has anyone worked on a Laser Design tool similar to the one for 3D printing?

I had looked at klipper long ago, but never looked at it that deeply.

Something else to look into. Also, that dremel blade sharpener trick is a

nice deal. Thank you for sharing.

Gene, you probably know/remember. I was an official developer for

LinuxCNC. I finally completely gave up on it due to the systematic

bit-rot. I remember one time I proposed a change (I forget what it was

specifically, this was circa 2003), but I do remember the screams of "DO

NOT TOUCH IT!" To be fair, a couple of the LinuxCNC members explained

off-list how it took them sometimes a year or more to get a machine

stabilized after a major update. Basically the entire community would get

something that works for small groups of the membership, and then they

would maintain that on their personal equipment -- until they had to

upgrade, or some feature was so desirable that it was worth spending the

time to upgrade. So, I ended up mostly hacking what I needed for my

personal projects and sending back minor bugs. I had great hopes with the

advent of MachineKit. But, over the pandemic, I ended up spending 100's of

hours and was never able to get the versions available at the time to even

fully run! That is when I completely gave up on LinuxCNC. Now if I

compare that with something like FluidNC, the code is clean, modern, and

has a more progressive support community. That said, the main code base

does not support backlash, and is something I would have to bring back in

from a previous branch. As we all know, with old iron, unmanaged backlash

is death. I would early love if LinuxCNC could be made viable, but my

personal experience has demonstrated repeatedly that it is not past taking

the time to get a single machine configuration working on very

specific hardware...

I cannot remember if I posted about it here, but a buddy of mine and I

hacked a printer driver onto a BeagleBone Black, with some filtering

programs to change the dialect of g-code produced by SolidWorks, and hooked

the BBB into the tape port of a 1989 Cincinnati Milicron lathe. It also

managed the tape's forward and reverse, so that it could page in blocks of

g-code. It should like I should be able to do the same thing with my

Creality Falcon-2 laser cutter. That will be a background project, but one

that would help save some time in the long run...

EBo --

On Sat, Jun 28, 2025 at 5:33 PM gene heskett via Discuss <

discuss@lists.openscad.org> wrote:

On 6/28/25 12:42, John David via Discuss wrote:

William, gcpdxf.py

https://github.com/WillAdams/gcodepreview/blob/main/gcpdxf.py looks

interesting. I will need to take a closer look at it. I have been

focusing on SVG because I have other tools that worked, but at the time I

could not get the DXF to work properly. But, I do not inherently care

if I

use SVG or DXF for the format as long as the various interface option

(LaserGRBL, LightBurn, Inkscape, etc.) all play nice. I will reach out

to

you off-list about both providing 2D DXF test CAD files. I will probably

start with a quick-release jig fixture for the Falcon-2 - it would be

nice

to have the lockable jig plates also have engraved rulers...

Gene, I'll put shoehorning a workflow into OctoPrint on to my ToDo list.

As far as I know, both LaserGRBL and LightBurn natively uses g-code. I

think it is more an issue of figuring out how to set up the

configuration.

Generally that assessment is good. I'm in favor of klipper, which

replaces both merlin and octoprint, with something that to me is

reconfigurable and a lot easier to extend to make the printer into a

send it a file, go get the part work flow. No baby sitting during the

warmup to clean nozzles and such. I've made the printer do that by

itself. My biggest problem is time, at 90 I'm running out of time to do

the things I can dream up.

wrote:

On Sat, Jun 28, 2025 at 6:22 AM John David via Discuss <

discuss@lists.openscad.org> wrote:

OpenSCAD has a Design tool for 3D printing. Has anyone worked on one

for laser cutters/engravers?

On Saturday, June 28, 2025 at 01:48:04 AM EDT, Guenther Sohler via

Discuss

discuss@lists.openscad.org wrote:

Did you check out

https://github.com/WillAdams/gcodepreview

Its based on openscad and it can help you to display the gcodes

This runs in a couple of modes, and is fully programmatic (but that

should

be okay for folks on this list).

https://github.com/WillAdams/gcodepreview/blob/main/gcpdxf.py

is a basic Python file which will make a multi-colour DXF (uploaded a

converted SVG version --- let me know if you have trouble making the

DXF)

I'm currently deep into a rewrite which flattens out the (currently)

ever

deeply more nested CSG unions and incorporating better support for

colour

should dovetail well with that.

