B

bob@rjcarlson.com

Tue, Nov 2, 2021 10:59 PM

I have a small library which generates shapes that are holes for screws. So I have a table of numbers describing the screws I use. I took the measurements myself. I want to convert it to use screw_into from BOSL2.

One type of screw hole is for self tapping screws. I assume the diameter of the hole should be the nominal diameter - a function of the pitch, presumably a percentage. What should that function be?

FYI, the library specifies a screw hole with

-

specs - the screw measurements, what I want to get from BOSL2/screws.scad

-

gap - space between the bottom of the head and the nut

-

clearS - clearance on the screw end

-

clearH - clearance on the head end

-

pos - one of 6 positions to return the hole in, top of the head, middle of gap, etc.

To the basic screw hole a slot for a captive nut can be added using the same parameters. The slot can slide a square or hex nut from the side, or drop in a hex nut longitudinally. The use of the “pos” parameter makes it easy to position the screw hole properly.

I have a small library which generates shapes that are holes for screws. So I have a table of numbers describing the screws I use. I took the measurements myself. I want to convert it to use screw_into from BOSL2.

One type of screw hole is for self tapping screws. I assume the diameter of the hole should be the nominal diameter - a function of the pitch, presumably a percentage. What should that function be?

FYI, the library specifies a screw hole with

* specs - the screw measurements, what I want to get from BOSL2/screws.scad

* gap - space between the bottom of the head and the nut

* clearS - clearance on the screw end

* clearH - clearance on the head end

* pos - one of 6 positions to return the hole in, top of the head, middle of gap, etc.

To the basic screw hole a slot for a captive nut can be added using the same parameters. The slot can slide a square or hex nut from the side, or drop in a hex nut longitudinally. The use of the “pos” parameter makes it easy to position the screw hole properly.

AM

Adrian Mariano

Wed, Nov 3, 2021 12:27 AM

I'm not sure I understand exactly what your parameters are. The BOSL2

screws library is machine screws, so it doesn't have dimensions for a

self-tapping wood (?) screw. So I'm not sure it's much help for that

application. I suspect wood screws are less standard than machine

screws, since they don't have to mate with anything, so I don't know

what kind of standards they adhere to. For machine screw clearance

holes I suppose the best way to do it would be to use the d_major that

you get for a nut and if you do that then the bolt should fit---if it

didn't it wouldn't be able to fit into the nut, so I don't see the

need for any adjustments assuming your fabrication is accurate.

I don't understand what the various clearance and gap parameters do.

Of course, the easiest way to make a clearance hole would just be

something like screw("#8", thread=0, length=25) and maybe a head if

you want a countersink. But that'll be undersized, so you'd need to

oversize it by some amount with the oversize parameter, so that's a

little less tidy than just starting with the right dimension.

If you're going to use BOSL2 then instead of returning "pos" you

should use the BOSL2 attachment capability to control positioning of

the hole.

On Tue, Nov 2, 2021 at 7:00 PM bob@rjcarlson.com wrote:

I have a small library which generates shapes that are holes for screws. So I have a table of numbers describing the screws I use. I took the measurements myself. I want to convert it to use screw_into from BOSL2.

One type of screw hole is for self tapping screws. I assume the diameter of the hole should be the nominal diameter - a function of the pitch, presumably a percentage. What should that function be?

FYI, the library specifies a screw hole with

specs - the screw measurements, what I want to get from BOSL2/screws.scad

gap - space between the bottom of the head and the nut

clearS - clearance on the screw end

clearH - clearance on the head end

pos - one of 6 positions to return the hole in, top of the head, middle of gap, etc.

To the basic screw hole a slot for a captive nut can be added using the same parameters. The slot can slide a square or hex nut from the side, or drop in a hex nut longitudinally. The use of the “pos” parameter makes it easy to position the screw hole properly.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

I'm not sure I understand exactly what your parameters are. The BOSL2

screws library is machine screws, so it doesn't have dimensions for a

self-tapping wood (?) screw. So I'm not sure it's much help for that

application. I suspect wood screws are less standard than machine

screws, since they don't have to mate with anything, so I don't know

what kind of standards they adhere to. For machine screw clearance

holes I suppose the best way to do it would be to use the d_major that

you get for a nut and if you do that then the bolt should fit---if it

didn't it wouldn't be able to fit into the nut, so I don't see the

need for any adjustments assuming your fabrication is accurate.

I don't understand what the various clearance and gap parameters do.

Of course, the easiest way to make a clearance hole would just be

something like screw("#8", thread=0, length=25) and maybe a head if

you want a countersink. But that'll be undersized, so you'd need to

oversize it by some amount with the oversize parameter, so that's a

little less tidy than just starting with the right dimension.

If you're going to use BOSL2 then instead of returning "pos" you

should use the BOSL2 attachment capability to control positioning of

the hole.

On Tue, Nov 2, 2021 at 7:00 PM <bob@rjcarlson.com> wrote:

>

> I have a small library which generates shapes that are holes for screws. So I have a table of numbers describing the screws I use. I took the measurements myself. I want to convert it to use screw_into from BOSL2.

>

> One type of screw hole is for self tapping screws. I assume the diameter of the hole should be the nominal diameter - a function of the pitch, presumably a percentage. What should that function be?

>

>

> FYI, the library specifies a screw hole with

>

> specs - the screw measurements, what I want to get from BOSL2/screws.scad

>

> gap - space between the bottom of the head and the nut

>

> clearS - clearance on the screw end

>

> clearH - clearance on the head end

>

> pos - one of 6 positions to return the hole in, top of the head, middle of gap, etc.

>

> To the basic screw hole a slot for a captive nut can be added using the same parameters. The slot can slide a square or hex nut from the side, or drop in a hex nut longitudinally. The use of the “pos” parameter makes it easy to position the screw hole properly.

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

NH

nop head

Wed, Nov 3, 2021 8:40 AM

For metric machine screws the pilot hole for tapping is just the outer

diameter minus the pitch. For self tappers and wood screws I think to some

extent it depends on the material it goes into and its thickness. I either

google it or measure the minor diameter with calipers and use that.

I have some constants for No 2, 4, 6, and 8 screws in my library but I just

noticed No4 and No6 are both 2mm holes and I can't remember why. The

comments do say into soft wood and it must have been the drill I used

making my first Mendel90 out of MDF. It doesn't really matter much into

soft wood but it is more important for printed holes.

On Tue, 2 Nov 2021 at 23:08, bob@rjcarlson.com wrote:

I have a small library which generates shapes that are holes for screws.

So I have a table of numbers describing the screws I use. I took the

measurements myself. I want to convert it to use screw_into from BOSL2.

One type of screw hole is for self tapping screws. I assume the diameter

of the hole should be the nominal diameter - a function of the pitch,

presumably a percentage. What should that function be?

FYI, the library specifies a screw hole with

-

specs - the screw measurements, what I want to get from

BOSL2/screws.scad

-

gap - space between the bottom of the head and the nut

-

clearS - clearance on the screw end

-

clearH - clearance on the head end

-

pos - one of 6 positions to return the hole in, top of the head,

middle of gap, etc.

To the basic screw hole a slot for a captive nut can be added using the

same parameters. The slot can slide a square or hex nut from the side, or

drop in a hex nut longitudinally. The use of the “pos” parameter makes it

easy to position the screw hole properly.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

For metric machine screws the pilot hole for tapping is just the outer

diameter minus the pitch. For self tappers and wood screws I think to some

extent it depends on the material it goes into and its thickness. I either

google it or measure the minor diameter with calipers and use that.

I have some constants for No 2, 4, 6, and 8 screws in my library but I just

noticed No4 and No6 are both 2mm holes and I can't remember why. The

comments do say into soft wood and it must have been the drill I used

making my first Mendel90 out of MDF. It doesn't really matter much into

soft wood but it is more important for printed holes.

On Tue, 2 Nov 2021 at 23:08, <bob@rjcarlson.com> wrote:

> I have a small library which generates shapes that are holes for screws.

> So I have a table of numbers describing the screws I use. I took the

> measurements myself. I want to convert it to use screw_into from BOSL2.

