BOLS2 Hinge question

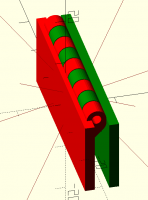

I want the two hinges in this example to have the flat parts lie flat

together, but cannot figure out how to modify the parameters to make

this happen.

// DNG Belly Support

include <BOSL2/std.scad>

include <BOSL2/hinges.scad>

inches = 25.4;

$fn=32;

eps = 0.01;

mw = 125; // max width

// left/middle/right

cX = 2;

cY = 40;

cZ = 15;

pd = 1.9; // pin diameter

module Hinge1h(th)

cuboid([th, cY, cZ])

position(TOP) orient(anchor=RIGHT)

knuckle_hinge(length=35, segs=9, offset=2, arm_height=1,

pin_diam=pd, clear_top=false);

*Hinge1();

module Hinge2h(th)

translate([0, 0, cZ])

rotate([180, 0, 0])

cuboid([th, cY, cZ])

position(TOP+RIGHT) orient(anchor=RIGHT)

knuckle_hinge(length=35, segs=9, offset=2,

arm_height=1, inner=true, pin_diam=pd, clear_top=false);

*Hinge2(th + bt + th);

th = 2; // thickness

bt = 7.2; // board thickness

sthd = 1; // stitch hole diameter

schd = 4; // screw hole diameter

lm = 0; // left mode

mm = 1;

rm = 2;

module Hinged(b, m) {

if (b) {

Hinge1h(cX);

}

else {

Hinge2h(cX);

}

}

color("red") Hinged(true);

color("green")

translate([5, 0, 15])

rotate([180, 0, 180])

Hinged(false);

--

This email has been checked for viruses by AVG antivirus software.

www.avg.com

On 5/11/25 13:53, Jon Bondy via Discuss wrote:

I want the two hinges in this example to have the flat parts lie flat

together, but cannot figure out how to modify the parameters to make

this happen.

In the form of a school lesson, no actual code.

Break it down into individual modules Jon. Start by making a flathead

screw which is the OD of the screw (minus the thread depth if self

threaded, making it with a cylinder of suitable diameter and length to

penetrate whatever the screw is going into, then cap one end of it with

the profile of a flat head screw using a short 2 diameter cylinder with

a short cylinder using an h=,d1=,d2= setting to exactly fill the

thickness of the hinge leaf. Pass a var that will make it as a bolt but

subtracting .45mm so if it is a bolt, its sized to sit with a flush top,

and the underside then matches the cone of a flat head screw. Either

geometry which I'm poor at, didn't get that far in school, or look it up

in the Machinery Handbook. close to 2000 pages of everything.

Then write a module that places 3 or 4 copies of the single bolt, into

the desired pattern.

Then write the module that uses that bolt pattern module, translated &

rotated into position in each leaf. But if its used as a difference in

the leaf add .45mm to the diameter of it all so the bolt sits flush, or

subtract that if actually making the bolt so the recess again fits

flush. might be 75 LOC, and by passing in vars in the calls, can be

totally parametric. I haven't found a limit but have passed as many as

4, either as numerical value or as var names. But above 2 such vars, I

find it difficult to follow a week later, poor short term memory at my age.

Old code:

// DNG Belly Support

include <BOSL2/std.scad>

include <BOSL2/hinges.scad>

inches = 25.4;

$fn=32;

eps = 0.01;

mw = 125; // max width

// left/middle/right

cX = 2;

cY = 40;

cZ = 15;

pd = 1.9; // pin diameter

module Hinge1h(th)

cuboid([th, cY, cZ])

position(TOP) orient(anchor=RIGHT)

knuckle_hinge(length=35, segs=9, offset=2, arm_height=1,

pin_diam=pd, clear_top=false);

*Hinge1();

module Hinge2h(th)

translate([0, 0, cZ])

rotate([180, 0, 0])

cuboid([th, cY, cZ])

position(TOP+RIGHT) orient(anchor=RIGHT)

knuckle_hinge(length=35, segs=9, offset=2,

arm_height=1, inner=true, pin_diam=pd, clear_top=false);

*Hinge2(th + bt + th);

th = 2; // thickness

bt = 7.2; // board thickness

sthd = 1; // stitch hole diameter

schd = 4; // screw hole diameter

lm = 0; // left mode

mm = 1;

rm = 2;

module Hinged(b, m) {

if (b) {

Hinge1h(cX);

}

else {

Hinge2h(cX);

}

}

color("red") Hinged(true);

color("green")

translate([5, 0, 15])

rotate([180, 0, 180])

Hinged(false);

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Hi Jon,

As an exercise ,I've just done it in pythonscad. Not too difficult. It

should be the same in openscad wrt simplicity.

