Creating inner bevel

Minkowski isn't nearly as slow as it used to be. For reference, the one I showed took 30 seconds to render (using a recent nightly build running on an M1 Mac). I've done this kind of job using complicated negative shapes constructed using cylinders, spheres, rotate_extrude, etc., but not only are methods using hull(), offset(), and (when necessary) minkowski easier to read, but the extra rendering time is nothing compared to the extra design time to make it the old fashioned way.

With the method I showed, you can develop your shape in 2d (with instant previewing) until all of the dimensions are correct, then wait to add (or to activate) the minkowski part until you think everything else is finished.

On Aug 15, 2024, at 15:49, Jordan Brown via Discuss discuss@lists.openscad.org wrote:

There has been a lot of detailed discussion, but little in the way of general discussion of the problem.

There are three basic approaches:

•

Create a 2D shape with holes, extrude it, and somehow (probably with Minkowski) round the corners.

• Create a 3D shape, and a shape that you want removed, and difference the two.

• Create the entire shape as a polyhedron, with the rounding designed in.

Minkowski can be really slow, so I generally don’t consider it. Also, it might be tricky to restrict its effect to the edges that you want rounded.

Creating a polyhedron is very very powerful and can be very very hard. I think BOSL2 might have the tools required to create a polyhedron like this, but I’m not familiar enough to be sure. Maybe Adrian can chime in there.

I would personally think in terms of the second option, subtracting the unwanted shape from the original shape.

Constructing the negative shape can be complex, but is generally straightforward even if tedious. For your oval slots, start with two cylinders joined by a cube.

I’m on my iPad so can’t experiment, but something like

difference() {

cube([50,50,10], center=true);

translate([-10,0,0]) cylinder(h=11, d=10, center=true);

translate([10,0,0]) cylinder(h=11, d=10, center=true);

cube([20,10,11], center=true);

}

That gets you a straight-sided slot. Sculpt it as desired by subtracting stuff from the negative piece. Note, for instance, that a cylinder is a rotationally-extruded square, so if you want round edges at the ends you might take a square, subtract a circle along one edge, and rotationally extrude that. Similarly, the cube in the middle is an extruded square, so take a square, subtract circles on each side, and extrude that. However you construct it, when you have your negative “die”, subtract it from the main object. Always remember to make the negative object a little thicker than the original, so that it protrudes from both sides.

If there is interest, I’ll write up a demo snippet in a few days when I get back to my desktop computer.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

My previous example, is additive, i.e, have a basic shape and add on

fillets, etc. That means, if you are wanting to deal with the overall

size, which is generally true, than the radius has to be taken off the

outside edges, and added to internal edges.

For shapes such as have been shown, then simple maths suffices, but more

complex shapes offset can be used. But Minkowski can be slow, as you

say, certainly at high resolution and complex profiles. The rounded

chamfers are the problem. For more basic shapes, boxes, etc., then I

generate a profile strip and difference with the edges. A question of

finding the best solution for a particular problem, one size does not

fit all, so to speak.

You can generate a profile, the negative of a sphere, and generate

'holes' in shapes such that when differenced will leave a rounded edge.

I've attached a bit of code. The advantage is that no maths is needed to

subtract the radius. The disadvantage is that Minkowski is much slower

with the complex profile, overall it is cumbersome, and often it breaks

the mesh when differencing.

The way in which I believe most folk think wrt rounding edges, is that

you start off with square edges, and remove the sharp edges. Bare

openscad can not do that easily. However there are plenty of other

software tools that can. In reality, it is often more expedient to

mechanically finish the object, files, emery-cloth, whatever. Possibly a

woodworker would think differently, since they often glue on mouldings.

d=10;

$fn=80;

module profile(){

rotate_extrude(){

difference(){

translate([-d/2,0])

square(d);

translate([0.01+d/2,d/2])

circle(d=d);

translate([-d-d,0]) //cut off lhs

square(d+d);

}

}

}

// profile();

module shape(){

linear_extrude(0.001){

difference(){

square (100);

translate([25,25]) square(50);

}

}

}

module stamp(){

minkowski(){

shape();

profile();

}

}

stamp();

On 15/08/2024 23:49, Jordan Brown via Discuss wrote:

There has been a lot of detailed discussion, but little in the way of

general discussion of the problem.

There are three basic approaches:

- Create a 2D shape with holes, extrude it, and somehow (probably

with Minkowski) round the corners. - Create a 3D shape, and a shape that you want removed, and

difference the two. - Create the entire shape as a polyhedron, with the rounding

designed in.

Minkowski can be really slow, so I generally don’t consider it. Also,

it might be tricky to restrict its effect to the edges that you want

rounded.

Creating a polyhedron is very very powerful and can be very very hard.

I think BOSL2 might have the tools required to create a polyhedron

like this, but I’m not familiar enough to be sure. Maybe Adrian can

chime in there.

I would personally think in terms of the second option, subtracting

the unwanted shape from the original shape.

Constructing the negative shape can be complex, but is generally

straightforward even if tedious. For your oval slots, start with two

cylinders joined by a cube.

I’m on my iPad so can’t experiment, but something like

difference() {

cube([50,50,10], center=true);

translate([-10,0,0]) cylinder(h=11, d=10, center=true);

translate([10,0,0]) cylinder(h=11, d=10, center=true);

cube([20,10,11], center=true);

}

That gets you a straight-sided slot. Sculpt it as desired by

subtracting stuff from the negative piece. Note, for instance, that a

cylinder is a rotationally-extruded square, so if you want round edges

at the ends you might take a square, subtract a circle along one edge,

and rotationally extrude that. Similarly, the cube in the middle is an

extruded square, so take a square, subtract circles on each side, and

extrude that. However you construct it, when you have your negative

“die”, subtract it from the main object. Always remember to make the

negative object a little thicker than the original, so that it

protrudes from both sides.

If there is interest, I’ll write up a demo snippet in a few days when

I get back to my desktop computer.

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

Yes, the size issue is interesting. I think what you said earlier about

reducing my size by the radius seems to be working. Originally my part was

created with Bols2 using the 3d library. I could not find a way to get the

inner rounded edges. I have now switched to Bols2 2D and the Minkowski as

suggested but wow is it ever slow. I increased my facets to 90 and my part

has been compiling for at least 30 minutes. I want to do a test print of

the first few layers to make sure the size is right. Interesting that you

suggested using two cylinders and a cube for the inside. I did the same

using 2 circles and a square in 2d then extruding.

My part is almost complete. I would like to share the code to see what

others would suggest in the future. I always welcome a better way. Is

anyone interested in seeing it?

On Fri, Aug 16, 2024 at 8:19 AM Raymond West via Discuss <

discuss@lists.openscad.org> wrote:

My previous example, is additive, i.e, have a basic shape and add on

fillets, etc. That means, if you are wanting to deal with the overall size,

which is generally true, than the radius has to be taken off the outside

edges, and added to internal edges.

For shapes such as have been shown, then simple maths suffices, but more

complex shapes offset can be used. But Minkowski can be slow, as you say,

certainly at high resolution and complex profiles. The rounded chamfers are

the problem. For more basic shapes, boxes, etc., then I generate a profile

strip and difference with the edges. A question of finding the best

solution for a particular problem, one size does not fit all, so to speak.

