GH

gene heskett

Tue, Apr 9, 2024 11:22 AM

On 4/9/24 06:54, Jon Bondy wrote:

I have used TPU for years, and have not experienced this hardening. Has

anyone else??

Jon

On 4/8/2024 11:33 PM, gene heskett via Discuss wrote:

On 4/8/24 21:46, Todd Allen via Discuss wrote:

I expect TPU, perhaps 95A or a bit softer, ought to be a good choice

for this.

I would question the long term softness of TPU. I figured it would be

ideal to serve as a bumper between the knob on the end of a vise

handle and the hole in the vise screw it ran thru. Nice, when freshly

printed, had the desired effect but a year later it is considerably

harder stuff.

This does not bode well for something I fully expect to last a century

or more with bare hands on it. What I bought and still have half a

roll of, was rated Shore 95. Does anyone have any advice for a more

stable with time product?

The other, less than ideal result was the excess stringing that took

considerable effort to clean up. Magic recipes to control that with

direct drive extruders welcomed.

Thanks all.

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

On 4/9/24 06:54, Jon Bondy wrote:

> I have used TPU for years, and have not experienced this hardening. Has

> anyone else??

>

> Jon

>

> On 4/8/2024 11:33 PM, gene heskett via Discuss wrote:

>> On 4/8/24 21:46, Todd Allen via Discuss wrote:

>>> I expect TPU, perhaps 95A or a bit softer, ought to be a good choice

>>> for this.

>>>

>> I would question the long term softness of TPU. I figured it would be

>> ideal to serve as a bumper between the knob on the end of a vise

>> handle and the hole in the vise screw it ran thru. Nice, when freshly

>> printed, had the desired effect but a year later it is considerably

>> harder stuff.

>>

>> This does not bode well for something I fully expect to last a century

>> or more with bare hands on it. What I bought and still have half a

>> roll of, was rated Shore 95. Does anyone have any advice for a more

>> stable with time product?

The other, less than ideal result was the excess stringing that took

considerable effort to clean up. Magic recipes to control that with

direct drive extruders welcomed.

Thanks all.

Cheers, Gene Heskett, CET.

--

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

JJ

jon jonbondy.com

Tue, Apr 9, 2024 11:38 AM

Stringing can be a problem, but I know that properly set up printers can

minimize this almost to the point of eliminating it. My Prusa MK3 was

perfect. The MK4 is OK, as is the XL, but there can be annoying

surprises. A small torch/flame can be helpful in melting the stringing

away.

Jon

On 4/9/2024 7:22 AM, gene heskett wrote:

On 4/9/24 06:54, Jon Bondy wrote:

I have used TPU for years, and have not experienced this hardening.

Has anyone else??

Jon

On 4/8/2024 11:33 PM, gene heskett via Discuss wrote:

On 4/8/24 21:46, Todd Allen via Discuss wrote:

I expect TPU, perhaps 95A or a bit softer, ought to be a good

choice for this.

I would question the long term softness of TPU. I figured it would

be ideal to serve as a bumper between the knob on the end of a vise

handle and the hole in the vise screw it ran thru. Nice, when

freshly printed, had the desired effect but a year later it is

considerably harder stuff.

This does not bode well for something I fully expect to last a

century or more with bare hands on it. What I bought and still have

half a roll of, was rated Shore 95. Does anyone have any advice for

a more stable with time product?

The other, less than ideal result was the excess stringing that took

considerable effort to clean up. Magic recipes to control that with

direct drive extruders welcomed.

Thanks all.

Cheers, Gene Heskett, CET.

Stringing can be a problem, but I know that properly set up printers can

minimize this almost to the point of eliminating it. My Prusa MK3 was

perfect. The MK4 is OK, as is the XL, but there can be annoying

surprises. A small torch/flame can be helpful in melting the stringing

away.

Jon

On 4/9/2024 7:22 AM, gene heskett wrote:

> On 4/9/24 06:54, Jon Bondy wrote:

>> I have used TPU for years, and have not experienced this hardening.

>> Has anyone else??

>>

>> Jon

>>

>> On 4/8/2024 11:33 PM, gene heskett via Discuss wrote:

>>> On 4/8/24 21:46, Todd Allen via Discuss wrote:

>>>> I expect TPU, perhaps 95A or a bit softer, ought to be a good

>>>> choice for this.

