vise screw question

Greetings all;

I think I may be in over my head.

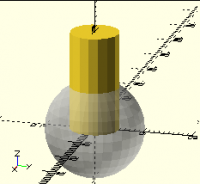

This code starts to make cap to go on the ends of the handle rod for

this screw,

the remainder of a spherical knob being printed from TPU so serve as a

bumper

when the user lets go of the handle and the handle slides thru the hole

until

it hits the knob on the end of the handle. Because they are cheap by the

25 lb

pail, I want to drill into the end of an oak dowel for a 4" long #10

deck screw.

But the deck screw has a tulip head, not the usual tapered conical of a

flat

headed wood screw.

So I need to model that tulip shape with another module to be the final

difference

in this code:

module handle_washer()

{ $fn=180;

translate([0,0,-12])difference()

{

sphere(d=40);

translate([-22.5,-22.5,-33])cube(45);

translate([0,0,16])cylinder(h=10,d=4,center=true);

}

}

Ideas on how to go about that?

The only idea I can come up with is a 3mm diameter disk extruded to a

usable

thickness, offset so as to form a tulip shape if rotated about the 4mm shank

of the deck screw, and that then used as a difference under a conical

cylinder.

That I may be able to do, but it seems to me there ought to be a different,

better way.

Is there?

Thank you all. Take care and stay well.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

A picture of a Tulip Head of a screw ... when I google the term I get lots

of surgical implant stuff ... you're not doing surgical equipment are you?

On Sun, 17 Jul 2022 at 17:16, gene heskett gheskett@shentel.net wrote:

Greetings all;

I think I may be in over my head.

This code starts to make cap to go on the ends of the handle rod for

this screw,

the remainder of a spherical knob being printed from TPU so serve as a

bumper

when the user lets go of the handle and the handle slides thru the hole

until

it hits the knob on the end of the handle. Because they are cheap by the

25 lb

pail, I want to drill into the end of an oak dowel for a 4" long #10

deck screw.

But the deck screw has a tulip head, not the usual tapered conical of a

flat

headed wood screw.

So I need to model that tulip shape with another module to be the final

difference

in this code:

module handle_washer()

{ $fn=180;

translate([0,0,-12])difference()

{

sphere(d=40);

translate([-22.5,-22.5,-33])cube(45);

translate([0,0,16])cylinder(h=10,d=4,center=true);

}

}

Ideas on how to go about that?

The only idea I can come up with is a 3mm diameter disk extruded to a

usable

thickness, offset so as to form a tulip shape if rotated about the 4mm

shank

of the deck screw, and that then used as a difference under a conical

cylinder.

That I may be able to do, but it seems to me there ought to be a different,

better way.

Is there?

Thank you all. Take care and stay well.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Is the screw head one of these?

https://en.wikipedia.org/wiki/Screw#Screw_head_shapes

Trygve

Den 17. juli 2022 kl. 19.05.33 +02.00 skrev Michael Möller private2michael@gmail.com:

A picture of a Tulip Head of a screw ... when I google the term I get lots of surgical implant stuff ... you're not doing surgical equipment are you?

On Sun, 17 Jul 2022 at 17:16, gene heskett <gheskett@shentel.net> wrote:

Greetings all;

I think I may be in over my head.

This code starts to make cap to go on the ends of the handle rod for

this screw,

the remainder of a spherical knob being printed from TPU so serve as a

bumper

when the user lets go of the handle and the handle slides thru the hole

until

it hits the knob on the end of the handle. Because they are cheap by the

25 lb

pail, I want to drill into the end of an oak dowel for a 4" long #10

deck screw.

But the deck screw has a tulip head, not the usual tapered conical of a

flat

headed wood screw.

So I need to model that tulip shape with another module to be the final

difference

in this code:

module handle_washer()

{ $fn=180;

translate([0,0,-12])difference()

{

sphere(d=40);

translate([-22.5,-22.5,-33])cube(45);

translate([0,0,16])cylinder(h=10,d=4,center=true);

}

}

Ideas on how to go about that?

The only idea I can come up with is a 3mm diameter disk extruded to a

usable

thickness, offset so as to form a tulip shape if rotated about the 4mm shank

of the deck screw, and that then used as a difference under a conical

cylinder.

That I may be able to do, but it seems to me there ought to be a different,

better way.

Is there?

Thank you all. Take care and stay well.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page <http://geneslinuxbox.net:6309/>

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On 7/17/22 13:09, Michael Möller wrote:

A picture of a Tulip Head of a screw ... when I google the term I get lots

of surgical implant stuff ... you're not doing surgical equipment are you?

Not hardly Michael, it's the knob on the end of a vise handle. And I am

changing my thinking a bit but the need for that shape isn't changed.

I'll move the flat face (the cube) to just clip off the the bottom, then

add a 19mm hole to fit over the end of the dowel, hollowing it out to

about the flat faces location. Then print a TPU sleeve with a 19mm bore

and a 25mm OD & 16 to 17mm long for the bumper.

This is the underside of the head of a commonly used here in the US

for a "deck" screw, holding the wooden planks of a front or back deck

or porch floor to its sub-framing on your house. Usually with a T25 or

so torx socket for a driving tool. google or DDG for deck screws should

get you some pix for reference.

I've got one of these making just to see if it fits the doweling.

module handle_washer()

{ $fn=180;

translate([0,0,15.50])difference()

{

sphere(d=40);

translate([-22.5,-22.5,-60.5])cube(45);

translate([0,0,16])cylinder(h=10,d=4,center=true);

translate([0,0,-2.1])cylinder(h=27,d=19,center=true);

}

}

but I still need to see about the screw head socket on top of it.

And watching it form, its plain to see 40mm is too big, so I've

reduced it to 28mm and adjusted the rest to fit, but I think I've

found a bug, the ! in front of the sphere I expected to make it

transparent so I could see whats inside, but what it does do is

not helpful at all as it just turns it grey and solid.

Is that the intended behavior?

So I'll make this one next after I test fit whats making now.

module handle_cap()

{ $fn=180;

translate([0,0,5.5])difference()

{

sphere(d=28);

translate([0,0,9])cylinder(h=10,d=4,center=true);

translate([0,0,-0.6])cylinder(h=11,d=19,center=true);

translate([-22.5,-22.5,-50.5])cube(45);

}

}

On Sun, 17 Jul 2022 at 17:16, gene heskett gheskett@shentel.net wrote:

Greetings all;

I think I may be in over my head.

This code starts to make cap to go on the ends of the handle rod for

this screw,

the remainder of a spherical knob being printed from TPU so serve as a

bumper

when the user lets go of the handle and the handle slides thru the hole

until

it hits the knob on the end of the handle. Because they are cheap by the

25 lb

pail, I want to drill into the end of an oak dowel for a 4" long #10

deck screw.

But the deck screw has a tulip head, not the usual tapered conical of a

flat

headed wood screw.

So I need to model that tulip shape with another module to be the final

difference

in this code:

Ideas on how to go about that?

The only idea I can come up with is a 3mm diameter disk extruded to a

usable

thickness, offset so as to form a tulip shape if rotated about the 4mm

shank

of the deck screw, and that then used as a difference under a conical

cylinder.

That I may be able to do, but it seems to me there ought to be a different,

better way.

Is there?

Thank you all. Take care and stay well.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

On 7/17/22 14:55, trygve@totallytrygve.com wrote:

Is the screw head one of these?

https://en.wikipedia.org/wiki/Screw#Screw_head_shapes

No, see attached pix, this is the screw I will be using, a #6 drywall

screw,

about 1.625" long. In looking at the #10 deck screws which are very

similarly

shaped, I came to the conclusion that drilling a pilot hole that big

would weaken

the oak at its position passing thru the bolt head, encouraging its

breakage.

So as mentioned in the last post, I've reduced the knob to 28mm in diameter

and adjusted the rest to fit. I've half or more of a 5lb box of this

screw, which will

not reach all the way thru the bolt's square head, needs a much smaller

pilot

hole etc. These screws are fairly hard steel, so the chances of popping the

head off are somewhere between slim and none.

But that should show the tulip shape I need to fit, somewhere around a

2.5 to

3mm radius with the outer edge being the preferred first contact point.

These have a #2 Phillips head. One Bosch #2 bit in variable speed drill

will drive

50 lbs of this screw. Unless you've a dummy running the drill. :o(>

Bosch makes

good stuff.

Trygve

Thank you. Take care and stay well.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

Gene,

My money would be on just forming a standard countersunk hole for the

head. I wouldn't worry about perfectly matching the curvature of the

deck screw. Once it's all together, It won't matter and this doesn't

sound like a structural joint that will be under a significant amount of

tension either.

Just my $0.02.

Bill Lugg

On 7/17/22 14:47, gene heskett wrote:

On 7/17/22 13:09, Michael Möller wrote:

A picture of a Tulip Head of a screw ... when I google the term I get lots

of surgical implant stuff ... you're not doing surgical equipment are you?

Not hardly Michael, it's the knob on the end of a vise handle. And I am

changing my thinking a bit but the need for that shape isn't changed.

I'll move the flat face (the cube) to just clip off the the bottom, then

add a 19mm hole to fit over the end of the dowel, hollowing it out to

about the flat faces location. Then print a TPU sleeve with a 19mm bore

and a 25mm OD & 16 to 17mm long for the bumper.

This is the underside of the head of a commonly used here in the US

for a "deck" screw, holding the wooden planks of a front or back deck

or porch floor to its sub-framing on your house. Usually with a T25 or

so torx socket for a driving tool. google or DDG for deck screws should

get you some pix for reference.

I've got one of these making just to see if it fits the doweling.

module handle_washer()

{ $fn=180;

translate([0,0,15.50])difference()

{

sphere(d=40);

translate([-22.5,-22.5,-60.5])cube(45);

translate([0,0,16])cylinder(h=10,d=4,center=true);

translate([0,0,-2.1])cylinder(h=27,d=19,center=true);

}

}

but I still need to see about the screw head socket on top of it.

And watching it form, its plain to see 40mm is too big, so I've

reduced it to 28mm and adjusted the rest to fit, but I think I've

found a bug, the ! in front of the sphere I expected to make it

transparent so I could see whats inside, but what it does do is

not helpful at all as it just turns it grey and solid.

Is that the intended behavior?

So I'll make this one next after I test fit whats making now.

module handle_cap()

{ $fn=180;

translate([0,0,5.5])difference()

{

sphere(d=28);

translate([0,0,9])cylinder(h=10,d=4,center=true);

translate([0,0,-0.6])cylinder(h=11,d=19,center=true);

translate([-22.5,-22.5,-50.5])cube(45);

}

}

On Sun, 17 Jul 2022 at 17:16, gene heskett gheskett@shentel.net wrote:

Greetings all;

I think I may be in over my head.

This code starts to make cap to go on the ends of the handle rod for

this screw,

the remainder of a spherical knob being printed from TPU so serve as a

bumper

when the user lets go of the handle and the handle slides thru the hole

until

it hits the knob on the end of the handle. Because they are cheap by the

25 lb

pail, I want to drill into the end of an oak dowel for a 4" long #10

deck screw.

But the deck screw has a tulip head, not the usual tapered conical of a

flat

headed wood screw.

So I need to model that tulip shape with another module to be the final

difference

in this code:

Ideas on how to go about that?

The only idea I can come up with is a 3mm diameter disk extruded to a

usable

thickness, offset so as to form a tulip shape if rotated about the 4mm

shank

of the deck screw, and that then used as a difference under a conical

cylinder.

That I may be able to do, but it seems to me there ought to be a different,

better way.

Is there?

Thank you all. Take care and stay well.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On 7/17/2022 1:47 PM, gene heskett wrote:

but I still need to see about the screw head socket on top of it.

And watching it form, its plain to see 40mm is too big, so I've

reduced it to 28mm and adjusted the rest to fit, but I think I've

found a bug, the ! in front of the sphere I expected to make it

transparent so I could see whats inside, but what it does do is

not helpful at all as it just turns it grey and solid.

"!" means "show only this object". You probably mean "%", which means

"make this object transparent-gray, and don't include it in the final

model".

On 7/18/22 13:07, Jordan Brown wrote:

On 7/17/2022 1:47 PM, gene heskett wrote:

but I still need to see about the screw head socket on top of it.

And watching it form, its plain to see 40mm is too big, so I've

reduced it to 28mm and adjusted the rest to fit, but I think I've

found a bug, the ! in front of the sphere I expected to make it

transparent so I could see whats inside, but what it does do is

not helpful at all as it just turns it grey and solid.

"!" means "show only this object". You probably mean "%", which means

"make this object transparent-gray, and don't include it in the final

model".

I tried both, neither gave me the xray view I needed. I needed to

see the penetration of a cylinder into a sphere, the cylinder being the

socket space inside the sphere for the end of the dowel/handle that

plugs into the sphere. This is the knob on the ends of a vise handle

that keeps the handle from falling plumb out of the screw head

when the user lets go of the handle.

Simple concept,but drove OpenSCAD into very slow rendering in 22 lines

of code. But it worked well. Unfortunately the printer bricked itself while

trying to fix a flow problem which was only 25% of the flow needed to

print the parts. Fun and games this isn't. Changing the main board in a

Prusa MK3S is not in my definition of fun. Digging post holes for new fence

is. I should do more of it, but at 87 I'd druther pay a younger person. :-)

Thanks, take care and stay well, jordan.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

On 7/18/2022 10:55 AM, gene heskett wrote:

I tried both, neither gave me the xray view I needed. I needed to

see the penetration of a cylinder into a sphere,

Like so?

difference() {

%sphere(r=10);

cylinder(r=5, h=20);

}

On 7/18/22 13:28, Jordan Brown wrote:

On 7/17/2022 1:47 PM, gene heskett wrote:

but I still need to see about the screw head socket on top of it.

And watching it form, its plain to see 40mm is too big, so I've

reduced it to 28mm and adjusted the rest to fit, but I think I've

found a bug, the ! in front of the sphere I expected to make it

transparent so I could see whats inside, but what it does do is

not helpful at all as it just turns it grey and solid.

"!" means "show only this object". You probably mean "%", which means

"make this object transparent-gray, and don't include it in the final

model".

That does make it grey, but there's nothing transparent about it,

its solid grey and nothing inside it can be seen. It also fouls the first

argument of a difference(), making line 2 the base against which lines

3,4,5 are subtracted, definitely not useful.

This is last months AppImage.

2022.04.29.ai11816 (git 68c63f61b)

Thank you Jordan, take care and stay well.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web pagehttp://geneslinuxbox.net:6309/