Do I have a bug?

Greetings all;

I finally got linear_extrude working. It was fat fingers triggering an

unwanted change in keyboard behavior from insert to overwrite.

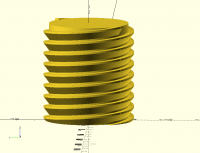

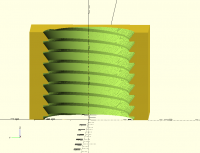

So here are two pix from an F5 preview, one of the bolt and one of the

halfnut. Looks pretty solid 3d to me.

But hit F6 on either and get this in the log window in about 2 minutes:

Parsing design (AST generation)...

Saved backup file: /home/gene/.local/share/OpenSCAD/backups/new-

buttress_vise_bolt_nut-backup-qQTWHGFE.scad

Compiling design (CSG Tree generation)...

Rendering Polygon Mesh using CGAL...

WARNING: [fast-csg] Corefinement corefinement mesh union #10019 failed

Rendering cancelled on first warning.

WARNING: No top level geometry to render

Bug?

code mistake?

I just now fixed it. I could see the z line laid separately from the base

of the tooth if I blew it up big enough. A translate([-.0005,0,0]) in

front of the rotate made it work. Now to see if it survives tipping the

tooth another 3.5 degrees. This gives a dead flat top to the tooth shape

on the high load face,but also warbles the x, putting a slight pattern

into the back slope of a buttress thread. It would be the ultimate fine

tuning if, rather than tipping the whole tooth, we could tip the basic

tooth shape ONLY on the Y axis, making the rectangle into a trapezoid,

then we could lay down a dead smooth surface on both sides of the

buttress thread.

Overall though, this is the easiest design software I've ever tried to

use.

Thank you all.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

The bolt renders in 1:50 on my Mac using 22.03.14 but throws a warning

WARNING: Object may not be a valid 2-manifold and may need repair!

You may have a gap between the thread and bolt infiltrated

On 2 May 2022, at 11:04, gene heskett gheskett@shentel.net wrote:

Greetings all;

I finally got linear_extrude working. It was fat fingers triggering an

unwanted change in keyboard behavior from insert to overwrite.

So here are two pix from an F5 preview, one of the bolt and one of the

halfnut. Looks pretty solid 3d to me.

But hit F6 on either and get this in the log window in about 2 minutes:

Parsing design (AST generation)...

Saved backup file: /home/gene/.local/share/OpenSCAD/backups/new-

buttress_vise_bolt_nut-backup-qQTWHGFE.scad

Compiling design (CSG Tree generation)...

Rendering Polygon Mesh using CGAL...

WARNING: [fast-csg] Corefinement corefinement mesh union #10019 failed

Rendering cancelled on first warning.

WARNING: No top level geometry to render

Bug?

code mistake?

I just now fixed it. I could see the z line laid separately from the base

of the tooth if I blew it up big enough. A translate([-.0005,0,0]) in

front of the rotate made it work. Now to see if it survives tipping the

tooth another 3.5 degrees. This gives a dead flat top to the tooth shape

on the high load face,but also warbles the x, putting a slight pattern

into the back slope of a buttress thread. It would be the ultimate fine

tuning if, rather than tipping the whole tooth, we could tip the basic

tooth shape ONLY on the Y axis, making the rectangle into a trapezoid,

then we could lay down a dead smooth surface on both sides of the

buttress thread.

Overall though, this is the easiest design software I've ever tried to

use.

Thank you all.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

<new-buttress_nut.png><new-buttress_vise_bolt.png><new-buttress_vise_bolt_nut.scad>_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

As I thought setting the cylinder diameter slightly larger

cylinder(h=54.25,d=mdt+tal+0.01)

removes the 2d manifold issue and speeds up rendering 300%

When creating a union I never place two object adjacent to each other I always add a minuscule overlap.

Cheers

Bob

On 2 May 2022, at 11:04, gene heskett gheskett@shentel.net wrote:

Greetings all;

I finally got linear_extrude working. It was fat fingers triggering an

unwanted change in keyboard behavior from insert to overwrite.