If someone would provide an example DXF file (where different colours

are

coded to different laser operations) and pseudocode for creating that

file,

I'll do my best to at least keep that in mind as I work on the re-write.

William

--

Sphinx of black quartz, judge my vow.

https://designinto3d.com/

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On 6/28/25 19:18, John David wrote:

I had looked at klipper long ago, but never looked at it that deeply.

Something else to look into. Also, that dremel blade sharpener trick is a

nice deal. Thank you for sharing.

Gene, you probably know/remember. I was an official developer for

LinuxCNC. I finally completely gave up on it due to the systematic

bit-rot. I remember one time I proposed a change (I forget what it was

specifically, this was circa 2003), but I do remember the screams of "DO

NOT TOUCH IT!" To be fair, a couple of the LinuxCNC members explained

off-list how it took them sometimes a year or more to get a machine

stabilized after a major update. Basically the entire community would get

something that works for small groups of the membership, and then they

would maintain that on their personal equipment -- until they had to

upgrade, or some feature was so desirable that it was worth spending the

time to upgrade. So, I ended up mostly hacking what I needed for my

personal projects and sending back minor bugs. I had great hopes with the

advent of MachineKit. But, over the pandemic, I ended up spending 100's of

hours and was never able to get the versions available at the time to even

fully run! That is when I completely gave up on LinuxCNC. Now if I

compare that with something like FluidNC, the code is clean, modern, and

has a more progressive support community. That said, the main code base

does not support backlash, and is something I would have to bring back in

from a previous branch. As we all know, with old iron, unmanaged backlash

is death. I would early love if LinuxCNC could be made viable, but my

personal experience has demonstrated repeatedly that it is not past taking

the time to get a single machine configuration working on very

specific hardware...

I have 4 machines running linuxcnc, started back quite some time before

the name change from emc2.

I long ago learned to write my own gcode, and hal stuff, the only

problem I ever had was something that should have been fixed about the

time the axis gui was written. It did not properly change the focus of

he teeny little axis buttons to correspond to register with the last

axis moved, so touch-offs were often inadvertently applied to the wrong

axis, making one start from scratch rehoming the machine. And it

litterally took years, 3 or 4, from my reporting that bug to getting it

fixed. Other than that, I have been able to make a machine do exactly as

I wanted it to do. In 20+ years, I haven't noticed any bit rot that

wasn't fixable by correcting an error in my .hal files. I also am not a

machinist other than making parts to keep a television transmitter on

the air for 50 years beyond its use by date, I am a CET, I can and have

taught papered EE's stuff they should have learned in school, but the

prof skipped it because he didn't understand it himself. Or maybe

miss-understood it and taught it wrong. I am amazed at the folks who

think Newtons 3rd law is optional, or that relativity doesn't apply to

the real world.

Please understand also that LinuxCNC is a 100% volunteer effort by

people who COULD be doing something generating a paycheck, most have a

$dayjob that might not even be linuxcnc related but that is not how

things started by NIST 50 or 60 years ago works. I have even offered

hardware to expand things, been turned down, there is not I have been

told, a mechanism in place that has a bank account. That means there is

no one an MBA can sue, a limiting factor in its popularity because MBA's

MUST have somebody to sue when their ideas wind up in the toilet. Its no

secret that I consider MBA's in the same category as lawyers when

Shakespear wrote "first we kill all the lawyers". OTOH that is what you

get from a 90 yo that tested at 147 on the Iowa test in the 7th grade,

made it 2 months into freshman in high school, got bored & quit and went

to work fixing what was then the brand new things we call tv's now.

I'm sorry your experience has not been that rosy. Mine on balance has

been quite good, and I thank the people that have made it what is is today.

