BC

Bob Carlson

Thu, Nov 4, 2021 6:20 PM

This is very helpful, both of you. I am looking at metric machine screws only and self tapping in plastic only. Subtracting the pitch seems like a nice easy heuristic. My background is strictly software, not mech engineering so this is all new to me. So far I have only worked with PLA.

I’m going to put together a little test print to check exactly what tolerances are needed to cleanly drop nuts into holes, etc. I just finished doing the BOSL2 test print for $slop. Coincidently I randomly picked t = .1 for my tolerance amount when I first started. I usually use 2*t for a tab that must insert into a lot and that has worked for me well enough. Oddly the $slop for my printer turns out to be … .1 mm.

-Bob

Tucson AZ

On Nov 3, 2021, at 04:05, nop head <nop.head@gmail.com mailto:nop.head@gmail.com> wrote:

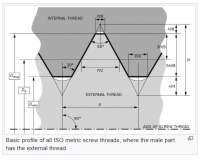

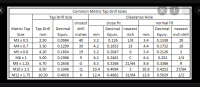

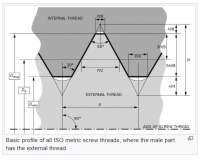

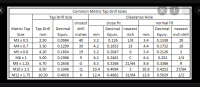

For metric screws the minor diameter is not nominal minus sqrt(3) times the pitch. That is the base of the triangle but it is fillited at 5/8 and 1/8. According to Wikipedia it is the major diameter minus 1.082532 times the pitch. Using standard drill sizes, that is close enough to 1 times the pitch.

<image.png>

<image.png>

On Wed, 3 Nov 2021 at 10:53, Adrian Mariano <avm4@cornell.edu mailto:avm4@cornell.edu> wrote:

He didn't say he wanted to do tapped machine screws. So using OD minus

pitch means you're making an assumption about the desired amount of

extra for tapping. The nominal ID will be the diameter mus

sqrt(3)*pitch so by subtracting only the pitch you are implicitly

making the hole larger than the screw ID by sqrt(3)-1 times the pitch,

or about .7 times the pitch. Is that always the right amount of

"extra" to leave for tapping? I don't know the answer. This rule of

thumb will work the same for UTS screws because they have the same

geometry.

On Wed, Nov 3, 2021 at 4:41 AM nop head <nop.head@gmail.com mailto:nop.head@gmail.com> wrote:

For metric machine screws the pilot hole for tapping is just the outer diameter minus the pitch. For self tappers and wood screws I think to some extent it depends on the material it goes into and its thickness. I either google it or measure the minor diameter with calipers and use that.

I have some constants for No 2, 4, 6, and 8 screws in my library but I just noticed No4 and No6 are both 2mm holes and I can't remember why. The comments do say into soft wood and it must have been the drill I used making my first Mendel90 out of MDF. It doesn't really matter much into soft wood but it is more important for printed holes.

On Tue, 2 Nov 2021 at 23:08, <bob@rjcarlson.com mailto:bob@rjcarlson.com> wrote:

I have a small library which generates shapes that are holes for screws. So I have a table of numbers describing the screws I use. I took the measurements myself. I want to convert it to use screw_into from BOSL2.

One type of screw hole is for self tapping screws. I assume the diameter of the hole should be the nominal diameter - a function of the pitch, presumably a percentage. What should that function be?

FYI, the library specifies a screw hole with

specs - the screw measurements, what I want to get from BOSL2/screws.scad

gap - space between the bottom of the head and the nut

clearS - clearance on the screw end

clearH - clearance on the head end

pos - one of 6 positions to return the hole in, top of the head, middle of gap, etc.

To the basic screw hole a slot for a captive nut can be added using the same parameters. The slot can slide a square or hex nut from the side, or drop in a hex nut longitudinally. The use of the “pos” parameter makes it easy to position the screw hole properly.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org mailto:discuss-leave@lists.openscad.org

This is very helpful, both of you. I am looking at metric machine screws only and self tapping in plastic only. Subtracting the pitch seems like a nice easy heuristic. My background is strictly software, not mech engineering so this is all new to me. So far I have only worked with PLA.

I’m going to put together a little test print to check exactly what tolerances are needed to cleanly drop nuts into holes, etc. I just finished doing the BOSL2 test print for $slop. Coincidently I randomly picked t = .1 for my tolerance amount when I first started. I usually use 2*t for a tab that must insert into a lot and that has worked for me well enough. Oddly the $slop for my printer turns out to be … .1 mm.

-Bob

Tucson AZ

On Nov 3, 2021, at 04:05, nop head <nop.head@gmail.com <mailto:nop.head@gmail.com>> wrote:

For metric screws the minor diameter is not nominal minus sqrt(3) times the pitch. That is the base of the triangle but it is fillited at 5/8 and 1/8. According to Wikipedia it is the major diameter minus 1.082532 times the pitch. Using standard drill sizes, that is close enough to 1 times the pitch.

<image.png>

<image.png>

On Wed, 3 Nov 2021 at 10:53, Adrian Mariano <avm4@cornell.edu <mailto:avm4@cornell.edu>> wrote:

He didn't say he wanted to do tapped machine screws. So using OD minus

pitch means you're making an assumption about the desired amount of

extra for tapping. The nominal ID will be the diameter mus

sqrt(3)*pitch so by subtracting only the pitch you are implicitly

making the hole larger than the screw ID by sqrt(3)-1 times the pitch,

or about .7 times the pitch. Is that always the right amount of

"extra" to leave for tapping? I don't know the answer. This rule of

thumb will work the same for UTS screws because they have the same

geometry.

On Wed, Nov 3, 2021 at 4:41 AM nop head <nop.head@gmail.com <mailto:nop.head@gmail.com>> wrote:

>

> For metric machine screws the pilot hole for tapping is just the outer diameter minus the pitch. For self tappers and wood screws I think to some extent it depends on the material it goes into and its thickness. I either google it or measure the minor diameter with calipers and use that.

>

> I have some constants for No 2, 4, 6, and 8 screws in my library but I just noticed No4 and No6 are both 2mm holes and I can't remember why. The comments do say into soft wood and it must have been the drill I used making my first Mendel90 out of MDF. It doesn't really matter much into soft wood but it is more important for printed holes.

>

> On Tue, 2 Nov 2021 at 23:08, <bob@rjcarlson.com <mailto:bob@rjcarlson.com>> wrote:

>>

>> I have a small library which generates shapes that are holes for screws. So I have a table of numbers describing the screws I use. I took the measurements myself. I want to convert it to use screw_into from BOSL2.

>>

>> One type of screw hole is for self tapping screws. I assume the diameter of the hole should be the nominal diameter - a function of the pitch, presumably a percentage. What should that function be?

>>

>>

>> FYI, the library specifies a screw hole with

>>

>> specs - the screw measurements, what I want to get from BOSL2/screws.scad

>>

>> gap - space between the bottom of the head and the nut

>>

>> clearS - clearance on the screw end

>>

>> clearH - clearance on the head end

>>

>> pos - one of 6 positions to return the hole in, top of the head, middle of gap, etc.

>>

>> To the basic screw hole a slot for a captive nut can be added using the same parameters. The slot can slide a square or hex nut from the side, or drop in a hex nut longitudinally. The use of the “pos” parameter makes it easy to position the screw hole properly.

>>

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org <mailto:discuss-leave@lists.openscad.org>

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org <mailto:discuss-leave@lists.openscad.org>

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org <mailto:discuss-leave@lists.openscad.org>

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org <mailto:discuss-leave@lists.openscad.org>

-Bob

Tucson AZ

AM

Adrian Mariano

Thu, Nov 4, 2021 8:50 PM

Tolerance parameters are ignored because one doesn't know what they are and

it would be a pain to deal with them. But since the original poster said

he was using BOSL2 and it provides screw dimensions with the actual

tolerances considered, why not use the real screw dimensions?

