pattern for brass nameplate

I'm hoping to create a simple pattern for a casting a couple of brass

nameplates. I would like to produce it as an stl for fdm printing. There

are a few problems. 1) I've created a 3d design approximating to the

desired size, but when extruding, there needs to be a draft angle of

about 3 degrees for each letter and the frame. 2) there needs to be a

fillet at the base of each character for easy pattern removal. 3)

ideally, it would be nice to individually adjust the width of the

strokes of the letters. The code, so far, is listed below.

As the lettering is simple, then I am wondering if it may be easier to

create a profile for a cross section, including the fillet, and extrude

a length, cut up and rotate and place accordingly. (it would be ten

pieces and the frame). I think that I could create the fillets, if I

could get the draft angle on the eletter strokes, by differencing into a

cube, and applying Minkowski with a small sphere, and differencing back

again.

Machining from solid is simpler, I use a profiled round-ended cutter to

get the draft angle and fillet in one pass, I could almost write the

g-code by hand for that....

Any suggestions? (being a bit of a Luddite, I am not going to be using

bos2l 😳 )

Best wishes,

Ray

////////////////////////////////////////////////////////////////////////////////////

// ken

module name(){

text ("KEN",font="Liberation

Sans:style=Bold",size=50,valign="center",halign="center");

}

module inround(){

difference(){

d=40;

r=20;

square(d,true);

translate([-r,-r])circle(d=d);

translate([-r,+r])circle(d=d);

translate([+r,-r])circle(d=d);

translate([+r,+r])circle(d=d);

}

}

module inframe(){

difference(){

square([220,80],true);

translate([-110,-40])inround();

translate([-110,+40])inround();

translate([+110,-40])inround();

translate([+110,+40])inround();

}

}

module frame(){

difference(){

offset(r=10) inframe();

inframe();

}

}

module base(){

linear_extrude(5){

offset(r=10) inframe();

}

}

base();

linear_extrude(10){

frame();

name();

}

You can always minkowski the text with a pseudo traffic-cone shape.

module rrect(size, r) {

hull() {

for (x = [-1,1], y = [-1,1])

translate([x*(size.x/2-r), y*(size.y/2-r)])

circle(r=r);

}

}

module plate(size, r, wall, base, height) {

linear_extrude(height=height) {

difference() {

rrect(size, r);

rrect(size-2*[wall,wall], r-wall);

}

}

linear_extrude(height=base) {

rrect(size, r);

}

}

module trumpet_horn(fillet, height, ang, n) {

tanx = fillet / cos(ang);

xoff = (height-fillet) * tan(ang);

cp = [tanx+xoff, fillet];

path = [

[0,height],

for (i = [0:1:n])

let( a = 180 + ang + (90-ang) * (i/n) )

cp + fillet * [cos(a),sin(a)],

[0,0]

];

rotate_extrude() polygon(path);

}

module name(text, fillet, height, ang, n) {

minkowski() {

translate([0,0,-0.1]) {

linear_extrude(height=0.1, center=false)

text(text, font="Liberation Sans:style=Bold", size=50, valign="center",halign="center");

}

trumpet_horn(fillet, height, ang, n);

}

}

module plaque(text, height, fillet, ang) {

union() {

translate([0,0,2])

name(text=text, fillet, height, ang, n=3);

plate(size=[220,90], r=20, wall=10, base=2, height=10);

}

}

plaque("KEN", height=10, fillet=3, ang=3);

- Revar

On May 2, 2024, at 2:46 PM, Raymond West via Discuss discuss@lists.openscad.org wrote:

I'm hoping to create a simple pattern for a casting a couple of brass nameplates. I would like to produce it as an stl for fdm printing. There are a few problems. 1) I've created a 3d design approximating to the desired size, but when extruding, there needs to be a draft angle of about 3 degrees for each letter and the frame. 2) there needs to be a fillet at the base of each character for easy pattern removal. 3) ideally, it would be nice to individually adjust the width of the strokes of the letters. The code, so far, is listed below.

As the lettering is simple, then I am wondering if it may be easier to create a profile for a cross section, including the fillet, and extrude a length, cut up and rotate and place accordingly. (it would be ten pieces and the frame). I think that I could create the fillets, if I could get the draft angle on the eletter strokes, by differencing into a cube, and applying Minkowski with a small sphere, and differencing back again.

Machining from solid is simpler, I use a profiled round-ended cutter to get the draft angle and fillet in one pass, I could almost write the g-code by hand for that....