>

> One type of screw hole is for self tapping screws. I assume the diameter

> of the hole should be the nominal diameter - a function of the pitch,

> presumably a percentage. What should that function be?

>

>

> FYI, the library specifies a screw hole with

>

> -

>

> specs - the screw measurements, what I want to get from

> BOSL2/screws.scad

> -

>

> gap - space between the bottom of the head and the nut

> -

>

> clearS - clearance on the screw end

> -

>

> clearH - clearance on the head end

> -

>

> pos - one of 6 positions to return the hole in, top of the head,

> middle of gap, etc.

>

> To the basic screw hole a slot for a captive nut can be added using the

> same parameters. The slot can slide a square or hex nut from the side, or

> drop in a hex nut longitudinally. The use of the “pos” parameter makes it

> easy to position the screw hole properly.

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

AM

Adrian Mariano

Wed, Nov 3, 2021 10:43 AM

He didn't say he wanted to do tapped machine screws. So using OD minus

pitch means you're making an assumption about the desired amount of

extra for tapping. The nominal ID will be the diameter mus

sqrt(3)*pitch so by subtracting only the pitch you are implicitly

making the hole larger than the screw ID by sqrt(3)-1 times the pitch,

or about .7 times the pitch. Is that always the right amount of

"extra" to leave for tapping? I don't know the answer. This rule of

thumb will work the same for UTS screws because they have the same

geometry.

On Wed, Nov 3, 2021 at 4:41 AM nop head nop.head@gmail.com wrote:

For metric machine screws the pilot hole for tapping is just the outer diameter minus the pitch. For self tappers and wood screws I think to some extent it depends on the material it goes into and its thickness. I either google it or measure the minor diameter with calipers and use that.

I have some constants for No 2, 4, 6, and 8 screws in my library but I just noticed No4 and No6 are both 2mm holes and I can't remember why. The comments do say into soft wood and it must have been the drill I used making my first Mendel90 out of MDF. It doesn't really matter much into soft wood but it is more important for printed holes.

On Tue, 2 Nov 2021 at 23:08, bob@rjcarlson.com wrote:

I have a small library which generates shapes that are holes for screws. So I have a table of numbers describing the screws I use. I took the measurements myself. I want to convert it to use screw_into from BOSL2.

One type of screw hole is for self tapping screws. I assume the diameter of the hole should be the nominal diameter - a function of the pitch, presumably a percentage. What should that function be?

FYI, the library specifies a screw hole with

specs - the screw measurements, what I want to get from BOSL2/screws.scad

gap - space between the bottom of the head and the nut

clearS - clearance on the screw end

clearH - clearance on the head end

pos - one of 6 positions to return the hole in, top of the head, middle of gap, etc.

To the basic screw hole a slot for a captive nut can be added using the same parameters. The slot can slide a square or hex nut from the side, or drop in a hex nut longitudinally. The use of the “pos” parameter makes it easy to position the screw hole properly.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

He didn't say he wanted to do tapped machine screws. So using OD minus

pitch means you're making an assumption about the desired amount of

extra for tapping. The nominal ID will be the diameter mus

sqrt(3)*pitch so by subtracting only the pitch you are implicitly

making the hole larger than the screw ID by sqrt(3)-1 times the pitch,

or about .7 times the pitch. Is that always the right amount of

"extra" to leave for tapping? I don't know the answer. This rule of

thumb will work the same for UTS screws because they have the same

geometry.

On Wed, Nov 3, 2021 at 4:41 AM nop head <nop.head@gmail.com> wrote:

>

> For metric machine screws the pilot hole for tapping is just the outer diameter minus the pitch. For self tappers and wood screws I think to some extent it depends on the material it goes into and its thickness. I either google it or measure the minor diameter with calipers and use that.

>

> I have some constants for No 2, 4, 6, and 8 screws in my library but I just noticed No4 and No6 are both 2mm holes and I can't remember why. The comments do say into soft wood and it must have been the drill I used making my first Mendel90 out of MDF. It doesn't really matter much into soft wood but it is more important for printed holes.

>

> On Tue, 2 Nov 2021 at 23:08, <bob@rjcarlson.com> wrote:

>>

>> I have a small library which generates shapes that are holes for screws. So I have a table of numbers describing the screws I use. I took the measurements myself. I want to convert it to use screw_into from BOSL2.

>>

>> One type of screw hole is for self tapping screws. I assume the diameter of the hole should be the nominal diameter - a function of the pitch, presumably a percentage. What should that function be?

>>

>>

>> FYI, the library specifies a screw hole with

>>

>> specs - the screw measurements, what I want to get from BOSL2/screws.scad

>>

>> gap - space between the bottom of the head and the nut

>>

>> clearS - clearance on the screw end

>>

>> clearH - clearance on the head end

>>

>> pos - one of 6 positions to return the hole in, top of the head, middle of gap, etc.

>>

>> To the basic screw hole a slot for a captive nut can be added using the same parameters. The slot can slide a square or hex nut from the side, or drop in a hex nut longitudinally. The use of the “pos” parameter makes it easy to position the screw hole properly.

>>

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

NH

nop head

Wed, Nov 3, 2021 11:05 AM

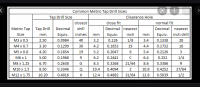

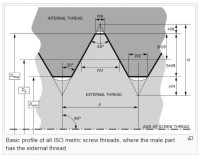

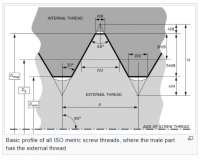

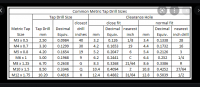

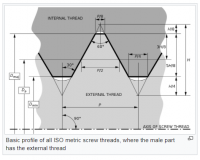

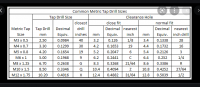

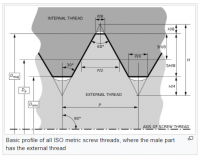

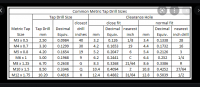

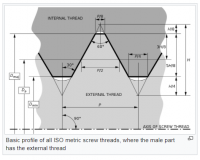

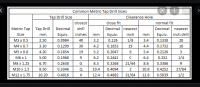

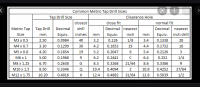

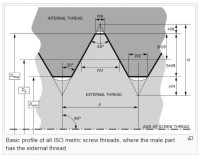

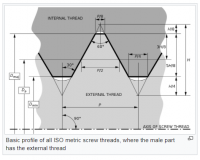

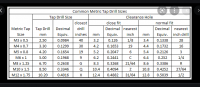

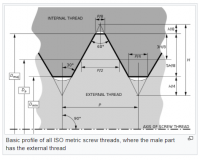

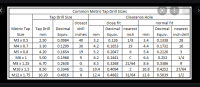

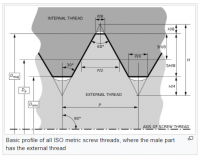

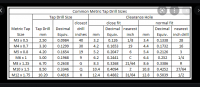

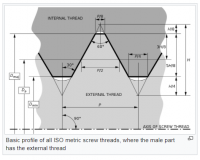

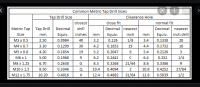

For metric screws the minor diameter is not nominal minus sqrt(3) times the

pitch. That is the base of the triangle but it is fillited at 5/8 and 1/8.

According to Wikipedia it is the major diameter minus 1.082532 times the

pitch. Using standard drill sizes, that is close enough to 1 times the

pitch.

[image: image.png]

[image: image.png]

On Wed, 3 Nov 2021 at 10:53, Adrian Mariano avm4@cornell.edu wrote:

He didn't say he wanted to do tapped machine screws. So using OD minus

pitch means you're making an assumption about the desired amount of

extra for tapping. The nominal ID will be the diameter mus

sqrt(3)*pitch so by subtracting only the pitch you are implicitly

making the hole larger than the screw ID by sqrt(3)-1 times the pitch,

or about .7 times the pitch. Is that always the right amount of

"extra" to leave for tapping? I don't know the answer. This rule of

thumb will work the same for UTS screws because they have the same

geometry.