Tech changes, usually for the better, so my machines are gradually being

converted from plain steppers to closed loop stepper/servo's, they can

be run on much higher voltages and the drivers control them MUCH faster

to higher accuracy's. One of my lathes is run by an rpi4b, runs so well

I wish it had been my first conversion, the other 3 running on wintel

stuff use 10x the ac power when idle.

Thank you.

I cannot remember if I posted about it here, but a buddy of mine and I

hacked a printer driver onto a BeagleBone Black, with some filtering

programs to change the dialect of g-code produced by SolidWorks, and hooked

the BBB into the tape port of a 1989 Cincinnati Milicron lathe. It also

managed the tape's forward and reverse, so that it could page in blocks of

g-code. It should like I should be able to do the same thing with my

Creality Falcon-2 laser cutter. That will be a background project, but one

that would help save some time in the long run...

Sounds interesting. Keep us posted.

EBo --

On Sat, Jun 28, 2025 at 5:33 PM gene heskett via Discuss <

discuss@lists.openscad.org> wrote:

On 6/28/25 12:42, John David via Discuss wrote:

William, gcpdxf.py

https://github.com/WillAdams/gcodepreview/blob/main/gcpdxf.py looks

interesting. I will need to take a closer look at it. I have been

focusing on SVG because I have other tools that worked, but at the time I

could not get the DXF to work properly. But, I do not inherently care

if I

use SVG or DXF for the format as long as the various interface option

(LaserGRBL, LightBurn, Inkscape, etc.) all play nice. I will reach out

to

you off-list about both providing 2D DXF test CAD files. I will probably

start with a quick-release jig fixture for the Falcon-2 - it would be

nice

to have the lockable jig plates also have engraved rulers...

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

re: LinuxCNC on an RPi4B...

What reversion of LinuxCNC did you use to get it to build and install on an

RPi4B? As I recall, it was exactly my experience with LCNC on one of the

RPi4's at the beginning of the pandemic is exactly what drove me to such

distraction... That said, that was 5 years ago. Hopefully

something changed. Let me know, and I will see if I can get it installed

on one of my RPi4's I have lying around. That project as a whole is about

287 down the list, but I do know I have a couple of RPi4's sitting in a

box, and I have a rebuilt Techno Isel router with a blown controller, and a

South Bend Turret Mill that I picked up with a broken controller, and other

machines that need lot's of love... Getting either of them up and running

would be more than useful.

re: small number of people maintaining LinuxCNC...

Back around 2003 Yodaiken actually hired me as a contractor to update then

EMC2 to run on their latest and greatest version of RTLinux - so that they

could give it away as demo's of all the coolness they were working on with

RTLinux. The hassles I had with the community at that time over any

changes, clued me into what all was going on. I then learned that 80 to 90%

of all changes were being made by only 4 people, and of those 4, the most

prolific one spent a total of maybe 5hrs/week averaged over an entire year.

When I compared the work I had done for Yodaiken at that time, it was

roughly the equivalent of a full year of volunteer effort of those 4

people! Yes, you are right that there are not many people to maintain it,

and I doubt there ever will be. When people, like myself and others, come

along, we get pushed off or eventually get so tired we go find other fun

stuff to do. I would dearly love to be wrong and find that I can spend a

day getting LCNC running on an RPi4, and get the axes moving, even if it

takes me days more to dial in the config. Back in 2020 I was not even able

to get any of the releases and release candidates running on that RPi.

re: High school experiences...

Sounds like you and I could swap a few stories about yesteryears. I took my

books home all of 4 times during my freshman year of high school (midterms

and finals). At the end of the year, I convinced the principle to grant me

a waver to apply to the early admittance program at the local college. I

started a month later (paying for it myself with money I made selling my

own pottery throughout the region -- I grew up in a family of professional

potters, and started professionally slinging mud at my mother's knee at the

age of 7). Now THAT is a stole down amnesia lane (thank you, Robin

Williams, from the Dead Poets Society).