You can generate a profile, the negative of a sphere, and generate 'holes'

in shapes such that when differenced will leave a rounded edge. I've

attached a bit of code. The advantage is that no maths is needed to

subtract the radius. The disadvantage is that Minkowski is much slower with

the complex profile, overall it is cumbersome, and often it breaks the

mesh when differencing.

The way in which I believe most folk think wrt rounding edges, is that you

start off with square edges, and remove the sharp edges. Bare openscad can

not do that easily. However there are plenty of other software tools that

can. In reality, it is often more expedient to mechanically finish the

object, files, emery-cloth, whatever. Possibly a woodworker would think

differently, since they often glue on mouldings.

d=10;

$fn=80;

module profile(){

rotate_extrude(){

difference(){

translate([-d/2,0])

square(d);

translate([0.01+d/2,d/2])

circle(d=d);

translate([-d-d,0]) //cut off lhs

square(d+d);

}

}

}

// profile();

module shape(){

linear_extrude(0.001){

difference(){

square (100);

translate([25,25]) square(50);

}

}

}

module stamp(){

minkowski(){

shape();

profile();

}

}

stamp();

On 15/08/2024 23:49, Jordan Brown via Discuss wrote:

There has been a lot of detailed discussion, but little in the way of

general discussion of the problem.

There are three basic approaches:

- Create a 2D shape with holes, extrude it, and somehow (probably with

Minkowski) round the corners.

- Create a 3D shape, and a shape that you want removed, and difference

the two.

- Create the entire shape as a polyhedron, with the rounding designed

in.

Minkowski can be really slow, so I generally don’t consider it. Also, it

might be tricky to restrict its effect to the edges that you want rounded.

Creating a polyhedron is very very powerful and can be very very hard. I

think BOSL2 might have the tools required to create a polyhedron like this,

but I’m not familiar enough to be sure. Maybe Adrian can chime in there.

I would personally think in terms of the second option, subtracting the

unwanted shape from the original shape.

Constructing the negative shape can be complex, but is generally

straightforward even if tedious. For your oval slots, start with two

cylinders joined by a cube.

I’m on my iPad so can’t experiment, but something like

difference() {

cube([50,50,10], center=true);

translate([-10,0,0]) cylinder(h=11, d=10, center=true);

translate([10,0,0]) cylinder(h=11, d=10, center=true);

cube([20,10,11], center=true);

}

That gets you a straight-sided slot. Sculpt it as desired by subtracting

stuff from the negative piece. Note, for instance, that a cylinder is a

rotationally-extruded square, so if you want round edges at the ends you

might take a square, subtract a circle along one edge, and rotationally

extrude that. Similarly, the cube in the middle is an extruded square, so

take a square, subtract circles on each side, and extrude that. However you

construct it, when you have your negative “die”, subtract it from the main

object. Always remember to make the negative object a little thicker than

the original, so that it protrudes from both sides.

If there is interest, I’ll write up a demo snippet in a few days when I

get back to my desktop computer.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

you can set $fn =20 for testing, see if it looks OK. Minkowski is then

fairly quick. When you have it looking right, then set $fn to 100, say,

for the final stl, and come back after lunch.

If it is only an stl that you want, it used to be you could feed the

scad file into AngelCad, and it used to produce an stl quite quickly.

I'm not sure if openscad has caught up wrt speed, or even if AngelCAD

accepts minkowski. Freecad can also import scad files and render. It

allows individual edges to be selected for filleting. It tends to export

back to openscad as a large polyhedron, you lose the individual cubes

and cylinders, etc. fwiw, bevels are better for printing, not round-overs.

On 16/08/2024 13:46, Michael Zimbaro via Discuss wrote:

Yes, the size issue is interesting. I think what you said earlier

about reducing my size by the radius seems to be working. Originally

my part was created with Bols2 using the 3d library. I could not find

a way to get the inner rounded edges. I have now switched to Bols2 2D

and the Minkowski as suggested but wow is it ever slow. I increased

my facets to 90 and my part has been compiling for at least 30

minutes. I want to do a test print of the first few layers to make

sure the size is right. Interesting that you suggested using two

cylinders and a cube for the inside. I did the same using 2 circles

and a square in 2d then extruding.

My part is almost complete. I would like to share the code to see

what others would suggest in the future. I always welcome a better

way. Is anyone interested in seeing it?

On Fri, Aug 16, 2024 at 8:19 AM Raymond West via Discuss

discuss@lists.openscad.org wrote:

My previous example, is additive, i.e, have a basic shape and add

on fillets, etc. That means, if you are wanting to deal with the

overall size, which is generally true, than the radius has to be

taken off the outside edges, and added to internal edges.

For shapes such as have been shown, then simple maths suffices,

but more complex shapes offset can be used. But Minkowski can be

slow, as you say, certainly at high resolution and complex

profiles. The rounded chamfers are the problem. For more basic

shapes, boxes, etc., then I generate a profile strip and

difference with the edges. A question of finding the best solution

for a particular problem, one size does not fit all, so to speak.

You can generate a profile, the negative of a sphere, and generate

'holes' in shapes such that when differenced will leave a rounded

edge. I've attached a bit of code. The advantage is that no maths

is needed to subtract the radius. The disadvantage is that

Minkowski is much slower with the complex profile, overall it is

cumbersome, and often it breaks the mesh when differencing.

The way in which I believe most folk think wrt rounding edges, is

that you start off with square edges, and remove the sharp edges.

Bare openscad can not do that easily. However there are plenty of

other software tools that can. In reality, it is often more

expedient to mechanically finish the object, files, emery-cloth,

whatever. Possibly a woodworker would think differently, since

they often glue on mouldings.

d=10;

$fn=80;

module profile(){

rotate_extrude(){

difference(){

translate([-d/2,0])

square(d);

translate([0.01+d/2,d/2])

circle(d=d);

translate([-d-d,0]) //cut off lhs

square(d+d);

}

}

}

// profile();

module shape(){

linear_extrude(0.001){

difference(){

square (100);

translate([25,25]) square(50);

}

}

}

module stamp(){

minkowski(){

shape();

profile();

}

}

stamp();

On 15/08/2024 23:49, Jordan Brown via Discuss wrote:

There has been a lot of detailed discussion, but little in the

way of general discussion of the problem.

There are three basic approaches:

* Create a 2D shape with holes, extrude it, and somehow

(probably with Minkowski) round the corners.

* Create a 3D shape, and a shape that you want removed, and

difference the two.

* Create the entire shape as a polyhedron, with the rounding

designed in.

Minkowski can be really slow, so I generally don’t consider it.

Also, it might be tricky to restrict its effect to the edges that

you want rounded.

Creating a polyhedron is very very powerful and can be very very

hard. I think BOSL2 might have the tools required to create a

polyhedron like this, but I’m not familiar enough to be sure.

Maybe Adrian can chime in there.

I would personally think in terms of the second option,

subtracting the unwanted shape from the original shape.

Constructing the negative shape can be complex, but is generally

straightforward even if tedious. For your oval slots, start with

two cylinders joined by a cube.