On Wed, Nov 3, 2021 at 4:41 AM nop head nop.head@gmail.com wrote:

For metric machine screws the pilot hole for tapping is just the outer

diameter minus the pitch. For self tappers and wood screws I think to some

extent it depends on the material it goes into and its thickness. I either

google it or measure the minor diameter with calipers and use that.

I have some constants for No 2, 4, 6, and 8 screws in my library but I

just noticed No4 and No6 are both 2mm holes and I can't remember why. The

comments do say into soft wood and it must have been the drill I used

making my first Mendel90 out of MDF. It doesn't really matter much into

soft wood but it is more important for printed holes.

I have a small library which generates shapes that are holes for

screws. So I have a table of numbers describing the screws I use. I took

the measurements myself. I want to convert it to use screw_into from BOSL2.

One type of screw hole is for self tapping screws. I assume the

diameter of the hole should be the nominal diameter - a function of the

pitch, presumably a percentage. What should that function be?

FYI, the library specifies a screw hole with

specs - the screw measurements, what I want to get from

gap - space between the bottom of the head and the nut

clearS - clearance on the screw end

clearH - clearance on the head end

pos - one of 6 positions to return the hole in, top of the head, middle

To the basic screw hole a slot for a captive nut can be added using the

same parameters. The slot can slide a square or hex nut from the side, or

drop in a hex nut longitudinally. The use of the “pos” parameter makes it

easy to position the screw hole properly.

For metric screws the minor diameter is not nominal minus sqrt(3) times the

pitch. That is the base of the triangle but it is fillited at 5/8 and 1/8.

According to Wikipedia it is the major diameter minus 1.082532 times the

pitch. Using standard drill sizes, that is close enough to 1 times the

pitch.

[image: image.png]

[image: image.png]

On Wed, 3 Nov 2021 at 10:53, Adrian Mariano <avm4@cornell.edu> wrote:

> He didn't say he wanted to do tapped machine screws. So using OD minus

> pitch means you're making an assumption about the desired amount of

> extra for tapping. The nominal ID will be the diameter mus

> sqrt(3)*pitch so by subtracting only the pitch you are implicitly

> making the hole larger than the screw ID by sqrt(3)-1 times the pitch,

> or about .7 times the pitch. Is that always the right amount of

> "extra" to leave for tapping? I don't know the answer. This rule of

> thumb will work the same for UTS screws because they have the same

> geometry.

>

> On Wed, Nov 3, 2021 at 4:41 AM nop head <nop.head@gmail.com> wrote:

> >

> > For metric machine screws the pilot hole for tapping is just the outer

> diameter minus the pitch. For self tappers and wood screws I think to some

> extent it depends on the material it goes into and its thickness. I either

> google it or measure the minor diameter with calipers and use that.

> >

> > I have some constants for No 2, 4, 6, and 8 screws in my library but I

> just noticed No4 and No6 are both 2mm holes and I can't remember why. The

> comments do say into soft wood and it must have been the drill I used

> making my first Mendel90 out of MDF. It doesn't really matter much into

> soft wood but it is more important for printed holes.

> >

> > On Tue, 2 Nov 2021 at 23:08, <bob@rjcarlson.com> wrote:

> >>

> >> I have a small library which generates shapes that are holes for

> screws. So I have a table of numbers describing the screws I use. I took

> the measurements myself. I want to convert it to use screw_into from BOSL2.

> >>

> >> One type of screw hole is for self tapping screws. I assume the

> diameter of the hole should be the nominal diameter - a function of the

> pitch, presumably a percentage. What should that function be?

> >>

> >>

> >> FYI, the library specifies a screw hole with

> >>

> >> specs - the screw measurements, what I want to get from

> BOSL2/screws.scad

> >>

> >> gap - space between the bottom of the head and the nut

> >>

> >> clearS - clearance on the screw end

> >>

> >> clearH - clearance on the head end

> >>

> >> pos - one of 6 positions to return the hole in, top of the head, middle

> of gap, etc.

> >>

> >> To the basic screw hole a slot for a captive nut can be added using the

> same parameters. The slot can slide a square or hex nut from the side, or

> drop in a hex nut longitudinally. The use of the “pos” parameter makes it

> easy to position the screw hole properly.

> >>

> >> _______________________________________________

> >> OpenSCAD mailing list

> >> To unsubscribe send an email to discuss-leave@lists.openscad.org

> >

> > _______________________________________________

> > OpenSCAD mailing list

> > To unsubscribe send an email to discuss-leave@lists.openscad.org

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

AM

Adrian Mariano

Wed, Nov 3, 2021 11:35 PM

Yeah, I forgot about the clipping of the top of the screw profile. But

what's the ideal tap hole size? Should it be equal to the ID of the

threaded hole? If that's the case, the original poster can just use that

value from the screw data. Note that d_major is not equal to the nominal

screw size---or rather, it's a range. So for M6 the spec requires d_major

to be between 6mm and 6.3mm. But subtracting the pitch from the nominal

diameter does seem to put the result in the middle of the inner diameter

range, which is 4.9mm to 5.1mm. Of course, it didn't look to me like the

original poster was interested in tapping machine screws. Another

question: should tapping diameter be different for plastic than for metal?

I think for tapping holes in wood for machine screws one may use a hole

undersized compared to the hole for metal tapping.

On Wed, Nov 3, 2021 at 7:06 AM nop head nop.head@gmail.com wrote:

For metric screws the minor diameter is not nominal minus sqrt(3) times

the pitch. That is the base of the triangle but it is fillited at 5/8 and

1/8. According to Wikipedia it is the major diameter minus 1.082532 times

the pitch. Using standard drill sizes, that is close enough to 1 times the

pitch.

[image: image.png]

[image: image.png]

On Wed, 3 Nov 2021 at 10:53, Adrian Mariano avm4@cornell.edu wrote:

He didn't say he wanted to do tapped machine screws. So using OD minus

pitch means you're making an assumption about the desired amount of

extra for tapping. The nominal ID will be the diameter mus

sqrt(3)*pitch so by subtracting only the pitch you are implicitly

making the hole larger than the screw ID by sqrt(3)-1 times the pitch,

or about .7 times the pitch. Is that always the right amount of

"extra" to leave for tapping? I don't know the answer. This rule of

thumb will work the same for UTS screws because they have the same

geometry.

On Wed, Nov 3, 2021 at 4:41 AM nop head nop.head@gmail.com wrote:

For metric machine screws the pilot hole for tapping is just the outer

diameter minus the pitch. For self tappers and wood screws I think to some

extent it depends on the material it goes into and its thickness. I either

google it or measure the minor diameter with calipers and use that.

I have some constants for No 2, 4, 6, and 8 screws in my library but I

just noticed No4 and No6 are both 2mm holes and I can't remember why. The

comments do say into soft wood and it must have been the drill I used

making my first Mendel90 out of MDF. It doesn't really matter much into

soft wood but it is more important for printed holes.

I have a small library which generates shapes that are holes for

screws. So I have a table of numbers describing the screws I use. I took

the measurements myself. I want to convert it to use screw_into from BOSL2.

One type of screw hole is for self tapping screws. I assume the

diameter of the hole should be the nominal diameter - a function of the

pitch, presumably a percentage. What should that function be?

FYI, the library specifies a screw hole with

specs - the screw measurements, what I want to get from

gap - space between the bottom of the head and the nut

clearS - clearance on the screw end

clearH - clearance on the head end

pos - one of 6 positions to return the hole in, top of the head,

To the basic screw hole a slot for a captive nut can be added using

the same parameters. The slot can slide a square or hex nut from the side,

or drop in a hex nut longitudinally. The use of the “pos” parameter makes

it easy to position the screw hole properly.

Yeah, I forgot about the clipping of the top of the screw profile. But

what's the ideal tap hole size? Should it be equal to the ID of the

threaded hole? If that's the case, the original poster can just use that

value from the screw data. Note that d_major is not equal to the nominal

screw size---or rather, it's a range. So for M6 the spec requires d_major

to be between 6mm and 6.3mm. But subtracting the pitch from the nominal

diameter does seem to put the result in the middle of the inner diameter

range, which is 4.9mm to 5.1mm. Of course, it didn't look to me like the

original poster was interested in tapping machine screws. Another

question: should tapping diameter be different for plastic than for metal?