>>>>

>>> I would question the long term softness of TPU. I figured it would

>>> be ideal to serve as a bumper between the knob on the end of a vise

>>> handle and the hole in the vise screw it ran thru. Nice, when

>>> freshly printed, had the desired effect but a year later it is

>>> considerably harder stuff.

>>>

>>> This does not bode well for something I fully expect to last a

>>> century or more with bare hands on it. What I bought and still have

>>> half a roll of, was rated Shore 95. Does anyone have any advice for

>>> a more stable with time product?

>

> The other, less than ideal result was the excess stringing that took

> considerable effort to clean up. Magic recipes to control that with

> direct drive extruders welcomed.

>

> Thanks all.

>

> Cheers, Gene Heskett, CET.

NH

nop head

Tue, Apr 9, 2024 12:12 PM

I have known Filaflex to fall to bits after a while. I switched the Ninja

for TPU and have not had any problems with that.

On Tue, 9 Apr 2024 at 12:39, jon jonbondy.com via Discuss <

discuss@lists.openscad.org> wrote:

Stringing can be a problem, but I know that properly set up printers can

minimize this almost to the point of eliminating it. My Prusa MK3 was

perfect. The MK4 is OK, as is the XL, but there can be annoying

surprises. A small torch/flame can be helpful in melting the stringing

away.

Jon

On 4/9/2024 7:22 AM, gene heskett wrote:

On 4/9/24 06:54, Jon Bondy wrote:

I have used TPU for years, and have not experienced this hardening.

Has anyone else??

Jon

On 4/8/2024 11:33 PM, gene heskett via Discuss wrote:

On 4/8/24 21:46, Todd Allen via Discuss wrote:

I expect TPU, perhaps 95A or a bit softer, ought to be a good

choice for this.

I would question the long term softness of TPU. I figured it would

be ideal to serve as a bumper between the knob on the end of a vise

handle and the hole in the vise screw it ran thru. Nice, when

freshly printed, had the desired effect but a year later it is

considerably harder stuff.

This does not bode well for something I fully expect to last a

century or more with bare hands on it. What I bought and still have

half a roll of, was rated Shore 95. Does anyone have any advice for

a more stable with time product?

The other, less than ideal result was the excess stringing that took

considerable effort to clean up. Magic recipes to control that with

direct drive extruders welcomed.

Thanks all.

Cheers, Gene Heskett, CET.

I have known Filaflex to fall to bits after a while. I switched the Ninja

for TPU and have not had any problems with that.

On Tue, 9 Apr 2024 at 12:39, jon jonbondy.com via Discuss <

discuss@lists.openscad.org> wrote:

> Stringing can be a problem, but I know that properly set up printers can

> minimize this almost to the point of eliminating it. My Prusa MK3 was

> perfect. The MK4 is OK, as is the XL, but there can be annoying

> surprises. A small torch/flame can be helpful in melting the stringing

> away.

>

> Jon

>

> On 4/9/2024 7:22 AM, gene heskett wrote:

> > On 4/9/24 06:54, Jon Bondy wrote:

> >> I have used TPU for years, and have not experienced this hardening.

> >> Has anyone else??

> >>

> >> Jon

> >>

> >> On 4/8/2024 11:33 PM, gene heskett via Discuss wrote:

> >>> On 4/8/24 21:46, Todd Allen via Discuss wrote:

> >>>> I expect TPU, perhaps 95A or a bit softer, ought to be a good

> >>>> choice for this.

> >>>>

> >>> I would question the long term softness of TPU. I figured it would

> >>> be ideal to serve as a bumper between the knob on the end of a vise

> >>> handle and the hole in the vise screw it ran thru. Nice, when

> >>> freshly printed, had the desired effect but a year later it is

> >>> considerably harder stuff.

> >>>

> >>> This does not bode well for something I fully expect to last a

> >>> century or more with bare hands on it. What I bought and still have

> >>> half a roll of, was rated Shore 95. Does anyone have any advice for

> >>> a more stable with time product?

> >

> > The other, less than ideal result was the excess stringing that took

> > considerable effort to clean up. Magic recipes to control that with

> > direct drive extruders welcomed.

> >

> > Thanks all.

> >

> > Cheers, Gene Heskett, CET.