We were talking about holes, meaning nuts, not screws. An M6 nut must have

an OD larger than its nominal size or it's not ISO compliant. I'm not sure

how you measure the OD of a nut. For machine screws the 6g tolerance

specifies a diameter between 5.797 mm and 5.974mm, but the 8g tolerance

would allow your 5.75mm screws. The dimensions of screws and nuts have to

be different or they wouldn't be able to screw together.

Are wood screws tightly specified, meaning that if I gather #8 wood screws

from 100 manufacturers they are all the same, with the same thread form and

dimensions? I don't see how that can be the case if there isn't a standard

document that we can read that tells us what the wood screw dimensions

are. I see wood screw manufacturers bragging about their superior threads

or other features, which make it sound like everybody is out there doing

their own thing.

Note that for small wood screws like #4 and below, I believe, it is

stronger to tap and use a machine screw than it is to use a wood screw.

I'm not sure exactly at what point that changes, and I imagine it might

depend on the wood species. When I installed my woodworking vise all the

hardware was attached to the wood with tapped holes in the wood using

machine screws (which was how the vise manufacturer specified that it be

done) even for #8 screws. Of course, another advantage of tapping wood for

machine screws is that you can remove and reinstall the item without loss

of holding power, which may not be true for regular wood screws.

On Thu, Nov 4, 2021 at 7:27 AM nop head nop.head@gmail.com wrote:

Well tolerance parameters are ignored when you drill holes for

tapping, you just use the table I posted. And your previous comment about

M6 being between 6.0 and 6.3 does not match my experience. All my machine

screws have an outer thread diameter slightly smaller than nominal. So my

M6 screws measure 5.75mm.

On Thu, 4 Nov 2021 at 10:35, Adrian Mariano avm4@cornell.edu wrote:

If the ideal tap size is the ID then that value can be used directly from

the screw parameters. Note that the ID is not just nominal OD minus

pitch*sqrt(3)*5/8 because that ignores the tolerance parameters. An actual

nut will have a larger ID than that value.

When I referred to wood I was talking about tapping wood for machine

screws, not using wood screws in wood.

I think self-tapping screws are basically like wood screws, a not very

well-specified screw with threads that are supposed to cut their way in.

On Thu, Nov 4, 2021 at 4:38 AM nop head nop.head@gmail.com wrote:

The ideal tap size for machine screws is the nominal OD minus the pitch

- sqrt(3) * 5 / 8. I.e. the ID of the internal thread. Rounded to the

nearest drill size it is just nominal minus pitch. If the hole was smaller

the tap would tend to bind as it has to widen the hole as well as cutting

the threads. If the hole is too big you get a weak thread because the OD is

too big.

For self tappers it is more complicated because they are often used in

thin sheets of metal and tables I found online have different values for

different thicknesses. To some extent you are forming the metal, rather

than just cutting it. But for thick materials I just use the thread ID,

which I often measure with calipers or eyeball the drill against the screw.

Wood screws are more forgiving because they have a tapered point and

wood is soft. So the hole can be considerably undersized or even none at

all.

On Wed, 3 Nov 2021 at 23:36, Adrian Mariano avm4@cornell.edu wrote:

Yeah, I forgot about the clipping of the top of the screw profile.

But what's the ideal tap hole size? Should it be equal to the ID of the

threaded hole? If that's the case, the original poster can just use that

value from the screw data. Note that d_major is not equal to the nominal

screw size---or rather, it's a range. So for M6 the spec requires d_major

to be between 6mm and 6.3mm. But subtracting the pitch from the nominal

diameter does seem to put the result in the middle of the inner diameter

range, which is 4.9mm to 5.1mm. Of course, it didn't look to me like the

original poster was interested in tapping machine screws. Another

question: should tapping diameter be different for plastic than for metal?

I think for tapping holes in wood for machine screws one may use a hole

undersized compared to the hole for metal tapping.

On Wed, Nov 3, 2021 at 7:06 AM nop head nop.head@gmail.com wrote:

For metric screws the minor diameter is not nominal minus sqrt(3)

times the pitch. That is the base of the triangle but it is fillited at 5/8

and 1/8. According to Wikipedia it is the major diameter minus 1.082532

times the pitch. Using standard drill sizes, that is close enough to 1

times the pitch.

[image: image.png]

[image: image.png]

On Wed, 3 Nov 2021 at 10:53, Adrian Mariano avm4@cornell.edu wrote:

He didn't say he wanted to do tapped machine screws. So using OD minus

pitch means you're making an assumption about the desired amount of

extra for tapping. The nominal ID will be the diameter mus

sqrt(3)*pitch so by subtracting only the pitch you are implicitly

making the hole larger than the screw ID by sqrt(3)-1 times the pitch,

or about .7 times the pitch. Is that always the right amount of

"extra" to leave for tapping? I don't know the answer. This rule of

thumb will work the same for UTS screws because they have the same

geometry.

On Wed, Nov 3, 2021 at 4:41 AM nop head nop.head@gmail.com wrote:

For metric machine screws the pilot hole for tapping is just the

outer diameter minus the pitch. For self tappers and wood screws I think to

some extent it depends on the material it goes into and its thickness. I

either google it or measure the minor diameter with calipers and use that.

I have some constants for No 2, 4, 6, and 8 screws in my library

but I just noticed No4 and No6 are both 2mm holes and I can't remember why.

The comments do say into soft wood and it must have been the drill I used

making my first Mendel90 out of MDF. It doesn't really matter much into

soft wood but it is more important for printed holes.

I have a small library which generates shapes that are holes for

screws. So I have a table of numbers describing the screws I use. I took

the measurements myself. I want to convert it to use screw_into from BOSL2.

One type of screw hole is for self tapping screws. I assume the

diameter of the hole should be the nominal diameter - a function of the

pitch, presumably a percentage. What should that function be?

FYI, the library specifies a screw hole with

specs - the screw measurements, what I want to get from

gap - space between the bottom of the head and the nut

clearS - clearance on the screw end

clearH - clearance on the head end

pos - one of 6 positions to return the hole in, top of the head,

To the basic screw hole a slot for a captive nut can be added

using the same parameters. The slot can slide a square or hex nut from the

side, or drop in a hex nut longitudinally. The use of the “pos” parameter

makes it easy to position the screw hole properly.

Tolerance parameters are ignored because one doesn't know what they are and

it would be a pain to deal with them. But since the original poster said

he was using BOSL2 and it provides screw dimensions with the actual

tolerances considered, why not use the real screw dimensions?

We were talking about holes, meaning nuts, not screws. An M6 nut must have

an OD larger than its nominal size or it's not ISO compliant. I'm not sure

how you measure the OD of a nut. For machine screws the 6g tolerance

specifies a diameter between 5.797 mm and 5.974mm, but the 8g tolerance

would allow your 5.75mm screws. The dimensions of screws and nuts have to

be different or they wouldn't be able to screw together.

Are wood screws tightly specified, meaning that if I gather #8 wood screws

from 100 manufacturers they are all the same, with the same thread form and

dimensions? I don't see how that can be the case if there isn't a standard

document that we can read that tells us what the wood screw dimensions

are. I see wood screw manufacturers bragging about their superior threads

or other features, which make it sound like everybody is out there doing

their own thing.

Note that for small wood screws like #4 and below, I believe, it is

stronger to tap and use a machine screw than it is to use a wood screw.

I'm not sure exactly at what point that changes, and I imagine it might

depend on the wood species. When I installed my woodworking vise all the

hardware was attached to the wood with tapped holes in the wood using

machine screws (which was how the vise manufacturer specified that it be

done) even for #8 screws. Of course, another advantage of tapping wood for

machine screws is that you can remove and reinstall the item without loss

of holding power, which may not be true for regular wood screws.

On Thu, Nov 4, 2021 at 7:27 AM nop head <nop.head@gmail.com> wrote:

> Well tolerance parameters are ignored when you drill holes for

> tapping, you just use the table I posted. And your previous comment about

> M6 being between 6.0 and 6.3 does not match my experience. All my machine

> screws have an outer thread diameter slightly smaller than nominal. So my

> M6 screws measure 5.75mm.

>

> On Thu, 4 Nov 2021 at 10:35, Adrian Mariano <avm4@cornell.edu> wrote:

>

>> If the ideal tap size is the ID then that value can be used directly from

>> the screw parameters. Note that the ID is not just nominal OD minus

>> pitch*sqrt(3)*5/8 because that ignores the tolerance parameters. An actual

>> nut will have a larger ID than that value.

>>

>> When I referred to wood I was talking about tapping wood for machine

>> screws, not using wood screws in wood.

>>

>> I think self-tapping screws are basically like wood screws, a not very

>> well-specified screw with threads that are supposed to cut their way in.

>>

>>

>> On Thu, Nov 4, 2021 at 4:38 AM nop head <nop.head@gmail.com> wrote:

>>

>>> The ideal tap size for machine screws is the nominal OD minus the pitch

>>> * sqrt(3) * 5 / 8. I.e. the ID of the internal thread. Rounded to the

>>> nearest drill size it is just nominal minus pitch. If the hole was smaller

>>> the tap would tend to bind as it has to widen the hole as well as cutting

>>> the threads. If the hole is too big you get a weak thread because the OD is

>>> too big.

>>>

>>> For self tappers it is more complicated because they are often used in

>>> thin sheets of metal and tables I found online have different values for

>>> different thicknesses. To some extent you are forming the metal, rather

>>> than just cutting it. But for thick materials I just use the thread ID,

>>> which I often measure with calipers or eyeball the drill against the screw.

>>>

>>> Wood screws are more forgiving because they have a tapered point and

>>> wood is soft. So the hole can be considerably undersized or even none at

>>> all.

>>>

>>> On Wed, 3 Nov 2021 at 23:36, Adrian Mariano <avm4@cornell.edu> wrote:

>>>

>>>> Yeah, I forgot about the clipping of the top of the screw profile.

>>>> But what's the ideal tap hole size? Should it be equal to the ID of the

>>>> threaded hole? If that's the case, the original poster can just use that

>>>> value from the screw data. Note that d_major is not equal to the nominal

>>>> screw size---or rather, it's a range. So for M6 the spec requires d_major

>>>> to be between 6mm and 6.3mm. But subtracting the pitch from the nominal

>>>> diameter does seem to put the result in the middle of the inner diameter

>>>> range, which is 4.9mm to 5.1mm. Of course, it didn't look to me like the

>>>> original poster was interested in tapping machine screws. Another

>>>> question: should tapping diameter be different for plastic than for metal?

>>>> I think for tapping holes in wood for machine screws one may use a hole

>>>> undersized compared to the hole for metal tapping.

>>>>

>>>> On Wed, Nov 3, 2021 at 7:06 AM nop head <nop.head@gmail.com> wrote:

>>>>

>>>>> For metric screws the minor diameter is not nominal minus sqrt(3)

>>>>> times the pitch. That is the base of the triangle but it is fillited at 5/8

>>>>> and 1/8. According to Wikipedia it is the major diameter minus 1.082532

>>>>> times the pitch. Using standard drill sizes, that is close enough to 1

>>>>> times the pitch.

>>>>>

>>>>> [image: image.png]

>>>>>

>>>>> [image: image.png]

>>>>>

>>>>> On Wed, 3 Nov 2021 at 10:53, Adrian Mariano <avm4@cornell.edu> wrote:

>>>>>

>>>>>> He didn't say he wanted to do tapped machine screws. So using OD minus

>>>>>> pitch means you're making an assumption about the desired amount of

>>>>>> extra for tapping. The nominal ID will be the diameter mus

>>>>>> sqrt(3)*pitch so by subtracting only the pitch you are implicitly

>>>>>> making the hole larger than the screw ID by sqrt(3)-1 times the pitch,

>>>>>> or about .7 times the pitch. Is that always the right amount of

>>>>>> "extra" to leave for tapping? I don't know the answer. This rule of

>>>>>> thumb will work the same for UTS screws because they have the same

>>>>>> geometry.

>>>>>>

>>>>>> On Wed, Nov 3, 2021 at 4:41 AM nop head <nop.head@gmail.com> wrote:

>>>>>> >

>>>>>> > For metric machine screws the pilot hole for tapping is just the

>>>>>> outer diameter minus the pitch. For self tappers and wood screws I think to

>>>>>> some extent it depends on the material it goes into and its thickness. I

>>>>>> either google it or measure the minor diameter with calipers and use that.

>>>>>> >

>>>>>> > I have some constants for No 2, 4, 6, and 8 screws in my library

>>>>>> but I just noticed No4 and No6 are both 2mm holes and I can't remember why.

>>>>>> The comments do say into soft wood and it must have been the drill I used

>>>>>> making my first Mendel90 out of MDF. It doesn't really matter much into

>>>>>> soft wood but it is more important for printed holes.

>>>>>> >

>>>>>> > On Tue, 2 Nov 2021 at 23:08, <bob@rjcarlson.com> wrote:

>>>>>> >>

>>>>>> >> I have a small library which generates shapes that are holes for

>>>>>> screws. So I have a table of numbers describing the screws I use. I took

>>>>>> the measurements myself. I want to convert it to use screw_into from BOSL2.

>>>>>> >>

>>>>>> >> One type of screw hole is for self tapping screws. I assume the

>>>>>> diameter of the hole should be the nominal diameter - a function of the

>>>>>> pitch, presumably a percentage. What should that function be?

>>>>>> >>

>>>>>> >>

>>>>>> >> FYI, the library specifies a screw hole with

>>>>>> >>

>>>>>> >> specs - the screw measurements, what I want to get from

>>>>>> BOSL2/screws.scad

>>>>>> >>

>>>>>> >> gap - space between the bottom of the head and the nut

>>>>>> >>

>>>>>> >> clearS - clearance on the screw end

>>>>>> >>

>>>>>> >> clearH - clearance on the head end

>>>>>> >>

>>>>>> >> pos - one of 6 positions to return the hole in, top of the head,

>>>>>> middle of gap, etc.

>>>>>> >>

>>>>>> >> To the basic screw hole a slot for a captive nut can be added

>>>>>> using the same parameters. The slot can slide a square or hex nut from the

>>>>>> side, or drop in a hex nut longitudinally. The use of the “pos” parameter

>>>>>> makes it easy to position the screw hole properly.

>>>>>> >>

>>>>>> >> _______________________________________________

>>>>>> >> OpenSCAD mailing list

>>>>>> >> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>>> >

>>>>>> > _______________________________________________

>>>>>> > OpenSCAD mailing list

>>>>>> > To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>>> _______________________________________________

>>>>>> OpenSCAD mailing list

>>>>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>>>

>>>>> _______________________________________________

>>>>> OpenSCAD mailing list

>>>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>>

>>>> _______________________________________________

>>>> OpenSCAD mailing list

>>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>>

>>> _______________________________________________

>>> OpenSCAD mailing list

>>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>>

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

GH

Gene Heskett

Thu, Nov 4, 2021 10:00 PM

On Thursday 04 November 2021 14:20:42 Bob Carlson wrote:

This is very helpful, both of you. I am looking at metric machine

screws only and self tapping in plastic only. Subtracting the pitch

seems like a nice easy heuristic. My background is strictly software,

not mech engineering so this is all new to me. So far I have only

worked with PLA.

I'm gonna get a bit opinionated here. I'm too old at 87 to waste time

argueing.

rant mode on:

PLA is too brittle to self tap into, generally speaking, so if using PLA

I'd consider the hole to be a pilot hole for the proper sized drill, and

then use a quality real carbide cutting tap and faith. You will need

lots of that.

PETG is an entirely different horse. So use PETG if putting threads into

a hole by any means.

Most printers with stock printheads that take the bowden tube clear thru

to the rear of the nozzle will not live long enough to find the optimum

settings for PETG, the capricorn slowly goes away at the 235C+ temps

PETG needs and leakage will destroy your prints by ripping them off the

build plate when the head comes by to lay the next layer and hits the

blob that dripped off the head onto the print and cooled there.

The BIQU BX's H2 head supposedly has a kit that will goto 500C, but no

one is stocking it or listing it for order including BIQU. I've 3 of

those H2 heads I'd like to buy that kit for, all failed and leaking like

a collander by the third print. The only other printer that eats PETG

over the long haul, and I've a room full of them from several makers

that claimed PETG compatability, is the Prusa MK3S kit.

So save your sheckels, get one and spend 3 days building the kit if you

want to use PETG on an everyday basis.

Look for printers that claim to have an E3D or better hot end. They don't

come stock on $150, or even $500 printers, not even on the nearly $2000

Dremel 3d45. The $800 Prusa kit does. With a titanium heat break, it

Just Works as long as you clean the hot nozzle with a brass toothbrush

to start the job every time.

/rant mode off.

I’m going to put together a little test print to check exactly what

tolerances are needed to cleanly drop nuts into holes, etc. I just

finished doing the BOSL2 test print for $slop. Coincidently I randomly

picked t = .1 for my tolerance amount when I first started. I usually

use 2*t for a tab that must insert into a lot and that has worked for

me well enough. Oddly the $slop for my printer turns out to be … .1

mm.

-Bob

Tucson AZ

On Nov 3, 2021, at 04:05, nop head <nop.head@gmail.com

mailto:nop.head@gmail.com> wrote:

For metric screws the minor diameter is not nominal minus sqrt(3)

times the pitch. That is the base of the triangle but it is fillited

at 5/8 and 1/8. According to Wikipedia it is the major diameter minus

1.082532 times the pitch. Using standard drill sizes, that is close

enough to 1 times the pitch.

<image.png>

<image.png>

On Wed, 3 Nov 2021 at 10:53, Adrian Mariano <avm4@cornell.edu

mailto:avm4@cornell.edu> wrote: He didn't say he wanted to do tapped

machine screws. So using OD minus pitch means you're making an

assumption about the desired amount of extra for tapping. The nominal

ID will be the diameter mus

sqrt(3)*pitch so by subtracting only the pitch you are implicitly

making the hole larger than the screw ID by sqrt(3)-1 times the pitch,

or about .7 times the pitch. Is that always the right amount of

"extra" to leave for tapping? I don't know the answer. This rule of

thumb will work the same for UTS screws because they have the same

geometry.

On Wed, Nov 3, 2021 at 4:41 AM nop head <nop.head@gmail.com

For metric machine screws the pilot hole for tapping is just the

outer diameter minus the pitch. For self tappers and wood screws I

think to some extent it depends on the material it goes into and its

thickness. I either google it or measure the minor diameter with

calipers and use that.

I have some constants for No 2, 4, 6, and 8 screws in my library but

I just noticed No4 and No6 are both 2mm holes and I can't remember

why. The comments do say into soft wood and it must have been the

drill I used making my first Mendel90 out of MDF. It doesn't really

matter much into soft wood but it is more important for printed

holes.

On Tue, 2 Nov 2021 at 23:08, <bob@rjcarlson.com

I have a small library which generates shapes that are holes for

screws. So I have a table of numbers describing the screws I use. I

took the measurements myself. I want to convert it to use

screw_into from BOSL2.

One type of screw hole is for self tapping screws. I assume the

diameter of the hole should be the nominal diameter - a function of

the pitch, presumably a percentage. What should that function be?

FYI, the library specifies a screw hole with

specs - the screw measurements, what I want to get from

BOSL2/screws.scad

gap - space between the bottom of the head and the nut

clearS - clearance on the screw end

clearH - clearance on the head end

pos - one of 6 positions to return the hole in, top of the head,

middle of gap, etc.

To the basic screw hole a slot for a captive nut can be added using

the same parameters. The slot can slide a square or hex nut from

the side, or drop in a hex nut longitudinally. The use of the “pos”

parameter makes it easy to position the screw hole properly.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

mailto:discuss-leave@lists.openscad.org

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

On Thursday 04 November 2021 14:20:42 Bob Carlson wrote:

> This is very helpful, both of you. I am looking at metric machine

> screws only and self tapping in plastic only. Subtracting the pitch

> seems like a nice easy heuristic. My background is strictly software,

> not mech engineering so this is all new to me. So far I have only

> worked with PLA.

I'm gonna get a bit opinionated here. I'm too old at 87 to waste time

argueing.

rant mode on:

PLA is too brittle to self tap into, generally speaking, so if using PLA

I'd consider the hole to be a pilot hole for the proper sized drill, and

then use a quality real carbide cutting tap and faith. You will need

lots of that.

PETG is an entirely different horse. So use PETG if putting threads into

a hole by any means.

Most printers with stock printheads that take the bowden tube clear thru

to the rear of the nozzle will not live long enough to find the optimum

settings for PETG, the capricorn slowly goes away at the 235C+ temps

PETG needs and leakage will destroy your prints by ripping them off the

build plate when the head comes by to lay the next layer and hits the

blob that dripped off the head onto the print and cooled there.

The BIQU BX's H2 head supposedly has a kit that will goto 500C, but no

one is stocking it or listing it for order including BIQU. I've 3 of

those H2 heads I'd like to buy that kit for, all failed and leaking like

a collander by the third print. The only other printer that eats PETG

over the long haul, and I've a room full of them from several makers

that claimed PETG compatability, is the Prusa MK3S kit.

So save your sheckels, get one and spend 3 days building the kit if you

want to use PETG on an everyday basis.

Look for printers that claim to have an E3D or better hot end. They don't

come stock on $150, or even $500 printers, not even on the nearly $2000

Dremel 3d45. The $800 Prusa kit does. With a titanium heat break, it

Just Works as long as you clean the hot nozzle with a brass toothbrush

to start the job every time.

/rant mode off.

> I’m going to put together a little test print to check exactly what

> tolerances are needed to cleanly drop nuts into holes, etc. I just

> finished doing the BOSL2 test print for $slop. Coincidently I randomly

> picked t = .1 for my tolerance amount when I first started. I usually

> use 2*t for a tab that must insert into a lot and that has worked for

> me well enough. Oddly the $slop for my printer turns out to be … .1

> mm.

>

> -Bob

> Tucson AZ

>

> On Nov 3, 2021, at 04:05, nop head <nop.head@gmail.com

> <mailto:nop.head@gmail.com>> wrote:

>

> For metric screws the minor diameter is not nominal minus sqrt(3)

> times the pitch. That is the base of the triangle but it is fillited

> at 5/8 and 1/8. According to Wikipedia it is the major diameter minus

> 1.082532 times the pitch. Using standard drill sizes, that is close

> enough to 1 times the pitch.

>

> <image.png>

>

> <image.png>

>

> On Wed, 3 Nov 2021 at 10:53, Adrian Mariano <avm4@cornell.edu

> <mailto:avm4@cornell.edu>> wrote: He didn't say he wanted to do tapped

> machine screws. So using OD minus pitch means you're making an

> assumption about the desired amount of extra for tapping. The nominal

> ID will be the diameter mus

> sqrt(3)*pitch so by subtracting only the pitch you are implicitly

> making the hole larger than the screw ID by sqrt(3)-1 times the pitch,

> or about .7 times the pitch. Is that always the right amount of

> "extra" to leave for tapping? I don't know the answer. This rule of

> thumb will work the same for UTS screws because they have the same

> geometry.

>

> On Wed, Nov 3, 2021 at 4:41 AM nop head <nop.head@gmail.com

<mailto:nop.head@gmail.com>> wrote:

> > For metric machine screws the pilot hole for tapping is just the

> > outer diameter minus the pitch. For self tappers and wood screws I

> > think to some extent it depends on the material it goes into and its

> > thickness. I either google it or measure the minor diameter with

> > calipers and use that.

> >

> > I have some constants for No 2, 4, 6, and 8 screws in my library but

> > I just noticed No4 and No6 are both 2mm holes and I can't remember

> > why. The comments do say into soft wood and it must have been the

> > drill I used making my first Mendel90 out of MDF. It doesn't really

> > matter much into soft wood but it is more important for printed

> > holes.

> >

> > On Tue, 2 Nov 2021 at 23:08, <bob@rjcarlson.com

<mailto:bob@rjcarlson.com>> wrote:

> >> I have a small library which generates shapes that are holes for

> >> screws. So I have a table of numbers describing the screws I use. I

> >> took the measurements myself. I want to convert it to use

> >> screw_into from BOSL2.

> >>

> >> One type of screw hole is for self tapping screws. I assume the

> >> diameter of the hole should be the nominal diameter - a function of

> >> the pitch, presumably a percentage. What should that function be?

> >>

> >>

> >> FYI, the library specifies a screw hole with

> >>

> >> specs - the screw measurements, what I want to get from

> >> BOSL2/screws.scad

> >>

> >> gap - space between the bottom of the head and the nut

> >>

> >> clearS - clearance on the screw end

> >>

> >> clearH - clearance on the head end

> >>

> >> pos - one of 6 positions to return the hole in, top of the head,

> >> middle of gap, etc.

> >>

> >> To the basic screw hole a slot for a captive nut can be added using

> >> the same parameters. The slot can slide a square or hex nut from

> >> the side, or drop in a hex nut longitudinally. The use of the “pos”

> >> parameter makes it easy to position the screw hole properly.

> >>

> >> _______________________________________________

> >> OpenSCAD mailing list

> >> To unsubscribe send an email to discuss-leave@lists.openscad.org

> >> <mailto:discuss-leave@lists.openscad.org>

> >

> > _______________________________________________

> > OpenSCAD mailing list

> > To unsubscribe send an email to discuss-leave@lists.openscad.org

> > <mailto:discuss-leave@lists.openscad.org>

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

> <mailto:discuss-leave@lists.openscad.org>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

> <mailto:discuss-leave@lists.openscad.org>

>

>

>

>

> -Bob

> Tucson AZ

Cheers, Gene Heskett.

--

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page <http://geneslinuxbox.net:6309/gene>

GH

Gene Heskett

Thu, Nov 4, 2021 10:26 PM

On Thursday 04 November 2021 16:50:23 Adrian Mariano wrote:

Tolerance parameters are ignored because one doesn't know what they

are and it would be a pain to deal with them. But since the original

poster said he was using BOSL2 and it provides screw dimensions with

the actual tolerances considered, why not use the real screw

dimensions?

We were talking about holes, meaning nuts, not screws. An M6 nut must

have an OD larger than its nominal size or it's not ISO compliant.

I'm not sure how you measure the OD of a nut. For machine screws the

6g tolerance specifies a diameter between 5.797 mm and 5.974mm, but

the 8g tolerance would allow your 5.75mm screws. The dimensions of

screws and nuts have to be different or they wouldn't be able to screw

together.

Are wood screws tightly specified, meaning that if I gather #8 wood

screws from 100 manufacturers they are all the same, with the same

thread form and dimensions? I don't see how that can be the case if

there isn't a standard document that we can read that tells us what

the wood screw dimensions are. I see wood screw manufacturers

bragging about their superior threads or other features, which make it

sound like everybody is out there doing their own thing.

Absolutely correct. if 100 makers, all will have their own private specs,

if only to get around O.P. patents which there must be hundreds of.

Note that for small wood screws like #4 and below, I believe, it is

stronger to tap and use a machine screw than it is to use a wood

screw. I'm not sure exactly at what point that changes, and I imagine

it might depend on the wood species.

It does, with clear maple and ash being good, mahogany nearly so while

oak might split on a grain boundary. The lower density stuff is often

better off just glued since the glue can penetrate the pores of bass,

balsa or butternut quite easily. But TBT, the only thing I've used

butternut for is as a slightly lighter colored walnut in kitchen cabinet

door panels. No screws there as they slide into slots in the door frame

stiles in otherwise BBLB cabinets in a 1970's national catalog house.

Butternut is actually a kissing cousin of american black walnut, but

about half the weight per cubic foot.

When I installed my woodworking

vise all the hardware was attached to the wood with tapped holes in

the wood using machine screws (which was how the vise manufacturer

specified that it be done) even for #8 screws.

Thats how I did mine too, in std pine legs & 2x4 top, etc.

Of course, another

advantage of tapping wood for machine screws is that you can remove

and reinstall the item without loss of holding power, which may not be

true for regular wood screws.

Unless, when replaceing the same screw in the same hole, the screw is

rotated backwards until it can be felt to have dropped into the old

threads. Sometimes you can get away with it if the new screw is from

the same box as the old one.

Well tolerance parameters are ignored when you drill holes for

tapping, you just use the table I posted. And your previous comment

about M6 being between 6.0 and 6.3 does not match my experience. All

my machine screws have an outer thread diameter slightly smaller

than nominal. So my M6 screws measure 5.75mm.

On Thu, 4 Nov 2021 at 10:35, Adrian Mariano avm4@cornell.edu wrote:

If the ideal tap size is the ID then that value can be used

directly from the screw parameters. Note that the ID is not just

nominal OD minus pitch*sqrt(3)*5/8 because that ignores the

tolerance parameters. An actual nut will have a larger ID than

that value.

When I referred to wood I was talking about tapping wood for

machine screws, not using wood screws in wood.

I think self-tapping screws are basically like wood screws, a not

very well-specified screw with threads that are supposed to cut

their way in.

And requires flexablity in the material surrounding the hole, something

sorely missing from the PLA for printers.

[...]

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

On Thursday 04 November 2021 16:50:23 Adrian Mariano wrote:

> Tolerance parameters are ignored because one doesn't know what they

> are and it would be a pain to deal with them. But since the original

> poster said he was using BOSL2 and it provides screw dimensions with

> the actual tolerances considered, why not use the real screw

> dimensions?

>

> We were talking about holes, meaning nuts, not screws. An M6 nut must

> have an OD larger than its nominal size or it's not ISO compliant.

> I'm not sure how you measure the OD of a nut. For machine screws the

> 6g tolerance specifies a diameter between 5.797 mm and 5.974mm, but

> the 8g tolerance would allow your 5.75mm screws. The dimensions of

> screws and nuts have to be different or they wouldn't be able to screw

> together.

>

> Are wood screws tightly specified, meaning that if I gather #8 wood

> screws from 100 manufacturers they are all the same, with the same

> thread form and dimensions? I don't see how that can be the case if

> there isn't a standard document that we can read that tells us what

> the wood screw dimensions are. I see wood screw manufacturers

> bragging about their superior threads or other features, which make it

> sound like everybody is out there doing their own thing.

Absolutely correct. if 100 makers, all will have their own private specs,

if only to get around O.P. patents which there must be hundreds of.

> Note that for small wood screws like #4 and below, I believe, it is

> stronger to tap and use a machine screw than it is to use a wood

> screw. I'm not sure exactly at what point that changes, and I imagine

> it might depend on the wood species.

It does, with clear maple and ash being good, mahogany nearly so while

oak might split on a grain boundary. The lower density stuff is often

better off just glued since the glue can penetrate the pores of bass,

balsa or butternut quite easily. But TBT, the only thing I've used

butternut for is as a slightly lighter colored walnut in kitchen cabinet

door panels. No screws there as they slide into slots in the door frame

stiles in otherwise BBLB cabinets in a 1970's national catalog house.

Butternut is actually a kissing cousin of american black walnut, but

about half the weight per cubic foot.

> When I installed my woodworking

> vise all the hardware was attached to the wood with tapped holes in

> the wood using machine screws (which was how the vise manufacturer

> specified that it be done) even for #8 screws.

Thats how I did mine too, in std pine legs & 2x4 top, etc.

> Of course, another

> advantage of tapping wood for machine screws is that you can remove

> and reinstall the item without loss of holding power, which may not be

> true for regular wood screws.

Unless, when replaceing the same screw in the same hole, the screw is

rotated backwards until it can be felt to have dropped into the old

threads. Sometimes you can get away with it if the new screw is from

the same box as the old one.

> On Thu, Nov 4, 2021 at 7:27 AM nop head <nop.head@gmail.com> wrote:

> > Well tolerance parameters are ignored when you drill holes for

> > tapping, you just use the table I posted. And your previous comment

> > about M6 being between 6.0 and 6.3 does not match my experience. All

> > my machine screws have an outer thread diameter slightly smaller

> > than nominal. So my M6 screws measure 5.75mm.

> >

> > On Thu, 4 Nov 2021 at 10:35, Adrian Mariano <avm4@cornell.edu> wrote:

> >> If the ideal tap size is the ID then that value can be used

> >> directly from the screw parameters. Note that the ID is not just

> >> nominal OD minus pitch*sqrt(3)*5/8 because that ignores the

> >> tolerance parameters. An actual nut will have a larger ID than

> >> that value.

> >>

> >> When I referred to wood I was talking about tapping wood for

> >> machine screws, not using wood screws in wood.

> >>

> >> I think self-tapping screws are basically like wood screws, a not

> >> very well-specified screw with threads that are supposed to cut

> >> their way in.

And requires flexablity in the material surrounding the hole, something

sorely missing from the PLA for printers.

[...]

Cheers, Gene Heskett.

--

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page <http://geneslinuxbox.net:6309/gene>

BC

Bob Carlson

Thu, Nov 4, 2021 11:43 PM

I have only used self tap screws a couple of times since I noticed how someone else had used them. I use them for parts I do not ever expect to have to disassemble. Perhaps I got lucky with my choice of diameter, but they’ve worked fine in PLA for me so far. They have been M3 or M4. I also put in a 1 mm “pilot” that is full nominal OD.

-Bob

Tucson AZ

On Nov 4, 2021, at 15:26, Gene Heskett gheskett@shentel.net wrote:

On Thursday 04 November 2021 16:50:23 Adrian Mariano wrote:

Tolerance parameters are ignored because one doesn't know what they

are and it would be a pain to deal with them. But since the original

poster said he was using BOSL2 and it provides screw dimensions with

the actual tolerances considered, why not use the real screw

dimensions?

We were talking about holes, meaning nuts, not screws. An M6 nut must

have an OD larger than its nominal size or it's not ISO compliant.

I'm not sure how you measure the OD of a nut. For machine screws the

6g tolerance specifies a diameter between 5.797 mm and 5.974mm, but

the 8g tolerance would allow your 5.75mm screws. The dimensions of

screws and nuts have to be different or they wouldn't be able to screw

together.

Are wood screws tightly specified, meaning that if I gather #8 wood

screws from 100 manufacturers they are all the same, with the same

thread form and dimensions? I don't see how that can be the case if

there isn't a standard document that we can read that tells us what

the wood screw dimensions are. I see wood screw manufacturers

bragging about their superior threads or other features, which make it

sound like everybody is out there doing their own thing.

Absolutely correct. if 100 makers, all will have their own private specs,

if only to get around O.P. patents which there must be hundreds of.

Note that for small wood screws like #4 and below, I believe, it is

stronger to tap and use a machine screw than it is to use a wood

screw. I'm not sure exactly at what point that changes, and I imagine

it might depend on the wood species.

It does, with clear maple and ash being good, mahogany nearly so while

oak might split on a grain boundary. The lower density stuff is often

better off just glued since the glue can penetrate the pores of bass,

balsa or butternut quite easily. But TBT, the only thing I've used

butternut for is as a slightly lighter colored walnut in kitchen cabinet

door panels. No screws there as they slide into slots in the door frame

stiles in otherwise BBLB cabinets in a 1970's national catalog house.

Butternut is actually a kissing cousin of american black walnut, but

about half the weight per cubic foot.

When I installed my woodworking

vise all the hardware was attached to the wood with tapped holes in

the wood using machine screws (which was how the vise manufacturer

specified that it be done) even for #8 screws.

Thats how I did mine too, in std pine legs & 2x4 top, etc.

Of course, another

advantage of tapping wood for machine screws is that you can remove

and reinstall the item without loss of holding power, which may not be

true for regular wood screws.

Unless, when replaceing the same screw in the same hole, the screw is

rotated backwards until it can be felt to have dropped into the old

threads. Sometimes you can get away with it if the new screw is from

the same box as the old one.

Well tolerance parameters are ignored when you drill holes for

tapping, you just use the table I posted. And your previous comment

about M6 being between 6.0 and 6.3 does not match my experience. All

my machine screws have an outer thread diameter slightly smaller

than nominal. So my M6 screws measure 5.75mm.

On Thu, 4 Nov 2021 at 10:35, Adrian Mariano avm4@cornell.edu wrote:

If the ideal tap size is the ID then that value can be used

directly from the screw parameters. Note that the ID is not just

nominal OD minus pitch*sqrt(3)*5/8 because that ignores the

tolerance parameters. An actual nut will have a larger ID than

that value.

When I referred to wood I was talking about tapping wood for

machine screws, not using wood screws in wood.

I think self-tapping screws are basically like wood screws, a not

very well-specified screw with threads that are supposed to cut

their way in.

And requires flexablity in the material surrounding the hole, something

sorely missing from the PLA for printers.

[...]

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

I have only used self tap screws a couple of times since I noticed how someone else had used them. I use them for parts I do not ever expect to have to disassemble. Perhaps I got lucky with my choice of diameter, but they’ve worked fine in PLA for me so far. They have been M3 or M4. I also put in a 1 mm “pilot” that is full nominal OD.

-Bob

Tucson AZ

On Nov 4, 2021, at 15:26, Gene Heskett <gheskett@shentel.net> wrote:

On Thursday 04 November 2021 16:50:23 Adrian Mariano wrote:

> Tolerance parameters are ignored because one doesn't know what they

> are and it would be a pain to deal with them. But since the original

> poster said he was using BOSL2 and it provides screw dimensions with

> the actual tolerances considered, why not use the real screw

> dimensions?

>

> We were talking about holes, meaning nuts, not screws. An M6 nut must

> have an OD larger than its nominal size or it's not ISO compliant.

> I'm not sure how you measure the OD of a nut. For machine screws the

> 6g tolerance specifies a diameter between 5.797 mm and 5.974mm, but

> the 8g tolerance would allow your 5.75mm screws. The dimensions of

> screws and nuts have to be different or they wouldn't be able to screw

> together.

>

> Are wood screws tightly specified, meaning that if I gather #8 wood

> screws from 100 manufacturers they are all the same, with the same

> thread form and dimensions? I don't see how that can be the case if

> there isn't a standard document that we can read that tells us what

> the wood screw dimensions are. I see wood screw manufacturers

> bragging about their superior threads or other features, which make it

> sound like everybody is out there doing their own thing.

Absolutely correct. if 100 makers, all will have their own private specs,

if only to get around O.P. patents which there must be hundreds of.

> Note that for small wood screws like #4 and below, I believe, it is

> stronger to tap and use a machine screw than it is to use a wood

> screw. I'm not sure exactly at what point that changes, and I imagine

> it might depend on the wood species.

It does, with clear maple and ash being good, mahogany nearly so while

oak might split on a grain boundary. The lower density stuff is often

better off just glued since the glue can penetrate the pores of bass,

balsa or butternut quite easily. But TBT, the only thing I've used

butternut for is as a slightly lighter colored walnut in kitchen cabinet

door panels. No screws there as they slide into slots in the door frame

stiles in otherwise BBLB cabinets in a 1970's national catalog house.

Butternut is actually a kissing cousin of american black walnut, but

about half the weight per cubic foot.

> When I installed my woodworking

> vise all the hardware was attached to the wood with tapped holes in

> the wood using machine screws (which was how the vise manufacturer

> specified that it be done) even for #8 screws.

Thats how I did mine too, in std pine legs & 2x4 top, etc.

> Of course, another

> advantage of tapping wood for machine screws is that you can remove

> and reinstall the item without loss of holding power, which may not be

> true for regular wood screws.

Unless, when replaceing the same screw in the same hole, the screw is

rotated backwards until it can be felt to have dropped into the old

threads. Sometimes you can get away with it if the new screw is from

the same box as the old one.

> On Thu, Nov 4, 2021 at 7:27 AM nop head <nop.head@gmail.com> wrote:

>> Well tolerance parameters are ignored when you drill holes for

>> tapping, you just use the table I posted. And your previous comment

>> about M6 being between 6.0 and 6.3 does not match my experience. All

>> my machine screws have an outer thread diameter slightly smaller

>> than nominal. So my M6 screws measure 5.75mm.

>>

>> On Thu, 4 Nov 2021 at 10:35, Adrian Mariano <avm4@cornell.edu> wrote:

>>> If the ideal tap size is the ID then that value can be used

>>> directly from the screw parameters. Note that the ID is not just

>>> nominal OD minus pitch*sqrt(3)*5/8 because that ignores the

>>> tolerance parameters. An actual nut will have a larger ID than

>>> that value.

>>>

>>> When I referred to wood I was talking about tapping wood for

>>> machine screws, not using wood screws in wood.

>>>

>>> I think self-tapping screws are basically like wood screws, a not

>>> very well-specified screw with threads that are supposed to cut

>>> their way in.

And requires flexablity in the material surrounding the hole, something

sorely missing from the PLA for printers.

[...]

Cheers, Gene Heskett.

--

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page <http://geneslinuxbox.net:6309/gene>

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

GH

Gene Heskett

Fri, Nov 5, 2021 12:17 AM

On Thursday 04 November 2021 19:43:32 Bob Carlson wrote:

I have only used self tap screws a couple of times since I noticed how

someone else had used them. I use them for parts I do not ever expect

to have to disassemble. Perhaps I got lucky with my choice of

diameter, but they’ve worked fine in PLA for me so far. They have been

M3 or M4. I also put in a 1 mm “pilot” that is full nominal OD.

That in PLA, might be the salvation. Bears trying for sure. If thick

enough, 2mm deep, on both ends of the hole, anything to relieve the

surface stress where the cracks always start.

-Bob

Tucson AZ

On Nov 4, 2021, at 15:26, Gene Heskett gheskett@shentel.net wrote:

On Thursday 04 November 2021 16:50:23 Adrian Mariano wrote:

Tolerance parameters are ignored because one doesn't know what they

are and it would be a pain to deal with them. But since the

original poster said he was using BOSL2 and it provides screw

dimensions with the actual tolerances considered, why not use the

real screw dimensions?

We were talking about holes, meaning nuts, not screws. An M6 nut

must have an OD larger than its nominal size or it's not ISO

compliant. I'm not sure how you measure the OD of a nut. For

machine screws the 6g tolerance specifies a diameter between 5.797

mm and 5.974mm, but the 8g tolerance would allow your 5.75mm screws.

The dimensions of screws and nuts have to be different or they

wouldn't be able to screw together.

Are wood screws tightly specified, meaning that if I gather #8 wood

screws from 100 manufacturers they are all the same, with the same

thread form and dimensions? I don't see how that can be the case if

there isn't a standard document that we can read that tells us what

the wood screw dimensions are. I see wood screw manufacturers

bragging about their superior threads or other features, which make

it sound like everybody is out there doing their own thing.

Absolutely correct. if 100 makers, all will have their own private

specs, if only to get around O.P. patents which there must be hundreds

of.

Note that for small wood screws like #4 and below, I believe, it is

stronger to tap and use a machine screw than it is to use a wood

screw. I'm not sure exactly at what point that changes, and I

imagine it might depend on the wood species.

It does, with clear maple and ash being good, mahogany nearly so while

oak might split on a grain boundary. The lower density stuff is often

better off just glued since the glue can penetrate the pores of bass,

balsa or butternut quite easily. But TBT, the only thing I've used

butternut for is as a slightly lighter colored walnut in kitchen

cabinet door panels. No screws there as they slide into slots in the

door frame stiles in otherwise BBLB cabinets in a 1970's national

catalog house. Butternut is actually a kissing cousin of american

black walnut, but about half the weight per cubic foot.

When I installed my woodworking

vise all the hardware was attached to the wood with tapped holes in

the wood using machine screws (which was how the vise manufacturer

specified that it be done) even for #8 screws.

Thats how I did mine too, in std pine legs & 2x4 top, etc.

Of course, another

advantage of tapping wood for machine screws is that you can remove

and reinstall the item without loss of holding power, which may not

be true for regular wood screws.

Unless, when replaceing the same screw in the same hole, the screw is

rotated backwards until it can be felt to have dropped into the old

threads. Sometimes you can get away with it if the new screw is from

the same box as the old one.

Well tolerance parameters are ignored when you drill holes for

tapping, you just use the table I posted. And your previous comment

about M6 being between 6.0 and 6.3 does not match my experience.

All my machine screws have an outer thread diameter slightly

smaller than nominal. So my M6 screws measure 5.75mm.

On Thu, 4 Nov 2021 at 10:35, Adrian Mariano avm4@cornell.edu

If the ideal tap size is the ID then that value can be used

directly from the screw parameters. Note that the ID is not just

nominal OD minus pitch*sqrt(3)*5/8 because that ignores the

tolerance parameters. An actual nut will have a larger ID than

that value.

When I referred to wood I was talking about tapping wood for

machine screws, not using wood screws in wood.

I think self-tapping screws are basically like wood screws, a not

very well-specified screw with threads that are supposed to cut

their way in.

And requires flexablity in the material surrounding the hole,

something sorely missing from the PLA for printers.

[...]

Cheers, Gene Heskett.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

On Thursday 04 November 2021 19:43:32 Bob Carlson wrote:

> I have only used self tap screws a couple of times since I noticed how

> someone else had used them. I use them for parts I do not ever expect

> to have to disassemble. Perhaps I got lucky with my choice of

> diameter, but they’ve worked fine in PLA for me so far. They have been

> M3 or M4. I also put in a 1 mm “pilot” that is full nominal OD.

That in PLA, might be the salvation. Bears trying for sure. If thick

enough, 2mm deep, on both ends of the hole, anything to relieve the

surface stress where the cracks always start.

> -Bob

> Tucson AZ

>

>

>

> On Nov 4, 2021, at 15:26, Gene Heskett <gheskett@shentel.net> wrote:

>

> On Thursday 04 November 2021 16:50:23 Adrian Mariano wrote:

> > Tolerance parameters are ignored because one doesn't know what they

> > are and it would be a pain to deal with them. But since the

> > original poster said he was using BOSL2 and it provides screw

> > dimensions with the actual tolerances considered, why not use the

> > real screw dimensions?

> >

> > We were talking about holes, meaning nuts, not screws. An M6 nut

> > must have an OD larger than its nominal size or it's not ISO

> > compliant. I'm not sure how you measure the OD of a nut. For

> > machine screws the 6g tolerance specifies a diameter between 5.797

> > mm and 5.974mm, but the 8g tolerance would allow your 5.75mm screws.

> > The dimensions of screws and nuts have to be different or they

> > wouldn't be able to screw together.

> >

> > Are wood screws tightly specified, meaning that if I gather #8 wood

> > screws from 100 manufacturers they are all the same, with the same

> > thread form and dimensions? I don't see how that can be the case if

> > there isn't a standard document that we can read that tells us what

> > the wood screw dimensions are. I see wood screw manufacturers

> > bragging about their superior threads or other features, which make

> > it sound like everybody is out there doing their own thing.

>

> Absolutely correct. if 100 makers, all will have their own private

> specs, if only to get around O.P. patents which there must be hundreds

> of.

>

> > Note that for small wood screws like #4 and below, I believe, it is

> > stronger to tap and use a machine screw than it is to use a wood

> > screw. I'm not sure exactly at what point that changes, and I

> > imagine it might depend on the wood species.

>

> It does, with clear maple and ash being good, mahogany nearly so while

> oak might split on a grain boundary. The lower density stuff is often

> better off just glued since the glue can penetrate the pores of bass,

> balsa or butternut quite easily. But TBT, the only thing I've used

> butternut for is as a slightly lighter colored walnut in kitchen

> cabinet door panels. No screws there as they slide into slots in the

> door frame stiles in otherwise BBLB cabinets in a 1970's national

> catalog house. Butternut is actually a kissing cousin of american

> black walnut, but about half the weight per cubic foot.

>

> > When I installed my woodworking

> > vise all the hardware was attached to the wood with tapped holes in

> > the wood using machine screws (which was how the vise manufacturer

> > specified that it be done) even for #8 screws.

>

> Thats how I did mine too, in std pine legs & 2x4 top, etc.

>

> > Of course, another

> > advantage of tapping wood for machine screws is that you can remove

> > and reinstall the item without loss of holding power, which may not

> > be true for regular wood screws.

>

> Unless, when replaceing the same screw in the same hole, the screw is

> rotated backwards until it can be felt to have dropped into the old

> threads. Sometimes you can get away with it if the new screw is from

> the same box as the old one.

>

> > On Thu, Nov 4, 2021 at 7:27 AM nop head <nop.head@gmail.com> wrote:

> >> Well tolerance parameters are ignored when you drill holes for

> >> tapping, you just use the table I posted. And your previous comment

> >> about M6 being between 6.0 and 6.3 does not match my experience.

> >> All my machine screws have an outer thread diameter slightly

> >> smaller than nominal. So my M6 screws measure 5.75mm.

> >>

> >> On Thu, 4 Nov 2021 at 10:35, Adrian Mariano <avm4@cornell.edu>

wrote:

> >>> If the ideal tap size is the ID then that value can be used

> >>> directly from the screw parameters. Note that the ID is not just

> >>> nominal OD minus pitch*sqrt(3)*5/8 because that ignores the

> >>> tolerance parameters. An actual nut will have a larger ID than

> >>> that value.

> >>>

> >>> When I referred to wood I was talking about tapping wood for

> >>> machine screws, not using wood screws in wood.

> >>>

> >>> I think self-tapping screws are basically like wood screws, a not

> >>> very well-specified screw with threads that are supposed to cut

> >>> their way in.

>

> And requires flexablity in the material surrounding the hole,

> something sorely missing from the PLA for printers.

>

> [...]

>

> Cheers, Gene Heskett.

Cheers, Gene Heskett.

--

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page <http://geneslinuxbox.net:6309/gene>

BC

Bob Carlson

Sat, Nov 6, 2021 10:45 PM

OK, I have done some test prints of holes for M5 nuts. Nominally these are supposed to be 8mm*4mm. The measured diameter of my nuts is around 7.85.

When the hole is vertical, ie the dimensions of the hole are in the XY plane, nominal plus .05 seems to work with a snug fit and nominal plus .1 definitely works.

If the 8mm dimension is parallel to the Z axis, then nominal plus .25 works, with nominal + .2 giving a very tight fit. To be clear the “top” of the hole is a roof.

I can see possibilities here. One is that the “roof” sags and causes the difference. This might be unavoidable if true. It’s only 4 mm long though.

A second is that my printer is not calibrated well enough so Z dimensions are off a bit.

Third is that the Z dimension is inherently less accurate in this kind of printer (MK3S+) so I just have to deal with it. Unavoidable again.

Thoughts?

Thanks!

-Bob

Tucson AZ

On Nov 4, 2021, at 11:20, Bob Carlson bob@rjcarlson.com wrote:

This is very helpful, both of you. I am looking at metric machine screws only and self tapping in plastic only. Subtracting the pitch seems like a nice easy heuristic. My background is strictly software, not mech engineering so this is all new to me. So far I have only worked with PLA.

I’m going to put together a little test print to check exactly what tolerances are needed to cleanly drop nuts into holes, etc. I just finished doing the BOSL2 test print for $slop. Coincidently I randomly picked t = .1 for my tolerance amount when I first started. I usually use 2*t for a tab that must insert into a lot and that has worked for me well enough. Oddly the $slop for my printer turns out to be … .1 mm.

-Bob

Tucson AZ

On Nov 3, 2021, at 04:05, nop head <nop.head@gmail.com mailto:nop.head@gmail.com> wrote:

For metric screws the minor diameter is not nominal minus sqrt(3) times the pitch. That is the base of the triangle but it is fillited at 5/8 and 1/8. According to Wikipedia it is the major diameter minus 1.082532 times the pitch. Using standard drill sizes, that is close enough to 1 times the pitch.

<image.png>

<image.png>

On Wed, 3 Nov 2021 at 10:53, Adrian Mariano <avm4@cornell.edu mailto:avm4@cornell.edu> wrote:

He didn't say he wanted to do tapped machine screws. So using OD minus

pitch means you're making an assumption about the desired amount of

extra for tapping. The nominal ID will be the diameter mus

sqrt(3)*pitch so by subtracting only the pitch you are implicitly

making the hole larger than the screw ID by sqrt(3)-1 times the pitch,

or about .7 times the pitch. Is that always the right amount of

"extra" to leave for tapping? I don't know the answer. This rule of

thumb will work the same for UTS screws because they have the same

geometry.

On Wed, Nov 3, 2021 at 4:41 AM nop head <nop.head@gmail.com mailto:nop.head@gmail.com> wrote:

For metric machine screws the pilot hole for tapping is just the outer diameter minus the pitch. For self tappers and wood screws I think to some extent it depends on the material it goes into and its thickness. I either google it or measure the minor diameter with calipers and use that.

I have some constants for No 2, 4, 6, and 8 screws in my library but I just noticed No4 and No6 are both 2mm holes and I can't remember why. The comments do say into soft wood and it must have been the drill I used making my first Mendel90 out of MDF. It doesn't really matter much into soft wood but it is more important for printed holes.

On Tue, 2 Nov 2021 at 23:08, <bob@rjcarlson.com mailto:bob@rjcarlson.com> wrote:

I have a small library which generates shapes that are holes for screws. So I have a table of numbers describing the screws I use. I took the measurements myself. I want to convert it to use screw_into from BOSL2.

One type of screw hole is for self tapping screws. I assume the diameter of the hole should be the nominal diameter - a function of the pitch, presumably a percentage. What should that function be?

FYI, the library specifies a screw hole with

specs - the screw measurements, what I want to get from BOSL2/screws.scad

gap - space between the bottom of the head and the nut

clearS - clearance on the screw end

clearH - clearance on the head end

pos - one of 6 positions to return the hole in, top of the head, middle of gap, etc.

To the basic screw hole a slot for a captive nut can be added using the same parameters. The slot can slide a square or hex nut from the side, or drop in a hex nut longitudinally. The use of the “pos” parameter makes it easy to position the screw hole properly.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org mailto:discuss-leave@lists.openscad.org

OK, I have done some test prints of holes for M5 nuts. Nominally these are supposed to be 8mm*4mm. The measured diameter of my nuts is around 7.85.

When the hole is vertical, ie the dimensions of the hole are in the XY plane, nominal plus .05 seems to work with a snug fit and nominal plus .1 definitely works.

If the 8mm dimension is parallel to the Z axis, then nominal plus .25 works, with nominal + .2 giving a very tight fit. To be clear the “top” of the hole is a roof.

I can see possibilities here. One is that the “roof” sags and causes the difference. This might be unavoidable if true. It’s only 4 mm long though.

A second is that my printer is not calibrated well enough so Z dimensions are off a bit.

Third is that the Z dimension is inherently less accurate in this kind of printer (MK3S+) so I just have to deal with it. Unavoidable again.

Thoughts?

Thanks!

-Bob

Tucson AZ

On Nov 4, 2021, at 11:20, Bob Carlson <bob@rjcarlson.com> wrote:

This is very helpful, both of you. I am looking at metric machine screws only and self tapping in plastic only. Subtracting the pitch seems like a nice easy heuristic. My background is strictly software, not mech engineering so this is all new to me. So far I have only worked with PLA.

I’m going to put together a little test print to check exactly what tolerances are needed to cleanly drop nuts into holes, etc. I just finished doing the BOSL2 test print for $slop. Coincidently I randomly picked t = .1 for my tolerance amount when I first started. I usually use 2*t for a tab that must insert into a lot and that has worked for me well enough. Oddly the $slop for my printer turns out to be … .1 mm.

-Bob

Tucson AZ

On Nov 3, 2021, at 04:05, nop head <nop.head@gmail.com <mailto:nop.head@gmail.com>> wrote: