,

where an un-machined end of a ball screw is inserted to a slotted sleeve

that is intended to be compressed to grip the screw as effectively as a

weld w/o the distortions you get from the welding heat. The slots, cut

to the depth of the socket drilled, are done with EDM because its very

precise and leaves no burrs to interfere with the fit. So I found I

could make a tapered thread, length of taper cut being one turn less

than the length of the thread, doing the thread ahead of the EDM

slotting, and I made nuts out of stock 3/8" nuts to fit it, both at 50

tpi. On a 7x12 cnc'ed lathe.

It got me the grip I needed, precisely on center with no runout And

never a hint of wanting to cross-thread because the working space was

way to small to get any fingers in to guide it. That was a decade + back

up the log and has not been touched since. So I'll make the claim that a

long enough straight taper cannot be cross threaded. Its self

correcting. I'd assume that characteristic would survive down to a taper

done as a single turn. 1/4 turn ramps I'm less certain of.

This is control you don't get using taps and dies. And its a single data

point from multiple such uses experience. YMMV.

Take care & stay well, all.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

On Mon, Feb 20, 2023 at 06:37:37AM -0500, Adrian Mariano wrote:

I looked for info on how screws are made and it sounds like the

normal way is indeed to press them between a pair of flat dies.

This process could not make a higbee end.

I checked out your link, because I didn't think the shape of a screw

could be pressed between two dies.

Turns out the ROLL the pre-screw between the two dies. In hindsight

The hint was there with the /flat/ dies, but for sure they cannot be

FLAT because that'd make them "cylindrical" instead of a screw.

(If I'm honest... I'd make the dies round (on the outside of a big

wheel (*)) so that you can rotate them. rotate them in opposite

directions so that the screws remain stationary. Then turn one

slightly faster so that after enough rotations it drops down between

the two big dies after enough of an impression has been made. Feed a

new pre-screw in due time. I'd think one machine can then thread 36000

screws per hour easily.)

Roger.

(*) You can calculate the size of the required wheel by knowing

howmany rotations of the screw you want between the dies (i.e. length

of the trajectory from original cylinder to "finished screw" )

--

** R.E.Wolff@BitWizard.nl ** https://www.BitWizard.nl/ ** +31-15-2049110 **

** Delftechpark 11 2628 XJ Delft, The Netherlands. KVK: 27239233 **

f equals m times a. When your f is steady, and your m is going down

your a is going up. -- Chris Hadfield about flying up the space shuttle.

Thinking some more about it, I think higbee only makes sense when you have

a thread already made and you want to clean up the end. The optimal end

shape is simply tapered when you can mould it or 3D print it.

On Mon, 20 Feb 2023 at 14:45, Rogier Wolff R.E.Wolff@bitwizard.nl wrote:

On Mon, Feb 20, 2023 at 06:37:37AM -0500, Adrian Mariano wrote:

I looked for info on how screws are made and it sounds like the

normal way is indeed to press them between a pair of flat dies.

This process could not make a higbee end.

I checked out your link, because I didn't think the shape of a screw

could be pressed between two dies.

Turns out the ROLL the pre-screw between the two dies. In hindsight

The hint was there with the /flat/ dies, but for sure they cannot be

FLAT because that'd make them "cylindrical" instead of a screw.

(If I'm honest... I'd make the dies round (on the outside of a big

wheel (*)) so that you can rotate them. rotate them in opposite

directions so that the screws remain stationary. Then turn one

slightly faster so that after enough rotations it drops down between

the two big dies after enough of an impression has been made. Feed a

new pre-screw in due time. I'd think one machine can then thread 36000

screws per hour easily.)

Roger.

(*) You can calculate the size of the required wheel by knowing

howmany rotations of the screw you want between the dies (i.e. length

of the trajectory from original cylinder to "finished screw" )

--

** R.E.Wolff@BitWizard.nl ** https://www.BitWizard.nl/ ** +31-15-2049110

**

** Delftechpark 11 2628 XJ Delft, The Netherlands. KVK: 27239233 **

f equals m times a. When your f is steady, and your m is going down

your a is going up. -- Chris Hadfield about flying up the space shuttle.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On 19/02/2023 22:09, Adrian Mariano wrote:

Is there anybody out there who is an expert in threading with a deep

understanding of how thread ends should be formed?

It depends somewhat on the the way the bolt or stud is manufactured, and

its final application. For example, the screws that hold a switch plate

to the wall box, will have a short length at core diameter, so that it

can 'find' the tapped hole in said box, and allow the bolt to be

straight, thus avoiding cross threading.

If threading a bar in a lathe, it is usual to bevel the end, and remove

sharp edges with a file, say, or if a quantity of them, by tumbling.

For common, mass produced thread-rolled bolts, the rolling process does

not normally leave sharp edges at the bolt end (and the end is recessed,

unless shaped for a specific application, e.g, shaft locking socket screws.)

Bottles and caps, also have to be easily removed from the mould. there

is usually a 'skirt' on the cap, and a short plain end of the top, to

allow it to be more easily aligned.

Large diameter, fine pitches are easy to cross thread, if you do not

know the technique, (for example the threads those holding a wheel hub

to the vehicle axle (and some hubs on some vehicles, often have lh

threads, to add to the novices fun...)

I've never heard of Bigbee, I think it is merely the manufacturer of

bolts/machinery, like GKN. Not mentioned in my 1990 Machinery handbook,

so get the guy to send you a decent drawing.

Whatever single solution you use, it will be wrong for many applications.