Final note - sorry for coming across so LCNC Downer. I have just seen so

many people lured in by the promise of production ready interfaces, only to

get turned off by how brittle the code is. I would love you to prove me

wrong, and if you do, I will publically apologize for my misstep.

EBo --

On Sat, Jun 28, 2025 at 11:38 PM gene heskett gheskett@shentel.net wrote:

On 6/28/25 19:18, John David wrote:

I had looked at klipper long ago, but never looked at it that deeply.

Something else to look into. Also, that dremel blade sharpener trick is

a

nice deal. Thank you for sharing.

Gene, you probably know/remember. I was an official developer for

LinuxCNC. I finally completely gave up on it due to the systematic

bit-rot. I remember one time I proposed a change (I forget what it was

specifically, this was circa 2003), but I do remember the screams of "DO

NOT TOUCH IT!" To be fair, a couple of the LinuxCNC members explained

off-list how it took them sometimes a year or more to get a machine

stabilized after a major update. Basically the entire community would

get

something that works for small groups of the membership, and then they

would maintain that on their personal equipment -- until they had to

upgrade, or some feature was so desirable that it was worth spending the

time to upgrade. So, I ended up mostly hacking what I needed for my

personal projects and sending back minor bugs. I had great hopes with

the

advent of MachineKit. But, over the pandemic, I ended up spending 100's

of

hours and was never able to get the versions available at the time to

even

fully run! That is when I completely gave up on LinuxCNC. Now if I

compare that with something like FluidNC, the code is clean, modern, and

has a more progressive support community. That said, the main code base

does not support backlash, and is something I would have to bring back in

from a previous branch. As we all know, with old iron, unmanaged

backlash

is death. I would early love if LinuxCNC could be made viable, but my

personal experience has demonstrated repeatedly that it is not past

taking

the time to get a single machine configuration working on very

specific hardware...

I have 4 machines running linuxcnc, started back quite some time before

the name change from emc2.

I long ago learned to write my own gcode, and hal stuff, the only

problem I ever had was something that should have been fixed about the

time the axis gui was written. It did not properly change the focus of

he teeny little axis buttons to correspond to register with the last

axis moved, so touch-offs were often inadvertently applied to the wrong

axis, making one start from scratch rehoming the machine. And it

litterally took years, 3 or 4, from my reporting that bug to getting it

fixed. Other than that, I have been able to make a machine do exactly as

I wanted it to do. In 20+ years, I haven't noticed any bit rot that

wasn't fixable by correcting an error in my .hal files. I also am not a

machinist other than making parts to keep a television transmitter on

the air for 50 years beyond its use by date, I am a CET, I can and have

taught papered EE's stuff they should have learned in school, but the

prof skipped it because he didn't understand it himself. Or maybe

miss-understood it and taught it wrong. I am amazed at the folks who

think Newtons 3rd law is optional, or that relativity doesn't apply to

the real world.

Please understand also that LinuxCNC is a 100% volunteer effort by

people who COULD be doing something generating a paycheck, most have a

$dayjob that might not even be linuxcnc related but that is not how

things started by NIST 50 or 60 years ago works. I have even offered

hardware to expand things, been turned down, there is not I have been

told, a mechanism in place that has a bank account. That means there is

no one an MBA can sue, a limiting factor in its popularity because MBA's

MUST have somebody to sue when their ideas wind up in the toilet. Its no

secret that I consider MBA's in the same category as lawyers when

Shakespear wrote "first we kill all the lawyers". OTOH that is what you

get from a 90 yo that tested at 147 on the Iowa test in the 7th grade,

made it 2 months into freshman in high school, got bored & quit and went

to work fixing what was then the brand new things we call tv's now.

I'm sorry your experience has not been that rosy. Mine on balance has

been quite good, and I thank the people that have made it what is is today.

Tech changes, usually for the better, so my machines are gradually being

converted from plain steppers to closed loop stepper/servo's, they can

be run on much higher voltages and the drivers control them MUCH faster

to higher accuracy's. One of my lathes is run by an rpi4b, runs so well

I wish it had been my first conversion, the other 3 running on wintel

stuff use 10x the ac power when idle.

Thank you.

I cannot remember if I posted about it here, but a buddy of mine and I

hacked a printer driver onto a BeagleBone Black, with some filtering

programs to change the dialect of g-code produced by SolidWorks, and

hooked

the BBB into the tape port of a 1989 Cincinnati Milicron lathe. It also

managed the tape's forward and reverse, so that it could page in blocks

of

g-code. It should like I should be able to do the same thing with my

Creality Falcon-2 laser cutter. That will be a background project, but

one

that would help save some time in the long run...

Sounds interesting. Keep us posted.

EBo --

On Sat, Jun 28, 2025 at 5:33 PM gene heskett via Discuss <

discuss@lists.openscad.org> wrote:

On 6/28/25 12:42, John David via Discuss wrote:

William, gcpdxf.py

https://github.com/WillAdams/gcodepreview/blob/main/gcpdxf.py looks

interesting. I will need to take a closer look at it. I have been

focusing on SVG because I have other tools that worked, but at the

time I

could not get the DXF to work properly. But, I do not inherently care

if I

use SVG or DXF for the format as long as the various interface option

(LaserGRBL, LightBurn, Inkscape, etc.) all play nice. I will reach out

to

you off-list about both providing 2D DXF test CAD files. I will

probably

start with a quick-release jig fixture for the Falcon-2 - it would be

nice

to have the lockable jig plates also have engraved rulers...

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

On Jun 28, 2025, at 20:38, gene heskett via Discuss discuss@lists.openscad.org wrote:

Its no secret that I consider MBA's in the same category as lawyers when Shakespear wrote "first we kill all the lawyers”.

Like almost everyone, you misunderstand that quote. It’s the bad guys in the play that say that. Without honest lawyers we are lost.

-Bob

Tucson AZ

On 6/29/25 01:49, Bob Carlson wrote:

On Jun 28, 2025, at 20:38, gene heskett via Discuss discuss@lists.openscad.org wrote:

Its no secret that I consider MBA's in the same category as lawyers when Shakespear wrote "first we kill all the lawyers”.

Like almost everyone, you misunderstand that quote. It’s the bad guys in the play that say that. Without honest lawyers we are lost.

Key word being HONEST. Generally most, say 90% are. I've met both

sides of that in my 90 years. MBA's OTOH will offer $18k/yr for a tv

Chief Engineer worth $90k/yr and think they are doing you a huge favor.

I don't work for people like that, just one of the reasons I turned that

chair at KTLA-tv, the #1 station in the country, down 30+ years ago when

a head hunter tried to poach me.. That $110k would have been a good

offer if it wasn't in LA. WV was/is good to me. Among other things it

gave me my 3rd wife for 31 years. Never had a fight. Passed from COPD

in late 2020. Real estate free and clear a/o 26 years ago. Now I'm just

a diabetic and alone old fart, the end in distant sight.

-Bob

Tucson AZ

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Sorry to hear about your loss and other changes. Yea, I was recently

surprised to run across a skilled machinist with 10+ years of experiences,

and was offering a little over minimum wage. Yea, some people and places

are not worth working for.

EBo --

On Sun, Jun 29, 2025 at 3:54 AM gene heskett gheskett@shentel.net wrote:

On 6/29/25 01:49, Bob Carlson wrote:

On Jun 28, 2025, at 20:38, gene heskett via Discuss <

discuss@lists.openscad.org> wrote:

Its no secret that I consider MBA's in the same category as lawyers

when Shakespear wrote "first we kill all the lawyers”.

Like almost everyone, you misunderstand that quote. It’s the bad guys in

the play that say that. Without honest lawyers we are lost.

Key word being HONEST. Generally most, say 90% are. I've met both

sides of that in my 90 years. MBA's OTOH will offer $18k/yr for a tv

Chief Engineer worth $90k/yr and think they are doing you a huge favor.