So here are two pix from an F5 preview, one of the bolt and one of the

halfnut. Looks pretty solid 3d to me.

But hit F6 on either and get this in the log window in about 2 minutes:

Parsing design (AST generation)...

Saved backup file: /home/gene/.local/share/OpenSCAD/backups/new-

buttress_vise_bolt_nut-backup-qQTWHGFE.scad

Compiling design (CSG Tree generation)...

Rendering Polygon Mesh using CGAL...

WARNING: [fast-csg] Corefinement corefinement mesh union #10019 failed

Rendering cancelled on first warning.

WARNING: No top level geometry to render

Bug?

code mistake?

I just now fixed it. I could see the z line laid separately from the base

of the tooth if I blew it up big enough. A translate([-.0005,0,0]) in

front of the rotate made it work. Now to see if it survives tipping the

tooth another 3.5 degrees. This gives a dead flat top to the tooth shape

on the high load face,but also warbles the x, putting a slight pattern

into the back slope of a buttress thread. It would be the ultimate fine

tuning if, rather than tipping the whole tooth, we could tip the basic

tooth shape ONLY on the Y axis, making the rectangle into a trapezoid,

then we could lay down a dead smooth surface on both sides of the

buttress thread.

Overall though, this is the easiest design software I've ever tried to

use.

Thank you all.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

<new-buttress_nut.png><new-buttress_vise_bolt.png><new-buttress_vise_bolt_nut.scad>_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On Monday, 2 May 2022 06:13:35 EDT Bob Carter wrote:

The bolt renders in 1:50 on my Mac using 22.03.14 but throws a warning

WARNING: Object may not be a valid 2-manifold and may need repair!

You may have a gap between the thread and bolt infiltrated

Chuckle... You are observant. :) That gap is intentional and only for

display and fitting checking as its thread clearance. They will neveer be

printed together as you see them in that pix.

Works nicely since that thread is formed by rendering the bolt a tad

oversize (.25 mm) and using it as the difference to form the nuts

threads. The bolt will be printed -.25mm undersized to verify the fit

but the final bolt in hard maple OTOH will be done by a 1/16" round nose

mill in a 4 axis milling machine I've heavily rebuilt, but should have

spent way more sheckles to buy something worth buying. Something with

500+ lbs of cast for a bed. Rigid, these alu extrusions used in the 6040

mill are not. Adjacent one's aren't even keyed together.

An unfunny thing for that half nut is that cura isn't filling the big gap

between the box walls and the threads, they are completely empty, no

infill at all in a ragged space between them. Finished, one might be able

to see it from the flat backside as this particular batch of PETG is

much less dyed but the same color as prusaments lipstick red, but you can

see thru several layers of it. Its also gummed up the wheels in the h2

head of my biqu bx printer, once. Seems the machine has babysteped itself

into dragging its PCD nozzle heavily on the bed, I had to up it by .07mm

to get it to lay the brim when it started the print.

Onward and upward but waiting on a better tailstock, when a much better

one arrives, this one will have a pretty flat trajectory headed for the

trash can in the garage. I can't clamp it tight enough to hold position,

yet the clamps are distorting the bed by around 5mm out of whatever

passes for flat. And the bore its center runs in allows over a mm of

wobble. A POS to be properly disposed of.

Thank you Bob, take care and stay well. Your threadshape module code

showed me how to do it much better and 20x faster.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

On Monday, 2 May 2022 07:36:18 EDT Bob Carter wrote:

As I thought setting the cylinder diameter slightly larger

cylinder(h=54.25,d=mdt+tal+0.01)

removes the 2d manifold issue and speeds up rendering 300%

I think my translate X-.0005 does the same thing, in threadshape.

When creating a union I never place two object adjacent to each other I

always add a minuscule overlap.

So do I, but I missed that one. Couldn't see that guilty gap until I had

blown the tooth up to fill the whole viewscreen.

Thanks Bob. Take care and stay well.

Cheers, Gene Heskett.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis