Nut for this threaded rod

Hi,

how should I model this kind of thread (see attached video). It is a

threaded rod d = 8 (exactly 7.8) mm, pitch 2 mm.

Roman

I have attached 1 file to this email:

- Threaded_rod.3gp

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

Size: 41,0 MB

Link souborů přes úložiště: Dropbox

Link:

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

On 5/20/23 11:16, rr156 wrote:

Hi,

how should I model this kind of thread (see attached video). It is a

threaded rod d = 8 (exactly 7.8) mm, pitch 2 mm.

Roman

I have attached 1 file to this email:

* Threaded_rod.3gp

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

Size: 41,0 MB

Link souborů přes úložiště: Dropbox

Link:

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

Pix not too clear, movie too shaky, looks like a multistart acme thread,

how many starts is it?

One method that has had fairly wide spread use for precise work like a

lathes leadscrew is to slice a piece of acetel in two, clamp it back

together and drill a hole thru it aligned with the slice, fit it in a

vice so it grips the screw and heat the screw while closing the vise,

forming very precise threads that are quite low backlash. Then carefully

rewelding it while the screw is still in it to make it one piece again,

using a hot air solder wand to supply the welding heat. Helpful to pad

the vise jaws with a heat resistant insulator material.

I'm printing quite usable 2 start 6mm tooth, 12mm pitch threads for a

buttress thread with a .4 nozzle but at 2" diameter that is easy, at 8mm

diameter for the screw you are are exceeding what the printer can do

well even with a .2mm nozzle. Because my design is 2 start, both half

nuts, printed face up, are identical. So I just do it twice in OpenSCAD,

translating it for two locations on the printer bed.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

On 5/20/23 12:09, gene heskett wrote:

On 5/20/23 11:16, rr156 wrote:

Hi,

how should I model this kind of thread (see attached video). It is a

threaded rod d = 8 (exactly 7.8) mm, pitch 2 mm.

Roman

I have attached 1 file to this email:

* Threaded_rod.3gp

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

Size: 41,0 MB

Link souborů přes úložiště: Dropbox

Link:

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

Pix not too clear, movie too shaky, looks like a multistart acme thread,

how many starts is it?

One method that has had fairly wide spread use for precise work like a

lathes leadscrew is to slice a piece of acetel in two, clamp it back

together and drill a hole thru it aligned with the slice, fit it in a

vice so it grips the screw and heat the screw while closing the vise,

forming very precise threads that are quite low backlash. Then carefully

rewelding it while the screw is still in it to make it one piece again,

using a hot air solder wand to supply the welding heat. Helpful to pad

the vise jaws with a heat resistant insulator material.

I'm printing quite usable 2 start 6mm tooth, 12mm pitch threads for a

buttress thread with a .4 nozzle but at 2" diameter that is easy, at 8mm

diameter for the screw you are are exceeding what the printer can do

well even with a .2mm nozzle. Because my design is 2 start, both half

nuts, printed face up, are identical. So I just do it twice in OpenSCAD,

translating it for two locations on the printer bed.

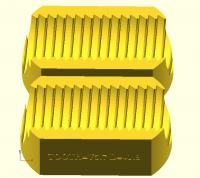

To give an idea how I generate the nuts, I first made a module for the

shape of the tooth. And extruded 7 point polygon. Tilted slightly to

match the pitch tilt.

Then I made a cylinder at the root diameter of a phantom bolt.

Then I used two for loops to wrap the tooth around the bolt at 1 degree

intervals, 180 degrees apart. Several turns extra

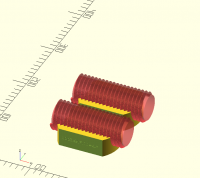

Then I added a clearance increase in the size, and rerendered the whole

thing, then subtracted that from the form that is the nut. You see that

"bolt" in red in this .png.