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

JJ

jon jonbondy.com

Tue, Apr 9, 2024 12:13 PM

I have been strictly using NinjaTek Cheetah for the last few years, with good success.

On 4/9/2024 8:12 AM, nop head wrote:

I have known Filaflex to fall to bits after a while. I switched the Ninja for TPU and have not had any problems with that.

On Tue, 9 Apr 2024 at 12:39, jon jonbondy.comhttp://jonbondy.com via Discuss <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org> wrote:

Stringing can be a problem, but I know that properly set up printers can

minimize this almost to the point of eliminating it. My Prusa MK3 was

perfect. The MK4 is OK, as is the XL, but there can be annoying

surprises. A small torch/flame can be helpful in melting the stringing

away.

Jon

On 4/9/2024 7:22 AM, gene heskett wrote:

On 4/9/24 06:54, Jon Bondy wrote:

I have used TPU for years, and have not experienced this hardening.

Has anyone else??

Jon

On 4/8/2024 11:33 PM, gene heskett via Discuss wrote:

On 4/8/24 21:46, Todd Allen via Discuss wrote:

I expect TPU, perhaps 95A or a bit softer, ought to be a good

choice for this.

I would question the long term softness of TPU. I figured it would

be ideal to serve as a bumper between the knob on the end of a vise

handle and the hole in the vise screw it ran thru. Nice, when

freshly printed, had the desired effect but a year later it is

considerably harder stuff.

This does not bode well for something I fully expect to last a

century or more with bare hands on it. What I bought and still have

half a roll of, was rated Shore 95. Does anyone have any advice for

a more stable with time product?

The other, less than ideal result was the excess stringing that took

considerable effort to clean up. Magic recipes to control that with

direct drive extruders welcomed.

Thanks all.

Cheers, Gene Heskett, CET.

I have been strictly using NinjaTek Cheetah for the last few years, with good success.

On 4/9/2024 8:12 AM, nop head wrote:

I have known Filaflex to fall to bits after a while. I switched the Ninja for TPU and have not had any problems with that.

On Tue, 9 Apr 2024 at 12:39, jon jonbondy.com<http://jonbondy.com> via Discuss <discuss@lists.openscad.org<mailto:discuss@lists.openscad.org>> wrote:

Stringing can be a problem, but I know that properly set up printers can

minimize this almost to the point of eliminating it. My Prusa MK3 was

perfect. The MK4 is OK, as is the XL, but there can be annoying

surprises. A small torch/flame can be helpful in melting the stringing

away.

Jon

On 4/9/2024 7:22 AM, gene heskett wrote:

> On 4/9/24 06:54, Jon Bondy wrote:

>> I have used TPU for years, and have not experienced this hardening.

>> Has anyone else??

>>

>> Jon

>>

>> On 4/8/2024 11:33 PM, gene heskett via Discuss wrote:

>>> On 4/8/24 21:46, Todd Allen via Discuss wrote:

>>>> I expect TPU, perhaps 95A or a bit softer, ought to be a good

>>>> choice for this.

>>>>

>>> I would question the long term softness of TPU. I figured it would

>>> be ideal to serve as a bumper between the knob on the end of a vise

>>> handle and the hole in the vise screw it ran thru. Nice, when

>>> freshly printed, had the desired effect but a year later it is

>>> considerably harder stuff.

>>>

>>> This does not bode well for something I fully expect to last a

>>> century or more with bare hands on it. What I bought and still have

>>> half a roll of, was rated Shore 95. Does anyone have any advice for

>>> a more stable with time product?

>

> The other, less than ideal result was the excess stringing that took

> considerable effort to clean up. Magic recipes to control that with

> direct drive extruders welcomed.

>

> Thanks all.

>

> Cheers, Gene Heskett, CET.

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org<mailto:discuss-leave@lists.openscad.org>

GH

gene heskett

Tue, Apr 9, 2024 3:23 PM

On 4/9/24 07:38, jon jonbondy.com wrote:

Stringing can be a problem, but I know that properly set up printers can

minimize this almost to the point of eliminating it. My Prusa MK3 was

perfect. The MK4 is OK, as is the XL, but there can be annoying

surprises. A small torch/flame can be helpful in melting the stringing

away.

Jon

Might be a good hint, bic's long bbq lighters are what I have. I'll

give it a try, thanks. As for the prusa's, I gave up on the mk3s, too

small for my project and I tried several brands of hot ends trying to

stop the leaks and gave up. Never fed it pla, but petg, and the 240C is

too hot for it. 240C is too hot for any hot end using an alu block, the

stuff is too soft to hold the nozzle thread. Best is a QIDI XMAX-3,

gobbles it all once flow is calibrated. A full corexy, no leaks, input

shaper std, 4x faster than the mk3s, near same price at under a kilo$.

325x325 bed. Will be the smallest when I'm done rebuilding 2 other even

bigger printers. An ender5+, and a tronxy-400.

Take care & stay well Jon,

On 4/9/2024 7:22 AM, gene heskett wrote:

On 4/9/24 06:54, Jon Bondy wrote:

I have used TPU for years, and have not experienced this hardening.

Has anyone else??

Jon

On 4/8/2024 11:33 PM, gene heskett via Discuss wrote:

On 4/8/24 21:46, Todd Allen via Discuss wrote:

I expect TPU, perhaps 95A or a bit softer, ought to be a good

choice for this.

I would question the long term softness of TPU. I figured it would

be ideal to serve as a bumper between the knob on the end of a vise

handle and the hole in the vise screw it ran thru. Nice, when

freshly printed, had the desired effect but a year later it is

considerably harder stuff.

This does not bode well for something I fully expect to last a

century or more with bare hands on it. What I bought and still have

half a roll of, was rated Shore 95. Does anyone have any advice for

a more stable with time product?

The other, less than ideal result was the excess stringing that took

considerable effort to clean up. Magic recipes to control that with

direct drive extruders welcomed.

Thanks all.

Cheers, Gene Heskett, CET.

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

On 4/9/24 07:38, jon jonbondy.com wrote:

> Stringing can be a problem, but I know that properly set up printers can

> minimize this almost to the point of eliminating it. My Prusa MK3 was

> perfect. The MK4 is OK, as is the XL, but there can be annoying

> surprises. A small torch/flame can be helpful in melting the stringing

> away.

>

> Jon

>

Might be a good hint, bic's long bbq lighters are what I have. I'll

give it a try, thanks. As for the prusa's, I gave up on the mk3s, too

small for my project and I tried several brands of hot ends trying to

stop the leaks and gave up. Never fed it pla, but petg, and the 240C is

too hot for it. 240C is too hot for any hot end using an alu block, the

stuff is too soft to hold the nozzle thread. Best is a QIDI XMAX-3,

gobbles it all once flow is calibrated. A full corexy, no leaks, input

shaper std, 4x faster than the mk3s, near same price at under a kilo$.

325x325 bed. Will be the smallest when I'm done rebuilding 2 other even

bigger printers. An ender5+, and a tronxy-400.

Take care & stay well Jon,

> On 4/9/2024 7:22 AM, gene heskett wrote:

>> On 4/9/24 06:54, Jon Bondy wrote:

>>> I have used TPU for years, and have not experienced this hardening.

>>> Has anyone else??

>>>

>>> Jon

>>>

>>> On 4/8/2024 11:33 PM, gene heskett via Discuss wrote:

>>>> On 4/8/24 21:46, Todd Allen via Discuss wrote:

>>>>> I expect TPU, perhaps 95A or a bit softer, ought to be a good

>>>>> choice for this.

>>>>>

>>>> I would question the long term softness of TPU. I figured it would

>>>> be ideal to serve as a bumper between the knob on the end of a vise

>>>> handle and the hole in the vise screw it ran thru. Nice, when

>>>> freshly printed, had the desired effect but a year later it is

>>>> considerably harder stuff.

>>>>

>>>> This does not bode well for something I fully expect to last a

>>>> century or more with bare hands on it. What I bought and still have

>>>> half a roll of, was rated Shore 95. Does anyone have any advice for

>>>> a more stable with time product?

>>

>> The other, less than ideal result was the excess stringing that took

>> considerable effort to clean up. Magic recipes to control that with

>> direct drive extruders welcomed.

>>

>> Thanks all.

>>

>> Cheers, Gene Heskett, CET.

Cheers, Gene Heskett, CET.

--

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

GH

gene heskett

Tue, Apr 9, 2024 3:43 PM

On 4/9/24 08:12, nop head wrote:

I have known Filaflex to fall to bits after a while. I switched the

Ninja for TPU and have not had any problems with that.

The roll I have has no label, The only roll of a bright blue I have.

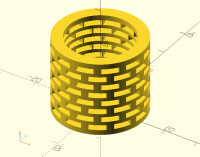

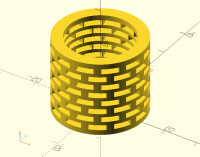

Very glossy stuff on the spool, would need 3 days in a dryer before any

future use. Makes this part: handle_bunper.png, fits 3/4" oak dowel for

vise handle.

On Tue, 9 Apr 2024 at 12:39, jon jonbondy.com http://jonbondy.com via

Discuss <discuss@lists.openscad.org mailto:discuss@lists.openscad.org>

wrote:

Stringing can be a problem, but I know that properly set up printers

can

minimize this almost to the point of eliminating it. My Prusa MK3 was

perfect. The MK4 is OK, as is the XL, but there can be annoying

surprises. A small torch/flame can be helpful in melting the stringing

away.

Jon

On 4/9/2024 7:22 AM, gene heskett wrote:

On 4/9/24 06:54, Jon Bondy wrote:

I have used TPU for years, and have not experienced this hardening.

Has anyone else??

Jon

On 4/8/2024 11:33 PM, gene heskett via Discuss wrote:

On 4/8/24 21:46, Todd Allen via Discuss wrote:

I expect TPU, perhaps 95A or a bit softer, ought to be a good

choice for this.

I would question the long term softness of TPU. I figured it would

be ideal to serve as a bumper between the knob on the end of a

handle and the hole in the vise screw it ran thru. Nice, when

freshly printed, had the desired effect but a year later it is

considerably harder stuff.

This does not bode well for something I fully expect to last a

century or more with bare hands on it. What I bought and still

half a roll of, was rated Shore 95. Does anyone have any

a more stable with time product?

The other, less than ideal result was the excess stringing that took

considerable effort to clean up. Magic recipes to control that with

direct drive extruders welcomed.

Thanks all.

Cheers, Gene Heskett, CET.

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

<mailto:discuss-leave@lists.openscad.org>

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

On 4/9/24 08:12, nop head wrote:

> I have known Filaflex to fall to bits after a while. I switched the

> Ninja for TPU and have not had any problems with that.

>

The roll I have has no label, The only roll of a bright blue I have.

Very glossy stuff on the spool, would need 3 days in a dryer before any

future use. Makes this part: handle_bunper.png, fits 3/4" oak dowel for

vise handle.

> On Tue, 9 Apr 2024 at 12:39, jon jonbondy.com <http://jonbondy.com> via

> Discuss <discuss@lists.openscad.org <mailto:discuss@lists.openscad.org>>

> wrote:

>

> Stringing can be a problem, but I know that properly set up printers

> can

> minimize this almost to the point of eliminating it. My Prusa MK3 was

> perfect. The MK4 is OK, as is the XL, but there can be annoying

> surprises. A small torch/flame can be helpful in melting the stringing

> away.

>

> Jon

>

> On 4/9/2024 7:22 AM, gene heskett wrote:

> > On 4/9/24 06:54, Jon Bondy wrote:

> >> I have used TPU for years, and have not experienced this hardening.

> >> Has anyone else??

> >>

> >> Jon

> >>

> >> On 4/8/2024 11:33 PM, gene heskett via Discuss wrote:

> >>> On 4/8/24 21:46, Todd Allen via Discuss wrote:

> >>>> I expect TPU, perhaps 95A or a bit softer, ought to be a good

> >>>> choice for this.

> >>>>

> >>> I would question the long term softness of TPU. I figured it would

> >>> be ideal to serve as a bumper between the knob on the end of a

> vise

> >>> handle and the hole in the vise screw it ran thru. Nice, when

> >>> freshly printed, had the desired effect but a year later it is

> >>> considerably harder stuff.

> >>>

> >>> This does not bode well for something I fully expect to last a

> >>> century or more with bare hands on it. What I bought and still

> have

> >>> half a roll of, was rated Shore 95. Does anyone have any

> advice for

> >>> a more stable with time product?

> >

> > The other, less than ideal result was the excess stringing that took

> > considerable effort to clean up. Magic recipes to control that with

> > direct drive extruders welcomed.

> >

> > Thanks all.

> >

> > Cheers, Gene Heskett, CET.

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

> <mailto:discuss-leave@lists.openscad.org>

>

Cheers, Gene Heskett, CET.

--

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

JD

John David

Tue, Apr 9, 2024 7:19 PM

If you use a print-head that can do nylon, it should be able to do at least

260C. I have a friend, and I think his print-head was designed to max out

at 300C. Here is a video on a Ender3 running a 300C max print head <

https://www.youtube.com/watch?v=qXUtxt61Ae0>

Hope that helps.

On Tue, Apr 9, 2024 at 11:43 AM gene heskett via Discuss <

discuss@lists.openscad.org> wrote:

On 4/9/24 08:12, nop head wrote:

I have known Filaflex to fall to bits after a while. I switched the

Ninja for TPU and have not had any problems with that.

The roll I have has no label, The only roll of a bright blue I have.

Very glossy stuff on the spool, would need 3 days in a dryer before any

future use. Makes this part: handle_bunper.png, fits 3/4" oak dowel for

vise handle.

wrote:

Stringing can be a problem, but I know that properly set up printers

can

minimize this almost to the point of eliminating it. My Prusa MK3 was

perfect. The MK4 is OK, as is the XL, but there can be annoying

surprises. A small torch/flame can be helpful in melting the

away.

Jon

On 4/9/2024 7:22 AM, gene heskett wrote:

On 4/9/24 06:54, Jon Bondy wrote:

I have used TPU for years, and have not experienced this

Has anyone else??

Jon

On 4/8/2024 11:33 PM, gene heskett via Discuss wrote:

On 4/8/24 21:46, Todd Allen via Discuss wrote:

I expect TPU, perhaps 95A or a bit softer, ought to be a good

choice for this.

I would question the long term softness of TPU. I figured it

be ideal to serve as a bumper between the knob on the end of a

handle and the hole in the vise screw it ran thru. Nice, when

freshly printed, had the desired effect but a year later it is

considerably harder stuff.

This does not bode well for something I fully expect to last a

century or more with bare hands on it. What I bought and still

half a roll of, was rated Shore 95. Does anyone have any

a more stable with time product?

The other, less than ideal result was the excess stringing that

considerable effort to clean up. Magic recipes to control that

direct drive extruders welcomed.

Thanks all.

Cheers, Gene Heskett, CET.

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

<mailto:discuss-leave@lists.openscad.org>

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

If you use a print-head that can do nylon, it should be able to do at least

260C. I have a friend, and I think his print-head was designed to max out

at 300C. Here is a video on a Ender3 running a 300C max print head <

https://www.youtube.com/watch?v=qXUtxt61Ae0>

Hope that helps.

On Tue, Apr 9, 2024 at 11:43 AM gene heskett via Discuss <

discuss@lists.openscad.org> wrote:

> On 4/9/24 08:12, nop head wrote:

> > I have known Filaflex to fall to bits after a while. I switched the

> > Ninja for TPU and have not had any problems with that.

> >

> The roll I have has no label, The only roll of a bright blue I have.

> Very glossy stuff on the spool, would need 3 days in a dryer before any

> future use. Makes this part: handle_bunper.png, fits 3/4" oak dowel for

> vise handle.

>

> > On Tue, 9 Apr 2024 at 12:39, jon jonbondy.com <http://jonbondy.com> via

> > Discuss <discuss@lists.openscad.org <mailto:discuss@lists.openscad.org>>

>

> > wrote:

> >

> > Stringing can be a problem, but I know that properly set up printers

> > can

> > minimize this almost to the point of eliminating it. My Prusa MK3 was

> > perfect. The MK4 is OK, as is the XL, but there can be annoying

> > surprises. A small torch/flame can be helpful in melting the

> stringing

> > away.

> >

> > Jon

> >

> > On 4/9/2024 7:22 AM, gene heskett wrote:

> > > On 4/9/24 06:54, Jon Bondy wrote:

> > >> I have used TPU for years, and have not experienced this

> hardening.

> > >> Has anyone else??

> > >>

> > >> Jon

> > >>

> > >> On 4/8/2024 11:33 PM, gene heskett via Discuss wrote:

> > >>> On 4/8/24 21:46, Todd Allen via Discuss wrote:

> > >>>> I expect TPU, perhaps 95A or a bit softer, ought to be a good

> > >>>> choice for this.

> > >>>>

> > >>> I would question the long term softness of TPU. I figured it

> would

> > >>> be ideal to serve as a bumper between the knob on the end of a

> > vise

> > >>> handle and the hole in the vise screw it ran thru. Nice, when

> > >>> freshly printed, had the desired effect but a year later it is

> > >>> considerably harder stuff.

> > >>>

> > >>> This does not bode well for something I fully expect to last a

> > >>> century or more with bare hands on it. What I bought and still

> > have

> > >>> half a roll of, was rated Shore 95. Does anyone have any

> > advice for

> > >>> a more stable with time product?

> > >

> > > The other, less than ideal result was the excess stringing that

> took

> > > considerable effort to clean up. Magic recipes to control that

> with

> > > direct drive extruders welcomed.

> > >

> > > Thanks all.

> > >

> > > Cheers, Gene Heskett, CET.

> > _______________________________________________

> > OpenSCAD mailing list

> > To unsubscribe send an email to discuss-leave@lists.openscad.org

> > <mailto:discuss-leave@lists.openscad.org>

> >

>

> Cheers, Gene Heskett, CET.

> --

> "There are four boxes to be used in defense of liberty:

> soap, ballot, jury, and ammo. Please use in that order."

> -Ed Howdershelt (Author, 1940)

> If we desire respect for the law, we must first make the law respectable.

> - Louis D. Brandeis

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

TA

Todd Allen

Tue, Apr 9, 2024 9:36 PM

Nice, when freshly printed, had the desired effect but a year later it is

considerably harder stuff.

I suggest trying more brands or varieties. I see variability in all

filament materials even basic PLA but TPU seems to have a wider range of

formulations than most filament materials. I have TPU filaments with

identical shore hardness ratings with widely differing feel with respect to

hardness, flexibility and elasticity. I've only had a single spool of it

though where I have noticed printed objects stiffen over time. Despite the

variability of feel of my TPUs I have been consistently satisfied with

their ruggedness and I expect that will help a lot with an item

intended for wear by a large dog.

On Mon, Apr 8, 2024 at 10:33 PM gene heskett via Discuss <

discuss@lists.openscad.org> wrote:

On 4/8/24 21:46, Todd Allen via Discuss wrote:

I expect TPU, perhaps 95A or a bit softer, ought to be a good choice for

this.

I would question the long term softness of TPU. I figured it would be

ideal to serve as a bumper between the knob on the end of a vise handle

and the hole in the vise screw it ran thru. Nice, when freshly printed,

had the desired effect but a year later it is considerably harder stuff.

This does not bode well for something I fully expect to last a century

or more with bare hands on it. What I bought and still have half a roll

of, was rated Shore 95. Does anyone have any advice for a more stable

with time product?

Thanks all.

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

>Nice, when freshly printed, had the desired effect but a year later it is

considerably harder stuff.

I suggest trying more brands or varieties. I see variability in all

filament materials even basic PLA but TPU seems to have a wider range of

formulations than most filament materials. I have TPU filaments with

identical shore hardness ratings with widely differing feel with respect to

hardness, flexibility and elasticity. I've only had a single spool of it

though where I have noticed printed objects stiffen over time. Despite the

variability of feel of my TPUs I have been consistently satisfied with

their ruggedness and I expect that will help a lot with an item

intended for wear by a large dog.

On Mon, Apr 8, 2024 at 10:33 PM gene heskett via Discuss <

discuss@lists.openscad.org> wrote:

> On 4/8/24 21:46, Todd Allen via Discuss wrote:

> > I expect TPU, perhaps 95A or a bit softer, ought to be a good choice for

> > this.

> >

> I would question the long term softness of TPU. I figured it would be

> ideal to serve as a bumper between the knob on the end of a vise handle

> and the hole in the vise screw it ran thru. Nice, when freshly printed,

> had the desired effect but a year later it is considerably harder stuff.

>

> This does not bode well for something I fully expect to last a century

> or more with bare hands on it. What I bought and still have half a roll

> of, was rated Shore 95. Does anyone have any advice for a more stable

> with time product?

>

> Thanks all.

>

> Cheers, Gene Heskett, CET.

> --

> "There are four boxes to be used in defense of liberty:

> soap, ballot, jury, and ammo. Please use in that order."

> -Ed Howdershelt (Author, 1940)

> If we desire respect for the law, we must first make the law respectable.

> - Louis D. Brandeis

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

TA

Todd Allen

Tue, Apr 9, 2024 10:04 PM

The other, less than ideal result was the excess stringing that took

considerable effort to clean up. Magic recipes to control that with

direct drive extruders welcomed.

Direct drive tends to be much better than bowden tube printheads for TPU.

No anti stringing magic, but some combination of slowing down, reducing

layer height and line width, lowering extrusion temp, tweaking of

retraction distance, speed, wipe and hop ought to fix it. Sometimes

redesigning an object or changing its orientation for printing can help.

Also try more brands of filament as each have different trade offs. In

general I find TPU to be an easy forgiving print material at least when

projects are small enough to not need high flow rates. Some TPUs,

especially the more soft and elastic ones, print very poorly at

typical print speeds and slowing way down can help a lot.

On Tue, Apr 9, 2024 at 6:23 AM gene heskett via Discuss <

discuss@lists.openscad.org> wrote:

On 4/9/24 06:54, Jon Bondy wrote:

I have used TPU for years, and have not experienced this hardening. Has

anyone else??

Jon

On 4/8/2024 11:33 PM, gene heskett via Discuss wrote:

On 4/8/24 21:46, Todd Allen via Discuss wrote:

I expect TPU, perhaps 95A or a bit softer, ought to be a good choice

for this.

I would question the long term softness of TPU. I figured it would be

ideal to serve as a bumper between the knob on the end of a vise

handle and the hole in the vise screw it ran thru. Nice, when freshly

printed, had the desired effect but a year later it is considerably

harder stuff.

This does not bode well for something I fully expect to last a century

or more with bare hands on it. What I bought and still have half a

roll of, was rated Shore 95. Does anyone have any advice for a more

stable with time product?

The other, less than ideal result was the excess stringing that took

considerable effort to clean up. Magic recipes to control that with

direct drive extruders welcomed.

Thanks all.

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

> The other, less than ideal result was the excess stringing that took

considerable effort to clean up. Magic recipes to control that with

direct drive extruders welcomed.

Direct drive tends to be much better than bowden tube printheads for TPU.

No anti stringing magic, but some combination of slowing down, reducing

layer height and line width, lowering extrusion temp, tweaking of

retraction distance, speed, wipe and hop ought to fix it. Sometimes

redesigning an object or changing its orientation for printing can help.

Also try more brands of filament as each have different trade offs. In

general I find TPU to be an easy forgiving print material at least when

projects are small enough to not need high flow rates. Some TPUs,

especially the more soft and elastic ones, print very poorly at

typical print speeds and slowing way down can help a lot.

On Tue, Apr 9, 2024 at 6:23 AM gene heskett via Discuss <

discuss@lists.openscad.org> wrote:

> On 4/9/24 06:54, Jon Bondy wrote:

> > I have used TPU for years, and have not experienced this hardening. Has

> > anyone else??

> >

> > Jon

> >

> > On 4/8/2024 11:33 PM, gene heskett via Discuss wrote:

> >> On 4/8/24 21:46, Todd Allen via Discuss wrote:

> >>> I expect TPU, perhaps 95A or a bit softer, ought to be a good choice

> >>> for this.

> >>>

> >> I would question the long term softness of TPU. I figured it would be

> >> ideal to serve as a bumper between the knob on the end of a vise

> >> handle and the hole in the vise screw it ran thru. Nice, when freshly

> >> printed, had the desired effect but a year later it is considerably

> >> harder stuff.

> >>

> >> This does not bode well for something I fully expect to last a century

> >> or more with bare hands on it. What I bought and still have half a

> >> roll of, was rated Shore 95. Does anyone have any advice for a more

> >> stable with time product?

>

> The other, less than ideal result was the excess stringing that took

> considerable effort to clean up. Magic recipes to control that with

> direct drive extruders welcomed.

>

> Thanks all.

>

> Cheers, Gene Heskett, CET.

> --

> "There are four boxes to be used in defense of liberty:

> soap, ballot, jury, and ammo. Please use in that order."

> -Ed Howdershelt (Author, 1940)

> If we desire respect for the law, we must first make the law respectable.

> - Louis D. Brandeis

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>