I’m on my iPad so can’t experiment, but something like

difference() {

cube([50,50,10], center=true);

translate([-10,0,0]) cylinder(h=11, d=10, center=true);

translate([10,0,0]) cylinder(h=11, d=10, center=true);

cube([20,10,11], center=true);

}

That gets you a straight-sided slot. Sculpt it as desired by

subtracting stuff from the negative piece. Note, for instance,

that a cylinder is a rotationally-extruded square, so if you want

round edges at the ends you might take a square, subtract a

circle along one edge, and rotationally extrude that. Similarly,

the cube in the middle is an extruded square, so take a square,

subtract circles on each side, and extrude that. However you

construct it, when you have your negative “die”, subtract it from

the main object. Always remember to make the negative object a

little thicker than the original, so that it protrudes from both

sides.

If there is interest, I’ll write up a demo snippet in a few days

when I get back to my desktop computer.

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

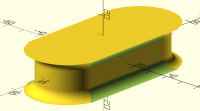

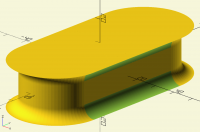

You might want to take a look at https://learn.cadhub.xyz/docs/round-anything/api-reference/#polyround

The library can round a path with square corners with variable radii. For this, you add the radius as the z coordinate in a 3vec. It can then extrude this path with a radius at the end. For the outer component you can use a positive radius for the under and top side. You can then make the inner shapes the same way and subtract them. However, you can then make the radii of the ends negative, which leaves a nice round shape.

The library could use some love. If your path contains undef it will hang ... :-( (Surprised OpenSCAD does not run the rendering in a background thread?) This is the function of the val() routine, to check this.

The quickly hacked together code.

use <lib/Round-Anything/polyround.scad>

$fn=50;

function val(p) = [for(i=p) assert( ! (is_undef(i.x) || is_undef(i.y)|| is_undef(i.y)))];

rect=[60,60];

round=[140,20];

a = 20;

/*

-rect.x/2 rect.x/2

a----------------b rect.y/2

| |

m-----n c-----d round.y

/ \

l+ + e

\ /

k-----j g-----f 0

| |

| |

i----------------h -rect.y/2

0

*/

l = -rect.x/2;

r = -l;

t = rect.y/2;

b = -t;

path = [

[l, t, 5], // a

[r, t, 5], // b

[r, round.y, 5], // c

[round.x/2-round.y, round.y, 5], // d

[round.x/2, round.y/2, round.y], // e

[round.x/2-round.y, 0, round.y], // f

[r, 0, 5], // g

[r, b, 5], // h

[l, b, 5], // i

[l, 0, 5], // j

[-round.x/2+round.y, 0, 5], // k

[-round.x/2, round.y/2, round.y], // l

[-round.x/2+round.y, round.y, round.y], // m

[l, round.y, 5], // n

];

function exclude( w, h ) = let(

adj = h/2,

path = [

[-w/2,0,adj],

[-w/2+adj,h/2,adj],

[w/2-adj,h/2,adj],

[w/2,0,adj],

[w/2-adj,-h/2,adj],

[-w/2+adj,-h/2,adj],

],

) path;

x=val(path);

difference() {

polyRoundExtrude(path,r1=2, r2=2);

translate([-round.x/2+30,10,0]) polyRoundExtrude(exclude(25,5),r1=-2, r2=-2);

translate([round.x/2-30,10,0]) polyRoundExtrude(exclude(25,5),r1=-2, r2=-2);

translate([0,10,0]) polyRoundExtrude(exclude(40,8),r1=-2, r2=-2);

translate([0,-10,0]) polyRoundExtrude(exclude(40,8),r1=-2, r2=-2);

}

On 16 Aug 2024, at 15:45, Raymond West via Discuss discuss@lists.openscad.org wrote:

you can set $fn =20 for testing, see if it looks OK. Minkowski is then fairly quick. When you have it looking right, then set $fn to 100, say, for the final stl, and come back after lunch.

If it is only an stl that you want, it used to be you could feed the scad file into AngelCad, and it used to produce an stl quite quickly. I'm not sure if openscad has caught up wrt speed, or even if AngelCAD accepts minkowski. Freecad can also import scad files and render. It allows individual edges to be selected for filleting. It tends to export back to openscad as a large polyhedron, you lose the individual cubes and cylinders, etc. fwiw, bevels are better for printing, not round-overs.

On 16/08/2024 13:46, Michael Zimbaro via Discuss wrote:

Yes, the size issue is interesting. I think what you said earlier about reducing my size by the radius seems to be working. Originally my part was created with Bols2 using the 3d library. I could not find a way to get the inner rounded edges. I have now switched to Bols2 2D and the Minkowski as suggested but wow is it ever slow. I increased my facets to 90 and my part has been compiling for at least 30 minutes. I want to do a test print of the first few layers to make sure the size is right. Interesting that you suggested using two cylinders and a cube for the inside. I did the same using 2 circles and a square in 2d then extruding.

My part is almost complete. I would like to share the code to see what others would suggest in the future. I always welcome a better way. Is anyone interested in seeing it?

On Fri, Aug 16, 2024 at 8:19 AM Raymond West via Discuss <discuss@lists.openscad.org mailto:discuss@lists.openscad.org> wrote:

My previous example, is additive, i.e, have a basic shape and add on fillets, etc. That means, if you are wanting to deal with the overall size, which is generally true, than the radius has to be taken off the outside edges, and added to internal edges.

For shapes such as have been shown, then simple maths suffices, but more complex shapes offset can be used. But Minkowski can be slow, as you say, certainly at high resolution and complex profiles. The rounded chamfers are the problem. For more basic shapes, boxes, etc., then I generate a profile strip and difference with the edges. A question of finding the best solution for a particular problem, one size does not fit all, so to speak.

You can generate a profile, the negative of a sphere, and generate 'holes' in shapes such that when differenced will leave a rounded edge. I've attached a bit of code. The advantage is that no maths is needed to subtract the radius. The disadvantage is that Minkowski is much slower with the complex profile, overall it is cumbersome, and often it breaks the mesh when differencing.

The way in which I believe most folk think wrt rounding edges, is that you start off with square edges, and remove the sharp edges. Bare openscad can not do that easily. However there are plenty of other software tools that can. In reality, it is often more expedient to mechanically finish the object, files, emery-cloth, whatever. Possibly a woodworker would think differently, since they often glue on mouldings.

d=10;

$fn=80;

module profile(){

rotate_extrude(){

difference(){

translate([-d/2,0])

square(d);

translate([0.01+d/2,d/2])

circle(d=d);

translate([-d-d,0]) //cut off lhs

square(d+d);

}

}

}

// profile();

module shape(){

linear_extrude(0.001){

difference(){

square (100);

translate([25,25]) square(50);

}

}

}

module stamp(){

minkowski(){

shape();

profile();

}

}

stamp();

On 15/08/2024 23:49, Jordan Brown via Discuss wrote:

There has been a lot of detailed discussion, but little in the way of general discussion of the problem.

There are three basic approaches:

Create a 2D shape with holes, extrude it, and somehow (probably with Minkowski) round the corners.