Knowing what my printer can do, this same procedure could model your

bolt, but I do not believe it would be printable using FDM tech like my

modified sapphire-5. A high res photo-resin printer might do it, sure

worth a try. I use PETG for this, but I've no clue as to the wearability

of the photo resins such a printer might use.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

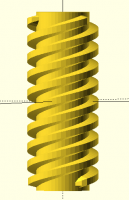

I never saw the original message, but if you need a multistart acme

threaded rod you could do that with BOSL2. See

https://github.com/revarbat/BOSL2/wiki/threading.scad#module-acme_threaded_rod

I have printed functioning threads at 1/4-20 size, so 6mm diam and 1.3mm

pitch using my FDM prusa, though you wouldn't want to hang heavy weights

from such a printed bolt. Printing a truncate bolt sideways may give a

stronger result.

include<BOSL2-fork/std.scad>

include<BOSL2-fork/threading.scad>

$fn=48;

acme_threaded_rod(length=20, d=8, pitch=2, starts=3);

[image: image.png]

On Sat, May 20, 2023 at 1:20 PM gene heskett gheskett@shentel.net wrote:

On 5/20/23 12:09, gene heskett wrote:

On 5/20/23 11:16, rr156 wrote:

Hi,

how should I model this kind of thread (see attached video). It is a

threaded rod d = 8 (exactly 7.8) mm, pitch 2 mm.

Roman

I have attached 1 file to this email:

- Threaded_rod.3gp

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

Size: 41,0 MB

Link souborů přes úložiště: Dropbox

Link:

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

Pix not too clear, movie too shaky, looks like a multistart acme thread,

how many starts is it?

One method that has had fairly wide spread use for precise work like a

lathes leadscrew is to slice a piece of acetel in two, clamp it back

together and drill a hole thru it aligned with the slice, fit it in a

vice so it grips the screw and heat the screw while closing the vise,

forming very precise threads that are quite low backlash. Then carefully

rewelding it while the screw is still in it to make it one piece again,

using a hot air solder wand to supply the welding heat. Helpful to pad

the vise jaws with a heat resistant insulator material.

I'm printing quite usable 2 start 6mm tooth, 12mm pitch threads for a

buttress thread with a .4 nozzle but at 2" diameter that is easy, at 8mm

diameter for the screw you are are exceeding what the printer can do

well even with a .2mm nozzle. Because my design is 2 start, both half

nuts, printed face up, are identical. So I just do it twice in OpenSCAD,

translating it for two locations on the printer bed.

To give an idea how I generate the nuts, I first made a module for the

shape of the tooth. And extruded 7 point polygon. Tilted slightly to

match the pitch tilt.

Then I made a cylinder at the root diameter of a phantom bolt.

Then I used two for loops to wrap the tooth around the bolt at 1 degree

intervals, 180 degrees apart. Several turns extra

Then I added a clearance increase in the size, and rerendered the whole

thing, then subtracted that from the form that is the nut. You see that

"bolt" in red in this .png.

Knowing what my printer can do, this same procedure could model your

bolt, but I do not believe it would be printable using FDM tech like my

modified sapphire-5. A high res photo-resin printer might do it, sure

worth a try. I use PETG for this, but I've no clue as to the wearability

of the photo resins such a printer might use.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

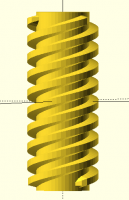

Metric trapezoidal threads are not exactly the same as ACME thread.

https://en.wikipedia.org/wiki/Trapezoidal_thread_form#Metric_trapezoidal_thread_characteristics

ACME uses 29 degree angle between flanks and metric trapezoidal uses 30

degree.

I can't be sure from the source video, i'm guessing it is a 4 start.

