J

jon

Mon, Jan 15, 2024 3:05 PM

William:

I purchased MeshCAM specifically so that I could take STLs generated by

OpenSCAD and create them on my Shapeoko. That works to a large extent,

but MeshCAM is a bit quirky and is not updated that often. Generating

the gCode directly from OpenSCAD would be interesting. MeshCAM includes

multiple passes (rough and finishing) with different cutting tools.

Perhaps too much to expect from your experiment. In any event, nice

seeing you thinking outside of the box

Jon

On 1/15/2024 9:56 AM, William F. Adams via Discuss wrote:

Would your code eventually be able to replace MeshCAM?

Maybe, for a much better programmer than me.

The idea is to model how a tool cuts, so one can create G-code w/o

needing a separate CAM program. This is a weird way to work in

OpenSCAD, but it works for me.

I suppose an absolutely brilliant programmer could use this to analyze

an STL and create G-code --- but such a person could probably just

write their own CAM tool w/o such a crutch.

I am currently concentrating on adding DXF support --- because the CAM

stuff is hard --- this will allow writing out DXF files, importing

them into a 3rd party CAM tool such as MeshCAM, then writing out

G-code using that.

The direct G-code generation will currently make anything which can be

done w/ straight lines (working to add arcs now) in a single pass

(there's a radial flattening example file on Github) --- but it needs

to be generalized for different shapes, and to have support added for

multiple passes.

Hopefully I'll have an announcement about arcs working presently.

If someone has a CNC and has a simple project as a test case which

they want cut out, I'd be glad to look into this with them.

William

--

Sphinx of black quartz, judge my vow.

https://designinto3d.com/

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

William:

I purchased MeshCAM specifically so that I could take STLs generated by

OpenSCAD and create them on my Shapeoko. That works to a large extent,

but MeshCAM is a bit quirky and is not updated that often. Generating

the gCode directly from OpenSCAD would be interesting. MeshCAM includes

multiple passes (rough and finishing) with different cutting tools.

Perhaps too much to expect from your experiment. In any event, nice

seeing you thinking outside of the box

Jon

On 1/15/2024 9:56 AM, William F. Adams via Discuss wrote:

> On Monday, January 15, 2024 at 08:39:53 AM EST, jon via Discuss

> <discuss@lists.openscad.org> wrote:

>

> >(not so) Privately.

>

> It happens.

>

> >Would your code eventually be able to replace MeshCAM?

>

> Maybe, for a much better programmer than me.

>

> The idea is to model how a tool cuts, so one can create G-code w/o

> needing a separate CAM program. This is a weird way to work in

> OpenSCAD, but it works for me.

>

> I suppose an absolutely brilliant programmer could use this to analyze

> an STL and create G-code --- but such a person could probably just

> write their own CAM tool w/o such a crutch.

>

> I am currently concentrating on adding DXF support --- because the CAM

> stuff is _hard_ --- this will allow writing out DXF files, importing

> them into a 3rd party CAM tool such as MeshCAM, then writing out

> G-code using that.

>

> The direct G-code generation will currently make anything which can be

> done w/ straight lines (working to add arcs now) in a single pass

> (there's a radial flattening example file on Github) --- but it needs

> to be generalized for different shapes, and to have support added for

> multiple passes.

>

> Hopefully I'll have an announcement about arcs working presently.

>

> If someone has a CNC and has a simple project as a test case which

> they want cut out, I'd be glad to look into this with them.

>

> William

>

> --

> Sphinx of black quartz, judge my vow.

> https://designinto3d.com/

>

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email todiscuss-leave@lists.openscad.org

BB

Bruno Boettcher

Mon, Jan 15, 2024 6:17 PM

Hello!

excuse the noob question, but it seems to me that writing a slicer is not a

trivial task? I am switching between cura and icesl (both have advantages

and disadvantages) and both are in heavy development for some time?