- make a cross-section of the hinge profile, basically a square with a

circle at one end. Make the circle, centred on the origin, say, the diam

of the hole for the pin plus twice the thickness of the leaf (name it d,

say)

2)linear extrude it the length of a hinge leaf, and make leaf1 and

leaf2 equal to that original leaf

3)make, n= the maximum number of segments on one leaf, 5 in your case,

so divide the length by n+n-1, to get to the spacing requirements

Then you need to think about the fitting tolerance, say tol=0.2 (but

test your code by making tol much bigger)

-

using for loops, say, difference a cylinder of diameter d+tol, and

height of tol+(leaf/(n+n-1) through leaf1, and offset by height (more or

less) for leaf2 -

this is not a print in place version

-

if needed add ornamentation, fixing holes, etc.

by drawing a cross section, and linear extrude, you can obviously simply

design cranked or other hinges.

I could post the python scad code if any use, but basically it follows

what I outlined above.

Best wishes,

Ray

On 11/05/2025 18:53, Jon Bondy via Discuss wrote:

I want the two hinges in this example to have the flat parts lie flat

together, but cannot figure out how to modify the parameters to make

this happen.

// DNG Belly Support

include <BOSL2/std.scad>

include <BOSL2/hinges.scad>

inches = 25.4;

$fn=32;

eps = 0.01;

mw = 125; // max width

// left/middle/right

cX = 2;

cY = 40;

cZ = 15;

pd = 1.9; // pin diameter

module Hinge1h(th)

cuboid([th, cY, cZ])

position(TOP) orient(anchor=RIGHT)

knuckle_hinge(length=35, segs=9, offset=2, arm_height=1,

pin_diam=pd, clear_top=false);

*Hinge1();

module Hinge2h(th)

translate([0, 0, cZ])

rotate([180, 0, 0])

cuboid([th, cY, cZ])

position(TOP+RIGHT) orient(anchor=RIGHT)

knuckle_hinge(length=35, segs=9, offset=2,

arm_height=1, inner=true, pin_diam=pd, clear_top=false);

*Hinge2(th + bt + th);

th = 2; // thickness

bt = 7.2; // board thickness

sthd = 1; // stitch hole diameter

schd = 4; // screw hole diameter

lm = 0; // left mode

mm = 1;

rm = 2;

module Hinged(b, m) {

if (b) {

Hinge1h(cX);

}

else {

Hinge2h(cX);

}

}

color("red") Hinged(true);

color("green")

translate([5, 0, 15])

rotate([180, 0, 180])

Hinged(false);

http://www.avg.com/email-signature?utm_medium=email&utm_source=link&utm_campaign=sig-email&utm_content=emailclient

Virus-free.www.avg.com

http://www.avg.com/email-signature?utm_medium=email&utm_source=link&utm_campaign=sig-email&utm_content=emailclient

<#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2>

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

On 5/11/2025 10:53 AM, Jon Bondy via Discuss wrote:

I want the two hinges in this example to have the flat parts lie flat

together, but cannot figure out how to modify the parameters to make

this happen.

I don't immediately see how either.

One key component is that each side needs space for the other side's

"knuckle" to be subtracted from it. It looks like the clear_knuckle

parameter is somehow tied to that, but it's only weakly documented and

doesn't appear to really be implemented.

Note also that to make this happen the hinge pin hole needs to drill

through the part, not just through the hinge. (Or the hinge needs to be

moved so that the hinge pin hole is entirely above the part.)

Here's an attached hinge, simply based on what I mentioned before. If

the reinforcement fillet is required, then it should be simple enough to

alter the profile. Depending on which side of the leaf you want the

fillet, then instead of differencing a cylinder+ tolerance, you'll need

to difference the cylinder+fillet+tolerance. I've not tested by printing

the .obj file, it should be good enough, but I could well have missed

something.

On 13/05/2025 03:29, Jordan Brown via Discuss wrote:

On 5/11/2025 10:53 AM, Jon Bondy via Discuss wrote:

I want the two hinges in this example to have the flat parts lie flat

together, but cannot figure out how to modify the parameters to make

this happen.

I don't immediately see how either.

One key component is that each side needs space for the other side's

"knuckle" to be subtracted from it. It looks like the clear_knuckle

parameter is somehow tied to that, but it's only weakly documented and

doesn't appear to really be implemented.

Note also that to make this happen the hinge pin hole needs to drill

through the part, not just through the hinge. (Or the hinge needs to

be moved so that the hinge pin hole is entirely above the part.)

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

Attached pythonscad script, fwiw

On 13/05/2025 12:49, Raymond West via Discuss wrote:

Here's an attached hinge, simply based on what I mentioned before. If

the reinforcement fillet is required, then it should be simple enough

to alter the profile. Depending on which side of the leaf you want the

fillet, then instead of differencing a cylinder+ tolerance, you'll

need to difference the cylinder+fillet+tolerance. I've not tested by

printing the .obj file, it should be good enough, but I could well

have missed something.

On 13/05/2025 03:29, Jordan Brown via Discuss wrote:

On 5/11/2025 10:53 AM, Jon Bondy via Discuss wrote:

I want the two hinges in this example to have the flat parts lie

flat together, but cannot figure out how to modify the parameters to

make this happen.

I don't immediately see how either.

One key component is that each side needs space for the other side's

"knuckle" to be subtracted from it. It looks like the clear_knuckle

parameter is somehow tied to that, but it's only weakly documented

and doesn't appear to really be implemented.

Note also that to make this happen the hinge pin hole needs to drill

through the part, not just through the hinge. (Or the hinge needs to

be moved so that the hinge pin hole is entirely above the part.)

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

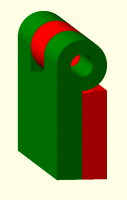

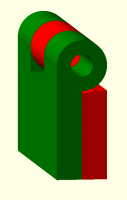

There are lots of ways to attach a hinge to something. To achieve what you

want, you need to design a hinge that has its centerpoint aligned with the

edge of the object it's attached to. Note that such a hinge won't actually

work in reality. You need clearance between the plates. I looked at a

couple real hinges and the expensive one is about 20mm long hinge with a

bit less than 1mm of space between the leaves when they are parallel. The

cheap one had much more space. But here's a way to do what you requested.

I also activated knuckle clearance, which appears to be working fine. How

did it not work for you, Jordan?

include<BOSL2/std.scad>

include<BOSL2/hinges.scad>

$fn=32;

kd=4;

color("green")

diff()

cuboid([20,kd/2,7],anchor=BACK)

position(TOP+BACK)

knuckle_hinge(20, segs=3, offset=kd/2, knuckle_clearance=0.2,

knuckle_diam=kd, arm_angle=90, arm_height=0,

clear_top=true);

color("red")

diff()

cuboid([20,kd/2,7],anchor=FWD)

position(TOP+FWD)

yflip()knuckle_hinge(20, segs=3, offset=kd/2, knuckle_clearance=.2,

inner=true,

knuckle_diam=kd, arm_angle=90, arm_height=0,

clear_top=true);

[image: image.png]

On Sun, May 11, 2025 at 1:53 PM Jon Bondy via Discuss <

discuss@lists.openscad.org> wrote:

I want the two hinges in this example to have the flat parts lie flat

together, but cannot figure out how to modify the parameters to make this

happen.

// DNG Belly Support

include <BOSL2/std.scad>

include <BOSL2/hinges.scad>

inches = 25.4;

$fn=32;

eps = 0.01;

mw = 125; // max width

// left/middle/right

cX = 2;

cY = 40;

cZ = 15;

pd = 1.9; // pin diameter

module Hinge1h(th)

cuboid([th, cY, cZ])

position(TOP) orient(anchor=RIGHT)

knuckle_hinge(length=35, segs=9, offset=2, arm_height=1,

pin_diam=pd, clear_top=false);

*Hinge1();

module Hinge2h(th)

translate([0, 0, cZ])

rotate([180, 0, 0])

cuboid([th, cY, cZ])

position(TOP+RIGHT) orient(anchor=RIGHT)

knuckle_hinge(length=35, segs=9, offset=2,

arm_height=1, inner=true, pin_diam=pd, clear_top=false);

*Hinge2(th + bt + th);

th = 2; // thickness

bt = 7.2; // board thickness

sthd = 1; // stitch hole diameter

schd = 4; // screw hole diameter

lm = 0; // left mode

mm = 1;

rm = 2;

module Hinged(b, m) {

if (b) {

Hinge1h(cX);

}

else {

Hinge2h(cX);

}

}

color("red") Hinged(true);

color("green")

translate([5, 0, 15])

rotate([180, 0, 180])

Hinged(false);

http://www.avg.com/email-signature?utm_medium=email&utm_source=link&utm_campaign=sig-email&utm_content=emailclient

Virus-free.www.avg.com

http://www.avg.com/email-signature?utm_medium=email&utm_source=link&utm_campaign=sig-email&utm_content=emailclient

<#m_-3935134853923460209_DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2>

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Thanks, Adrian. I think this would be a good addition to the hinge

examples.

Jon

On 5/13/2025 4:19 PM, Adrian Mariano via Discuss wrote:

There are lots of ways to attach a hinge to something. To achieve

what you want, you need to design a hinge that has its centerpoint

aligned with the edge of the object it's attached to. Note that such

a hinge won't actually work in reality. You need clearance between the

plates. I looked at a couple real hinges and the expensive one is

about 20mm long hinge with a bit less than 1mm of space between the

leaves when they are parallel. The cheap one had much more space.

But here's a way to do what you requested. I also activated knuckle

clearance, which appears to be working fine. How did it not work for

you, Jordan?

include<BOSL2/std.scad>

include<BOSL2/hinges.scad>

$fn=32;

kd=4;

color("green")

diff()

cuboid([20,kd/2,7],anchor=BACK)

position(TOP+BACK)

knuckle_hinge(20, segs=3, offset=kd/2, knuckle_clearance=0.2,

knuckle_diam=kd, arm_angle=90, arm_height=0,

clear_top=true);

color("red")

diff()

cuboid([20,kd/2,7],anchor=FWD)

position(TOP+FWD)

yflip()knuckle_hinge(20, segs=3, offset=kd/2,

knuckle_clearance=.2, inner=true,

knuckle_diam=kd, arm_angle=90, arm_height=0,

clear_top=true);

image.png

On Sun, May 11, 2025 at 1:53 PM Jon Bondy via Discuss

discuss@lists.openscad.org wrote:

I want the two hinges in this example to have the flat parts lie

flat together, but cannot figure out how to modify the parameters

to make this happen.

// DNG Belly Support

include <BOSL2/std.scad>

include <BOSL2/hinges.scad>

inches = 25.4;

$fn=32;

eps = 0.01;

mw = 125; // max width

// left/middle/right

cX = 2;

cY = 40;

cZ = 15;

pd = 1.9; // pin diameter

module Hinge1h(th)

cuboid([th, cY, cZ])

position(TOP) orient(anchor=RIGHT)

knuckle_hinge(length=35, segs=9, offset=2,

arm_height=1, pin_diam=pd, clear_top=false);

*Hinge1();

module Hinge2h(th)

translate([0, 0, cZ])

rotate([180, 0, 0])

cuboid([th, cY, cZ])

position(TOP+RIGHT) orient(anchor=RIGHT)

knuckle_hinge(length=35, segs=9, offset=2,

arm_height=1, inner=true, pin_diam=pd, clear_top=false);

*Hinge2(th + bt + th);

th = 2; // thickness

bt = 7.2; // board thickness

sthd = 1; // stitch hole diameter

schd = 4; // screw hole diameter

lm = 0; // left mode

mm = 1;

rm = 2;

module Hinged(b, m) {

if (b) {

Hinge1h(cX);

}

else {

Hinge2h(cX);

}

}

color("red") Hinged(true);

color("green")

translate([5, 0, 15])

rotate([180, 0, 180])

Hinged(false);

<http://www.avg.com/email-signature?utm_medium=email&utm_source=link&utm_campaign=sig-email&utm_content=emailclient>

Virus-free.www.avg.com

<http://www.avg.com/email-signature?utm_medium=email&utm_source=link&utm_campaign=sig-email&utm_content=emailclient>

<#m_-3935134853923460209_DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2>

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

--

This email has been checked for viruses by AVG antivirus software.

www.avg.com

On 5/13/2025 1:19 PM, Adrian Mariano via Discuss wrote:

I also activated knuckle clearance, which appears to be working fine.

How did it not work for you, Jordan?

The documentation says clear_knuckle, and does not list

knuckle_clearance. (In the primary parameter list. I do see it now in

the examples.)