Any suggestions? (being a bit of a Luddite, I am not going to be using bos2l 😳 )

Best wishes,

Ray

////////////////////////////////////////////////////////////////////////////////////

// ken

module name(){

text ("KEN",font="Liberation Sans:style=Bold",size=50,valign="center",halign="center");

}

module inround(){

difference(){

d=40;

r=20;

square(d,true);

translate([-r,-r])circle(d=d);

translate([-r,+r])circle(d=d);

translate([+r,-r])circle(d=d);

translate([+r,+r])circle(d=d);

}

}

module inframe(){

difference(){

square([220,80],true);

translate([-110,-40])inround();

translate([-110,+40])inround();

translate([+110,-40])inround();

translate([+110,+40])inround();

}

}

module frame(){

difference(){

offset(r=10) inframe();

inframe();

}

}

module base(){

linear_extrude(5){

offset(r=10) inframe();

}

}

base();

linear_extrude(10){

frame();

name();

}

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

I realized after posing that the the plate itself needed filleting:

module rrect(size, r) {

hull() {

for (x = [-1,1], y = [-1,1])

translate([x*(size.x/2-r), y*(size.y/2-r)])

circle(r=r);

}

}

module plate(size, r, wall, base, height, fillet, ang=3, n=3) {

linear_extrude(height=height) {

difference() {

rrect(size, r);

rrect(size-2*[wall,wall], r-wall);

}

}

minkowski() {

translate([0,0,base-0.1]) {

linear_extrude(height=0.1) {

difference() {

rrect(size-1.9*[wall,wall], r-0.95wall);

rrect(size-2[wall,wall], r-wall);

}

}

}

trumpet_horn(fillet, height-base, ang, n);

}

linear_extrude(height=base) {

rrect(size, r);

}

}

module trumpet_horn(fillet, height, ang=3, n=3) {

tanx = fillet / cos(ang);

xoff = (height-fillet) * tan(ang);

cp = [tanx+xoff, fillet];

path = [

[0,height],

for (i = [0:1:n])

let( a = 180 + ang + (90-ang) * (i/n) )

cp + fillet * [cos(a),sin(a)],

[0,0]

];

rotate_extrude() polygon(path);

}

module name(text, fillet, height, ang=3, n=3) {

minkowski() {

translate([0,0,-0.1]) {

linear_extrude(height=0.1, center=false)

text(text, font="Liberation Sans:style=Bold", size=50, valign="center",halign="center");

}

trumpet_horn(fillet, height, ang, n);

}

}

module plaque(text, height, fillet, ang=3) {

union() {

translate([0,0,2])

name(text=text, fillet, height, ang, n=3);

plate(size=[220,90], r=20, wall=10, base=2, height=10, fillet=fillet, ang=ang);

}

}

plaque("KEN", height=10, fillet=3, ang=3);

- Revar

On May 2, 2024, at 2:46 PM, Raymond West via Discuss discuss@lists.openscad.org wrote:

I'm hoping to create a simple pattern for a casting a couple of brass nameplates. I would like to produce it as an stl for fdm printing. There are a few problems. 1) I've created a 3d design approximating to the desired size, but when extruding, there needs to be a draft angle of about 3 degrees for each letter and the frame. 2) there needs to be a fillet at the base of each character for easy pattern removal. 3) ideally, it would be nice to individually adjust the width of the strokes of the letters. The code, so far, is listed below.

As the lettering is simple, then I am wondering if it may be easier to create a profile for a cross section, including the fillet, and extrude a length, cut up and rotate and place accordingly. (it would be ten pieces and the frame). I think that I could create the fillets, if I could get the draft angle on the eletter strokes, by differencing into a cube, and applying Minkowski with a small sphere, and differencing back again.

Machining from solid is simpler, I use a profiled round-ended cutter to get the draft angle and fillet in one pass, I could almost write the g-code by hand for that....

Any suggestions? (being a bit of a Luddite, I am not going to be using bos2l 😳 )

Best wishes,

Ray

////////////////////////////////////////////////////////////////////////////////////

// ken

module name(){

text ("KEN",font="Liberation Sans:style=Bold",size=50,valign="center",halign="center");

}

module inround(){

difference(){

d=40;

r=20;

square(d,true);

translate([-r,-r])circle(d=d);

translate([-r,+r])circle(d=d);

translate([+r,-r])circle(d=d);

translate([+r,+r])circle(d=d);

}

}

module inframe(){

difference(){

square([220,80],true);

translate([-110,-40])inround();

translate([-110,+40])inround();

translate([+110,-40])inround();

translate([+110,+40])inround();

}

}

module frame(){

difference(){

offset(r=10) inframe();

inframe();

}

}

module base(){

linear_extrude(5){

offset(r=10) inframe();

}

}

base();

linear_extrude(10){

frame();

name();

}

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Thanks Revar,

Just what I needed. I realise now that I created a sort of x y problem

for myself, having always used a sphere for rounding edges with

Minkowski, I'd completely forgotten that other solids were possible,

never mind hull for corner rounded squares. 🙁

Best wishes,

Ray

On 03/05/2024 01:16, Revar Desmera wrote:

I realized after posing that the the plate itself needed filleting:

module rrect(size, r) {

hull() {

for (x = [-1,1], y = [-1,1])

translate([x*(size.x/2-r), y*(size.y/2-r)])

circle(r=r);

}

}

module plate(size, r, wall, base, height, fillet, ang=3, n=3) {

linear_extrude(height=height) {

difference() {

rrect(size, r);

rrect(size-2*[wall,wall], r-wall);

}

}

minkowski() {

translate([0,0,base-0.1]) {

linear_extrude(height=0.1) {

difference() {

rrect(size-1.9*[wall,wall], r-0.95*wall);

rrect(size-2*[wall,wall], r-wall);

}

}

}

trumpet_horn(fillet, height-base, ang, n);

}

linear_extrude(height=base) {

rrect(size, r);

}

}

module trumpet_horn(fillet, height, ang=3, n=3) {

tanx = fillet / cos(ang);

xoff = (height-fillet) * tan(ang);

cp = [tanx+xoff, fillet];

path = [

[0,height],

for (i = [0:1:n])

let( a = 180 + ang + (90-ang) * (i/n) )

cp + fillet * [cos(a),sin(a)],

[0,0]

];

rotate_extrude() polygon(path);

}

module name(text, fillet, height, ang=3, n=3) {

minkowski() {

translate([0,0,-0.1]) {

linear_extrude(height=0.1, center=false)

text(text, font="Liberation Sans:style=Bold",

size=50, valign="center",halign="center");

}

trumpet_horn(fillet, height, ang, n);

}

}

module plaque(text, height, fillet, ang=3) {

union() {

translate([0,0,2])

name(text=text, fillet, height, ang, n=3);

plate(size=[220,90], r=20, wall=10, base=2, height=10,

fillet=fillet, ang=ang);

}

}

plaque("KEN", height=10, fillet=3, ang=3);

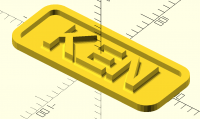

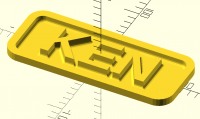

Screenshot 2024-05-02 at 5.15.50 PM.png

- Revar

On May 2, 2024, at 2:46 PM, Raymond West via Discuss

discuss@lists.openscad.org wrote:

I'm hoping to create a simple pattern for a casting a couple of brass

nameplates. I would like to produce it as an stl for fdm printing.

There are a few problems. 1) I've created a 3d design approximating

to the desired size, but when extruding, there needs to be a draft

angle of about 3 degrees for each letter and the frame. 2) there

needs to be a fillet at the base of each character for easy pattern

removal. 3) ideally, it would be nice to individually adjust the

width of the strokes of the letters. The code, so far, is listed below.

As the lettering is simple, then I am wondering if it may be easier

to create a profile for a cross section, including the fillet, and

extrude a length, cut up and rotate and place accordingly. (it would

be ten pieces and the frame). I think that I could create the

fillets, if I could get the draft angle on the eletter strokes, by

differencing into a cube, and applying Minkowski with a small sphere,

and differencing back again.

Machining from solid is simpler, I use a profiled round-ended cutter

to get the draft angle and fillet in one pass, I could almost write

the g-code by hand for that....

Any suggestions? (being a bit of a Luddite, I am not going to be

using bos2l 😳 )

Best wishes,

Ray

////////////////////////////////////////////////////////////////////////////////////

// ken

module name(){

text ("KEN",font="Liberation

Sans:style=Bold",size=50,valign="center",halign="center");

}

module inround(){

difference(){

d=40;

r=20;

square(d,true);

translate([-r,-r])circle(d=d);

translate([-r,+r])circle(d=d);

translate([+r,-r])circle(d=d);

translate([+r,+r])circle(d=d);

}

}

module inframe(){

difference(){

square([220,80],true);

translate([-110,-40])inround();

translate([-110,+40])inround();

translate([+110,-40])inround();

translate([+110,+40])inround();

}

}

module frame(){

difference(){

offset(r=10) inframe();

inframe();

}

}

module base(){

linear_extrude(5){

offset(r=10) inframe();

}

}

base();

linear_extrude(10){

frame();

name();

}

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

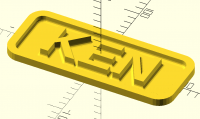

I made it parametric, with customizer, and did a quick test print. -

On 03/05/2024 10:33, Raymond West via Discuss wrote:

Thanks Revar,

Just what I needed. I realise now that I created a sort of x y

problem for myself, having always used a sphere for rounding edges

with Minkowski, I'd completely forgotten that other solids were

possible, never mind hull for corner rounded squares. 🙁

Best wishes,

Ray

Normally if you are casting, sharp corners will always create problem.

Draft and fillets needs to be provided to avoid scoring, sticking and metal

filling issues.

For one off castings maybe fine though.

Regards

On Sat, 4 May, 2024, 1:07 am Raymond West via Discuss, <

discuss@lists.openscad.org> wrote:

I made it parametric, with customizer, and did a quick test print. -

On 03/05/2024 10:33, Raymond West via Discuss wrote:

Thanks Revar,

Just what I needed. I realise now that I created a sort of x y problem

for myself, having always used a sphere for rounding edges with Minkowski,

I'd completely forgotten that other solids were possible, never mind hull

for corner rounded squares. 🙁

Best wishes,

Ray

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org