I think for tapping holes in wood for machine screws one may use a hole

undersized compared to the hole for metal tapping.

On Wed, Nov 3, 2021 at 7:06 AM nop head <nop.head@gmail.com> wrote:

> For metric screws the minor diameter is not nominal minus sqrt(3) times

> the pitch. That is the base of the triangle but it is fillited at 5/8 and

> 1/8. According to Wikipedia it is the major diameter minus 1.082532 times

> the pitch. Using standard drill sizes, that is close enough to 1 times the

> pitch.

>

> [image: image.png]

>

> [image: image.png]

>

> On Wed, 3 Nov 2021 at 10:53, Adrian Mariano <avm4@cornell.edu> wrote:

>

>> He didn't say he wanted to do tapped machine screws. So using OD minus

>> pitch means you're making an assumption about the desired amount of

>> extra for tapping. The nominal ID will be the diameter mus

>> sqrt(3)*pitch so by subtracting only the pitch you are implicitly

>> making the hole larger than the screw ID by sqrt(3)-1 times the pitch,

>> or about .7 times the pitch. Is that always the right amount of

>> "extra" to leave for tapping? I don't know the answer. This rule of

>> thumb will work the same for UTS screws because they have the same

>> geometry.

>>

>> On Wed, Nov 3, 2021 at 4:41 AM nop head <nop.head@gmail.com> wrote:

>> >

>> > For metric machine screws the pilot hole for tapping is just the outer

>> diameter minus the pitch. For self tappers and wood screws I think to some

>> extent it depends on the material it goes into and its thickness. I either

>> google it or measure the minor diameter with calipers and use that.

>> >

>> > I have some constants for No 2, 4, 6, and 8 screws in my library but I

>> just noticed No4 and No6 are both 2mm holes and I can't remember why. The

>> comments do say into soft wood and it must have been the drill I used

>> making my first Mendel90 out of MDF. It doesn't really matter much into

>> soft wood but it is more important for printed holes.

>> >

>> > On Tue, 2 Nov 2021 at 23:08, <bob@rjcarlson.com> wrote:

>> >>

>> >> I have a small library which generates shapes that are holes for

>> screws. So I have a table of numbers describing the screws I use. I took

>> the measurements myself. I want to convert it to use screw_into from BOSL2.

>> >>

>> >> One type of screw hole is for self tapping screws. I assume the

>> diameter of the hole should be the nominal diameter - a function of the

>> pitch, presumably a percentage. What should that function be?

>> >>

>> >>

>> >> FYI, the library specifies a screw hole with

>> >>

>> >> specs - the screw measurements, what I want to get from

>> BOSL2/screws.scad

>> >>

>> >> gap - space between the bottom of the head and the nut

>> >>

>> >> clearS - clearance on the screw end

>> >>

>> >> clearH - clearance on the head end

>> >>

>> >> pos - one of 6 positions to return the hole in, top of the head,

>> middle of gap, etc.

>> >>

>> >> To the basic screw hole a slot for a captive nut can be added using

>> the same parameters. The slot can slide a square or hex nut from the side,

>> or drop in a hex nut longitudinally. The use of the “pos” parameter makes

>> it easy to position the screw hole properly.

>> >>

>> >> _______________________________________________

>> >> OpenSCAD mailing list

>> >> To unsubscribe send an email to discuss-leave@lists.openscad.org

>> >

>> > _______________________________________________

>> > OpenSCAD mailing list

>> > To unsubscribe send an email to discuss-leave@lists.openscad.org

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

NH

nop head

Thu, Nov 4, 2021 8:37 AM

The ideal tap size for machine screws is the nominal OD minus the pitch *

sqrt(3) * 5 / 8. I.e. the ID of the internal thread. Rounded to the nearest

drill size it is just nominal minus pitch. If the hole was smaller the tap

would tend to bind as it has to widen the hole as well as cutting the

threads. If the hole is too big you get a weak thread because the OD is too

big.

For self tappers it is more complicated because they are often used in thin

sheets of metal and tables I found online have different values for

different thicknesses. To some extent you are forming the metal, rather

than just cutting it. But for thick materials I just use the thread ID,

which I often measure with calipers or eyeball the drill against the screw.

Wood screws are more forgiving because they have a tapered point and wood

is soft. So the hole can be considerably undersized or even none at all.

On Wed, 3 Nov 2021 at 23:36, Adrian Mariano avm4@cornell.edu wrote:

Yeah, I forgot about the clipping of the top of the screw profile. But

what's the ideal tap hole size? Should it be equal to the ID of the

threaded hole? If that's the case, the original poster can just use that

value from the screw data. Note that d_major is not equal to the nominal

screw size---or rather, it's a range. So for M6 the spec requires d_major

to be between 6mm and 6.3mm. But subtracting the pitch from the nominal

diameter does seem to put the result in the middle of the inner diameter

range, which is 4.9mm to 5.1mm. Of course, it didn't look to me like the

original poster was interested in tapping machine screws. Another

question: should tapping diameter be different for plastic than for metal?

I think for tapping holes in wood for machine screws one may use a hole

undersized compared to the hole for metal tapping.

On Wed, Nov 3, 2021 at 7:06 AM nop head nop.head@gmail.com wrote:

For metric screws the minor diameter is not nominal minus sqrt(3) times

the pitch. That is the base of the triangle but it is fillited at 5/8 and

1/8. According to Wikipedia it is the major diameter minus 1.082532 times

the pitch. Using standard drill sizes, that is close enough to 1 times the

pitch.

[image: image.png]

[image: image.png]

On Wed, 3 Nov 2021 at 10:53, Adrian Mariano avm4@cornell.edu wrote:

He didn't say he wanted to do tapped machine screws. So using OD minus

pitch means you're making an assumption about the desired amount of

extra for tapping. The nominal ID will be the diameter mus

sqrt(3)*pitch so by subtracting only the pitch you are implicitly

making the hole larger than the screw ID by sqrt(3)-1 times the pitch,

or about .7 times the pitch. Is that always the right amount of

"extra" to leave for tapping? I don't know the answer. This rule of

thumb will work the same for UTS screws because they have the same

geometry.

On Wed, Nov 3, 2021 at 4:41 AM nop head nop.head@gmail.com wrote:

For metric machine screws the pilot hole for tapping is just the outer

diameter minus the pitch. For self tappers and wood screws I think to some

extent it depends on the material it goes into and its thickness. I either

google it or measure the minor diameter with calipers and use that.

I have some constants for No 2, 4, 6, and 8 screws in my library but I

just noticed No4 and No6 are both 2mm holes and I can't remember why. The

comments do say into soft wood and it must have been the drill I used

making my first Mendel90 out of MDF. It doesn't really matter much into

soft wood but it is more important for printed holes.

I have a small library which generates shapes that are holes for

screws. So I have a table of numbers describing the screws I use. I took

the measurements myself. I want to convert it to use screw_into from BOSL2.

One type of screw hole is for self tapping screws. I assume the

diameter of the hole should be the nominal diameter - a function of the

pitch, presumably a percentage. What should that function be?

FYI, the library specifies a screw hole with

specs - the screw measurements, what I want to get from

gap - space between the bottom of the head and the nut

clearS - clearance on the screw end

clearH - clearance on the head end

pos - one of 6 positions to return the hole in, top of the head,

To the basic screw hole a slot for a captive nut can be added using

the same parameters. The slot can slide a square or hex nut from the side,

or drop in a hex nut longitudinally. The use of the “pos” parameter makes

it easy to position the screw hole properly.

The ideal tap size for machine screws is the nominal OD minus the pitch *

sqrt(3) * 5 / 8. I.e. the ID of the internal thread. Rounded to the nearest

drill size it is just nominal minus pitch. If the hole was smaller the tap

would tend to bind as it has to widen the hole as well as cutting the

threads. If the hole is too big you get a weak thread because the OD is too

big.

For self tappers it is more complicated because they are often used in thin

sheets of metal and tables I found online have different values for

different thicknesses. To some extent you are forming the metal, rather

than just cutting it. But for thick materials I just use the thread ID,

which I often measure with calipers or eyeball the drill against the screw.

Wood screws are more forgiving because they have a tapered point and wood

is soft. So the hole can be considerably undersized or even none at all.

On Wed, 3 Nov 2021 at 23:36, Adrian Mariano <avm4@cornell.edu> wrote:

> Yeah, I forgot about the clipping of the top of the screw profile. But

> what's the ideal tap hole size? Should it be equal to the ID of the

> threaded hole? If that's the case, the original poster can just use that

> value from the screw data. Note that d_major is not equal to the nominal

> screw size---or rather, it's a range. So for M6 the spec requires d_major

> to be between 6mm and 6.3mm. But subtracting the pitch from the nominal

> diameter does seem to put the result in the middle of the inner diameter

> range, which is 4.9mm to 5.1mm. Of course, it didn't look to me like the

> original poster was interested in tapping machine screws. Another

> question: should tapping diameter be different for plastic than for metal?

> I think for tapping holes in wood for machine screws one may use a hole

> undersized compared to the hole for metal tapping.

>

> On Wed, Nov 3, 2021 at 7:06 AM nop head <nop.head@gmail.com> wrote:

>

>> For metric screws the minor diameter is not nominal minus sqrt(3) times

>> the pitch. That is the base of the triangle but it is fillited at 5/8 and

>> 1/8. According to Wikipedia it is the major diameter minus 1.082532 times

>> the pitch. Using standard drill sizes, that is close enough to 1 times the

>> pitch.

>>

>> [image: image.png]

>>

>> [image: image.png]

>>

>> On Wed, 3 Nov 2021 at 10:53, Adrian Mariano <avm4@cornell.edu> wrote:

>>

>>> He didn't say he wanted to do tapped machine screws. So using OD minus

>>> pitch means you're making an assumption about the desired amount of

>>> extra for tapping. The nominal ID will be the diameter mus

>>> sqrt(3)*pitch so by subtracting only the pitch you are implicitly

>>> making the hole larger than the screw ID by sqrt(3)-1 times the pitch,

>>> or about .7 times the pitch. Is that always the right amount of

>>> "extra" to leave for tapping? I don't know the answer. This rule of

>>> thumb will work the same for UTS screws because they have the same

>>> geometry.

>>>

>>> On Wed, Nov 3, 2021 at 4:41 AM nop head <nop.head@gmail.com> wrote:

>>> >

>>> > For metric machine screws the pilot hole for tapping is just the outer

>>> diameter minus the pitch. For self tappers and wood screws I think to some

>>> extent it depends on the material it goes into and its thickness. I either

>>> google it or measure the minor diameter with calipers and use that.

>>> >

>>> > I have some constants for No 2, 4, 6, and 8 screws in my library but I

>>> just noticed No4 and No6 are both 2mm holes and I can't remember why. The

>>> comments do say into soft wood and it must have been the drill I used

>>> making my first Mendel90 out of MDF. It doesn't really matter much into

>>> soft wood but it is more important for printed holes.

>>> >

>>> > On Tue, 2 Nov 2021 at 23:08, <bob@rjcarlson.com> wrote:

>>> >>

>>> >> I have a small library which generates shapes that are holes for

>>> screws. So I have a table of numbers describing the screws I use. I took

>>> the measurements myself. I want to convert it to use screw_into from BOSL2.

>>> >>

>>> >> One type of screw hole is for self tapping screws. I assume the

>>> diameter of the hole should be the nominal diameter - a function of the

>>> pitch, presumably a percentage. What should that function be?

>>> >>

>>> >>

>>> >> FYI, the library specifies a screw hole with

>>> >>

>>> >> specs - the screw measurements, what I want to get from

>>> BOSL2/screws.scad

>>> >>

>>> >> gap - space between the bottom of the head and the nut

>>> >>

>>> >> clearS - clearance on the screw end

>>> >>

>>> >> clearH - clearance on the head end

>>> >>

>>> >> pos - one of 6 positions to return the hole in, top of the head,

>>> middle of gap, etc.

>>> >>

>>> >> To the basic screw hole a slot for a captive nut can be added using

>>> the same parameters. The slot can slide a square or hex nut from the side,

>>> or drop in a hex nut longitudinally. The use of the “pos” parameter makes

>>> it easy to position the screw hole properly.

>>> >>

>>> >> _______________________________________________

>>> >> OpenSCAD mailing list

>>> >> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>> >

>>> > _______________________________________________

>>> > OpenSCAD mailing list

>>> > To unsubscribe send an email to discuss-leave@lists.openscad.org

>>> _______________________________________________

>>> OpenSCAD mailing list

>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

AM

Adrian Mariano

Thu, Nov 4, 2021 10:35 AM

If the ideal tap size is the ID then that value can be used directly from

the screw parameters. Note that the ID is not just nominal OD minus

pitch*sqrt(3)*5/8 because that ignores the tolerance parameters. An actual

nut will have a larger ID than that value.

When I referred to wood I was talking about tapping wood for machine

screws, not using wood screws in wood.

I think self-tapping screws are basically like wood screws, a not very

well-specified screw with threads that are supposed to cut their way in.

On Thu, Nov 4, 2021 at 4:38 AM nop head nop.head@gmail.com wrote:

The ideal tap size for machine screws is the nominal OD minus the pitch *

sqrt(3) * 5 / 8. I.e. the ID of the internal thread. Rounded to the nearest

drill size it is just nominal minus pitch. If the hole was smaller the tap

would tend to bind as it has to widen the hole as well as cutting the

threads. If the hole is too big you get a weak thread because the OD is too

big.

For self tappers it is more complicated because they are often used in

thin sheets of metal and tables I found online have different values for

different thicknesses. To some extent you are forming the metal, rather

than just cutting it. But for thick materials I just use the thread ID,

which I often measure with calipers or eyeball the drill against the screw.

Wood screws are more forgiving because they have a tapered point and wood

is soft. So the hole can be considerably undersized or even none at all.

On Wed, 3 Nov 2021 at 23:36, Adrian Mariano avm4@cornell.edu wrote:

Yeah, I forgot about the clipping of the top of the screw profile. But

what's the ideal tap hole size? Should it be equal to the ID of the

threaded hole? If that's the case, the original poster can just use that

value from the screw data. Note that d_major is not equal to the nominal

screw size---or rather, it's a range. So for M6 the spec requires d_major

to be between 6mm and 6.3mm. But subtracting the pitch from the nominal

diameter does seem to put the result in the middle of the inner diameter

range, which is 4.9mm to 5.1mm. Of course, it didn't look to me like the

original poster was interested in tapping machine screws. Another

question: should tapping diameter be different for plastic than for metal?

I think for tapping holes in wood for machine screws one may use a hole

undersized compared to the hole for metal tapping.

On Wed, Nov 3, 2021 at 7:06 AM nop head nop.head@gmail.com wrote:

For metric screws the minor diameter is not nominal minus sqrt(3) times

the pitch. That is the base of the triangle but it is fillited at 5/8 and

1/8. According to Wikipedia it is the major diameter minus 1.082532 times

the pitch. Using standard drill sizes, that is close enough to 1 times the

pitch.

[image: image.png]

[image: image.png]

On Wed, 3 Nov 2021 at 10:53, Adrian Mariano avm4@cornell.edu wrote:

He didn't say he wanted to do tapped machine screws. So using OD minus

pitch means you're making an assumption about the desired amount of

extra for tapping. The nominal ID will be the diameter mus

sqrt(3)*pitch so by subtracting only the pitch you are implicitly

making the hole larger than the screw ID by sqrt(3)-1 times the pitch,

or about .7 times the pitch. Is that always the right amount of

"extra" to leave for tapping? I don't know the answer. This rule of

thumb will work the same for UTS screws because they have the same

geometry.

On Wed, Nov 3, 2021 at 4:41 AM nop head nop.head@gmail.com wrote:

For metric machine screws the pilot hole for tapping is just the

outer diameter minus the pitch. For self tappers and wood screws I think to

some extent it depends on the material it goes into and its thickness. I

either google it or measure the minor diameter with calipers and use that.

I have some constants for No 2, 4, 6, and 8 screws in my library but

I just noticed No4 and No6 are both 2mm holes and I can't remember why. The

comments do say into soft wood and it must have been the drill I used

making my first Mendel90 out of MDF. It doesn't really matter much into

soft wood but it is more important for printed holes.

I have a small library which generates shapes that are holes for

screws. So I have a table of numbers describing the screws I use. I took

the measurements myself. I want to convert it to use screw_into from BOSL2.

One type of screw hole is for self tapping screws. I assume the

diameter of the hole should be the nominal diameter - a function of the

pitch, presumably a percentage. What should that function be?

FYI, the library specifies a screw hole with

specs - the screw measurements, what I want to get from

gap - space between the bottom of the head and the nut

clearS - clearance on the screw end

clearH - clearance on the head end

pos - one of 6 positions to return the hole in, top of the head,

To the basic screw hole a slot for a captive nut can be added using

the same parameters. The slot can slide a square or hex nut from the side,

or drop in a hex nut longitudinally. The use of the “pos” parameter makes

it easy to position the screw hole properly.

If the ideal tap size is the ID then that value can be used directly from

the screw parameters. Note that the ID is not just nominal OD minus

pitch*sqrt(3)*5/8 because that ignores the tolerance parameters. An actual

nut will have a larger ID than that value.

When I referred to wood I was talking about tapping wood for machine

screws, not using wood screws in wood.

I think self-tapping screws are basically like wood screws, a not very

well-specified screw with threads that are supposed to cut their way in.

On Thu, Nov 4, 2021 at 4:38 AM nop head <nop.head@gmail.com> wrote:

> The ideal tap size for machine screws is the nominal OD minus the pitch *

> sqrt(3) * 5 / 8. I.e. the ID of the internal thread. Rounded to the nearest

> drill size it is just nominal minus pitch. If the hole was smaller the tap

> would tend to bind as it has to widen the hole as well as cutting the

> threads. If the hole is too big you get a weak thread because the OD is too

> big.

>

> For self tappers it is more complicated because they are often used in

> thin sheets of metal and tables I found online have different values for

> different thicknesses. To some extent you are forming the metal, rather

> than just cutting it. But for thick materials I just use the thread ID,

> which I often measure with calipers or eyeball the drill against the screw.

>

> Wood screws are more forgiving because they have a tapered point and wood

> is soft. So the hole can be considerably undersized or even none at all.

>

> On Wed, 3 Nov 2021 at 23:36, Adrian Mariano <avm4@cornell.edu> wrote:

>

>> Yeah, I forgot about the clipping of the top of the screw profile. But

>> what's the ideal tap hole size? Should it be equal to the ID of the

>> threaded hole? If that's the case, the original poster can just use that

>> value from the screw data. Note that d_major is not equal to the nominal

>> screw size---or rather, it's a range. So for M6 the spec requires d_major

>> to be between 6mm and 6.3mm. But subtracting the pitch from the nominal

>> diameter does seem to put the result in the middle of the inner diameter

>> range, which is 4.9mm to 5.1mm. Of course, it didn't look to me like the

>> original poster was interested in tapping machine screws. Another

>> question: should tapping diameter be different for plastic than for metal?

>> I think for tapping holes in wood for machine screws one may use a hole

>> undersized compared to the hole for metal tapping.

>>

>> On Wed, Nov 3, 2021 at 7:06 AM nop head <nop.head@gmail.com> wrote:

>>

>>> For metric screws the minor diameter is not nominal minus sqrt(3) times

>>> the pitch. That is the base of the triangle but it is fillited at 5/8 and

>>> 1/8. According to Wikipedia it is the major diameter minus 1.082532 times

>>> the pitch. Using standard drill sizes, that is close enough to 1 times the

>>> pitch.

>>>

>>> [image: image.png]

>>>

>>> [image: image.png]

>>>

>>> On Wed, 3 Nov 2021 at 10:53, Adrian Mariano <avm4@cornell.edu> wrote:

>>>

>>>> He didn't say he wanted to do tapped machine screws. So using OD minus

>>>> pitch means you're making an assumption about the desired amount of

>>>> extra for tapping. The nominal ID will be the diameter mus

>>>> sqrt(3)*pitch so by subtracting only the pitch you are implicitly

>>>> making the hole larger than the screw ID by sqrt(3)-1 times the pitch,

>>>> or about .7 times the pitch. Is that always the right amount of

>>>> "extra" to leave for tapping? I don't know the answer. This rule of

>>>> thumb will work the same for UTS screws because they have the same

>>>> geometry.

>>>>

>>>> On Wed, Nov 3, 2021 at 4:41 AM nop head <nop.head@gmail.com> wrote:

>>>> >

>>>> > For metric machine screws the pilot hole for tapping is just the

>>>> outer diameter minus the pitch. For self tappers and wood screws I think to

>>>> some extent it depends on the material it goes into and its thickness. I

>>>> either google it or measure the minor diameter with calipers and use that.

>>>> >

>>>> > I have some constants for No 2, 4, 6, and 8 screws in my library but

>>>> I just noticed No4 and No6 are both 2mm holes and I can't remember why. The

>>>> comments do say into soft wood and it must have been the drill I used

>>>> making my first Mendel90 out of MDF. It doesn't really matter much into

>>>> soft wood but it is more important for printed holes.

>>>> >

>>>> > On Tue, 2 Nov 2021 at 23:08, <bob@rjcarlson.com> wrote:

>>>> >>

>>>> >> I have a small library which generates shapes that are holes for

>>>> screws. So I have a table of numbers describing the screws I use. I took

>>>> the measurements myself. I want to convert it to use screw_into from BOSL2.

>>>> >>

>>>> >> One type of screw hole is for self tapping screws. I assume the

>>>> diameter of the hole should be the nominal diameter - a function of the

>>>> pitch, presumably a percentage. What should that function be?

>>>> >>

>>>> >>

>>>> >> FYI, the library specifies a screw hole with

>>>> >>

>>>> >> specs - the screw measurements, what I want to get from

>>>> BOSL2/screws.scad

>>>> >>

>>>> >> gap - space between the bottom of the head and the nut

>>>> >>

>>>> >> clearS - clearance on the screw end

>>>> >>

>>>> >> clearH - clearance on the head end

>>>> >>

>>>> >> pos - one of 6 positions to return the hole in, top of the head,

>>>> middle of gap, etc.

>>>> >>

>>>> >> To the basic screw hole a slot for a captive nut can be added using

>>>> the same parameters. The slot can slide a square or hex nut from the side,

>>>> or drop in a hex nut longitudinally. The use of the “pos” parameter makes

>>>> it easy to position the screw hole properly.

>>>> >>

>>>> >> _______________________________________________

>>>> >> OpenSCAD mailing list

>>>> >> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>> >

>>>> > _______________________________________________

>>>> > OpenSCAD mailing list

>>>> > To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>> _______________________________________________

>>>> OpenSCAD mailing list

>>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>

>>> _______________________________________________

>>> OpenSCAD mailing list

>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

NH

nop head

Thu, Nov 4, 2021 11:26 AM

Well tolerance parameters are ignored when you drill holes for tapping, you

just use the table I posted. And your previous comment about M6 being

between 6.0 and 6.3 does not match my experience. All my machine screws

have an outer thread diameter slightly smaller than nominal. So my M6

screws measure 5.75mm.

On Thu, 4 Nov 2021 at 10:35, Adrian Mariano avm4@cornell.edu wrote:

If the ideal tap size is the ID then that value can be used directly from

the screw parameters. Note that the ID is not just nominal OD minus

pitch*sqrt(3)*5/8 because that ignores the tolerance parameters. An actual

nut will have a larger ID than that value.

When I referred to wood I was talking about tapping wood for machine

screws, not using wood screws in wood.

I think self-tapping screws are basically like wood screws, a not very

well-specified screw with threads that are supposed to cut their way in.

On Thu, Nov 4, 2021 at 4:38 AM nop head nop.head@gmail.com wrote:

The ideal tap size for machine screws is the nominal OD minus the pitch *

sqrt(3) * 5 / 8. I.e. the ID of the internal thread. Rounded to the nearest

drill size it is just nominal minus pitch. If the hole was smaller the tap

would tend to bind as it has to widen the hole as well as cutting the

threads. If the hole is too big you get a weak thread because the OD is too

big.

For self tappers it is more complicated because they are often used in

thin sheets of metal and tables I found online have different values for

different thicknesses. To some extent you are forming the metal, rather

than just cutting it. But for thick materials I just use the thread ID,

which I often measure with calipers or eyeball the drill against the screw.

Wood screws are more forgiving because they have a tapered point and wood

is soft. So the hole can be considerably undersized or even none at all.

On Wed, 3 Nov 2021 at 23:36, Adrian Mariano avm4@cornell.edu wrote:

Yeah, I forgot about the clipping of the top of the screw profile. But

what's the ideal tap hole size? Should it be equal to the ID of the

threaded hole? If that's the case, the original poster can just use that

value from the screw data. Note that d_major is not equal to the nominal

screw size---or rather, it's a range. So for M6 the spec requires d_major

to be between 6mm and 6.3mm. But subtracting the pitch from the nominal

diameter does seem to put the result in the middle of the inner diameter

range, which is 4.9mm to 5.1mm. Of course, it didn't look to me like the

original poster was interested in tapping machine screws. Another

question: should tapping diameter be different for plastic than for metal?

I think for tapping holes in wood for machine screws one may use a hole

undersized compared to the hole for metal tapping.

On Wed, Nov 3, 2021 at 7:06 AM nop head nop.head@gmail.com wrote:

For metric screws the minor diameter is not nominal minus sqrt(3) times

the pitch. That is the base of the triangle but it is fillited at 5/8 and

1/8. According to Wikipedia it is the major diameter minus 1.082532 times

the pitch. Using standard drill sizes, that is close enough to 1 times the

pitch.

[image: image.png]

[image: image.png]

On Wed, 3 Nov 2021 at 10:53, Adrian Mariano avm4@cornell.edu wrote:

He didn't say he wanted to do tapped machine screws. So using OD minus

pitch means you're making an assumption about the desired amount of

extra for tapping. The nominal ID will be the diameter mus

sqrt(3)*pitch so by subtracting only the pitch you are implicitly

making the hole larger than the screw ID by sqrt(3)-1 times the pitch,

or about .7 times the pitch. Is that always the right amount of

"extra" to leave for tapping? I don't know the answer. This rule of

thumb will work the same for UTS screws because they have the same

geometry.

On Wed, Nov 3, 2021 at 4:41 AM nop head nop.head@gmail.com wrote:

For metric machine screws the pilot hole for tapping is just the

outer diameter minus the pitch. For self tappers and wood screws I think to

some extent it depends on the material it goes into and its thickness. I

either google it or measure the minor diameter with calipers and use that.

I have some constants for No 2, 4, 6, and 8 screws in my library but

I just noticed No4 and No6 are both 2mm holes and I can't remember why. The

comments do say into soft wood and it must have been the drill I used

making my first Mendel90 out of MDF. It doesn't really matter much into

soft wood but it is more important for printed holes.

I have a small library which generates shapes that are holes for

screws. So I have a table of numbers describing the screws I use. I took

the measurements myself. I want to convert it to use screw_into from BOSL2.

One type of screw hole is for self tapping screws. I assume the

diameter of the hole should be the nominal diameter - a function of the

pitch, presumably a percentage. What should that function be?

FYI, the library specifies a screw hole with

specs - the screw measurements, what I want to get from

gap - space between the bottom of the head and the nut

clearS - clearance on the screw end

clearH - clearance on the head end

pos - one of 6 positions to return the hole in, top of the head,

To the basic screw hole a slot for a captive nut can be added using

the same parameters. The slot can slide a square or hex nut from the side,

or drop in a hex nut longitudinally. The use of the “pos” parameter makes

it easy to position the screw hole properly.

Well tolerance parameters are ignored when you drill holes for tapping, you

just use the table I posted. And your previous comment about M6 being

between 6.0 and 6.3 does not match my experience. All my machine screws

have an outer thread diameter slightly smaller than nominal. So my M6

screws measure 5.75mm.

On Thu, 4 Nov 2021 at 10:35, Adrian Mariano <avm4@cornell.edu> wrote:

> If the ideal tap size is the ID then that value can be used directly from

> the screw parameters. Note that the ID is not just nominal OD minus

> pitch*sqrt(3)*5/8 because that ignores the tolerance parameters. An actual

> nut will have a larger ID than that value.

>

> When I referred to wood I was talking about tapping wood for machine

> screws, not using wood screws in wood.

>

> I think self-tapping screws are basically like wood screws, a not very

> well-specified screw with threads that are supposed to cut their way in.

>

>

> On Thu, Nov 4, 2021 at 4:38 AM nop head <nop.head@gmail.com> wrote:

>

>> The ideal tap size for machine screws is the nominal OD minus the pitch *

>> sqrt(3) * 5 / 8. I.e. the ID of the internal thread. Rounded to the nearest

>> drill size it is just nominal minus pitch. If the hole was smaller the tap

>> would tend to bind as it has to widen the hole as well as cutting the

>> threads. If the hole is too big you get a weak thread because the OD is too

>> big.

>>

>> For self tappers it is more complicated because they are often used in

>> thin sheets of metal and tables I found online have different values for

>> different thicknesses. To some extent you are forming the metal, rather

>> than just cutting it. But for thick materials I just use the thread ID,

>> which I often measure with calipers or eyeball the drill against the screw.

>>

>> Wood screws are more forgiving because they have a tapered point and wood

>> is soft. So the hole can be considerably undersized or even none at all.

>>

>> On Wed, 3 Nov 2021 at 23:36, Adrian Mariano <avm4@cornell.edu> wrote:

>>

>>> Yeah, I forgot about the clipping of the top of the screw profile. But

>>> what's the ideal tap hole size? Should it be equal to the ID of the

>>> threaded hole? If that's the case, the original poster can just use that

>>> value from the screw data. Note that d_major is not equal to the nominal

>>> screw size---or rather, it's a range. So for M6 the spec requires d_major

>>> to be between 6mm and 6.3mm. But subtracting the pitch from the nominal

>>> diameter does seem to put the result in the middle of the inner diameter

>>> range, which is 4.9mm to 5.1mm. Of course, it didn't look to me like the

>>> original poster was interested in tapping machine screws. Another

>>> question: should tapping diameter be different for plastic than for metal?

>>> I think for tapping holes in wood for machine screws one may use a hole

>>> undersized compared to the hole for metal tapping.

>>>

>>> On Wed, Nov 3, 2021 at 7:06 AM nop head <nop.head@gmail.com> wrote:

>>>

>>>> For metric screws the minor diameter is not nominal minus sqrt(3) times

>>>> the pitch. That is the base of the triangle but it is fillited at 5/8 and

>>>> 1/8. According to Wikipedia it is the major diameter minus 1.082532 times

>>>> the pitch. Using standard drill sizes, that is close enough to 1 times the

>>>> pitch.

>>>>

>>>> [image: image.png]

>>>>

>>>> [image: image.png]

>>>>

>>>> On Wed, 3 Nov 2021 at 10:53, Adrian Mariano <avm4@cornell.edu> wrote:

>>>>

>>>>> He didn't say he wanted to do tapped machine screws. So using OD minus

>>>>> pitch means you're making an assumption about the desired amount of

>>>>> extra for tapping. The nominal ID will be the diameter mus

>>>>> sqrt(3)*pitch so by subtracting only the pitch you are implicitly

>>>>> making the hole larger than the screw ID by sqrt(3)-1 times the pitch,

>>>>> or about .7 times the pitch. Is that always the right amount of

>>>>> "extra" to leave for tapping? I don't know the answer. This rule of

>>>>> thumb will work the same for UTS screws because they have the same

>>>>> geometry.

>>>>>

>>>>> On Wed, Nov 3, 2021 at 4:41 AM nop head <nop.head@gmail.com> wrote:

>>>>> >

>>>>> > For metric machine screws the pilot hole for tapping is just the

>>>>> outer diameter minus the pitch. For self tappers and wood screws I think to

>>>>> some extent it depends on the material it goes into and its thickness. I

>>>>> either google it or measure the minor diameter with calipers and use that.

>>>>> >

>>>>> > I have some constants for No 2, 4, 6, and 8 screws in my library but

>>>>> I just noticed No4 and No6 are both 2mm holes and I can't remember why. The

>>>>> comments do say into soft wood and it must have been the drill I used

>>>>> making my first Mendel90 out of MDF. It doesn't really matter much into

>>>>> soft wood but it is more important for printed holes.

>>>>> >

>>>>> > On Tue, 2 Nov 2021 at 23:08, <bob@rjcarlson.com> wrote:

>>>>> >>

>>>>> >> I have a small library which generates shapes that are holes for

>>>>> screws. So I have a table of numbers describing the screws I use. I took

>>>>> the measurements myself. I want to convert it to use screw_into from BOSL2.

>>>>> >>

>>>>> >> One type of screw hole is for self tapping screws. I assume the

>>>>> diameter of the hole should be the nominal diameter - a function of the

>>>>> pitch, presumably a percentage. What should that function be?

>>>>> >>

>>>>> >>

>>>>> >> FYI, the library specifies a screw hole with

>>>>> >>

>>>>> >> specs - the screw measurements, what I want to get from

>>>>> BOSL2/screws.scad

>>>>> >>

>>>>> >> gap - space between the bottom of the head and the nut

>>>>> >>

>>>>> >> clearS - clearance on the screw end

>>>>> >>

>>>>> >> clearH - clearance on the head end

>>>>> >>

>>>>> >> pos - one of 6 positions to return the hole in, top of the head,

>>>>> middle of gap, etc.

>>>>> >>

>>>>> >> To the basic screw hole a slot for a captive nut can be added using

>>>>> the same parameters. The slot can slide a square or hex nut from the side,

>>>>> or drop in a hex nut longitudinally. The use of the “pos” parameter makes

>>>>> it easy to position the screw hole properly.

>>>>> >>

>>>>> >> _______________________________________________

>>>>> >> OpenSCAD mailing list

>>>>> >> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>> >

>>>>> > _______________________________________________

>>>>> > OpenSCAD mailing list

>>>>> > To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>> _______________________________________________

>>>>> OpenSCAD mailing list

>>>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>>

>>>> _______________________________________________

>>>> OpenSCAD mailing list

>>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>

>>> _______________________________________________

>>> OpenSCAD mailing list

>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

RW

Ray West

Thu, Nov 4, 2021 1:14 PM

Some years ago I made a chart for common tapping size's and put it on

one of my web sites http://yertiz.com/cnc/index.htm under the

'something for nothing' section. It was mainly aimed at amateur use in

metals such as aluminium, brass and copper. For harder materials, it is

usual to use a bigger tapping drill. Plenty of on-line charts for that.

In practice, the diameter will depend on the material, the tightening

torques, the machining method and many other parameters. Roll forming

taps, another ball game. If talking about 3d printing, try whatever

works for you, The freely available charts for tapping drill sizes are

only for guidance, in most instances. Self tapping and wood screws are

very tightly specified, it is just we don't know what the specifications

are. Tapping soft materials, (wood/plastic) you need a sharp tap, you

most likely Wil not be able to use all three, (taper, bottom, plug) and

you can't use normal coolant or lubrication in most instances either, so

chip evacuation can be a problem.

A number 8 wood screw, 1.5 turns into an oak beam will support the

weight of a man - my dad said, so it was right, and this guy proved it

for me https://www.youtube.com/watch?v=2KaJlDC0ZdM&t=159s. I don't think

a machine screw into wood will do that. The 60deg metric thread angle is

far from ideal for many materials, but it looks easy.

Best wishes,

Ray

On 04/11/2021 10:35, Adrian Mariano wrote:

If the ideal tap size is the ID then that value can be used directly

from the screw parameters. Note that the ID is not just nominal OD

minus pitch*sqrt(3)*5/8 because that ignores the tolerance

parameters. An actual nut will have a larger ID than that value.

When I referred to wood I was talking about tapping wood for machine

screws, not using wood screws in wood.

I think self-tapping screws are basically like wood screws, a not very

well-specified screw with threads that are supposed to cut their way in.

On Thu, Nov 4, 2021 at 4:38 AM nop head nop.head@gmail.com wrote:

The ideal tap size for machine screws is the nominal OD minus the

pitch * sqrt(3) * 5 / 8. I.e. the ID of the internal thread.

Rounded to the nearest drill size it is just nominal minus pitch.

If the hole was smaller the tap would tend to bind as it has to

widen the hole as well as cutting the threads. If the hole is too

big you get a weak thread because the OD is too big.

For self tappers it is more complicated because they are often

used in thin sheets of metal and tables I found online have

different values for different thicknesses. To some extent you are

forming the metal, rather than just cutting it. But for thick

materials I just use the thread ID, which I often measure with

calipers or eyeball the drill against the screw.

Wood screws are more forgiving because they have a tapered point

and wood is soft. So the hole can be considerably undersized or

even none at all.

On Wed, 3 Nov 2021 at 23:36, Adrian Mariano <avm4@cornell.edu> wrote:

Yeah, I forgot about the clipping of the top of the screw

profile. But what's the ideal tap hole size? Should it be

equal to the ID of the threaded hole? If that's the case, the

original poster can just use that value from the screw data.

Note that d_major is not equal to the nominal screw size---or

rather, it's a range. So for M6 the spec requires d_major to

be between 6mm and 6.3mm. But subtracting the pitch from the

nominal diameter does seem to put the result in the middle of

the inner diameter range, which is 4.9mm to 5.1mm. Of

course, it didn't look to me like the original poster was

interested in tapping machine screws. Another question:

should tapping diameter be different for plastic than for

metal? I think for tapping holes in wood for machine screws

one may use a hole undersized compared to the hole for metal

tapping.

On Wed, Nov 3, 2021 at 7:06 AM nop head <nop.head@gmail.com>

wrote:

For metric screws the minor diameter is not nominal minus

sqrt(3) times the pitch. That is the base of the triangle

but it is fillited at 5/8 and 1/8. According to Wikipedia

it is the major diameter minus 1.082532 times the pitch.

Using standard drill sizes, that is close enough to 1

times the pitch.

image.png

image.png

On Wed, 3 Nov 2021 at 10:53, Adrian Mariano

<avm4@cornell.edu> wrote:

He didn't say he wanted to do tapped machine screws.

So using OD minus

pitch means you're making an assumption about the

desired amount of

extra for tapping. The nominal ID will be the

diameter mus

sqrt(3)*pitch so by subtracting only the pitch you are

implicitly

making the hole larger than the screw ID by sqrt(3)-1

times the pitch,

or about .7 times the pitch. Is that always the right

amount of

"extra" to leave for tapping? I don't know the

answer. This rule of

thumb will work the same for UTS screws because they

have the same

geometry.

On Wed, Nov 3, 2021 at 4:41 AM nop head

<nop.head@gmail.com> wrote:

For metric machine screws the pilot hole for tapping

is just the outer diameter minus the pitch. For self

tappers and wood screws I think to some extent it

depends on the material it goes into and its

thickness. I either google it or measure the minor

diameter with calipers and use that.

I have some constants for No 2, 4, 6, and 8 screws

in my library but I just noticed No4 and No6 are both

2mm holes and I can't remember why. The comments do

say into soft wood and it must have been the drill I

used making my first Mendel90 out of MDF. It doesn't

really matter much into soft wood but it is more

important for printed holes.

I have a small library which generates shapes that

are holes for screws. So I have a table of numbers

describing the screws I use. I took the measurements

myself. I want to convert it to use screw_into from BOSL2.

One type of screw hole is for self tapping screws.

I assume the diameter of the hole should be the

nominal diameter - a function of the pitch, presumably

a percentage. What should that function be?

FYI, the library specifies a screw hole with

specs - the screw measurements, what I want to get

gap - space between the bottom of the head and the nut

clearS - clearance on the screw end

clearH - clearance on the head end

pos - one of 6 positions to return the hole in, top

of the head, middle of gap, etc.

To the basic screw hole a slot for a captive nut

can be added using the same parameters. The slot can

slide a square or hex nut from the side, or drop in a

hex nut longitudinally. The use of the “pos” parameter

makes it easy to position the screw hole properly.

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

Some years ago I made a chart for common tapping size's and put it on

one of my web sites http://yertiz.com/cnc/index.htm under the