I think the standard way this is denoted is: Tr8x8(P2)

Which stands for: (Tr)apezoidal thread, 8mm nominal diameter, 8mm lead

(travel per revolution), 2mm (P)itch

lead = (# of starts)*pitch

On Sat, May 20, 2023 at 2:59 PM Adrian Mariano avm4@cornell.edu wrote:

I never saw the original message, but if you need a multistart acme

threaded rod you could do that with BOSL2. See

https://github.com/revarbat/BOSL2/wiki/threading.scad#module-acme_threaded_rod

I have printed functioning threads at 1/4-20 size, so 6mm diam and 1.3mm

pitch using my FDM prusa, though you wouldn't want to hang heavy weights

from such a printed bolt. Printing a truncate bolt sideways may give a

stronger result.

include<BOSL2-fork/std.scad>

include<BOSL2-fork/threading.scad>

$fn=48;

acme_threaded_rod(length=20, d=8, pitch=2, starts=3);

[image: image.png]

On Sat, May 20, 2023 at 1:20 PM gene heskett gheskett@shentel.net wrote:

On 5/20/23 12:09, gene heskett wrote:

On 5/20/23 11:16, rr156 wrote:

Hi,

how should I model this kind of thread (see attached video). It is a

threaded rod d = 8 (exactly 7.8) mm, pitch 2 mm.

Roman

I have attached 1 file to this email:

- Threaded_rod.3gp

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

Size: 41,0 MB

Link souborů přes úložiště: Dropbox

Link:

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

Pix not too clear, movie too shaky, looks like a multistart acme

thread,

how many starts is it?

One method that has had fairly wide spread use for precise work like a

lathes leadscrew is to slice a piece of acetel in two, clamp it back

together and drill a hole thru it aligned with the slice, fit it in a

vice so it grips the screw and heat the screw while closing the vise,

forming very precise threads that are quite low backlash. Then

carefully

rewelding it while the screw is still in it to make it one piece again,

using a hot air solder wand to supply the welding heat. Helpful to pad

the vise jaws with a heat resistant insulator material.

I'm printing quite usable 2 start 6mm tooth, 12mm pitch threads for a

buttress thread with a .4 nozzle but at 2" diameter that is easy, at

8mm

diameter for the screw you are are exceeding what the printer can do

well even with a .2mm nozzle. Because my design is 2 start, both half

nuts, printed face up, are identical. So I just do it twice in

OpenSCAD,

translating it for two locations on the printer bed.

To give an idea how I generate the nuts, I first made a module for the

shape of the tooth. And extruded 7 point polygon. Tilted slightly to

match the pitch tilt.

Then I made a cylinder at the root diameter of a phantom bolt.

Then I used two for loops to wrap the tooth around the bolt at 1 degree

intervals, 180 degrees apart. Several turns extra

Then I added a clearance increase in the size, and rerendered the whole

thing, then subtracted that from the form that is the nut. You see that

"bolt" in red in this .png.

Knowing what my printer can do, this same procedure could model your

bolt, but I do not believe it would be printable using FDM tech like my

modified sapphire-5. A high res photo-resin printer might do it, sure

worth a try. I use PETG for this, but I've no clue as to the wearability

of the photo resins such a printer might use.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On 5/20/23 19:25, Hans L wrote:

Metric trapezoidal threads are not exactly the same as ACME thread.

https://en.wikipedia.org/wiki/Trapezoidal_thread_form#Metric_trapezoidal_thread_characteristics

ACME uses 29 degree angle between flanks and metric trapezoidal uses 30

degree.

I can't be sure from the source video, i'm guessing it is a 4 start.

I think the standard way this is denoted is: Tr8x8(P2)

Which stands for: (Tr)apezoidal thread, 8mm nominal diameter, 8mm lead

(travel per revolution), 2mm (P)itch

lead = (# of starts)*pitch

That can be done in OpenSCAD with much the same code idea as I am using

for 2 start, but the end result seems like a fdm printer is beyond its

limits for good detail. The higher resolution photo resin based stuff

might be able to do it though.

That's the reason I mentioned the heat molding using acetal, the screw

will be perfectly matched and will not have appreciable backlash until

its worn by dragging in dirt. One of the reasons I enclosed both ball

screws to keep them clean on my Sheldon conversion. Z with bellows on

both sides of the nut with an air passage thru the nut, x by sealing up

the channel in the cross slide.

On Sat, May 20, 2023 at 2:59 PM Adrian Mariano avm4@cornell.edu wrote:

I never saw the original message, but if you need a multistart acme

threaded rod you could do that with BOSL2. See

https://github.com/revarbat/BOSL2/wiki/threading.scad#module-acme_threaded_rod

I have printed functioning threads at 1/4-20 size, so 6mm diam and 1.3mm

pitch using my FDM prusa, though you wouldn't want to hang heavy weights

from such a printed bolt. Printing a truncate bolt sideways may give a

stronger result.

include<BOSL2-fork/std.scad>

include<BOSL2-fork/threading.scad>

$fn=48;

acme_threaded_rod(length=20, d=8, pitch=2, starts=3);

[image: image.png]

On Sat, May 20, 2023 at 1:20 PM gene heskett gheskett@shentel.net wrote:

On 5/20/23 12:09, gene heskett wrote:

On 5/20/23 11:16, rr156 wrote:

Hi,

how should I model this kind of thread (see attached video). It is a

threaded rod d = 8 (exactly 7.8) mm, pitch 2 mm.

Roman

I have attached 1 file to this email:

* Threaded_rod.3gp

<https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0>

Size: 41,0 MB

Link souborů přes úložiště: Dropbox

Link:

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

<https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0>

Pix not too clear, movie too shaky, looks like a multistart acme

thread,

how many starts is it?

One method that has had fairly wide spread use for precise work like a

lathes leadscrew is to slice a piece of acetel in two, clamp it back

together and drill a hole thru it aligned with the slice, fit it in a

vice so it grips the screw and heat the screw while closing the vise,

forming very precise threads that are quite low backlash. Then

carefully

rewelding it while the screw is still in it to make it one piece again,

using a hot air solder wand to supply the welding heat. Helpful to pad

the vise jaws with a heat resistant insulator material.

I'm printing quite usable 2 start 6mm tooth, 12mm pitch threads for a

buttress thread with a .4 nozzle but at 2" diameter that is easy, at

8mm

diameter for the screw you are are exceeding what the printer can do

well even with a .2mm nozzle. Because my design is 2 start, both half

nuts, printed face up, are identical. So I just do it twice in

OpenSCAD,

translating it for two locations on the printer bed.

To give an idea how I generate the nuts, I first made a module for the

shape of the tooth. And extruded 7 point polygon. Tilted slightly to

match the pitch tilt.

Then I made a cylinder at the root diameter of a phantom bolt.

Then I used two for loops to wrap the tooth around the bolt at 1 degree

intervals, 180 degrees apart. Several turns extra

Then I added a clearance increase in the size, and rerendered the whole

thing, then subtracted that from the form that is the nut. You see that

"bolt" in red in this .png.

Knowing what my printer can do, this same procedure could model your

bolt, but I do not believe it would be printable using FDM tech like my

modified sapphire-5. A high res photo-resin printer might do it, sure

worth a try. I use PETG for this, but I've no clue as to the wearability

of the photo resins such a printer might use.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/

Thank you all for your support and ideas.

Roman

Dne 20.5.2023 v 17:16 rr156 napsal(a):

Hi,

how should I model this kind of thread (see attached video). It is a

threaded rod d = 8 (exactly 7.8) mm, pitch 2 mm.

Roman

I have attached 1 file to this email:

* Threaded_rod.3gp

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

Size: 41,0 MB

Link souborů přes úložiště: Dropbox

Link:

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Hi,

I have one question please:

When I need to screw the acme nut counter-clockwise, is it enough to

enter a negative pitch angle or is it more complicated?

Roman

Dne 22.5.2023 v 10:56 rr156 napsal(a):

Thank you all for your support and ideas.

Roman

Dne 20.5.2023 v 17:16 rr156 napsal(a):

Hi,

how should I model this kind of thread (see attached video). It is a

threaded rod d = 8 (exactly 7.8) mm, pitch 2 mm.

Roman

I have attached 1 file to this email:

* Threaded_rod.3gp

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

Size: 41,0 MB

Link souborů přes úložiště: Dropbox

Link:

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

https://www.dropbox.com/s/lctxv4zdrntdsla/Threaded_rod.3gp?dl=0

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org