TR

Thomas Richter

Thu, Dec 26, 2024 5:31 PM

Oh, I see. I never tested with that high values of the arm pitch. That is a stepping problem: The outline of the shape is generated in a for loop. Imagine that a beam turns counterclockwise around the z-axis in the xy plane in steps of one degree. For every step the radius of the outer shape is calculated and the corresponding point (the intersection of the beam and the outline) on the xy plane becomes part of the points array of the polygon forming the outer shape. At the positions you mention a step of one degree leads to a quite large step along the outline because at those positions the "beam" is almost parallel to the outline. If you reduce the step in the for loop from 1 to 0.1 this disappears. But that would lead to huge numbers of faces. So maybe in the future I will compensate for that with smaller steps at certain positions depending on the scalar product of the current outline and the "beam".

I understand your comments. This thing has developed its own life, currently going way further than it was intended in the first place, more and more becoming an intellectual game. Nonetheless, many people in my university's fab lab are quite happy I made and shared this.

Currently, I learn a lot about analytical geometry (actually re-memorizing things learnt decades ago in school) and about for me so far unknown ways to produce things in OpenSCAD. I could have let it go a long time ago, but the challenge of learning and speeding up the calculation now really appeals to me.

Although the calculations may look confusing, it is mainly just the application of the sine and cosine theorems to scalene triangles.

Am 26.12.2024 um 17:57 schrieb Adrian Mariano via Discuss discuss@lists.openscad.org:

Sanding well enough to produce a model that looks good is going to be a ton of work---more work than I would put forth for a model. Casting is obviously a different application, where appearance doesn't matter. But if you're planning to offer a generator to people, I would guess most people are in my camp: no interest in a bunch of post processing of the model. If I had a project with 8 knobs it would loom even larger as a nuisance. What would make sense for this is solvent smoothing...but I don't do that either. (Not really feasible with PLA.)

Building structures analytically is generally very fast if you have a reasonably straight forward analytic approach. I can't quite understand your method to know what the result would look like---definitely post your final result.

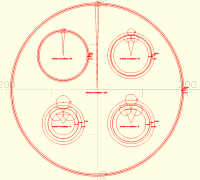

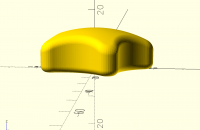

Regarding the corners, it's not super visible in the model as you gave it, but when I changed armPitch to 3 I got this<image.png>

The corner is very clear here. So if your math is producing a corner when armPitch=3 then most likely there is exactly one value of armPitch (other parameters held fixed) that generates a model where the tangents match and there is no corner. I didn't try to understand your code enough to know what's going on there. The corner is more subtle with less extreme parameter choices, but may be tactile even if not obvious in the model on screen.

At armPitch of 3.2 there are now two obvious corners:

<image.png>

And these parameter values seem plausible use cases, not crazy outlier values, so if you're providing a parameterized model it seems like they should work.

On Thu, Dec 26, 2024 at 11:26 AM Thomas Richter via Discuss discuss@lists.openscad.org wrote:

Thank you for your insights. I get good results printing the rounded surface upside down and sanding it. You are right about the distance of the top layers, this tends to be visible the closer it gets to flat, but it's fine after sanding. Nonetheless, if you take a look at printables, there are also flat versions of the knobs.

I don't just print the knobs but use the sanded prints to create molds for brass castings.

The tangents of the tips and the notches actually match in both the version on printables (made with boolean operations) and the analytical version posted in this thread. The small edgy stripes between tips and notches are subject to low $fn values of the cylinders when creating the knob with boolean operations. With an analytically generated outline they don't appear at all. Could you please elaborate on the problems you experienced?

I make good progress creating the rounded top analytically. I generate a polyhedron from several layers of outlines with the radius changing with the cosine of the current step's angle. It is fast as hell, even with 360 steps around the edge it takes less than 50 milliseconds for two layers and I expect to be fine with about ten layers for the rounded edge. I can post the solution here later if someone is interested.

One interesting thing I noticed with the solution I posted in this thread are strangely shaped faces at the rounded edge after doing the minkowski. The Prusa Slicer finds 20 errors in the resulting stl. This will also disappear with the analytical solution.

Am 26.12.2024 um 16:03 schrieb Adrian Mariano via Discuss discuss@lists.openscad.org:

I'm not sure what Ray has against rounded edges. I use them all the time and think they look and feel great in my FDM printed models.

What does NOT look great in my experience is something like the gradual dome top of the knob, which tends to have a very exposed layer line step-structure with very wide and visible steps that I think look and feel pretty bad. That will be worse the closer you are to flat---I don't know how bad it would look with the model as shown. I printed a knob to go on my audio amp and my first version had a domed top like shown and I scratched that and went back to flat after I felt the model in hand.

The other thing that does NOT look great is a roundover printed upside down. That needs to be a chamfer or teardrop for the best result. So I'd probably do something like this for a flat topped model:

include<BOSL2/std.scad>

include<BOSL2/rounding.scad>

offset_sweep(deduplicate(points,closed=true), h=20, bot=os_teardrop(r=2), top=os_circle(r=2),steps=9);

to get that effect. There is another thing I'd probably try to fix, which is the corners where the tip circles meet the notch circles. For a truly beautiful knob the tangents should match so that you don't have corners there.

Oh, and one other thing that will make this faster no matter how you proceed is to stop using so many points. The smallest facet is 0.22 mm in the posted version. That's unnecessarily small.

I don't see an easy way to create the original shape using an analytic method. You'd need to form a grid over the top of the knob to form the polyhedral face of the top, and that seems pretty difficult to do.

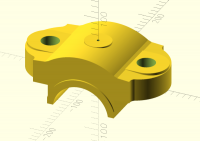

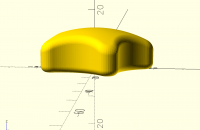

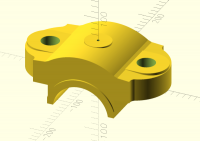

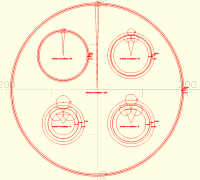

Here's what the knot from the above code looks like from the top and bottom:

<image.png>

<image.png>

Avoiding the lower angle at the bottom by switching to a chamfer will ensure good printing.

On Thu, Dec 26, 2024 at 7:21 AM Raymond West via Discuss discuss@lists.openscad.org wrote:

If the knob is to be 3d fdm printed by others, then the rounded edges will look awful. Minkowski is slow, especially if $fn is large. I would suggest a redesign of the knob. I posted on here, a few weeks ago (re: bad children) some simple bevel modules. (They sliced at 0.1mm intervals, but that and the profile could be varied). It gives much faster results than using Minkowski. Basically, you could draw the profile of the knob in 2d, linear extrude it to the desired thickness, then apply the bevel/rounding modules.

On 26/12/2024 08:12, pca006132 via Discuss wrote:

Another way would be to do the convex decomposition by yourself, I think it can be split into 5 convex components?

On Thu, Dec 26, 2024, 4:07 PM Chun Kit LAM john.lck40@gmail.com wrote:

The slowness is really in the CGAL convex decomposition code path, and

sadly there is no plan to make a faster one for now.

If you want this to be fast, the best way might be to do it

analytically, considering you already computed the knob outline

analytically, it may not be that hard.

On 12/26/24 15:53, Thomas Richter via Discuss wrote:

This is related to a question I asked a couple of days ago (problems with not closed mesh) but a different problem. Should I have asked in the old thread anyway?

I create star shaped knobs for hex screws (see https://www.printables.com/model/1116311-parametric-knob-for-hex-nuts-and-allen-screws-knau). The rounded top surface is achieved by subtracting from a large sphere (see prototype code below) and the rounded edges are created with the minkowski sum. Since the sphere must be large for a low rounding it needs a large $fn value (120 currently). Thus, the minkowski sum needs about 80 seconds (M3 CPU) to generate the object with manifold backend.

This is already an optimized version since I create the basic star shape analytically instead of using unions and differences. This way I was able to reduce the computing time by about 80% already.

Does someone here have an idea how I could reduce the computing time even further? The reason: I create a web based configuration tool and would like to provide the stl file in less than ten seconds.