I don't work for people like that, just one of the reasons I turned that

chair at KTLA-tv, the #1 station in the country, down 30+ years ago when

a head hunter tried to poach me.. That $110k would have been a good

offer if it wasn't in LA. WV was/is good to me. Among other things it

gave me my 3rd wife for 31 years. Never had a fight. Passed from COPD

in late 2020. Real estate free and clear a/o 26 years ago. Now I'm just

a diabetic and alone old fart, the end in distant sight.

-Bob

Tucson AZ

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

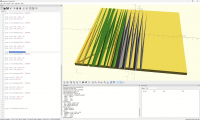

Okay, I added a command for changing colour:

setcolour("Gray")

(see attached screen grab)

One interesting complication/consideration is that there is a limited intersection in named colours betwixt OpenSCAD's support of the named Web Colors (see article on Wikipedia) and the basic numbered colours in the DXF format:

\item "Black" (0)

\item "Red" (1)

\item "Yellow" (2)

\item "Green" (3)

\item "Cyan" (4)

\item "Blue" (5)

\item "Magenta" (6)

\item "White" (7)

\item "Dark Gray" (8)

\item "Light Gray" (9)

with the common options being:

\item Black

\item Red

\item Yellow

\item Green

\item Blue

\item White

\item (Dark) Gray

Black and White aren't that useful/are potentially confusing since at least one program toggles them so as to make Dark Mode work, so we are down to red, yellow, green, blue, and (dark) gray --- can those be made to work for this?

William

On 6/29/25 04:23, John David wrote:

Sorry to hear about your loss and other changes. Yea, I was recently

surprised to run across a skilled machinist with 10+ years of experiences,

and was offering a little over minimum wage. Yea, some people and places

are not worth working for.

10 yrs of experience does not always make a "machinist"...

I was, in the later 50's, involved with the building of the tv cameras

that were on the Navy's Trieste when it made that one trip to the bottom

of the mohole, the deepest place in the pacific, nearly 38,000 feet

deep. We needed pressure cases for the cameras we were making, so

Oceanographic Engineering bought a huge LeBlonde lathe and hired a

machinist. Since the pressure at that depth, about 18,000 psia, is

great enough to compress water, he followed the navy's math, and carved

two camera cases out of bronze, starting with two 12" diameter and 22"

long billets of bronze. The cameras were 2.5" in diameter and around 13"

long w/o lenses. The navy supplied the solid quartz windows the cameras

looked thru. He knew how much that bronze would compress under that

pressure, doubled it and put elastic pads around the cameras pcb's, same

for the quartz windows. And designed a bnc connector for the i/o

connection that could withstand that pressure w/o taking on any

seawater. Watching him work was amazing. Him, I would call a

machinist. FWIW the cameras worked flawlessly although one of the pan &

tilt assemblies came back up full of water. The bnc connector was what

we started with but transitioned to a single strand of 16 ga packard

automotive wire, no coax, as we had only 6 conductors into the 6' cast

iron gondola on the bottom of the Trieste. One of the company founders

was good with relay logic and designed a system that let us use

sequential push buttons to control the lights and both pan & tilt units

with the remaining 4 wires.

Pure serendipity has put me in other places to make what is now

forgotten history. I've had what one might call a good ride thru an

interesting time in human technological history.

Cheers, Gene Heskett, CET.

--

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

On 6/29/25 00:52, John David wrote:

re: LinuxCNC on an RPi4B...

What reversion of LinuxCNC did you use to get it to build and install on an

RPi4B? As I recall, it was exactly my experience with LCNC on one of the

RPi4's at the beginning of the pandemic is exactly what drove me to such

distraction... That said, that was 5 years ago. Hopefully

something changed. Let me know, and I will see if I can get it installed

on one of my RPi4's I have lying around.

I started out with an rpi3b, with whatever was b4 stretch, but running a

realtime preempt kernel I built. zero help from the foundation as the

3rd time I asked their forum about a realtime kernel I was given a link

to a 4.19 src, and banned forever. So I did get it to compile, then

figured out how to make a 27 megabyte tarball I could unpack to the u-sd

card that installed it. Then I hacked up the hal file quite a bit and

made linuxcnc run with an occasional stutter because even with all the

tricks, the rpi3b was a little too slow. So the rpi3b got replaced with

an rpi4b when the 4b came out. For about the last year its been running

flawlessly on bookworm built for me by Rod Webster. The current

preempt-rt kernel has a poorer latency than mine, but is still adequate.

I replaced the original steppers with closed loop stepper/servo's which

improved the finish while doubling the rapids. So it currently claims

its running debian 12. Rod may still have that image. My setup might

not be available from mesa today but if interested I can tarball my

config, but be aware there's lots of candy in my version that isn't std

LinuxCNC.

That project as a whole is about

287 down the list, but I do know I have a couple of RPi4's sitting in a

box, and I have a rebuilt Techno Isel router with a blown controller, and a

South Bend Turret Mill that I picked up with a broken controller, and other

machines that need lot's of love... Getting either of them up and running

would be more than useful.

re: small number of people maintaining LinuxCNC...

Back around 2003 Yodaiken actually hired me as a contractor to update then

EMC2 to run on their latest and greatest version of RTLinux - so that they

could give it away as demo's of all the coolness they were working on with

RTLinux. The hassles I had with the community at that time over any

changes, clued me into what all was going on. I then learned that 80 to 90%

of all changes were being made by only 4 people, and of those 4, the most

prolific one spent a total of maybe 5hrs/week averaged over an entire year.

When I compared the work I had done for Yodaiken at that time, it was

roughly the equivalent of a full year of volunteer effort of those 4

people! Yes, you are right that there are not many people to maintain it,

and I doubt there ever will be. When people, like myself and others, come

along, we get pushed off or eventually get so tired we go find other fun

stuff to do. I would dearly love to be wrong and find that I can spend a

day getting LCNC running on an RPi4, and get the axes moving, even if it

takes me days more to dial in the config. Back in 2020 I was not even able

to get any of the releases and release candidates running on that RPi.

re: High school experiences...

Sounds like you and I could swap a few stories about yesteryears. I took my

books home all of 4 times during my freshman year of high school (midterms

and finals). At the end of the year, I convinced the principle to grant me

a waver to apply to the early admittance program at the local college. I

started a month later (paying for it myself with money I made selling my

own pottery throughout the region -- I grew up in a family of professional

potters, and started professionally slinging mud at my mother's knee at the

age of 7). Now THAT is a stole down amnesia lane (thank you, Robin

Williams, from the Dead Poets Society).

Yeah, we could trade history's and bore the crowd but much of mine isn't

LinuxCNC related.

Final note - sorry for coming across so LCNC Downer. I have just seen so

many people lured in by the promise of production ready interfaces, only to

get turned off by how brittle the code is. I would love you to prove me

wrong, and if you do, I will publically apologize for my misstep.

EBo --

On Sat, Jun 28, 2025 at 11:38 PM gene heskett gheskett@shentel.net wrote:

On 6/28/25 19:18, John David wrote:

I had looked at klipper long ago, but never looked at it that deeply.

Something else to look into. Also, that dremel blade sharpener trick is

a

nice deal. Thank you for sharing.

Gene, you probably know/remember. I was an official developer for

LinuxCNC. I finally completely gave up on it due to the systematic

bit-rot. I remember one time I proposed a change (I forget what it was

specifically, this was circa 2003), but I do remember the screams of "DO

NOT TOUCH IT!" To be fair, a couple of the LinuxCNC members explained

off-list how it took them sometimes a year or more to get a machine

stabilized after a major update. Basically the entire community would

get

something that works for small groups of the membership, and then they

would maintain that on their personal equipment -- until they had to

upgrade, or some feature was so desirable that it was worth spending the

time to upgrade. So, I ended up mostly hacking what I needed for my

personal projects and sending back minor bugs. I had great hopes with

the

advent of MachineKit. But, over the pandemic, I ended up spending 100's

of

hours and was never able to get the versions available at the time to

even

fully run! That is when I completely gave up on LinuxCNC. Now if I

compare that with something like FluidNC, the code is clean, modern, and

has a more progressive support community. That said, the main code base

does not support backlash, and is something I would have to bring back in

from a previous branch. As we all know, with old iron, unmanaged

backlash

is death. I would early love if LinuxCNC could be made viable, but my

personal experience has demonstrated repeatedly that it is not past

taking

the time to get a single machine configuration working on very

specific hardware...

I have 4 machines running linuxcnc, started back quite some time before

the name change from emc2.

I long ago learned to write my own gcode, and hal stuff, the only

problem I ever had was something that should have been fixed about the

time the axis gui was written. It did not properly change the focus of

he teeny little axis buttons to correspond to register with the last

axis moved, so touch-offs were often inadvertently applied to the wrong

axis, making one start from scratch rehoming the machine. And it

litterally took years, 3 or 4, from my reporting that bug to getting it

fixed. Other than that, I have been able to make a machine do exactly as

I wanted it to do. In 20+ years, I haven't noticed any bit rot that

wasn't fixable by correcting an error in my .hal files. I also am not a

machinist other than making parts to keep a television transmitter on

the air for 50 years beyond its use by date, I am a CET, I can and have

taught papered EE's stuff they should have learned in school, but the

prof skipped it because he didn't understand it himself. Or maybe

miss-understood it and taught it wrong. I am amazed at the folks who

think Newtons 3rd law is optional, or that relativity doesn't apply to

the real world.

Please understand also that LinuxCNC is a 100% volunteer effort by

people who COULD be doing something generating a paycheck, most have a

$dayjob that might not even be linuxcnc related but that is not how

things started by NIST 50 or 60 years ago works. I have even offered

hardware to expand things, been turned down, there is not I have been

told, a mechanism in place that has a bank account. That means there is

no one an MBA can sue, a limiting factor in its popularity because MBA's

MUST have somebody to sue when their ideas wind up in the toilet. Its no

secret that I consider MBA's in the same category as lawyers when

Shakespear wrote "first we kill all the lawyers". OTOH that is what you

get from a 90 yo that tested at 147 on the Iowa test in the 7th grade,

made it 2 months into freshman in high school, got bored & quit and went

to work fixing what was then the brand new things we call tv's now.

I'm sorry your experience has not been that rosy. Mine on balance has

been quite good, and I thank the people that have made it what is is today.

Tech changes, usually for the better, so my machines are gradually being

converted from plain steppers to closed loop stepper/servo's, they can

be run on much higher voltages and the drivers control them MUCH faster

to higher accuracy's. One of my lathes is run by an rpi4b, runs so well

I wish it had been my first conversion, the other 3 running on wintel

stuff use 10x the ac power when idle.

Thank you.

I cannot remember if I posted about it here, but a buddy of mine and I

hacked a printer driver onto a BeagleBone Black, with some filtering

programs to change the dialect of g-code produced by SolidWorks, and

hooked

the BBB into the tape port of a 1989 Cincinnati Milicron lathe. It also

managed the tape's forward and reverse, so that it could page in blocks

of

g-code. It should like I should be able to do the same thing with my

Creality Falcon-2 laser cutter. That will be a background project, but

one

that would help save some time in the long run...

Sounds interesting. Keep us posted.

EBo --

On Sat, Jun 28, 2025 at 5:33 PM gene heskett via Discuss <

discuss@lists.openscad.org> wrote:

On 6/28/25 12:42, John David via Discuss wrote:

William, gcpdxf.py

https://github.com/WillAdams/gcodepreview/blob/main/gcpdxf.py looks

interesting. I will need to take a closer look at it. I have been

focusing on SVG because I have other tools that worked, but at the

time I

could not get the DXF to work properly. But, I do not inherently care

if I

use SVG or DXF for the format as long as the various interface option

(LaserGRBL, LightBurn, Inkscape, etc.) all play nice. I will reach out

to

you off-list about both providing 2D DXF test CAD files. I will

probably

start with a quick-release jig fixture for the Falcon-2 - it would be

nice

to have the lockable jig plates also have engraved rulers...

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis