PETG vs bed adhesion

Greetings all;

I tried the polyprop, zero bed adhesion. Plugged up the hot end and spent

about 4 hours trying to get it cleaned out enough to flow.

Washed the magicgoo off three times, and recoated it with layerneer 3

times. cleaned it off and resanded the bed. Rezeroed bed height several

times, but where PETG was happy on an earlier printer at 80C bed, there

is now no bed adhesion at 80C. What is the best fix?

Thanks all;

Cheers, Gene Heskett

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/gene

The only thing PP sticks to is PP. I.e. you need a bed with PP film or a PP

sheet on it.

On Sat, 3 Jul 2021 at 21:09, Gene Heskett gheskett@shentel.net wrote:

Greetings all;

I tried the polyprop, zero bed adhesion. Plugged up the hot end and spent

about 4 hours trying to get it cleaned out enough to flow.

Washed the magicgoo off three times, and recoated it with layerneer 3

times. cleaned it off and resanded the bed. Rezeroed bed height several

times, but where PETG was happy on an earlier printer at 80C bed, there

is now no bed adhesion at 80C. What is the best fix?

Thanks all;

Cheers, Gene Heskett

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/gene

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Am Sa., 3. Juli 2021 um 22:22 Uhr schrieb nop head nop.head@gmail.com:

The only thing PP sticks to is PP. I.e. you need a bed with PP film or a

PP sheet on it.

definitely! There is NO comparison to PETG! It is c.o.m.p.l.e.t.e.l.y

different. Additionally PP has stronger warping. I have very good

experience with PP adhesive film

https://smile.amazon.de/gp/product/B001AVL0Y8

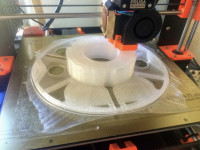

Look at this Foto: it warped like crazy but still sticked to the bed and

the print could be ended and I can use this master spool.

[image: 55FD34D8-7A7B-451B-A879-479F036EDDA1_1_105_c.jpeg]

On Sat, 3 Jul 2021 at 21:09, Gene Heskett gheskett@shentel.net wrote:

Greetings all;

I tried the polyprop, zero bed adhesion. Plugged up the hot end and spent

about 4 hours trying to get it cleaned out enough to flow.

Washed the magicgoo off three times, and recoated it with layerneer 3

times. cleaned it off and resanded the bed. Rezeroed bed height several

times, but where PETG was happy on an earlier printer at 80C bed, there

is now no bed adhesion at 80C. What is the best fix?

Thanks all;

Cheers, Gene Heskett

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/gene

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On Saturday 03 July 2021 16:21:43 nop head wrote:

The only thing PP sticks to is PP. I.e. you need a bed with PP film or

a PP sheet on it.

But Magigoo is supposed to work with PP.

But I'm now back to PETG, which was working great with a 50C bed

thursday. Now, after all the treatment, even sanding with 320 grit to

recover from that $100 debacle, nothing sticks. At any bed temp.

But I am slowly developing a theory, and it looks like I have composed in

OpenSCAD, an object cura cannot print. This spline ring code:

module innerspline()

{// PETG now on printer, PolyProp (PP?) has arrived. And its a disaster,

went back to PETG

// and the nozzle troubles started, plugged up whole damned hotend. 3

times so far

// Magicgoo for PP must be very caustic warnings galore

// new example, low ratio 30/1 harmonic drive floating splined belt.

teeth = 60; // define number of teeth

arcx = ( 360 / teeth ); // arc of circle per tooth

$fr = 0.000000;

// adjust this to just barely get an overlap at inner corners of spline

triangle

toothdia = arcx/1.60;

// adjust this for outer teeth fit in internal spline

toothrad=53.5 / 2.000;// make radius was 53.0, reduce backlash but dont

compress it either

// adjust this to thin or thicken flex valleys

linerdia=51.7; // thins web at bottom of spline, helps flex if larger,

was 52.2

height=12;

tranz=height / 2.000;

echo (177,teeth,arcx,toothrad,linerdia) ;

difference()

{ // inside smoother

// make splines first

for($fr=[ 0: 6 : 359 ])

{ //can't pass $fd to this for, why?

rotate([0, 0, $fr]) // works, finally

translate([toothrad, 0, tranz]) // mv x=[$lr + $r1] y,z=0

cylinder(d=toothdia, h=height, $fn=3, center=true);

};// made triangle

// above is first of difference now subtract a smoothing inner liner

translate([0,0,tranz])

cylinder(d=linerdia, h=height+.01, $fn=360,center=true);

}; //but the innards needs smooth finish

};

generates the 60 splines, then trims the inner face smooth, removeing the

bottoms of the splines infavor of a 1 degree of straight lines=fine

inner finish.

But cura renders just the outer facing portion of the tooth, doing 60 6mm

retractions at the end of each "tooth", then lays down the inner wall

ring, with the nozzle so close to the V it laid down that it catches the

top of the V and knocks it loose, ruining the print so I might as well

kill it. I even reverted to the last 4.9.1 version of cura from 4.10.0

But it had no effect on this.

But, 4.9.1 printed 3 of these and a 6 pack of bearing races thursday with

none of these problems, the only cleanup was the bump where cura did a

turnaround, and I've a dremel ball diamond thats just the right size to

remove those bumps, 5 minutes or less per race pair.

The only REAL change to this code since thursday, is the thickness of the

web connecting the bottoms of the teeth. Then it was about 2mm thicker,

which made the thing too stiff to survive the flexing. I'm about to

rewrite it, to make the smooth inner liner into a 1mm thick ring, and

make that a union with the base of the spline just to see it that will

fix cura. But before I do that, I want 2 good, matching, bearing race

pairs, which were failing in 10 minutes running at 2k+ rpms, because the

plastic web was so thin at the bottoms of the ball grooves that the

outer ring was breaking at the bottom of the groove. So the size of the

groove was better matched with the bb, and the code changed to allow a

thicker outer ring, but that affects the final size of everything

outside of that bearing, including this part which rides on the OD of

those bearings with zero clearance, and this part is adjusted to remove

as much stretching stress as possible while not needing a drop or 2 of

superglue to lock them togeher. But printer/cura problems are very

discouraging.

Will my union idea fix cura from thinking the tooth and the liner ring

are 2 separate items? All those hundreds of retractions only plugs up

the printhead.

Thanks everybody.

[...]

Cheers, Gene Heskett

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/gene

On Saturday 03 July 2021 16:42:11 dpa wrote:

Am Sa., 3. Juli 2021 um 22:22 Uhr schrieb nop head

The only thing PP sticks to is PP. I.e. you need a bed with PP film

or a PP sheet on it.

definitely! There is NO comparison to PETG! It is c.o.m.p.l.e.t.e.l.y

different. Additionally PP has stronger warping. I have very good

experience with PP adhesive film

https://smile.amazon.de/gp/product/B001AVL0Y8

Look at this Foto: it warped like crazy but still sticked to the bed

and the print could be ended and I can use this master spool.

[image: 55FD34D8-7A7B-451B-A879-479F036EDDA1_1_105_c.jpeg]

That is an impressive amount of warping!

On Sat, 3 Jul 2021 at 21:09, Gene Heskett gheskett@shentel.net

wrote:

Greetings all;

I tried the polyprop, zero bed adhesion. Plugged up the hot end and

spent about 4 hours trying to get it cleaned out enough to flow.

Washed the magicgoo off three times, and recoated it with layerneer

3 times. cleaned it off and resanded the bed. Rezeroed bed height

several times, but where PETG was happy on an earlier printer at

80C bed, there is now no bed adhesion at 80C. What is the best

fix?

It wouldn't do the bearing either, I rehomed it to reset the starting gap

and that is when I twigged on the fact that the side fan snoot was

dragging on the build plate, so I wedged the putty knife under it and

loosened all 5 of the screws which mount the fan and cover since the

replacement for the broken fan arrived yesterday, and retightened them,

and now it clears the plate by about a mm. But it went right back down,

so I removed it, and found it was warped by contact with the hot block.

It was doomed the instant I dialed up the higher nozzle heat for

something hotter than PLA.

The printer actually worked fine w/o the fan, so I left the %#@&^ snoot

off. Rehomed it about .4mm closer to the bed since the primer run up

the left edge measured .55mm, shoulda been about .2mm and its working

normally now, building a bearing race pair. Thermoplastic casting, 2

parts snap together, cost me 2 damn days screwing with it. I think its

evident I am not a happy camper.

Thanks for reading my off-topic rant.

Cheers, Gene Heskett

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/gene

On 07-03-2021 4:21 PM, nop head wrote:

The only thing PP sticks to is PP. I.e. you need a bed with PP film or

a PP sheet on it.

I've had excellent results printing polypropylene using clear packing

tape (commonly used to seal cardboard boxes) stuck to the bed. No heat

on the bed and no cooling of the hot end needed.

- Michele

That will be because sellotape is made from polypropylene.

On Sun, 4 Jul 2021 at 17:03, Michele Denber mdenber@gmx.com wrote:

On 07-03-2021 4:21 PM, nop head wrote:

The only thing PP sticks to is PP. I.e. you need a bed with PP film or

a PP sheet on it.

I've had excellent results printing polypropylene using clear packing

tape (commonly used to seal cardboard boxes) stuck to the bed. No heat

on the bed and no cooling of the hot end needed.

- Michele

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On Sunday 04 July 2021 12:03:45 Michele Denber wrote:

On 07-03-2021 4:21 PM, nop head wrote:

The only thing PP sticks to is PP. I.e. you need a bed with PP film

or a PP sheet on it.

I've had excellent results printing polypropylene using clear packing

tape (commonly used to seal cardboard boxes) stuck to the bed. No

heat on the bed and no cooling of the hot end needed.

- Michele

Thanks Michele, I'll give that a shot when this project is done.

I decided to throw money at it, again, so by late wednesday there s/b a

biqu hx sitting on that table, smaller than the CR10, no bowden tube but

all the other bells and whistles. And about $150 cheaper.

Cheers, Gene Heskett

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/gene