/**

- prototype code

*/

ARMS = 5;

// knobDiameter

kd = 40;

rKnob = kd / 2;

// armPitch

ap = 2;

// notchRatio

nr = 3;

// radius of the arm circles

rK = PI * rKnob / ((ap + 1) * ARMS + PI);

// radius of the notch circles

rN = nr * rK;

// radius of the circle to place the arms (rbk)

rPosK = rKnob - rK;

// angle between arm and notch (360 / ARMS / 2)

alpha = 180 / ARMS;

// angle between center of knob, center of notch, center of arm

gamma = asin(sin(alpha) * rPosK / (rN + rK));

// angle between center of knob, center of arm, center of notch

beta = 180 - alpha - gamma;

// radius of the circle to place the notches (rbn)

rPosN = abs(rPosK * sin(beta) / sin(gamma));

// radius of the knob's core: distance from center to touch point of arm and notch (rc)

rCore = sqrt(rPosK^2 + rK^2 - 2 * rPosK * rK * cos(beta));

// angle to touch point

alphaC = asin(rK * sin(beta) / rCore);

armAngle = 360 / ARMS;

points = [

for (phi = [0: 1: 360])

let (arm = floor(phi / armAngle))

let (phiTemp = phi - (arm * armAngle))

// only half of an arm is uniquely defined, the rest can be determined

// by rotation and mirroring

let (phiNorm = phiTemp > armAngle / 2

? armAngle - phiTemp

: phiTemp)

let (rx = abs(phiNorm) < 1e-6

? rKnob

: abs(phiNorm - armAngle / 2) < 1e-6

? rPosN - rN

: phiNorm < alphaC

?

let (gamma2 = asin(rPosK * sin(phiNorm) / rK))

let (beta2 = 180 - phiNorm - gamma2)

rK * sin(beta2) / sin(phiNorm)

:

let (delta = alpha - phiNorm)

let (epsilon = 180 - asin(rPosN * sin(delta) / rN))

let (rho = 180 - delta - epsilon)

rN * sin(rho) / sin(delta)

)

[rx * cos(phi), rx * sin(phi)]

];

// quick and dirty prototype for testing

minkowski() {

sphere(2, $fn = 36);

difference() {

translate([0, 0, -30]) sphere(d = 99, $fn = 120);

difference () {

translate([0, 0, -35]) cube(110, center = true);

linear_extrude(20) polygon(points);

}

}

}

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Oh, I see. I never tested with that high values of the arm pitch. That is a stepping problem: The outline of the shape is generated in a for loop. Imagine that a beam turns counterclockwise around the z-axis in the xy plane in steps of one degree. For every step the radius of the outer shape is calculated and the corresponding point (the intersection of the beam and the outline) on the xy plane becomes part of the points array of the polygon forming the outer shape. At the positions you mention a step of one degree leads to a quite large step along the outline because at those positions the "beam" is almost parallel to the outline. If you reduce the step in the for loop from 1 to 0.1 this disappears. But that would lead to huge numbers of faces. So maybe in the future I will compensate for that with smaller steps at certain positions depending on the scalar product of the current outline and the "beam".

I understand your comments. This thing has developed its own life, currently going way further than it was intended in the first place, more and more becoming an intellectual game. Nonetheless, many people in my university's fab lab are quite happy I made and shared this.

Currently, I learn a lot about analytical geometry (actually re-memorizing things learnt decades ago in school) and about for me so far unknown ways to produce things in OpenSCAD. I could have let it go a long time ago, but the challenge of learning and speeding up the calculation now really appeals to me.

Although the calculations may look confusing, it is mainly just the application of the sine and cosine theorems to scalene triangles.

> Am 26.12.2024 um 17:57 schrieb Adrian Mariano via Discuss <discuss@lists.openscad.org>:

>

> Sanding well enough to produce a model that looks good is going to be a ton of work---more work than I would put forth for a model. Casting is obviously a different application, where appearance doesn't matter. But if you're planning to offer a generator to people, I would guess most people are in my camp: no interest in a bunch of post processing of the model. If I had a project with 8 knobs it would loom even larger as a nuisance. What would make sense for this is solvent smoothing...but I don't do that either. (Not really feasible with PLA.)

>

> Building structures analytically is generally very fast if you have a reasonably straight forward analytic approach. I can't quite understand your method to know what the result would look like---definitely post your final result.

>

> Regarding the corners, it's not super visible in the model as you gave it, but when I changed armPitch to 3 I got this<image.png>

>

>

> The corner is very clear here. So if your math is producing a corner when armPitch=3 then most likely there is exactly one value of armPitch (other parameters held fixed) that generates a model where the tangents match and there is no corner. I didn't try to understand your code enough to know what's going on there. The corner is more subtle with less extreme parameter choices, but may be tactile even if not obvious in the model on screen.

>

> At armPitch of 3.2 there are now two obvious corners:

>

> <image.png>

>

> And these parameter values seem plausible use cases, not crazy outlier values, so if you're providing a parameterized model it seems like they should work.

>

> On Thu, Dec 26, 2024 at 11:26 AM Thomas Richter via Discuss <discuss@lists.openscad.org> wrote:

> Thank you for your insights. I get good results printing the rounded surface upside down _and sanding_ it. You are right about the distance of the top layers, this tends to be visible the closer it gets to flat, but it's fine after sanding. Nonetheless, if you take a look at printables, there are also flat versions of the knobs.

>

> I don't just print the knobs but use the sanded prints to create molds for brass castings.

>

> The tangents of the tips and the notches actually match in both the version on printables (made with boolean operations) and the analytical version posted in this thread. The small edgy stripes between tips and notches are subject to low $fn values of the cylinders when creating the knob with boolean operations. With an analytically generated outline they don't appear at all. Could you please elaborate on the problems you experienced?

>

> I make good progress creating the rounded top analytically. I generate a polyhedron from several layers of outlines with the radius changing with the cosine of the current step's angle. It is fast as hell, even with 360 steps around the edge it takes less than 50 milliseconds for two layers and I expect to be fine with about ten layers for the rounded edge. I can post the solution here later if someone is interested.

>

> One interesting thing I noticed with the solution I posted in this thread are strangely shaped faces at the rounded edge after doing the minkowski. The Prusa Slicer finds 20 errors in the resulting stl. This will also disappear with the analytical solution.

>

>

> > Am 26.12.2024 um 16:03 schrieb Adrian Mariano via Discuss <discuss@lists.openscad.org>:

> >

> > I'm not sure what Ray has against rounded edges. I use them all the time and think they look and feel great in my FDM printed models.

> >

> > What does NOT look great in my experience is something like the gradual dome top of the knob, which tends to have a very exposed layer line step-structure with very wide and visible steps that I think look and feel pretty bad. That will be worse the closer you are to flat---I don't know how bad it would look with the model as shown. I printed a knob to go on my audio amp and my first version had a domed top like shown and I scratched that and went back to flat after I felt the model in hand.

> >

> > The other thing that does NOT look great is a roundover printed upside down. That needs to be a chamfer or teardrop for the best result. So I'd probably do something like this for a flat topped model:

> >

> > include<BOSL2/std.scad>

> > include<BOSL2/rounding.scad>

> > offset_sweep(deduplicate(points,closed=true), h=20, bot=os_teardrop(r=2), top=os_circle(r=2),steps=9);

> >

> > to get that effect. There is another thing I'd probably try to fix, which is the corners where the tip circles meet the notch circles. For a truly beautiful knob the tangents should match so that you don't have corners there.

> >

> > Oh, and one other thing that will make this faster no matter how you proceed is to stop using so many points. The smallest facet is 0.22 mm in the posted version. That's unnecessarily small.

> >

> > I don't see an easy way to create the original shape using an analytic method. You'd need to form a grid over the top of the knob to form the polyhedral face of the top, and that seems pretty difficult to do.

> >

> > Here's what the knot from the above code looks like from the top and bottom:

> >

> > <image.png>

> >

> > <image.png>

> > Avoiding the lower angle at the bottom by switching to a chamfer will ensure good printing.

> >

> > On Thu, Dec 26, 2024 at 7:21 AM Raymond West via Discuss <discuss@lists.openscad.org> wrote:

> > If the knob is to be 3d fdm printed by others, then the rounded edges will look awful. Minkowski is slow, especially if $fn is large. I would suggest a redesign of the knob. I posted on here, a few weeks ago (re: bad children) some simple bevel modules. (They sliced at 0.1mm intervals, but that and the profile could be varied). It gives much faster results than using Minkowski. Basically, you could draw the profile of the knob in 2d, linear extrude it to the desired thickness, then apply the bevel/rounding modules.