Create a 3D shape, and a shape that you want removed, and difference the two.

Create the entire shape as a polyhedron, with the rounding designed in.

Minkowski can be really slow, so I generally don’t consider it. Also, it might be tricky to restrict its effect to the edges that you want rounded.

Creating a polyhedron is very very powerful and can be very very hard. I think BOSL2 might have the tools required to create a polyhedron like this, but I’m not familiar enough to be sure. Maybe Adrian can chime in there.

I would personally think in terms of the second option, subtracting the unwanted shape from the original shape.

Constructing the negative shape can be complex, but is generally straightforward even if tedious. For your oval slots, start with two cylinders joined by a cube.

I’m on my iPad so can’t experiment, but something like

difference() {

cube([50,50,10], center=true);

translate([-10,0,0]) cylinder(h=11, d=10, center=true);

translate([10,0,0]) cylinder(h=11, d=10, center=true);

cube([20,10,11], center=true);

}

That gets you a straight-sided slot. Sculpt it as desired by subtracting stuff from the negative piece. Note, for instance, that a cylinder is a rotationally-extruded square, so if you want round edges at the ends you might take a square, subtract a circle along one edge, and rotationally extrude that. Similarly, the cube in the middle is an extruded square, so take a square, subtract circles on each side, and extrude that. However you construct it, when you have your negative “die”, subtract it from the main object. Always remember to make the negative object a little thicker than the original, so that it protrudes from both sides.

If there is interest, I’ll write up a demo snippet in a few days when I get back to my desktop computer.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org mailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org mailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org mailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

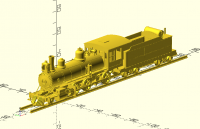

Oh, I love Round-Anything's polyRound() module...

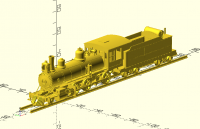

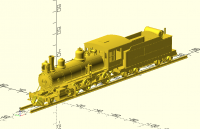

I modeled a complete steam locomotive with it, using it 83 times to make

the rounded shapes 1880's steam locomotive designers so loved:

On 8/16/2024 8:55 AM, Peter Kriens via Discuss wrote:

You might want to take a look at

https://learn.cadhub.xyz/docs/round-anything/api-reference/#polyround

PastedGraphic-1.png

The library can round a path with square corners with variable radii.

For this, you add the radius as the z coordinate in a 3vec. It can

then extrude this path with a radius at the end. For the outer

component you can use a positive radius for the under and top side.

You can then make the inner shapes the same way and subtract them.

However, you can then make the radii of the ends negative, which

leaves a nice round shape.

The library could use some love. If your path contains undef it will

hang ... :-( (Surprised OpenSCAD does not run the rendering in a

background thread?) This is the function of the val() routine, to

check this.

The quickly hacked together code.

use <lib/Round-Anything/polyround.scad>

$fn=50;

function val(p) = [for(i=p) assert( ! (is_undef(i.x) ||

is_undef(i.y)|| is_undef(i.y)))];

rect=[60,60];

round=[140,20];

a = 20;

/*

-rect.x/2 rect.x/2

a----------------b rect.y/2

| |

m-----n c-----d round.y

/ \

l+ + e

\ /

k-----j g-----f 0

| |

| |

i----------------h -rect.y/2

0

*/

l = -rect.x/2;

r = -l;

t = rect.y/2;

b = -t;

path = [

[l, t, 5], // a

[r, t, 5], // b

[r, round.y, 5], // c

[round.x/2-round.y, round.y, 5], // d

[round.x/2, round.y/2, round.y], // e

[round.x/2-round.y, 0, round.y], // f

[r, 0, 5], // g

[r, b, 5], // h

[l, b, 5], // i

[l, 0, 5], // j

[-round.x/2+round.y, 0, 5], // k

[-round.x/2, round.y/2, round.y], // l

[-round.x/2+round.y, round.y, round.y], // m

[l, round.y, 5], // n

];

function exclude( w, h ) = let(

adj = h/2,

path = [

[-w/2,0,adj],

[-w/2+adj,h/2,adj],

[w/2-adj,h/2,adj],

[w/2,0,adj],

[w/2-adj,-h/2,adj],

[-w/2+adj,-h/2,adj],

],

) path;

x=val(path);

difference() {

polyRoundExtrude(path,r1=2, r2=2);

translate([-round.x/2+30,10,0])

polyRoundExtrude(exclude(25,5),r1=-2, r2=-2);

translate([round.x/2-30,10,0])

polyRoundExtrude(exclude(25,5),r1=-2, r2=-2);

translate([0,10,0]) polyRoundExtrude(exclude(40,8),r1=-2, r2=-2);

translate([0,-10,0]) polyRoundExtrude(exclude(40,8),r1=-2, r2=-2);

}

On 16 Aug 2024, at 15:45, Raymond West via Discuss

discuss@lists.openscad.org wrote:

you can set $fn =20 for testing, see if it looks OK. Minkowski is

then fairly quick. When you have it looking right, then set $fn to

100, say, for the final stl, and come back after lunch.

If it is only an stl that you want, it used to be you could feed the

scad file into AngelCad, and it used to produce an stl quite quickly.

I'm not sure if openscad has caught up wrt speed, or even if AngelCAD

accepts minkowski. Freecad can also import scad files and render. It

allows individual edges to be selected for filleting. It tends to

export back to openscad as a large polyhedron, you lose the

individual cubes and cylinders, etc. fwiw, bevels are better for

printing, not round-overs.

On 16/08/2024 13:46, Michael Zimbaro via Discuss wrote:

Yes, the size issue is interesting. I think what you said earlier

about reducing my size by the radius seems to be working.

Originally my part was created with Bols2 using the 3d library. I

could not find a way to get the inner rounded edges. I have now

switched to Bols2 2D and the Minkowski as suggested but wow is it

ever slow. I increased my facets to 90 and my part has been

compiling for at least 30 minutes. I want to do a test print of the

first few layers to make sure the size is right. Interesting that

you suggested using two cylinders and a cube for the inside. I did

the same using 2 circles and a square in 2d then extruding.

My part is almost complete. I would like to share the code to see

what others would suggest in the future. I always welcome a better

way. Is anyone interested in seeing it?

On Fri, Aug 16, 2024 at 8:19 AM Raymond West via Discuss

discuss@lists.openscad.org wrote:

My previous example, is additive, i.e, have a basic shape and

add on fillets, etc. That means, if you are wanting to deal with

the overall size, which is generally true, than the radius has

to be taken off the outside edges, and added to internal edges.

For shapes such as have been shown, then simple maths suffices,

but more complex shapes offset can be used. But Minkowski can be

slow, as you say, certainly at high resolution and complex

profiles. The rounded chamfers are the problem. For more basic

shapes, boxes, etc., then I generate a profile strip and

difference with the edges. A question of finding the best

solution for a particular problem, one size does not fit all, so

to speak.

You can generate a profile, the negative of a sphere, and

generate 'holes' in shapes such that when differenced will leave

a rounded edge. I've attached a bit of code. The advantage is

that no maths is needed to subtract the radius. The disadvantage

is that Minkowski is much slower with the complex profile,

overall it is cumbersome, and often it breaks the mesh when

differencing.

