Re: Any other TeX users here? Processing lists and analyzing geometry

On 4/16/2021 12:34 PM, William F. Adams via Discuss wrote:

Am I dense, or does OpenSCAD lack the programming constructs to

readily and directly put all the parts into a list, and then parse

each object in the list for its geometry and then work out how to fit

them together so as to efficiently cut them out of a wooden board? (In

particular, in retrospect I should have rotated one of the ends 180

degrees so that they could have fit more closely together).

OpenSCAD has decent, perhaps not great, list support.

What it doesn't have is any way to extract geometry information out of

constructed objects.

That is, you can describe a cube like so:

c = [

[ // points

[0,0,0],

[0,0,1],

[0,1,0],

[0,1,1],

[1,0,0],

[1,0,1],

[1,1,0],

[1,1,1]

], [ // faces

[0,2,3,1], // left

[0,4,6,2], // bottom

[0,1,5,4], // front

[1,3,7,5], // top

[4,5,7,6], // right

[2,6,7,3], // back

]

];

polyhedron(points=c[0], faces=c[1]);

and do whatever you like to the points before you hand them to

polyhedron(), but if you use a primitive to construct your cube:

cube(1);

then you can't get any information whatsoever about it.

For the kind of project you're talking about, I would define each slab

as a module, and then I would assemble those modules twice, once to form

the finished object (so as to check fit and look) and once to form the

as-printed components. (Or, in your case, as-cut.)

There are other similar techniques. One that I've used is to have two

translations and two rotations for each piece, where one

position/rotation is the as-assembled position, and the other is the

as-printed position. It's then not too hard to animate between the two,

so that the pieces fly from the print bed to the constructed model and

back again.

On 4/16/2021 2:16 PM, Jordan Brown wrote:

There are other similar techniques. One that I've used is to have two

translations and two rotations for each piece, where one

position/rotation is the as-assembled position, and the other is the

as-printed position. It's then not too hard to animate between the

two, so that the pieces fly from the print bed to the constructed

model and back again.

Like so, if I've got the attachment right:

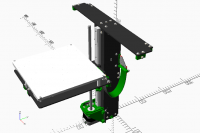

I don't make lists of parts in scad, I form then into structured assemblies

using modules to represent each level:

[image: image.png]

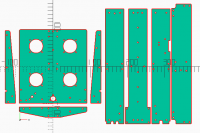

Since all the panels are created parametrically I always have access to

their dimensions, so laying them out for cutting is just a matter of

translating using those dimensions and rotating. When I press F6 I draw the

laid out dxfs instead of the assembly view using $preview:

[image: image.png]

Python scripts then export all the dxfs and stls, etc. In this case

the framework makes spine.dxf and table.dxf by calling spine.scad and

table.scad that it finds in a panels folder. It gets a list of dxfs from

the BOM information emitted by echo statements and can work out that, for

example, table.dxf covers z_table.dxf, brace.dxf and spar.dxf, so they get

removed from the folder of files to be routed and replaced by table.dxf.

There is nothing automatic about the layout because how I group things for

cutting depends on my stock sizes as well as build order, etc, but once

coded everything adjusts itself if the dimensions change.

On Fri, 16 Apr 2021 at 22:34, Jordan Brown openscad@jordan.maileater.net

wrote:

On 4/16/2021 2:16 PM, Jordan Brown wrote:

There are other similar techniques. One that I've used is to have two

translations and two rotations for each piece, where one position/rotation

is the as-assembled position, and the other is the as-printed position.

It's then not too hard to animate between the two, so that the pieces fly

from the print bed to the constructed model and back again.

Like so, if I've got the attachment right:

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org