> > On 26/12/2024 08:12, pca006132 via Discuss wrote:

> >> Another way would be to do the convex decomposition by yourself, I think it can be split into 5 convex components?

> >>

> >> On Thu, Dec 26, 2024, 4:07 PM Chun Kit LAM <john.lck40@gmail.com> wrote:

> >> The slowness is really in the CGAL convex decomposition code path, and

> >> sadly there is no plan to make a faster one for now.

> >>

> >> If you want this to be fast, the best way might be to do it

> >> analytically, considering you already computed the knob outline

> >> analytically, it may not be that hard.

> >>

> >> On 12/26/24 15:53, Thomas Richter via Discuss wrote:

> >> > This is related to a question I asked a couple of days ago (problems with not closed mesh) but a different problem. Should I have asked in the old thread anyway?

> >> >

> >> > I create star shaped knobs for hex screws (see https://www.printables.com/model/1116311-parametric-knob-for-hex-nuts-and-allen-screws-knau). The rounded top surface is achieved by subtracting from a large sphere (see prototype code below) and the rounded edges are created with the minkowski sum. Since the sphere must be large for a low rounding it needs a large $fn value (120 currently). Thus, the minkowski sum needs about 80 seconds (M3 CPU) to generate the object with manifold backend.

> >> >

> >> > This is already an optimized version since I create the basic star shape analytically instead of using unions and differences. This way I was able to reduce the computing time by about 80% already.

> >> >

> >> > Does someone here have an idea how I could reduce the computing time even further? The reason: I create a web based configuration tool and would like to provide the stl file in less than ten seconds.

> >> >

> >> > /**

> >> > * prototype code

> >> > */

> >> > ARMS = 5;

> >> >

> >> > // knobDiameter

> >> > kd = 40;

> >> > rKnob = kd / 2;

> >> > // armPitch

> >> > ap = 2;

> >> > // notchRatio

> >> > nr = 3;

> >> >

> >> > // radius of the arm circles

> >> > rK = PI * rKnob / ((ap + 1) * ARMS + PI);

> >> > // radius of the notch circles

> >> > rN = nr * rK;

> >> >

> >> > // radius of the circle to place the arms (rbk)

> >> > rPosK = rKnob - rK;

> >> >

> >> > // angle between arm and notch (360 / ARMS / 2)

> >> > alpha = 180 / ARMS;

> >> >

> >> > // angle between center of knob, center of notch, center of arm

> >> > gamma = asin(sin(alpha) * rPosK / (rN + rK));

> >> >

> >> > // angle between center of knob, center of arm, center of notch

> >> > beta = 180 - alpha - gamma;

> >> >

> >> > // radius of the circle to place the notches (rbn)

> >> > rPosN = abs(rPosK * sin(beta) / sin(gamma));

> >> >

> >> > // radius of the knob's core: distance from center to touch point of arm and notch (rc)

> >> > rCore = sqrt(rPosK^2 + rK^2 - 2 * rPosK * rK * cos(beta));

> >> >

> >> > // angle to touch point

> >> > alphaC = asin(rK * sin(beta) / rCore);

> >> >

> >> > armAngle = 360 / ARMS;

> >> >

> >> > points = [

> >> >

> >> > for (phi = [0: 1: 360])

> >> > let (arm = floor(phi / armAngle))

> >> > let (phiTemp = phi - (arm * armAngle))

> >> > // only half of an arm is uniquely defined, the rest can be determined

> >> > // by rotation and mirroring

> >> > let (phiNorm = phiTemp > armAngle / 2

> >> > ? armAngle - phiTemp

> >> > : phiTemp)

> >> > let (rx = abs(phiNorm) < 1e-6

> >> > ? rKnob

> >> > : abs(phiNorm - armAngle / 2) < 1e-6

> >> > ? rPosN - rN

> >> > : phiNorm < alphaC

> >> > ?

> >> > let (gamma2 = asin(rPosK * sin(phiNorm) / rK))

> >> > let (beta2 = 180 - phiNorm - gamma2)

> >> > rK * sin(beta2) / sin(phiNorm)

> >> > :

> >> > let (delta = alpha - phiNorm)

> >> > let (epsilon = 180 - asin(rPosN * sin(delta) / rN))

> >> > let (rho = 180 - delta - epsilon)

> >> > rN * sin(rho) / sin(delta)

> >> > )

> >> >

> >> > [rx * cos(phi), rx * sin(phi)]

> >> > ];

> >> >

> >> > // quick and dirty prototype for testing

> >> > minkowski() {

> >> > sphere(2, $fn = 36);

> >> >

> >> > difference() {

> >> > translate([0, 0, -30]) sphere(d = 99, $fn = 120);

> >> >

> >> > difference () {

> >> > translate([0, 0, -35]) cube(110, center = true);

> >> >

> >> > linear_extrude(20) polygon(points);

> >> > }

> >> > }

> >> > }

> >> > _______________________________________________

> >> > OpenSCAD mailing list

> >> > To unsubscribe send an email to discuss-leave@lists.openscad.org

> >>

> >> _______________________________________________

> >> OpenSCAD mailing list

> >> To unsubscribe send an email to discuss-leave@lists.openscad.org

> >>

> > _______________________________________________

> > OpenSCAD mailing list

> > To unsubscribe send an email to discuss-leave@lists.openscad.org

> > _______________________________________________

> > OpenSCAD mailing list

> > To unsubscribe send an email to discuss-leave@lists.openscad.org

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

RW

Raymond West

Thu, Dec 26, 2024 7:00 PM

On 26/12/2024 15:03, Adrian Mariano via Discuss wrote:

I'm not sure what Ray has against rounded edges. I use them all the

time and think they look and feel great in my FDM printed models.

What does NOT look great in my experience is something like the

gradual dome top of the knob, which tends to have a very exposed layer

line step-structure with very wide and visible steps that I think look

and feel pretty bad. That will be worse the closer you are to

flat---I don't know how bad it would look with the model as shown. I

printed a knob to go on my audio amp and my first version had a domed

top like shown and I scratched that and went back to flat after I felt

the model in hand.

The other thing that does NOT look great is a roundover printed upside

down.

Hi Adrian, you half answered your own question to me, and nop head gave

the top half answer, wrt adaptive.

On 26/12/2024 15:03, Adrian Mariano via Discuss wrote:

> I'm not sure what Ray has against rounded edges. I use them all the

> time and think they look and feel great in my FDM printed models.

>

> What does NOT look great in my experience is something like the

> gradual dome top of the knob, which tends to have a very exposed layer

> line step-structure with very wide and visible steps that I think look

> and feel pretty bad. That will be worse the closer you are to

> flat---I don't know how bad it would look with the model as shown. I

> printed a knob to go on my audio amp and my first version had a domed

> top like shown and I scratched that and went back to flat after I felt

> the model in hand.

>

> The other thing that does NOT look great is a roundover printed upside

> down.

>

Hi Adrian, you half answered your own question to me, and nop head gave

the top half answer, wrt adaptive.

AM

Adrian Mariano

Thu, Dec 26, 2024 7:02 PM

I tried jacking up the sample rate and indeed it looks smoother, but to my

eye it appears that there is still a corner. But maybe I'm imagining it.

It's a pretty subtle corner if it's real, so it probably doesn't matter.

You are mating two curves, one when phiNorm<alphaC and one when

phiNorm>=alphaC. Have you designed them to have matching tangents?

But to eliminate the visual corners without going crazy on sample rate I

think you need to change your sampling method to sample the two arcs

separately and then join them. That way the arcs can be sampled uniformly

over their length instead of sampled based on the global polar coordinate

and the sample rate will be appropriate for the curvature of each part.

This will fix the sampled problems created by using global polar

coordinates, which obviously doesn't work properly for knobs with thinner

or concave arms. The code for what I propose is actually probably simpler

if the design is indeed two circular arcs. (I can't tell on brief

inspection what that code is doing.)

On Thu, Dec 26, 2024 at 12:31 PM Thomas Richter via Discuss <

discuss@lists.openscad.org> wrote:

Oh, I see. I never tested with that high values of the arm pitch. That is

a stepping problem: The outline of the shape is generated in a for loop.