The way in which I believe most folk think wrt rounding edges,

is that you start off with square edges, and remove the sharp

edges. Bare openscad can not do that easily. However there are

plenty of other software tools that can. In reality, it is often

more expedient to mechanically finish the object, files,

emery-cloth, whatever. Possibly a woodworker would think

differently, since they often glue on mouldings.

d=10;

$fn=80;

module profile(){

rotate_extrude(){

difference(){

translate([-d/2,0])

square(d);

translate([0.01+d/2,d/2])

circle(d=d);

translate([-d-d,0]) //cut off lhs

square(d+d);

}

}

}

// profile();

module shape(){

linear_extrude(0.001){

difference(){

square (100);

translate([25,25]) square(50);

}

}

}

module stamp(){

minkowski(){

shape();

profile();

}

}

stamp();

On 15/08/2024 23:49, Jordan Brown via Discuss wrote:

There has been a lot of detailed discussion, but little in the

way of general discussion of the problem.

There are three basic approaches:

* Create a 2D shape with holes, extrude it, and somehow

(probably with Minkowski) round the corners.

* Create a 3D shape, and a shape that you want removed, and

difference the two.

* Create the entire shape as a polyhedron, with the rounding

designed in.

Minkowski can be really slow, so I generally don’t consider it.

Also, it might be tricky to restrict its effect to the edges

that you want rounded.

Creating a polyhedron is very very powerful and can be very

very hard. I think BOSL2 might have the tools required to

create a polyhedron like this, but I’m not familiar enough to

be sure. Maybe Adrian can chime in there.

I would personally think in terms of the second option,

subtracting the unwanted shape from the original shape.

Constructing the negative shape can be complex, but is

generally straightforward even if tedious. For your oval slots,

start with two cylinders joined by a cube.

I’m on my iPad so can’t experiment, but something like

difference() {

cube([50,50,10], center=true);

translate([-10,0,0]) cylinder(h=11, d=10, center=true);

translate([10,0,0]) cylinder(h=11, d=10, center=true);

cube([20,10,11], center=true);

}

That gets you a straight-sided slot. Sculpt it as desired by

subtracting stuff from the negative piece. Note, for instance,

that a cylinder is a rotationally-extruded square, so if you

want round edges at the ends you might take a square, subtract

a circle along one edge, and rotationally extrude that.

Similarly, the cube in the middle is an extruded square, so

take a square, subtract circles on each side, and extrude that.

However you construct it, when you have your negative “die”,

subtract it from the main object. Always remember to make the

negative object a little thicker than the original, so that it

protrudes from both sides.

If there is interest, I’ll write up a demo snippet in a few

days when I get back to my desktop computer.

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

With BOSL2 you can make an interior rounding mask using negative radius roundings. For example:

cuboid([30,50,20], rounding=-5);

ycopies(50) cyl(d=30,h=20,rounding=-5);

I do note that there seems to be a slight imperfection to the mask, though.

- Revar

On Aug 16, 2024, at 5:46 AM, Michael Zimbaro via Discuss discuss@lists.openscad.org wrote:

Yes, the size issue is interesting. I think what you said earlier about reducing my size by the radius seems to be working. Originally my part was created with Bols2 using the 3d library. I could not find a way to get the inner rounded edges. I have now switched to Bols2 2D and the Minkowski as suggested but wow is it ever slow. I increased my facets to 90 and my part has been compiling for at least 30 minutes. I want to do a test print of the first few layers to make sure the size is right. Interesting that you suggested using two cylinders and a cube for the inside. I did the same using 2 circles and a square in 2d then extruding.

My part is almost complete. I would like to share the code to see what others would suggest in the future. I always welcome a better way. Is anyone interested in seeing it?

On Fri, Aug 16, 2024 at 8:19 AM Raymond West via Discuss <discuss@lists.openscad.org mailto:discuss@lists.openscad.org> wrote:

My previous example, is additive, i.e, have a basic shape and add on fillets, etc. That means, if you are wanting to deal with the overall size, which is generally true, than the radius has to be taken off the outside edges, and added to internal edges.

For shapes such as have been shown, then simple maths suffices, but more complex shapes offset can be used. But Minkowski can be slow, as you say, certainly at high resolution and complex profiles. The rounded chamfers are the problem. For more basic shapes, boxes, etc., then I generate a profile strip and difference with the edges. A question of finding the best solution for a particular problem, one size does not fit all, so to speak.

You can generate a profile, the negative of a sphere, and generate 'holes' in shapes such that when differenced will leave a rounded edge. I've attached a bit of code. The advantage is that no maths is needed to subtract the radius. The disadvantage is that Minkowski is much slower with the complex profile, overall it is cumbersome, and often it breaks the mesh when differencing.

The way in which I believe most folk think wrt rounding edges, is that you start off with square edges, and remove the sharp edges. Bare openscad can not do that easily. However there are plenty of other software tools that can. In reality, it is often more expedient to mechanically finish the object, files, emery-cloth, whatever. Possibly a woodworker would think differently, since they often glue on mouldings.

d=10;

$fn=80;

module profile(){

rotate_extrude(){

difference(){

translate([-d/2,0])

square(d);

translate([0.01+d/2,d/2])

circle(d=d);

translate([-d-d,0]) //cut off lhs

square(d+d);

}

}

}

// profile();

module shape(){

linear_extrude(0.001){

difference(){

square (100);

translate([25,25]) square(50);

}

}

}

module stamp(){

minkowski(){

shape();

profile();

}

}

stamp();

On 15/08/2024 23:49, Jordan Brown via Discuss wrote:

There has been a lot of detailed discussion, but little in the way of general discussion of the problem.

There are three basic approaches:

Create a 2D shape with holes, extrude it, and somehow (probably with Minkowski) round the corners.

Create a 3D shape, and a shape that you want removed, and difference the two.

Create the entire shape as a polyhedron, with the rounding designed in.

Minkowski can be really slow, so I generally don’t consider it. Also, it might be tricky to restrict its effect to the edges that you want rounded.

Creating a polyhedron is very very powerful and can be very very hard. I think BOSL2 might have the tools required to create a polyhedron like this, but I’m not familiar enough to be sure. Maybe Adrian can chime in there.

I would personally think in terms of the second option, subtracting the unwanted shape from the original shape.

Constructing the negative shape can be complex, but is generally straightforward even if tedious. For your oval slots, start with two cylinders joined by a cube.

I’m on my iPad so can’t experiment, but something like

difference() {

cube([50,50,10], center=true);

translate([-10,0,0]) cylinder(h=11, d=10, center=true);

translate([10,0,0]) cylinder(h=11, d=10, center=true);

cube([20,10,11], center=true);

}

That gets you a straight-sided slot. Sculpt it as desired by subtracting stuff from the negative piece. Note, for instance, that a cylinder is a rotationally-extruded square, so if you want round edges at the ends you might take a square, subtract a circle along one edge, and rotationally extrude that. Similarly, the cube in the middle is an extruded square, so take a square, subtract circles on each side, and extrude that. However you construct it, when you have your negative “die”, subtract it from the main object. Always remember to make the negative object a little thicker than the original, so that it protrudes from both sides.

If there is interest, I’ll write up a demo snippet in a few days when I get back to my desktop computer.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org mailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org mailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Actually, the imperfection was user error. I forgot to specify edges="Y" in the cuboid():

include <BOSL2/std.scad>

$fn=72;

cuboid([30,50,20], edges="Y", rounding=-5);

ycopies(50) cyl(d=30,h=20,rounding=-5);

- Revar

On Aug 17, 2024, at 1:12 AM, Revar Desmera revarbat@gmail.com wrote:

With BOSL2 you can make an interior rounding mask using negative radius roundings. For example:

cuboid([30,50,20], rounding=-5);

ycopies(50) cyl(d=30,h=20,rounding=-5);

<Screenshot 2024-08-17 at 1.10.44 AM.png>

I do note that there seems to be a slight imperfection to the mask, though.

- Revar

On Aug 16, 2024, at 5:46 AM, Michael Zimbaro via Discuss discuss@lists.openscad.org wrote:

Yes, the size issue is interesting. I think what you said earlier about reducing my size by the radius seems to be working. Originally my part was created with Bols2 using the 3d library. I could not find a way to get the inner rounded edges. I have now switched to Bols2 2D and the Minkowski as suggested but wow is it ever slow. I increased my facets to 90 and my part has been compiling for at least 30 minutes. I want to do a test print of the first few layers to make sure the size is right. Interesting that you suggested using two cylinders and a cube for the inside. I did the same using 2 circles and a square in 2d then extruding.

My part is almost complete. I would like to share the code to see what others would suggest in the future. I always welcome a better way. Is anyone interested in seeing it?

On Fri, Aug 16, 2024 at 8:19 AM Raymond West via Discuss <discuss@lists.openscad.org mailto:discuss@lists.openscad.org> wrote:

My previous example, is additive, i.e, have a basic shape and add on fillets, etc. That means, if you are wanting to deal with the overall size, which is generally true, than the radius has to be taken off the outside edges, and added to internal edges.

For shapes such as have been shown, then simple maths suffices, but more complex shapes offset can be used. But Minkowski can be slow, as you say, certainly at high resolution and complex profiles. The rounded chamfers are the problem. For more basic shapes, boxes, etc., then I generate a profile strip and difference with the edges. A question of finding the best solution for a particular problem, one size does not fit all, so to speak.

You can generate a profile, the negative of a sphere, and generate 'holes' in shapes such that when differenced will leave a rounded edge. I've attached a bit of code. The advantage is that no maths is needed to subtract the radius. The disadvantage is that Minkowski is much slower with the complex profile, overall it is cumbersome, and often it breaks the mesh when differencing.

The way in which I believe most folk think wrt rounding edges, is that you start off with square edges, and remove the sharp edges. Bare openscad can not do that easily. However there are plenty of other software tools that can. In reality, it is often more expedient to mechanically finish the object, files, emery-cloth, whatever. Possibly a woodworker would think differently, since they often glue on mouldings.

d=10;

$fn=80;

module profile(){

rotate_extrude(){

difference(){

translate([-d/2,0])

square(d);

translate([0.01+d/2,d/2])

circle(d=d);

translate([-d-d,0]) //cut off lhs

square(d+d);

}

}

}

// profile();

module shape(){

linear_extrude(0.001){

difference(){

square (100);

translate([25,25]) square(50);

}

}

}

module stamp(){

minkowski(){

shape();

profile();

}

}

stamp();

On 15/08/2024 23:49, Jordan Brown via Discuss wrote:

There has been a lot of detailed discussion, but little in the way of general discussion of the problem.

There are three basic approaches:

Create a 2D shape with holes, extrude it, and somehow (probably with Minkowski) round the corners.

Create a 3D shape, and a shape that you want removed, and difference the two.

Create the entire shape as a polyhedron, with the rounding designed in.

Minkowski can be really slow, so I generally don’t consider it. Also, it might be tricky to restrict its effect to the edges that you want rounded.

Creating a polyhedron is very very powerful and can be very very hard. I think BOSL2 might have the tools required to create a polyhedron like this, but I’m not familiar enough to be sure. Maybe Adrian can chime in there.

I would personally think in terms of the second option, subtracting the unwanted shape from the original shape.

Constructing the negative shape can be complex, but is generally straightforward even if tedious. For your oval slots, start with two cylinders joined by a cube.

I’m on my iPad so can’t experiment, but something like

difference() {

cube([50,50,10], center=true);

translate([-10,0,0]) cylinder(h=11, d=10, center=true);

translate([10,0,0]) cylinder(h=11, d=10, center=true);

cube([20,10,11], center=true);

}

That gets you a straight-sided slot. Sculpt it as desired by subtracting stuff from the negative piece. Note, for instance, that a cylinder is a rotationally-extruded square, so if you want round edges at the ends you might take a square, subtract a circle along one edge, and rotationally extrude that. Similarly, the cube in the middle is an extruded square, so take a square, subtract circles on each side, and extrude that. However you construct it, when you have your negative “die”, subtract it from the main object. Always remember to make the negative object a little thicker than the original, so that it protrudes from both sides.

If there is interest, I’ll write up a demo snippet in a few days when I get back to my desktop computer.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org mailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org mailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Wow, impressive!

On 16 Aug 2024, at 23:27, Glenn Butcher via Discuss discuss@lists.openscad.org wrote:

Oh, I love Round-Anything's polyRound() module...

I modeled a complete steam locomotive with it, using it 83 times to make the rounded shapes 1880's steam locomotive designers so loved:

<integration-_2024-06-24.png>

On 8/16/2024 8:55 AM, Peter Kriens via Discuss wrote:

You might want to take a look at https://learn.cadhub.xyz/docs/round-anything/api-reference/#polyround

<PastedGraphic-1.png>

The library can round a path with square corners with variable radii. For this, you add the radius as the z coordinate in a 3vec. It can then extrude this path with a radius at the end. For the outer component you can use a positive radius for the under and top side. You can then make the inner shapes the same way and subtract them. However, you can then make the radii of the ends negative, which leaves a nice round shape.

The library could use some love. If your path contains undef it will hang ... :-( (Surprised OpenSCAD does not run the rendering in a background thread?) This is the function of the val() routine, to check this.