Imagine that a beam turns counterclockwise around the z-axis in the xy

plane in steps of one degree. For every step the radius of the outer shape

is calculated and the corresponding point (the intersection of the beam and

the outline) on the xy plane becomes part of the points array of the

polygon forming the outer shape. At the positions you mention a step of one

degree leads to a quite large step along the outline because at those

positions the "beam" is almost parallel to the outline. If you reduce the

step in the for loop from 1 to 0.1 this disappears. But that would lead to

huge numbers of faces. So maybe in the future I will compensate for that

with smaller steps at certain positions depending on the scalar product of

the current outline and the "beam".

I understand your comments. This thing has developed its own life,

currently going way further than it was intended in the first place, more

and more becoming an intellectual game. Nonetheless, many people in my

university's fab lab are quite happy I made and shared this.

Currently, I learn a lot about analytical geometry (actually re-memorizing

things learnt decades ago in school) and about for me so far unknown ways

to produce things in OpenSCAD. I could have let it go a long time ago, but

the challenge of learning and speeding up the calculation now really

appeals to me.

Although the calculations may look confusing, it is mainly just the

application of the sine and cosine theorems to scalene triangles.

Am 26.12.2024 um 17:57 schrieb Adrian Mariano via Discuss <

Sanding well enough to produce a model that looks good is going to be a

ton of work---more work than I would put forth for a model. Casting is

obviously a different application, where appearance doesn't matter. But if

you're planning to offer a generator to people, I would guess most people

are in my camp: no interest in a bunch of post processing of the model. If

I had a project with 8 knobs it would loom even larger as a nuisance. What

would make sense for this is solvent smoothing...but I don't do that

either. (Not really feasible with PLA.)

Building structures analytically is generally very fast if you have a

reasonably straight forward analytic approach. I can't quite understand

your method to know what the result would look like---definitely post your

final result.

Regarding the corners, it's not super visible in the model as you gave

it, but when I changed armPitch to 3 I got this<image.png>

The corner is very clear here. So if your math is producing a corner

when armPitch=3 then most likely there is exactly one value of armPitch

(other parameters held fixed) that generates a model where the tangents

match and there is no corner. I didn't try to understand your code enough

to know what's going on there. The corner is more subtle with less

extreme parameter choices, but may be tactile even if not obvious in the

model on screen.

At armPitch of 3.2 there are now two obvious corners:

<image.png>

And these parameter values seem plausible use cases, not crazy outlier

values, so if you're providing a parameterized model it seems like they

should work.

On Thu, Dec 26, 2024 at 11:26 AM Thomas Richter via Discuss <

Thank you for your insights. I get good results printing the rounded

surface upside down and sanding it. You are right about the distance of

the top layers, this tends to be visible the closer it gets to flat, but

it's fine after sanding. Nonetheless, if you take a look at printables,

there are also flat versions of the knobs.

I don't just print the knobs but use the sanded prints to create molds

The tangents of the tips and the notches actually match in both the

version on printables (made with boolean operations) and the analytical

version posted in this thread. The small edgy stripes between tips and

notches are subject to low $fn values of the cylinders when creating the

knob with boolean operations. With an analytically generated outline they

don't appear at all. Could you please elaborate on the problems you

experienced?

I make good progress creating the rounded top analytically. I generate a

polyhedron from several layers of outlines with the radius changing with

the cosine of the current step's angle. It is fast as hell, even with 360

steps around the edge it takes less than 50 milliseconds for two layers and

I expect to be fine with about ten layers for the rounded edge. I can post

the solution here later if someone is interested.

One interesting thing I noticed with the solution I posted in this

thread are strangely shaped faces at the rounded edge after doing the

minkowski. The Prusa Slicer finds 20 errors in the resulting stl. This will

also disappear with the analytical solution.

Am 26.12.2024 um 16:03 schrieb Adrian Mariano via Discuss <

I'm not sure what Ray has against rounded edges. I use them all the

time and think they look and feel great in my FDM printed models.

What does NOT look great in my experience is something like the

gradual dome top of the knob, which tends to have a very exposed layer line

step-structure with very wide and visible steps that I think look and feel

pretty bad. That will be worse the closer you are to flat---I don't know

how bad it would look with the model as shown. I printed a knob to go on

my audio amp and my first version had a domed top like shown and I

scratched that and went back to flat after I felt the model in hand.

The other thing that does NOT look great is a roundover printed upside

down. That needs to be a chamfer or teardrop for the best result. So I'd

probably do something like this for a flat topped model:

include<BOSL2/std.scad>

include<BOSL2/rounding.scad>

offset_sweep(deduplicate(points,closed=true), h=20,

bot=os_teardrop(r=2), top=os_circle(r=2),steps=9);

to get that effect. There is another thing I'd probably try to fix,

which is the corners where the tip circles meet the notch circles. For a

truly beautiful knob the tangents should match so that you don't have

corners there.

Oh, and one other thing that will make this faster no matter how you

proceed is to stop using so many points. The smallest facet is 0.22 mm in

the posted version. That's unnecessarily small.

I don't see an easy way to create the original shape using an analytic

method. You'd need to form a grid over the top of the knob to form the

polyhedral face of the top, and that seems pretty difficult to do.

Here's what the knot from the above code looks like from the top and

<image.png>

<image.png>

Avoiding the lower angle at the bottom by switching to a chamfer will

On Thu, Dec 26, 2024 at 7:21 AM Raymond West via Discuss <

If the knob is to be 3d fdm printed by others, then the rounded edges

will look awful. Minkowski is slow, especially if $fn is large. I would

suggest a redesign of the knob. I posted on here, a few weeks ago (re: bad

children) some simple bevel modules. (They sliced at 0.1mm intervals, but

that and the profile could be varied). It gives much faster results than

using Minkowski. Basically, you could draw the profile of the knob in 2d,

linear extrude it to the desired thickness, then apply the bevel/rounding

modules.

On 26/12/2024 08:12, pca006132 via Discuss wrote:

Another way would be to do the convex decomposition by yourself, I

think it can be split into 5 convex components?

The slowness is really in the CGAL convex decomposition code path,

sadly there is no plan to make a faster one for now.

If you want this to be fast, the best way might be to do it

analytically, considering you already computed the knob outline

analytically, it may not be that hard.

On 12/26/24 15:53, Thomas Richter via Discuss wrote:

This is related to a question I asked a couple of days ago

(problems with not closed mesh) but a different problem. Should I have

asked in the old thread anyway?

I create star shaped knobs for hex screws (see

This is already an optimized version since I create the basic star

shape analytically instead of using unions and differences. This way I was

able to reduce the computing time by about 80% already.

Does someone here have an idea how I could reduce the computing

time even further? The reason: I create a web based configuration tool and

would like to provide the stl file in less than ten seconds.

/**

- prototype code

*/

ARMS = 5;

// knobDiameter

kd = 40;

rKnob = kd / 2;

// armPitch

ap = 2;

// notchRatio

nr = 3;

// radius of the arm circles

rK = PI * rKnob / ((ap + 1) * ARMS + PI);

// radius of the notch circles

rN = nr * rK;

// radius of the circle to place the arms (rbk)

rPosK = rKnob - rK;

// angle between arm and notch (360 / ARMS / 2)

alpha = 180 / ARMS;

// angle between center of knob, center of notch, center of arm

gamma = asin(sin(alpha) * rPosK / (rN + rK));

// angle between center of knob, center of arm, center of notch

beta = 180 - alpha - gamma;

// radius of the circle to place the notches (rbn)

rPosN = abs(rPosK * sin(beta) / sin(gamma));

// radius of the knob's core: distance from center to touch point

rCore = sqrt(rPosK^2 + rK^2 - 2 * rPosK * rK * cos(beta));

// angle to touch point

alphaC = asin(rK * sin(beta) / rCore);

armAngle = 360 / ARMS;

points = [

for (phi = [0: 1: 360])

let (arm = floor(phi / armAngle))

let (phiTemp = phi - (arm * armAngle))

// only half of an arm is uniquely defined, the rest can be

// by rotation and mirroring

let (phiNorm = phiTemp > armAngle / 2

? armAngle - phiTemp

: phiTemp)

let (rx = abs(phiNorm) < 1e-6

? rKnob

: abs(phiNorm - armAngle / 2) < 1e-6

? rPosN - rN

: phiNorm < alphaC

?

let (gamma2 = asin(rPosK * sin(phiNorm) / rK))

let (beta2 = 180 - phiNorm - gamma2)

rK * sin(beta2) / sin(phiNorm)

:

let (delta = alpha - phiNorm)

let (epsilon = 180 - asin(rPosN * sin(delta) / rN))

let (rho = 180 - delta - epsilon)

rN * sin(rho) / sin(delta)

)

[rx * cos(phi), rx * sin(phi)]

];

// quick and dirty prototype for testing

minkowski() {

sphere(2, $fn = 36);

difference() {

translate([0, 0, -30]) sphere(d = 99, $fn = 120);

difference () {

translate([0, 0, -35]) cube(110, center = true);

linear_extrude(20) polygon(points);

}

}

}

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

I tried jacking up the sample rate and indeed it looks smoother, but to my

eye it appears that there is still a corner. But maybe I'm imagining it.

It's a pretty subtle corner if it's real, so it probably doesn't matter.

You are mating two curves, one when phiNorm<alphaC and one when

phiNorm>=alphaC. Have you designed them to have matching tangents?

But to eliminate the visual corners without going crazy on sample rate I

think you need to change your sampling method to sample the two arcs

separately and then join them. That way the arcs can be sampled uniformly

over their length instead of sampled based on the global polar coordinate

and the sample rate will be appropriate for the curvature of each part.

This will fix the sampled problems created by using global polar

coordinates, which obviously doesn't work properly for knobs with thinner

or concave arms. The code for what I propose is actually probably simpler

if the design is indeed two circular arcs. (I can't tell on brief

inspection what that code is doing.)

On Thu, Dec 26, 2024 at 12:31 PM Thomas Richter via Discuss <

discuss@lists.openscad.org> wrote:

> Oh, I see. I never tested with that high values of the arm pitch. That is

> a stepping problem: The outline of the shape is generated in a for loop.

> Imagine that a beam turns counterclockwise around the z-axis in the xy

> plane in steps of one degree. For every step the radius of the outer shape

> is calculated and the corresponding point (the intersection of the beam and

> the outline) on the xy plane becomes part of the points array of the

> polygon forming the outer shape. At the positions you mention a step of one

> degree leads to a quite large step along the outline because at those

> positions the "beam" is almost parallel to the outline. If you reduce the

> step in the for loop from 1 to 0.1 this disappears. But that would lead to

> huge numbers of faces. So maybe in the future I will compensate for that

> with smaller steps at certain positions depending on the scalar product of

> the current outline and the "beam".

>

> I understand your comments. This thing has developed its own life,

> currently going way further than it was intended in the first place, more

> and more becoming an intellectual game. Nonetheless, many people in my

> university's fab lab are quite happy I made and shared this.

>

> Currently, I learn a lot about analytical geometry (actually re-memorizing

> things learnt decades ago in school) and about for me so far unknown ways

> to produce things in OpenSCAD. I could have let it go a long time ago, but

> the challenge of learning and speeding up the calculation now really

> appeals to me.

>

> Although the calculations may look confusing, it is mainly just the

> application of the sine and cosine theorems to scalene triangles.

>

> > Am 26.12.2024 um 17:57 schrieb Adrian Mariano via Discuss <

> discuss@lists.openscad.org>:

> >

> > Sanding well enough to produce a model that looks good is going to be a

> ton of work---more work than I would put forth for a model. Casting is

> obviously a different application, where appearance doesn't matter. But if

> you're planning to offer a generator to people, I would guess most people

> are in my camp: no interest in a bunch of post processing of the model. If

> I had a project with 8 knobs it would loom even larger as a nuisance. What

> would make sense for this is solvent smoothing...but I don't do that

> either. (Not really feasible with PLA.)

> >

> > Building structures analytically is generally very fast if you have a

> reasonably straight forward analytic approach. I can't quite understand

> your method to know what the result would look like---definitely post your

> final result.

> >

> > Regarding the corners, it's not super visible in the model as you gave

> it, but when I changed armPitch to 3 I got this<image.png>

> >

> >

> > The corner is very clear here. So if your math is producing a corner

> when armPitch=3 then most likely there is exactly one value of armPitch

> (other parameters held fixed) that generates a model where the tangents

> match and there is no corner. I didn't try to understand your code enough

> to know what's going on there. The corner is more subtle with less

> extreme parameter choices, but may be tactile even if not obvious in the

> model on screen.

> >

> > At armPitch of 3.2 there are now two obvious corners:

> >

> > <image.png>

> >

> > And these parameter values seem plausible use cases, not crazy outlier

> values, so if you're providing a parameterized model it seems like they

> should work.

> >

> > On Thu, Dec 26, 2024 at 11:26 AM Thomas Richter via Discuss <

> discuss@lists.openscad.org> wrote:

> > Thank you for your insights. I get good results printing the rounded

> surface upside down _and sanding_ it. You are right about the distance of

> the top layers, this tends to be visible the closer it gets to flat, but

> it's fine after sanding. Nonetheless, if you take a look at printables,

> there are also flat versions of the knobs.

> >

> > I don't just print the knobs but use the sanded prints to create molds

> for brass castings.

> >

> > The tangents of the tips and the notches actually match in both the

> version on printables (made with boolean operations) and the analytical

> version posted in this thread. The small edgy stripes between tips and

> notches are subject to low $fn values of the cylinders when creating the

> knob with boolean operations. With an analytically generated outline they

> don't appear at all. Could you please elaborate on the problems you

> experienced?

> >

> > I make good progress creating the rounded top analytically. I generate a

> polyhedron from several layers of outlines with the radius changing with

> the cosine of the current step's angle. It is fast as hell, even with 360

> steps around the edge it takes less than 50 milliseconds for two layers and

> I expect to be fine with about ten layers for the rounded edge. I can post

> the solution here later if someone is interested.

> >

> > One interesting thing I noticed with the solution I posted in this

> thread are strangely shaped faces at the rounded edge after doing the

> minkowski. The Prusa Slicer finds 20 errors in the resulting stl. This will

> also disappear with the analytical solution.

> >

> >

> > > Am 26.12.2024 um 16:03 schrieb Adrian Mariano via Discuss <

> discuss@lists.openscad.org>:

> > >

> > > I'm not sure what Ray has against rounded edges. I use them all the

> time and think they look and feel great in my FDM printed models.

> > >

> > > What does NOT look great in my experience is something like the

> gradual dome top of the knob, which tends to have a very exposed layer line

> step-structure with very wide and visible steps that I think look and feel

> pretty bad. That will be worse the closer you are to flat---I don't know

> how bad it would look with the model as shown. I printed a knob to go on

> my audio amp and my first version had a domed top like shown and I

> scratched that and went back to flat after I felt the model in hand.

> > >

> > > The other thing that does NOT look great is a roundover printed upside

> down. That needs to be a chamfer or teardrop for the best result. So I'd

> probably do something like this for a flat topped model:

> > >

> > > include<BOSL2/std.scad>

> > > include<BOSL2/rounding.scad>

> > > offset_sweep(deduplicate(points,closed=true), h=20,

> bot=os_teardrop(r=2), top=os_circle(r=2),steps=9);

> > >

> > > to get that effect. There is another thing I'd probably try to fix,

> which is the corners where the tip circles meet the notch circles. For a

> truly beautiful knob the tangents should match so that you don't have

> corners there.

> > >

> > > Oh, and one other thing that will make this faster no matter how you

> proceed is to stop using so many points. The smallest facet is 0.22 mm in

> the posted version. That's unnecessarily small.

> > >

> > > I don't see an easy way to create the original shape using an analytic

> method. You'd need to form a grid over the top of the knob to form the

> polyhedral face of the top, and that seems pretty difficult to do.

> > >

> > > Here's what the knot from the above code looks like from the top and

> bottom:

> > >

> > > <image.png>

> > >

> > > <image.png>

> > > Avoiding the lower angle at the bottom by switching to a chamfer will

> ensure good printing.

> > >

> > > On Thu, Dec 26, 2024 at 7:21 AM Raymond West via Discuss <

> discuss@lists.openscad.org> wrote:

> > > If the knob is to be 3d fdm printed by others, then the rounded edges

> will look awful. Minkowski is slow, especially if $fn is large. I would

> suggest a redesign of the knob. I posted on here, a few weeks ago (re: bad

> children) some simple bevel modules. (They sliced at 0.1mm intervals, but

> that and the profile could be varied). It gives much faster results than

> using Minkowski. Basically, you could draw the profile of the knob in 2d,

> linear extrude it to the desired thickness, then apply the bevel/rounding

> modules.

> > > On 26/12/2024 08:12, pca006132 via Discuss wrote:

> > >> Another way would be to do the convex decomposition by yourself, I

> think it can be split into 5 convex components?

> > >>

> > >> On Thu, Dec 26, 2024, 4:07 PM Chun Kit LAM <john.lck40@gmail.com>

> wrote:

> > >> The slowness is really in the CGAL convex decomposition code path,

> and

> > >> sadly there is no plan to make a faster one for now.

> > >>

> > >> If you want this to be fast, the best way might be to do it

> > >> analytically, considering you already computed the knob outline

> > >> analytically, it may not be that hard.

> > >>

> > >> On 12/26/24 15:53, Thomas Richter via Discuss wrote:

> > >> > This is related to a question I asked a couple of days ago

> (problems with not closed mesh) but a different problem. Should I have

> asked in the old thread anyway?

> > >> >

> > >> > I create star shaped knobs for hex screws (see

> https://www.printables.com/model/1116311-parametric-knob-for-hex-nuts-and-allen-screws-knau).

> The rounded top surface is achieved by subtracting from a large sphere (see

> prototype code below) and the rounded edges are created with the minkowski

> sum. Since the sphere must be large for a low rounding it needs a large $fn

> value (120 currently). Thus, the minkowski sum needs about 80 seconds (M3

> CPU) to generate the object with manifold backend.

> > >> >

> > >> > This is already an optimized version since I create the basic star

> shape analytically instead of using unions and differences. This way I was

> able to reduce the computing time by about 80% already.

> > >> >

> > >> > Does someone here have an idea how I could reduce the computing

> time even further? The reason: I create a web based configuration tool and

> would like to provide the stl file in less than ten seconds.

> > >> >

> > >> > /**

> > >> > * prototype code

> > >> > */

> > >> > ARMS = 5;

> > >> >

> > >> > // knobDiameter

> > >> > kd = 40;

> > >> > rKnob = kd / 2;

> > >> > // armPitch

> > >> > ap = 2;

> > >> > // notchRatio

> > >> > nr = 3;

> > >> >

> > >> > // radius of the arm circles

> > >> > rK = PI * rKnob / ((ap + 1) * ARMS + PI);

> > >> > // radius of the notch circles

> > >> > rN = nr * rK;

> > >> >

> > >> > // radius of the circle to place the arms (rbk)

> > >> > rPosK = rKnob - rK;

> > >> >

> > >> > // angle between arm and notch (360 / ARMS / 2)

> > >> > alpha = 180 / ARMS;

> > >> >

> > >> > // angle between center of knob, center of notch, center of arm

> > >> > gamma = asin(sin(alpha) * rPosK / (rN + rK));

> > >> >

> > >> > // angle between center of knob, center of arm, center of notch

> > >> > beta = 180 - alpha - gamma;

> > >> >

> > >> > // radius of the circle to place the notches (rbn)

> > >> > rPosN = abs(rPosK * sin(beta) / sin(gamma));

> > >> >

> > >> > // radius of the knob's core: distance from center to touch point

> of arm and notch (rc)

> > >> > rCore = sqrt(rPosK^2 + rK^2 - 2 * rPosK * rK * cos(beta));

> > >> >

> > >> > // angle to touch point

> > >> > alphaC = asin(rK * sin(beta) / rCore);

> > >> >

> > >> > armAngle = 360 / ARMS;

> > >> >

> > >> > points = [

> > >> >

> > >> > for (phi = [0: 1: 360])

> > >> > let (arm = floor(phi / armAngle))

> > >> > let (phiTemp = phi - (arm * armAngle))

> > >> > // only half of an arm is uniquely defined, the rest can be

> determined

> > >> > // by rotation and mirroring

> > >> > let (phiNorm = phiTemp > armAngle / 2

> > >> > ? armAngle - phiTemp

> > >> > : phiTemp)

> > >> > let (rx = abs(phiNorm) < 1e-6

> > >> > ? rKnob

> > >> > : abs(phiNorm - armAngle / 2) < 1e-6

> > >> > ? rPosN - rN

> > >> > : phiNorm < alphaC

> > >> > ?

> > >> > let (gamma2 = asin(rPosK * sin(phiNorm) / rK))

> > >> > let (beta2 = 180 - phiNorm - gamma2)

> > >> > rK * sin(beta2) / sin(phiNorm)

> > >> > :

> > >> > let (delta = alpha - phiNorm)

> > >> > let (epsilon = 180 - asin(rPosN * sin(delta) / rN))

> > >> > let (rho = 180 - delta - epsilon)

> > >> > rN * sin(rho) / sin(delta)

> > >> > )

> > >> >

> > >> > [rx * cos(phi), rx * sin(phi)]

> > >> > ];

> > >> >

> > >> > // quick and dirty prototype for testing

> > >> > minkowski() {

> > >> > sphere(2, $fn = 36);

> > >> >

> > >> > difference() {

> > >> > translate([0, 0, -30]) sphere(d = 99, $fn = 120);

> > >> >

> > >> > difference () {

> > >> > translate([0, 0, -35]) cube(110, center = true);

> > >> >

> > >> > linear_extrude(20) polygon(points);

> > >> > }

> > >> > }

> > >> > }

> > >> > _______________________________________________

> > >> > OpenSCAD mailing list

> > >> > To unsubscribe send an email to discuss-leave@lists.openscad.org

> > >>

> > >> _______________________________________________

> > >> OpenSCAD mailing list

> > >> To unsubscribe send an email to discuss-leave@lists.openscad.org

> > >>

> > > _______________________________________________

> > > OpenSCAD mailing list

> > > To unsubscribe send an email to discuss-leave@lists.openscad.org

> > > _______________________________________________

> > > OpenSCAD mailing list

> > > To unsubscribe send an email to discuss-leave@lists.openscad.org

> > _______________________________________________

> > OpenSCAD mailing list

> > To unsubscribe send an email to discuss-leave@lists.openscad.org

> > _______________________________________________

> > OpenSCAD mailing list

> > To unsubscribe send an email to discuss-leave@lists.openscad.org

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

AM

Adrian Mariano

Thu, Dec 26, 2024 7:06 PM

Ray, are you saying it's only the upside-down rounded edges that you think

are "awful"? I don't really understand. I basically round every edge I

possibly can in my models---but that doesn't include upside-down ones.

I'll have to look into that adaptive layer thickness.

On Thu, Dec 26, 2024 at 2:00 PM Raymond West via Discuss <

discuss@lists.openscad.org> wrote:

On 26/12/2024 15:03, Adrian Mariano via Discuss wrote:

I'm not sure what Ray has against rounded edges. I use them all the time

and think they look and feel great in my FDM printed models.

What does NOT look great in my experience is something like the gradual

dome top of the knob, which tends to have a very exposed layer line

step-structure with very wide and visible steps that I think look and feel

pretty bad. That will be worse the closer you are to flat---I don't know

how bad it would look with the model as shown. I printed a knob to go on

my audio amp and my first version had a domed top like shown and I

scratched that and went back to flat after I felt the model in hand.

The other thing that does NOT look great is a roundover printed upside

down.

Hi Adrian, you half answered your own question to me, and nop head gave

the top half answer, wrt adaptive.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Ray, are you saying it's only the upside-down rounded edges that you think

are "awful"? I don't really understand. I basically round every edge I

possibly can in my models---but that doesn't include upside-down ones.

I'll have to look into that adaptive layer thickness.

On Thu, Dec 26, 2024 at 2:00 PM Raymond West via Discuss <

discuss@lists.openscad.org> wrote:

>

> On 26/12/2024 15:03, Adrian Mariano via Discuss wrote:

>

> I'm not sure what Ray has against rounded edges. I use them all the time

> and think they look and feel great in my FDM printed models.

>

> What does NOT look great in my experience is something like the gradual

> dome top of the knob, which tends to have a very exposed layer line

> step-structure with very wide and visible steps that I think look and feel

> pretty bad. That will be worse the closer you are to flat---I don't know

> how bad it would look with the model as shown. I printed a knob to go on

> my audio amp and my first version had a domed top like shown and I

> scratched that and went back to flat after I felt the model in hand.

>

> The other thing that does NOT look great is a roundover printed upside

> down.

>

> Hi Adrian, you half answered your own question to me, and nop head gave

> the top half answer, wrt adaptive.

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

TR

Thomas Richter

Thu, Dec 26, 2024 7:30 PM

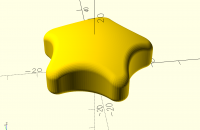

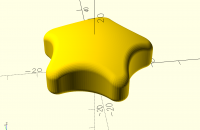

angleC is the polar(!) angle where the two circles touch: the circle that makes the tip / arm and the circle that makes the notch. So, they are tangent at that position. I need to switch the calculation method there because they have different radii and different orientiation (the notch circles' center ist outside the knob, the arms' is inside).

A couple days ago I had already made a solution using arcs instead of polar coordinates in Javascript and I will probably adapt this solution to OpenSCAD. It will make this problem disappear as you recommend. But currently I figure out the geometry of the top surface. Rounded edge works analytically already, rounded top surface is still to come. I have attached a screenshot of the current prototype. This renders in 87 milliseconds.

I am very grateful for the help from all of you.

Am 26.12.2024 um 20:02 schrieb Adrian Mariano via Discuss discuss@lists.openscad.org:

I tried jacking up the sample rate and indeed it looks smoother, but to my eye it appears that there is still a corner. But maybe I'm imagining it. It's a pretty subtle corner if it's real, so it probably doesn't matter. You are mating two curves, one when phiNorm<alphaC and one when phiNorm>=alphaC. Have you designed them to have matching tangents?

But to eliminate the visual corners without going crazy on sample rate I think you need to change your sampling method to sample the two arcs separately and then join them. That way the arcs can be sampled uniformly over their length instead of sampled based on the global polar coordinate and the sample rate will be appropriate for the curvature of each part. This will fix the sampled problems created by using global polar coordinates, which obviously doesn't work properly for knobs with thinner or concave arms. The code for what I propose is actually probably simpler if the design is indeed two circular arcs. (I can't tell on brief inspection what that code is doing.)

On Thu, Dec 26, 2024 at 12:31 PM Thomas Richter via Discuss discuss@lists.openscad.org wrote:

Oh, I see. I never tested with that high values of the arm pitch. That is a stepping problem: The outline of the shape is generated in a for loop. Imagine that a beam turns counterclockwise around the z-axis in the xy plane in steps of one degree. For every step the radius of the outer shape is calculated and the corresponding point (the intersection of the beam and the outline) on the xy plane becomes part of the points array of the polygon forming the outer shape. At the positions you mention a step of one degree leads to a quite large step along the outline because at those positions the "beam" is almost parallel to the outline. If you reduce the step in the for loop from 1 to 0.1 this disappears. But that would lead to huge numbers of faces. So maybe in the future I will compensate for that with smaller steps at certain positions depending on the scalar product of the current outline and the "beam".

I understand your comments. This thing has developed its own life, currently going way further than it was intended in the first place, more and more becoming an intellectual game. Nonetheless, many people in my university's fab lab are quite happy I made and shared this.

Currently, I learn a lot about analytical geometry (actually re-memorizing things learnt decades ago in school) and about for me so far unknown ways to produce things in OpenSCAD. I could have let it go a long time ago, but the challenge of learning and speeding up the calculation now really appeals to me.

Although the calculations may look confusing, it is mainly just the application of the sine and cosine theorems to scalene triangles.

Am 26.12.2024 um 17:57 schrieb Adrian Mariano via Discuss discuss@lists.openscad.org:

Sanding well enough to produce a model that looks good is going to be a ton of work---more work than I would put forth for a model. Casting is obviously a different application, where appearance doesn't matter. But if you're planning to offer a generator to people, I would guess most people are in my camp: no interest in a bunch of post processing of the model. If I had a project with 8 knobs it would loom even larger as a nuisance. What would make sense for this is solvent smoothing...but I don't do that either. (Not really feasible with PLA.)

Building structures analytically is generally very fast if you have a reasonably straight forward analytic approach. I can't quite understand your method to know what the result would look like---definitely post your final result.

Regarding the corners, it's not super visible in the model as you gave it, but when I changed armPitch to 3 I got this<image.png>

The corner is very clear here. So if your math is producing a corner when armPitch=3 then most likely there is exactly one value of armPitch (other parameters held fixed) that generates a model where the tangents match and there is no corner. I didn't try to understand your code enough to know what's going on there. The corner is more subtle with less extreme parameter choices, but may be tactile even if not obvious in the model on screen.

At armPitch of 3.2 there are now two obvious corners:

<image.png>

And these parameter values seem plausible use cases, not crazy outlier values, so if you're providing a parameterized model it seems like they should work.

On Thu, Dec 26, 2024 at 11:26 AM Thomas Richter via Discuss discuss@lists.openscad.org wrote:

Thank you for your insights. I get good results printing the rounded surface upside down and sanding it. You are right about the distance of the top layers, this tends to be visible the closer it gets to flat, but it's fine after sanding. Nonetheless, if you take a look at printables, there are also flat versions of the knobs.

I don't just print the knobs but use the sanded prints to create molds for brass castings.

The tangents of the tips and the notches actually match in both the version on printables (made with boolean operations) and the analytical version posted in this thread. The small edgy stripes between tips and notches are subject to low $fn values of the cylinders when creating the knob with boolean operations. With an analytically generated outline they don't appear at all. Could you please elaborate on the problems you experienced?

I make good progress creating the rounded top analytically. I generate a polyhedron from several layers of outlines with the radius changing with the cosine of the current step's angle. It is fast as hell, even with 360 steps around the edge it takes less than 50 milliseconds for two layers and I expect to be fine with about ten layers for the rounded edge. I can post the solution here later if someone is interested.

One interesting thing I noticed with the solution I posted in this thread are strangely shaped faces at the rounded edge after doing the minkowski. The Prusa Slicer finds 20 errors in the resulting stl. This will also disappear with the analytical solution.

Am 26.12.2024 um 16:03 schrieb Adrian Mariano via Discuss discuss@lists.openscad.org:

I'm not sure what Ray has against rounded edges. I use them all the time and think they look and feel great in my FDM printed models.

What does NOT look great in my experience is something like the gradual dome top of the knob, which tends to have a very exposed layer line step-structure with very wide and visible steps that I think look and feel pretty bad. That will be worse the closer you are to flat---I don't know how bad it would look with the model as shown. I printed a knob to go on my audio amp and my first version had a domed top like shown and I scratched that and went back to flat after I felt the model in hand.

The other thing that does NOT look great is a roundover printed upside down. That needs to be a chamfer or teardrop for the best result. So I'd probably do something like this for a flat topped model:

include<BOSL2/std.scad>

include<BOSL2/rounding.scad>

offset_sweep(deduplicate(points,closed=true), h=20, bot=os_teardrop(r=2), top=os_circle(r=2),steps=9);

to get that effect. There is another thing I'd probably try to fix, which is the corners where the tip circles meet the notch circles. For a truly beautiful knob the tangents should match so that you don't have corners there.

Oh, and one other thing that will make this faster no matter how you proceed is to stop using so many points. The smallest facet is 0.22 mm in the posted version. That's unnecessarily small.

I don't see an easy way to create the original shape using an analytic method. You'd need to form a grid over the top of the knob to form the polyhedral face of the top, and that seems pretty difficult to do.

Here's what the knot from the above code looks like from the top and bottom:

<image.png>

<image.png>

Avoiding the lower angle at the bottom by switching to a chamfer will ensure good printing.

On Thu, Dec 26, 2024 at 7:21 AM Raymond West via Discuss discuss@lists.openscad.org wrote:

If the knob is to be 3d fdm printed by others, then the rounded edges will look awful. Minkowski is slow, especially if $fn is large. I would suggest a redesign of the knob. I posted on here, a few weeks ago (re: bad children) some simple bevel modules. (They sliced at 0.1mm intervals, but that and the profile could be varied). It gives much faster results than using Minkowski. Basically, you could draw the profile of the knob in 2d, linear extrude it to the desired thickness, then apply the bevel/rounding modules.

On 26/12/2024 08:12, pca006132 via Discuss wrote:

Another way would be to do the convex decomposition by yourself, I think it can be split into 5 convex components?

On Thu, Dec 26, 2024, 4:07 PM Chun Kit LAM john.lck40@gmail.com wrote:

The slowness is really in the CGAL convex decomposition code path, and

sadly there is no plan to make a faster one for now.

If you want this to be fast, the best way might be to do it

analytically, considering you already computed the knob outline

analytically, it may not be that hard.

On 12/26/24 15:53, Thomas Richter via Discuss wrote:

This is related to a question I asked a couple of days ago (problems with not closed mesh) but a different problem. Should I have asked in the old thread anyway?

I create star shaped knobs for hex screws (see https://www.printables.com/model/1116311-parametric-knob-for-hex-nuts-and-allen-screws-knau). The rounded top surface is achieved by subtracting from a large sphere (see prototype code below) and the rounded edges are created with the minkowski sum. Since the sphere must be large for a low rounding it needs a large $fn value (120 currently). Thus, the minkowski sum needs about 80 seconds (M3 CPU) to generate the object with manifold backend.

This is already an optimized version since I create the basic star shape analytically instead of using unions and differences. This way I was able to reduce the computing time by about 80% already.

Does someone here have an idea how I could reduce the computing time even further? The reason: I create a web based configuration tool and would like to provide the stl file in less than ten seconds.

/**

- prototype code

*/

ARMS = 5;

// knobDiameter

kd = 40;

rKnob = kd / 2;

// armPitch

ap = 2;

// notchRatio

nr = 3;

// radius of the arm circles

rK = PI * rKnob / ((ap + 1) * ARMS + PI);

// radius of the notch circles

rN = nr * rK;

// radius of the circle to place the arms (rbk)

rPosK = rKnob - rK;

// angle between arm and notch (360 / ARMS / 2)

alpha = 180 / ARMS;

// angle between center of knob, center of notch, center of arm

gamma = asin(sin(alpha) * rPosK / (rN + rK));

// angle between center of knob, center of arm, center of notch

beta = 180 - alpha - gamma;

// radius of the circle to place the notches (rbn)

rPosN = abs(rPosK * sin(beta) / sin(gamma));

// radius of the knob's core: distance from center to touch point of arm and notch (rc)

rCore = sqrt(rPosK^2 + rK^2 - 2 * rPosK * rK * cos(beta));

// angle to touch point

alphaC = asin(rK * sin(beta) / rCore);

armAngle = 360 / ARMS;

points = [

for (phi = [0: 1: 360])

let (arm = floor(phi / armAngle))

let (phiTemp = phi - (arm * armAngle))

// only half of an arm is uniquely defined, the rest can be determined

// by rotation and mirroring

let (phiNorm = phiTemp > armAngle / 2

? armAngle - phiTemp

: phiTemp)

let (rx = abs(phiNorm) < 1e-6

? rKnob

: abs(phiNorm - armAngle / 2) < 1e-6

? rPosN - rN

: phiNorm < alphaC

?

let (gamma2 = asin(rPosK * sin(phiNorm) / rK))

let (beta2 = 180 - phiNorm - gamma2)

rK * sin(beta2) / sin(phiNorm)

:

let (delta = alpha - phiNorm)

let (epsilon = 180 - asin(rPosN * sin(delta) / rN))

let (rho = 180 - delta - epsilon)

rN * sin(rho) / sin(delta)

)

[rx * cos(phi), rx * sin(phi)]

];

// quick and dirty prototype for testing

minkowski() {

sphere(2, $fn = 36);

difference() {

translate([0, 0, -30]) sphere(d = 99, $fn = 120);

difference () {

translate([0, 0, -35]) cube(110, center = true);

linear_extrude(20) polygon(points);

}

}

}

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

angleC is the polar(!) angle where the two circles touch: the circle that makes the tip / arm and the circle that makes the notch. So, they are tangent at that position. I need to switch the calculation method there because they have different radii and different orientiation (the notch circles' center ist outside the knob, the arms' is inside).

A couple days ago I had already made a solution using arcs instead of polar coordinates in Javascript and I will probably adapt this solution to OpenSCAD. It will make this problem disappear as you recommend. But currently I figure out the geometry of the top surface. Rounded edge works analytically already, rounded top surface is still to come. I have attached a screenshot of the current prototype. This renders in 87 milliseconds.

I am very grateful for the help from all of you.

> Am 26.12.2024 um 20:02 schrieb Adrian Mariano via Discuss <discuss@lists.openscad.org>:

>

> I tried jacking up the sample rate and indeed it looks smoother, but to my eye it appears that there is still a corner. But maybe I'm imagining it. It's a pretty subtle corner if it's real, so it probably doesn't matter. You are mating two curves, one when phiNorm<alphaC and one when phiNorm>=alphaC. Have you designed them to have matching tangents?

>

> But to eliminate the visual corners without going crazy on sample rate I think you need to change your sampling method to sample the two arcs separately and then join them. That way the arcs can be sampled uniformly over their length instead of sampled based on the global polar coordinate and the sample rate will be appropriate for the curvature of each part. This will fix the sampled problems created by using global polar coordinates, which obviously doesn't work properly for knobs with thinner or concave arms. The code for what I propose is actually probably simpler if the design is indeed two circular arcs. (I can't tell on brief inspection what that code is doing.)

>

>

>

>

>

>

>

> On Thu, Dec 26, 2024 at 12:31 PM Thomas Richter via Discuss <discuss@lists.openscad.org> wrote:

> Oh, I see. I never tested with that high values of the arm pitch. That is a stepping problem: The outline of the shape is generated in a for loop. Imagine that a beam turns counterclockwise around the z-axis in the xy plane in steps of one degree. For every step the radius of the outer shape is calculated and the corresponding point (the intersection of the beam and the outline) on the xy plane becomes part of the points array of the polygon forming the outer shape. At the positions you mention a step of one degree leads to a quite large step along the outline because at those positions the "beam" is almost parallel to the outline. If you reduce the step in the for loop from 1 to 0.1 this disappears. But that would lead to huge numbers of faces. So maybe in the future I will compensate for that with smaller steps at certain positions depending on the scalar product of the current outline and the "beam".

>

> I understand your comments. This thing has developed its own life, currently going way further than it was intended in the first place, more and more becoming an intellectual game. Nonetheless, many people in my university's fab lab are quite happy I made and shared this.

>

> Currently, I learn a lot about analytical geometry (actually re-memorizing things learnt decades ago in school) and about for me so far unknown ways to produce things in OpenSCAD. I could have let it go a long time ago, but the challenge of learning and speeding up the calculation now really appeals to me.

>

> Although the calculations may look confusing, it is mainly just the application of the sine and cosine theorems to scalene triangles.

>

> > Am 26.12.2024 um 17:57 schrieb Adrian Mariano via Discuss <discuss@lists.openscad.org>:

> >

> > Sanding well enough to produce a model that looks good is going to be a ton of work---more work than I would put forth for a model. Casting is obviously a different application, where appearance doesn't matter. But if you're planning to offer a generator to people, I would guess most people are in my camp: no interest in a bunch of post processing of the model. If I had a project with 8 knobs it would loom even larger as a nuisance. What would make sense for this is solvent smoothing...but I don't do that either. (Not really feasible with PLA.)

> >

> > Building structures analytically is generally very fast if you have a reasonably straight forward analytic approach. I can't quite understand your method to know what the result would look like---definitely post your final result.

> >

> > Regarding the corners, it's not super visible in the model as you gave it, but when I changed armPitch to 3 I got this<image.png>

> >

> >

> > The corner is very clear here. So if your math is producing a corner when armPitch=3 then most likely there is exactly one value of armPitch (other parameters held fixed) that generates a model where the tangents match and there is no corner. I didn't try to understand your code enough to know what's going on there. The corner is more subtle with less extreme parameter choices, but may be tactile even if not obvious in the model on screen.

> >

> > At armPitch of 3.2 there are now two obvious corners:

> >

> > <image.png>

> >

> > And these parameter values seem plausible use cases, not crazy outlier values, so if you're providing a parameterized model it seems like they should work.

> >

> > On Thu, Dec 26, 2024 at 11:26 AM Thomas Richter via Discuss <discuss@lists.openscad.org> wrote:

> > Thank you for your insights. I get good results printing the rounded surface upside down _and sanding_ it. You are right about the distance of the top layers, this tends to be visible the closer it gets to flat, but it's fine after sanding. Nonetheless, if you take a look at printables, there are also flat versions of the knobs.

> >

> > I don't just print the knobs but use the sanded prints to create molds for brass castings.

> >