The quickly hacked together code.

use <lib/Round-Anything/polyround.scad>

$fn=50;

function val(p) = [for(i=p) assert( ! (is_undef(i.x) || is_undef(i.y)|| is_undef(i.y)))];

rect=[60,60];

round=[140,20];

a = 20;

/*

-rect.x/2 rect.x/2

a----------------b rect.y/2

| |

m-----n c-----d round.y

/ \

l+ + e

\ /

k-----j g-----f 0

| |

| |

i----------------h -rect.y/2

0

*/

l = -rect.x/2;

r = -l;

t = rect.y/2;

b = -t;

path = [

[l, t, 5], // a

[r, t, 5], // b

[r, round.y, 5], // c

[round.x/2-round.y, round.y, 5], // d

[round.x/2, round.y/2, round.y], // e

[round.x/2-round.y, 0, round.y], // f

[r, 0, 5], // g

[r, b, 5], // h

[l, b, 5], // i

[l, 0, 5], // j

[-round.x/2+round.y, 0, 5], // k

[-round.x/2, round.y/2, round.y], // l

[-round.x/2+round.y, round.y, round.y], // m

[l, round.y, 5], // n

];

function exclude( w, h ) = let(

adj = h/2,

path = [

[-w/2,0,adj],

[-w/2+adj,h/2,adj],

[w/2-adj,h/2,adj],

[w/2,0,adj],

[w/2-adj,-h/2,adj],

[-w/2+adj,-h/2,adj],

],

) path;

x=val(path);

difference() {

polyRoundExtrude(path,r1=2, r2=2);

translate([-round.x/2+30,10,0]) polyRoundExtrude(exclude(25,5),r1=-2, r2=-2);

translate([round.x/2-30,10,0]) polyRoundExtrude(exclude(25,5),r1=-2, r2=-2);

translate([0,10,0]) polyRoundExtrude(exclude(40,8),r1=-2, r2=-2);

translate([0,-10,0]) polyRoundExtrude(exclude(40,8),r1=-2, r2=-2);

}

On 16 Aug 2024, at 15:45, Raymond West via Discuss discuss@lists.openscad.org mailto:discuss@lists.openscad.org wrote:

you can set $fn =20 for testing, see if it looks OK. Minkowski is then fairly quick. When you have it looking right, then set $fn to 100, say, for the final stl, and come back after lunch.

If it is only an stl that you want, it used to be you could feed the scad file into AngelCad, and it used to produce an stl quite quickly. I'm not sure if openscad has caught up wrt speed, or even if AngelCAD accepts minkowski. Freecad can also import scad files and render. It allows individual edges to be selected for filleting. It tends to export back to openscad as a large polyhedron, you lose the individual cubes and cylinders, etc. fwiw, bevels are better for printing, not round-overs.

On 16/08/2024 13:46, Michael Zimbaro via Discuss wrote:

Yes, the size issue is interesting. I think what you said earlier about reducing my size by the radius seems to be working. Originally my part was created with Bols2 using the 3d library. I could not find a way to get the inner rounded edges. I have now switched to Bols2 2D and the Minkowski as suggested but wow is it ever slow. I increased my facets to 90 and my part has been compiling for at least 30 minutes. I want to do a test print of the first few layers to make sure the size is right. Interesting that you suggested using two cylinders and a cube for the inside. I did the same using 2 circles and a square in 2d then extruding.

My part is almost complete. I would like to share the code to see what others would suggest in the future. I always welcome a better way. Is anyone interested in seeing it?

On Fri, Aug 16, 2024 at 8:19 AM Raymond West via Discuss <discuss@lists.openscad.org mailto:discuss@lists.openscad.org> wrote:

My previous example, is additive, i.e, have a basic shape and add on fillets, etc. That means, if you are wanting to deal with the overall size, which is generally true, than the radius has to be taken off the outside edges, and added to internal edges.

For shapes such as have been shown, then simple maths suffices, but more complex shapes offset can be used. But Minkowski can be slow, as you say, certainly at high resolution and complex profiles. The rounded chamfers are the problem. For more basic shapes, boxes, etc., then I generate a profile strip and difference with the edges. A question of finding the best solution for a particular problem, one size does not fit all, so to speak.

You can generate a profile, the negative of a sphere, and generate 'holes' in shapes such that when differenced will leave a rounded edge. I've attached a bit of code. The advantage is that no maths is needed to subtract the radius. The disadvantage is that Minkowski is much slower with the complex profile, overall it is cumbersome, and often it breaks the mesh when differencing.

The way in which I believe most folk think wrt rounding edges, is that you start off with square edges, and remove the sharp edges. Bare openscad can not do that easily. However there are plenty of other software tools that can. In reality, it is often more expedient to mechanically finish the object, files, emery-cloth, whatever. Possibly a woodworker would think differently, since they often glue on mouldings.

d=10;

$fn=80;

module profile(){

rotate_extrude(){

difference(){

translate([-d/2,0])

square(d);

translate([0.01+d/2,d/2])

circle(d=d);

translate([-d-d,0]) //cut off lhs

square(d+d);

}

}

}

// profile();

module shape(){

linear_extrude(0.001){

difference(){

square (100);

translate([25,25]) square(50);

}

}

}

module stamp(){

minkowski(){

shape();

profile();

}

}

stamp();

On 15/08/2024 23:49, Jordan Brown via Discuss wrote:

There has been a lot of detailed discussion, but little in the way of general discussion of the problem.

There are three basic approaches:

Create a 2D shape with holes, extrude it, and somehow (probably with Minkowski) round the corners.

Create a 3D shape, and a shape that you want removed, and difference the two.

Create the entire shape as a polyhedron, with the rounding designed in.

Minkowski can be really slow, so I generally don’t consider it. Also, it might be tricky to restrict its effect to the edges that you want rounded.

Creating a polyhedron is very very powerful and can be very very hard. I think BOSL2 might have the tools required to create a polyhedron like this, but I’m not familiar enough to be sure. Maybe Adrian can chime in there.

I would personally think in terms of the second option, subtracting the unwanted shape from the original shape.

Constructing the negative shape can be complex, but is generally straightforward even if tedious. For your oval slots, start with two cylinders joined by a cube.

I’m on my iPad so can’t experiment, but something like

difference() {

cube([50,50,10], center=true);

translate([-10,0,0]) cylinder(h=11, d=10, center=true);

translate([10,0,0]) cylinder(h=11, d=10, center=true);

cube([20,10,11], center=true);

}

That gets you a straight-sided slot. Sculpt it as desired by subtracting stuff from the negative piece. Note, for instance, that a cylinder is a rotationally-extruded square, so if you want round edges at the ends you might take a square, subtract a circle along one edge, and rotationally extrude that. Similarly, the cube in the middle is an extruded square, so take a square, subtract circles on each side, and extrude that. However you construct it, when you have your negative “die”, subtract it from the main object. Always remember to make the negative object a little thicker than the original, so that it protrudes from both sides.

If there is interest, I’ll write up a demo snippet in a few days when I get back to my desktop computer.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org mailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org mailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org mailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org mailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org mailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Really impressive indeed

On Sat, 17 Aug, 2024, 2:57 am Glenn Butcher via Discuss, <

discuss@lists.openscad.org> wrote:

Oh, I love Round-Anything's polyRound() module...

I modeled a complete steam locomotive with it, using it 83 times to make

the rounded shapes 1880's steam locomotive designers so loved:

On 8/16/2024 8:55 AM, Peter Kriens via Discuss wrote:

You might want to take a look at

https://learn.cadhub.xyz/docs/round-anything/api-reference/#polyround

[image: PastedGraphic-1.png]

The library can round a path with square corners with variable radii. For

this, you add the radius as the z coordinate in a 3vec. It can then extrude

this path with a radius at the end. For the outer component you can use a

positive radius for the under and top side. You can then make the inner

shapes the same way and subtract them. However, you can then make the radii

of the ends negative, which leaves a nice round shape.

The library could use some love. If your path contains undef it will hang

... :-( (Surprised OpenSCAD does not run the rendering in a background

thread?) This is the function of the val() routine, to check this.

The quickly hacked together code.

use <lib/Round-Anything/polyround.scad>

$fn=50;

function val(p) = [for(i=p) assert( ! (is_undef(i.x) || is_undef(i.y)||

is_undef(i.y)))];

rect=[60,60];

round=[140,20];

a = 20;

/*

-rect.x/2 rect.x/2

a----------------b rect.y/2

| |

m-----n c-----d round.y

/ \

l+ + e

\ /

k-----j g-----f 0

| |

| |

i----------------h -rect.y/2

0

*/

l = -rect.x/2;

r = -l;

t = rect.y/2;

b = -t;

path = [

[l, t, 5], // a

[r, t, 5], // b

[r, round.y, 5], // c

[round.x/2-round.y, round.y, 5], // d

[round.x/2, round.y/2, round.y], // e

[round.x/2-round.y, 0, round.y], // f

[r, 0, 5], // g

[r, b, 5], // h

[l, b, 5], // i

[l, 0, 5], // j

[-round.x/2+round.y, 0, 5], // k

[-round.x/2, round.y/2, round.y], // l

[-round.x/2+round.y, round.y, round.y], // m

[l, round.y, 5], // n

];

function exclude( w, h ) = let(

adj = h/2,

path = [

[-w/2,0,adj],

[-w/2+adj,h/2,adj],

[w/2-adj,h/2,adj],

[w/2,0,adj],

[w/2-adj,-h/2,adj],

[-w/2+adj,-h/2,adj],

],

) path;

x=val(path);

difference() {

polyRoundExtrude(path,r1=2, r2=2);

translate([-round.x/2+30,10,0]) polyRoundExtrude(exclude(25,5),r1=-2,

r2=-2);

translate([round.x/2-30,10,0]) polyRoundExtrude(exclude(25,5),r1=-2,

r2=-2);

translate([0,10,0]) polyRoundExtrude(exclude(40,8),r1=-2, r2=-2);

translate([0,-10,0]) polyRoundExtrude(exclude(40,8),r1=-2, r2=-2);

}

On 16 Aug 2024, at 15:45, Raymond West via Discuss

discuss@lists.openscad.org discuss@lists.openscad.org wrote:

you can set $fn =20 for testing, see if it looks OK. Minkowski is then

fairly quick. When you have it looking right, then set $fn to 100, say, for

the final stl, and come back after lunch.

If it is only an stl that you want, it used to be you could feed the scad

file into AngelCad, and it used to produce an stl quite quickly. I'm not

sure if openscad has caught up wrt speed, or even if AngelCAD accepts

minkowski. Freecad can also import scad files and render. It allows

individual edges to be selected for filleting. It tends to export back to

openscad as a large polyhedron, you lose the individual cubes and

cylinders, etc. fwiw, bevels are better for printing, not round-overs.

On 16/08/2024 13:46, Michael Zimbaro via Discuss wrote:

Yes, the size issue is interesting. I think what you said earlier about

reducing my size by the radius seems to be working. Originally my part was

created with Bols2 using the 3d library. I could not find a way to get the

inner rounded edges. I have now switched to Bols2 2D and the Minkowski as

suggested but wow is it ever slow. I increased my facets to 90 and my part

has been compiling for at least 30 minutes. I want to do a test print of

the first few layers to make sure the size is right. Interesting that you

suggested using two cylinders and a cube for the inside. I did the same

using 2 circles and a square in 2d then extruding.

My part is almost complete. I would like to share the code to see what

others would suggest in the future. I always welcome a better way. Is

anyone interested in seeing it?

On Fri, Aug 16, 2024 at 8:19 AM Raymond West via Discuss <

discuss@lists.openscad.org> wrote:

My previous example, is additive, i.e, have a basic shape and add on

fillets, etc. That means, if you are wanting to deal with the overall size,

which is generally true, than the radius has to be taken off the outside

edges, and added to internal edges.

For shapes such as have been shown, then simple maths suffices, but more

complex shapes offset can be used. But Minkowski can be slow, as you say,

certainly at high resolution and complex profiles. The rounded chamfers are

the problem. For more basic shapes, boxes, etc., then I generate a profile

strip and difference with the edges. A question of finding the best

solution for a particular problem, one size does not fit all, so to speak.

You can generate a profile, the negative of a sphere, and generate

'holes' in shapes such that when differenced will leave a rounded edge.

I've attached a bit of code. The advantage is that no maths is needed to

subtract the radius. The disadvantage is that Minkowski is much slower with

the complex profile, overall it is cumbersome, and often it breaks the

mesh when differencing.

The way in which I believe most folk think wrt rounding edges, is that

you start off with square edges, and remove the sharp edges. Bare openscad

can not do that easily. However there are plenty of other software tools

that can. In reality, it is often more expedient to mechanically finish

the object, files, emery-cloth, whatever. Possibly a woodworker would think

differently, since they often glue on mouldings.

d=10;

$fn=80;

module profile(){

rotate_extrude(){

difference(){

translate([-d/2,0])

square(d);

translate([0.01+d/2,d/2])

circle(d=d);

translate([-d-d,0]) //cut off lhs

square(d+d);

}

}

}

// profile();

module shape(){

linear_extrude(0.001){

difference(){

square (100);

translate([25,25]) square(50);

}

}

}

module stamp(){

minkowski(){

shape();

profile();

}

}

stamp();

On 15/08/2024 23:49, Jordan Brown via Discuss wrote:

There has been a lot of detailed discussion, but little in the way of

general discussion of the problem.

There are three basic approaches:

- Create a 2D shape with holes, extrude it, and somehow (probably

with Minkowski) round the corners.

- Create a 3D shape, and a shape that you want removed, and

difference the two.

- Create the entire shape as a polyhedron, with the rounding designed

in.

Minkowski can be really slow, so I generally don’t consider it. Also, it

might be tricky to restrict its effect to the edges that you want rounded.

Creating a polyhedron is very very powerful and can be very very hard. I

think BOSL2 might have the tools required to create a polyhedron like this,

but I’m not familiar enough to be sure. Maybe Adrian can chime in there.

I would personally think in terms of the second option, subtracting the

unwanted shape from the original shape.

Constructing the negative shape can be complex, but is generally

straightforward even if tedious. For your oval slots, start with two

cylinders joined by a cube.

I’m on my iPad so can’t experiment, but something like

difference() {

cube([50,50,10], center=true);

translate([-10,0,0]) cylinder(h=11, d=10, center=true);

translate([10,0,0]) cylinder(h=11, d=10, center=true);

cube([20,10,11], center=true);

}

That gets you a straight-sided slot. Sculpt it as desired by subtracting

stuff from the negative piece. Note, for instance, that a cylinder is a

rotationally-extruded square, so if you want round edges at the ends you

might take a square, subtract a circle along one edge, and rotationally

extrude that. Similarly, the cube in the middle is an extruded square, so

take a square, subtract circles on each side, and extrude that. However you

construct it, when you have your negative “die”, subtract it from the main

object. Always remember to make the negative object a little thicker than

the original, so that it protrudes from both sides.

If there is interest, I’ll write up a demo snippet in a few days when I

get back to my desktop computer.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org