So if you absolutely don't want to switch programs,probably a named pipe

towards e.g. icesl (which is open source too) would be better than

reinventing the wheel?

excuse me if i am offtopic :D but the problem seemed weird to me....

ciao

bboett

Am Mo., 15. Jan. 2024 um 16:06 Uhr schrieb jon via Discuss <

discuss@lists.openscad.org>:

William:

I purchased MeshCAM specifically so that I could take STLs generated by

OpenSCAD and create them on my Shapeoko. That works to a large extent, but

MeshCAM is a bit quirky and is not updated that often. Generating the

gCode directly from OpenSCAD would be interesting. MeshCAM includes

multiple passes (rough and finishing) with different cutting tools.

Perhaps too much to expect from your experiment. In any event, nice seeing

you thinking outside of the box

Jon

On 1/15/2024 9:56 AM, William F. Adams via Discuss wrote:

On Monday, January 15, 2024 at 08:39:53 AM EST, jon via Discuss

discuss@lists.openscad.org discuss@lists.openscad.org wrote:

Would your code eventually be able to replace MeshCAM?

Maybe, for a much better programmer than me.

The idea is to model how a tool cuts, so one can create G-code w/o needing

a separate CAM program. This is a weird way to work in OpenSCAD, but it

works for me.

I suppose an absolutely brilliant programmer could use this to analyze an

STL and create G-code --- but such a person could probably just write their

own CAM tool w/o such a crutch.

I am currently concentrating on adding DXF support --- because the CAM

stuff is hard --- this will allow writing out DXF files, importing them

into a 3rd party CAM tool such as MeshCAM, then writing out G-code using

that.

The direct G-code generation will currently make anything which can be

done w/ straight lines (working to add arcs now) in a single pass (there's

a radial flattening example file on Github) --- but it needs to be

generalized for different shapes, and to have support added for multiple

passes.

Hopefully I'll have an announcement about arcs working presently.

If someone has a CNC and has a simple project as a test case which they

want cut out, I'd be glad to look into this with them.

William

--

Sphinx of black quartz, judge my vow.

https://designinto3d.com/

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Hello!

excuse the noob question, but it seems to me that writing a slicer is not a

trivial task? I am switching between cura and icesl (both have advantages

and disadvantages) and both are in heavy development for some time?

So if you absolutely don't want to switch programs,probably a named pipe

towards e.g. icesl (which is open source too) would be better than

reinventing the wheel?

excuse me if i am offtopic :D but the problem seemed weird to me....

ciao

bboett

Am Mo., 15. Jan. 2024 um 16:06 Uhr schrieb jon via Discuss <

discuss@lists.openscad.org>:

> William:

>

> I purchased MeshCAM specifically so that I could take STLs generated by

> OpenSCAD and create them on my Shapeoko. That works to a large extent, but

> MeshCAM is a bit quirky and is not updated that often. Generating the

> gCode directly from OpenSCAD would be interesting. MeshCAM includes

> multiple passes (rough and finishing) with different cutting tools.

> Perhaps too much to expect from your experiment. In any event, nice seeing

> you thinking outside of the box

>

> Jon

> On 1/15/2024 9:56 AM, William F. Adams via Discuss wrote:

>

> On Monday, January 15, 2024 at 08:39:53 AM EST, jon via Discuss

> <discuss@lists.openscad.org> <discuss@lists.openscad.org> wrote:

>

> >(not so) Privately.

>

> It happens.

>

> >Would your code eventually be able to replace MeshCAM?

>

> Maybe, for a much better programmer than me.

>

> The idea is to model how a tool cuts, so one can create G-code w/o needing

> a separate CAM program. This is a weird way to work in OpenSCAD, but it

> works for me.

>

> I suppose an absolutely brilliant programmer could use this to analyze an

> STL and create G-code --- but such a person could probably just write their

> own CAM tool w/o such a crutch.

>

> I am currently concentrating on adding DXF support --- because the CAM

> stuff is _hard_ --- this will allow writing out DXF files, importing them

> into a 3rd party CAM tool such as MeshCAM, then writing out G-code using

> that.

>

> The direct G-code generation will currently make anything which can be

> done w/ straight lines (working to add arcs now) in a single pass (there's

> a radial flattening example file on Github) --- but it needs to be

> generalized for different shapes, and to have support added for multiple

> passes.

>

> Hopefully I'll have an announcement about arcs working presently.

>

> If someone has a CNC and has a simple project as a test case which they

> want cut out, I'd be glad to look into this with them.

>

> William

>

> --

> Sphinx of black quartz, judge my vow.

> https://designinto3d.com/

>

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

--

ciao

Bruno

===========================================

http://nohkumado.eu/, <http://bboett.free.fr>http://aikido.nohkumado.eu/,

<http://bboett.free.fr>

http://aikido.zorn.free.fr

TP

Torsten Paul

Mon, Jan 15, 2024 7:43 PM

On 15.01.24 19:17, Bruno Boettcher via Discuss wrote:

towards e.g. icesl (which is open source too) would be better than

reinventing the wheel?

What? Where?

All I can see is a "binary" license which in strict reading would not

even permit normal private use, it only mentions "research use".

Where's the source code?

ciao,

Torsten.

On 15.01.24 19:17, Bruno Boettcher via Discuss wrote:

> towards e.g. icesl (which is open source too) would be better than

> reinventing the wheel?

What? Where?

All I can see is a "binary" license which in strict reading would not

even permit normal private use, it only mentions "research use".

Where's the source code?

ciao,

Torsten.

WF

William F. Adams

Mon, Jan 15, 2024 8:16 PM

excuse the noob question, but it seems to me that writing a slicer is not a trivial task?

Decidedly not, hence my weird approach.

I am switching between cura and icesl (both have advantages and disadvantages) and both are in heavy development for some time?

This G-code is for a subtractive CNC router (or mill).

So if you absolutely don't want to switch programs,probably a named pipe towards e.g. icesl (which is open source too) would be better than reinventing the wheel?

I don't know of any similar projects --- the closest would be CAMotics:

https://camotics.org/

but I don't like Javascript, and since they did a controller for a company which competes with the one I work for, that's not an option.

excuse me if i am offtopic :D but the problem seemed weird to me....

It is weird.

The idea is to avoid the need for CAM software (or to simplify using CAM software) by directly modeling the tool movement, and recording that either as G-code, or in a DXF.

A good example of a problem which this works around is slots which are exactly the same diameter as the tool --- when describing as outlines it is necessary to add 10% or so so that rounding issues won't interfere with the calculations of whether the tool fits or no.

I'm going to post a template file to my Github now, then work on adding support for arcs --- once I've got that done I'll try to work up an example file which explains this better.

I did do one compleat example, a flattening file:

https://github.com/WillAdams/gcodepreview/blob/main/flatten.graph.tres

which when opened in OpenSCAD Graph Editor should show a radial flattening toolpath (some configuration will be necessary, including installing gcodepreview).

William

On Monday, January 15, 2024 at 01:18:18 PM EST, Bruno Boettcher via Discuss <discuss@lists.openscad.org> wrote:

>excuse the noob question, but it seems to me that writing a slicer is not a trivial task?

Decidedly not, hence my weird approach.

>I am switching between cura and icesl (both have advantages and disadvantages) and both are in heavy development for some time?

This G-code is for a subtractive CNC router (or mill).

>So if you absolutely don't want to switch programs,probably a named pipe towards e.g. icesl (which is open source too) would be better than reinventing the wheel?

I don't know of any similar projects --- the closest would be CAMotics:

https://camotics.org/

but I don't like Javascript, and since they did a controller for a company which competes with the one I work for, that's not an option.

>excuse me if i am offtopic :D but the problem seemed weird to me....

It is weird.

The idea is to avoid the need for CAM software (or to simplify using CAM software) by directly modeling the tool movement, and recording that either as G-code, or in a DXF.

A good example of a problem which this works around is slots which are exactly the same diameter as the tool --- when describing as outlines it is necessary to add 10% or so so that rounding issues won't interfere with the calculations of whether the tool fits or no.

I'm going to post a template file to my Github now, then work on adding support for arcs --- once I've got that done I'll try to work up an example file which explains this better.

I did do one compleat example, a flattening file:

https://github.com/WillAdams/gcodepreview/blob/main/flatten.graph.tres

which when opened in OpenSCAD Graph Editor should show a radial flattening toolpath (some configuration will be necessary, including installing gcodepreview).

William

BB

Bruno Boettcher

Mon, Jan 15, 2024 9:17 PM

On 15.01.24 19:17, Bruno Boettcher via Discuss wrote:

towards e.g. icesl (which is open source too) would be better than

reinventing the wheel?

What? Where?

All I can see is a "binary" license which in strict reading would not

even permit normal private use, it only mentions "research use".

Where's the source code?

ciao,

Torsten.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Ah yes, you have to ask them directly...

French universities still have problems with public code repositories....

Ciao

Bruno Böttcher

--

35 rue de la république, FR-6720 Schwindratzheim

email: bboett@adlp.org, mobile:bboett@gmail.com

Fon:+33 3 88 89 91, Mob:+33 6 76 55 82 68

-------------------------------------------------

Dev: Java/Perl/PHP OS:GNU/LINUX, Android

Aïkido: http://aikido.zorn.free.fr, http://www.aikido-club-saverne.fr

Torsten Paul via Discuss <discuss@lists.openscad.org> schrieb am Mo., 15.

Jan. 2024, 20:44:

> On 15.01.24 19:17, Bruno Boettcher via Discuss wrote:

> > towards e.g. icesl (which is open source too) would be better than

> > reinventing the wheel?

>

> What? Where?

>

> All I can see is a "binary" license which in strict reading would not

> even permit normal private use, it only mentions "research use".

>

> Where's the source code?

>

> ciao,

> Torsten.

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

JB

Jordan Brown

Mon, Jan 15, 2024 10:22 PM

I have to wonder whether a good (better?) answer for this mightn't be to

use a conventional programming language to emit gcode, and a gcode viewer.

Admittedly most of the gcode viewers that I know of are for

filament-style 3D printing, not for subtractive technologies. You would

want one that knows how to display the path differently for different

tool shapes.

I keep wanting to do CNC the same way I do 3DP, OpenSCAD -> STL ->

gcode, but that doesn't seem to work all that well because (a) CNC at my

level is 2.5D, not 3D, (b) tool shape matters, (c) feeds and speeds

matter (more), and (d) cut path matters (more), e.g. concentric vs

raster. Still, a programmatic CAD that feeds into a CAM toolchain seems

like a big win. I don't want to control it at the gcode level,

controlling every tool movement, but I do want to programmatically say

"put holes in a 10cm grid". How exactly that would interact with the

desire to do bulk cutting with a big bit and then switch to a smaller

bit to fill in the details, I don't know.

I have to wonder whether a good (better?) answer for this mightn't be to

use a conventional programming language to emit gcode, and a gcode viewer.

Admittedly most of the gcode viewers that I know of are for

filament-style 3D printing, not for subtractive technologies. You would

want one that knows how to display the path differently for different

tool shapes.

I keep wanting to do CNC the same way I do 3DP, OpenSCAD -> STL ->

gcode, but that doesn't seem to work all that well because (a) CNC at my

level is 2.5D, not 3D, (b) tool shape matters, (c) feeds and speeds

matter (more), and (d) cut path matters (more), e.g. concentric vs

raster. Still, a programmatic CAD that feeds into a CAM toolchain seems

like a big win. I don't want to control it at the gcode level,

controlling every tool movement, but I do want to programmatically say

"put holes in a 10cm grid". How exactly that would interact with the

desire to do bulk cutting with a big bit and then switch to a smaller

bit to fill in the details, I don't know.

LM

Leonard Martin Struttmann

Tue, Jan 16, 2024 3:15 AM

UPDATE: So I finally got CadQuery/CQ-editor installed and spent about three

hours playing with it today to design a simple part.

Conclusion: I will probably NOT be switching over to CadQuery.

I found the user interface to be clunky, and the editor is very basic with

little in the way of preferences.

CadQuery is very flexible, but flexibility breeds complexity. The learning

curve is very steep.

In practice, I found it to work just as if you were documenting each step

you would take if you were using a drawing program such as TinkerCAD,

FreeCADD, etc. For simple parts, each line of code (or each layer in the

stack of functions) corresponds with a similar action on a drawing program:

Select a plane, do some 2D drawing, then cut or extrude, select some edges,

apply chamfer/fillets, and then repeat.

The devil is in the details and in understanding what is going on under the

hood (bonnet). For example, I could extrude a regular polygon, but I could

not extrude a polyline (created from a list of points). After much

searching, I found that one must use the .close() function between the

polyline and the extrude.

Of course, your mileage may vary and if you are transitioning from a

drawing program you may find it easier than this old guy.

End of report.

On Mon, Jan 15, 2024 at 7:44 AM jon via Discuss discuss@lists.openscad.org

wrote:

Great. Not so privately. Sigh.

When Reply does not mean Reply.

On 1/15/2024 8:39 AM, jon via Discuss wrote:

Privately.

Would your code eventually be able to replace MeshCAM?

Jon

On 1/14/2024 10:16 PM, William F. Adams via Discuss wrote:

I tried CadQuery a while back --- it was confusing because they were just

transitioning from being a workbench in FreeCAD (which I was hopeful of) to

being a stand-alone project (which I found off-putting and which lacked the

synergy w/ a graphical program I was hoping for).

Agree that there was a striking absence of example files/code, and the

ones which I could find seemed arcane and confusing in how they were coded.

The nascent effort to put Python into OpenSCAD has been a lot more

approachable to me:

http://pythonscad.org/

https://github.com/openscad/openscad/issues/4880

(but I don't know if anyone would want to do anything the way I do it:

https://github.com/WillAdams/gcodepreview )

William

--

Sphinx of black quartz, judge my vow.

https://designinto3d.com/

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

UPDATE: So I finally got CadQuery/CQ-editor installed and spent about three

hours playing with it today to design a simple part.

Conclusion: I will probably NOT be switching over to CadQuery.

I found the user interface to be clunky, and the editor is very basic with

little in the way of preferences.

CadQuery is very flexible, but flexibility breeds complexity. The learning

curve is very steep.

In practice, I found it to work just as if you were documenting each step

you would take if you were using a drawing program such as TinkerCAD,

FreeCADD, etc. For simple parts, each line of code (or each layer in the

stack of functions) corresponds with a similar action on a drawing program:

Select a plane, do some 2D drawing, then cut or extrude, select some edges,

apply chamfer/fillets, and then repeat.

The devil is in the details and in understanding what is going on under the

hood (bonnet). For example, I could extrude a regular polygon, but I could

not extrude a polyline (created from a list of points). After much

searching, I found that one must use the .close() function between the

polyline and the extrude.

Of course, your mileage may vary and if you are transitioning from a

drawing program you may find it easier than this old guy.

End of report.

On Mon, Jan 15, 2024 at 7:44 AM jon via Discuss <discuss@lists.openscad.org>

wrote:

> Great. Not so privately. Sigh.

>

> When Reply does not mean Reply.

>

>

> On 1/15/2024 8:39 AM, jon via Discuss wrote:

>

> Privately.

>

> Would your code eventually be able to replace MeshCAM?

>

> Jon

>

>

> On 1/14/2024 10:16 PM, William F. Adams via Discuss wrote:

>

> I tried CadQuery a while back --- it was confusing because they were just

> transitioning from being a workbench in FreeCAD (which I was hopeful of) to

> being a stand-alone project (which I found off-putting and which lacked the

> synergy w/ a graphical program I was hoping for).

>

> Agree that there was a striking absence of example files/code, and the

> ones which I could find seemed arcane and confusing in how they were coded.

>

> The nascent effort to put Python into OpenSCAD has been a lot more

> approachable to me:

>

> http://pythonscad.org/

>

> https://github.com/openscad/openscad/issues/4880

>

> (but I don't know if anyone would want to do anything the way I do it:

> https://github.com/WillAdams/gcodepreview )

>

> William

>

> --

> Sphinx of black quartz, judge my vow.

> https://designinto3d.com/

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

TP

Torsten Paul

Tue, Jan 16, 2024 4:56 AM

On 15.01.24 22:17, Bruno Boettcher via Discuss wrote:

Ah yes, you have to ask them directly...

French universities still have problems with public code repositories....

That is not how open source works. At all.

CGAL is Universtity/French based too, so I don't really buy that claim

(https://geometryfactory.com/who-we-are/).

Quote "Andreas founded GeometryFactory in 2003 in order to commercialize

the technology accumulated through a series of European research

projects developing the CGAL library."

That is exactly what IceSL did/does.

ciao,

Torsten.

On 15.01.24 22:17, Bruno Boettcher via Discuss wrote:

> Ah yes, you have to ask them directly...

> French universities still have problems with public code repositories....

That is not how open source works. At all.

CGAL is Universtity/French based too, so I don't really buy that claim

(https://geometryfactory.com/who-we-are/).

Quote "Andreas founded GeometryFactory in 2003 in order to commercialize

the technology accumulated through a series of European research

projects developing the CGAL library."

That is *exactly* what IceSL did/does.

ciao,

Torsten.

BB

Bruno Boettcher

Tue, Jan 16, 2024 5:17 AM

Well as said, french universities have, usually, indeed a problem with open

source (I made my PhD at one...) since in the administrative layers there's

the big illusion of successful software/hardware patents and the big

money....

But also, usually, it's possible to retrieve, under the guise of a

federated project, the stuff under a Eugpl like license (since the people

writing the stuff usually are in the inverse opinion) ...

But no matter, indeed I didn't knew there weren't any open source CNC

"slicers"

Ciao

Bruno Böttcher

35 rue de la république, FR-6720 Schwindratzheim

email: bboett@adlp.org, mobile:bboett@gmail.com

Fon:+33 3 88 89 91, Mob:+33 6 76 55 82 68

Dev: Java/Perl/PHP OS:GNU/LINUX, Android

Aïkido: http://aikido.zorn.free.fr, http://www.aikido-club-saverne.fr

Torsten Paul via Discuss discuss@lists.openscad.org schrieb am Di., 16.

Jan. 2024, 05:56:

On 15.01.24 22:17, Bruno Boettcher via Discuss wrote:

Ah yes, you have to ask them directly...

French universities still have problems with public code repositories....

That is not how open source works. At all.

CGAL is Universtity/French based too, so I don't really buy that claim

(https://geometryfactory.com/who-we-are/).

Quote "Andreas founded GeometryFactory in 2003 in order to commercialize

the technology accumulated through a series of European research

projects developing the CGAL library."

That is exactly what IceSL did/does.

ciao,

Torsten.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Well as said, french universities have, usually, indeed a problem with open

source (I made my PhD at one...) since in the administrative layers there's

the big illusion of successful software/hardware patents and the big

money....

But also, usually, it's possible to retrieve, under the guise of a

federated project, the stuff under a Eugpl like license (since the people

writing the stuff usually are in the inverse opinion) ...

But no matter, indeed I didn't knew there weren't any open source CNC

"slicers"

Ciao

Bruno Böttcher

--

35 rue de la république, FR-6720 Schwindratzheim

email: bboett@adlp.org, mobile:bboett@gmail.com

Fon:+33 3 88 89 91, Mob:+33 6 76 55 82 68

-------------------------------------------------

Dev: Java/Perl/PHP OS:GNU/LINUX, Android

Aïkido: http://aikido.zorn.free.fr, http://www.aikido-club-saverne.fr

Torsten Paul via Discuss <discuss@lists.openscad.org> schrieb am Di., 16.

Jan. 2024, 05:56:

> On 15.01.24 22:17, Bruno Boettcher via Discuss wrote:

> > Ah yes, you have to ask them directly...

> > French universities still have problems with public code repositories....

>

> That is not how open source works. At all.

>

> CGAL is Universtity/French based too, so I don't really buy that claim

> (https://geometryfactory.com/who-we-are/).

>

> Quote "Andreas founded GeometryFactory in 2003 in order to commercialize

> the technology accumulated through a series of European research

> projects developing the CGAL library."

>

> That is *exactly* what IceSL did/does.

>

> ciao,

> Torsten.

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

N

neri-engineering

Tue, Jan 16, 2024 7:08 AM

CadQuery is very powerful; it's for the power user, much like UNIX can be compared to Windows. A power user who does not fear learning things would always gravitate towards UNIX or a UNIX-like system (even MacOS I suppose).

Yes you're right, the installation of CadQuery and of cq-editor was a bit more difficult than is typical, and it's because these tools live in "Python world" which needs to know how to load libs etc. That's why they have tools such as conda, anaconda, mambaforge, etc. to handle library dependencies and library installations. Even I was not an expert in Python but I was able to install these tools after careful reading and a few trial and error steps. Yes it took a couple of hours in my case as well.

I still do like OpenSCAD, but for me it's crucial to have a tool that generates STEP files for CNC machining at my disposal. This is why I had to look beyond just OpenSCAD. Furthermore I'm very repulsed with the idea of using graphical user interfaces to create parts that are very similar to each other, with minor differences in between. In other words having a language with which to "program parts" is very agreeable with me; this is exactly what drew me to OpenSCAD initially.

Because CadQuery uses a B-rep lib as its backend, things like "shelling", "fillet", or even "chamfer" are built-ins. In other words smoothing things is easy; it's part of the backend library. These are frequently discussed topics on this forum. 'Helix' and other complex operations are also built-ins. Yes there is a learning curve with the extensive API, but once you start working on simple examples it becomes clearer and clearer. STL can be generated by CadQuery.

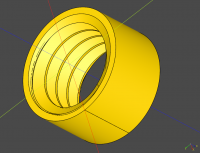

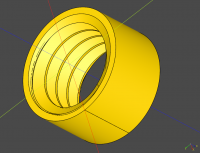

Well here is an example. Threads for screws are very easy to program. With about 300 lines of code I was able to write a complete thread library in two days, which generates both internal and external threads, with many options. (Now of course I will be maintaining it when I find bugs, which is expected because I'm using this in all of my projects.)

If you are interested in trying the thread generation code, it is here:

https://sourceforge.net/p/nl10/code/HEAD/tree/cq-code/common/metric_threads.py

If you add these few lines of code

show_object(internal_metric_thread(diameter=3.0,

pitch=0.5,

length=2.0,

bottom_chamfer=True,

base_tube_od=3.5))

to the bottom of thread lib linked above, opening in cq-editor will get you this:

[threads.png]

Cheers.

Sent with Proton Mail secure email.

On Monday, January 15th, 2024 at 9:15 PM, Leonard Martin Struttmann via Discuss discuss@lists.openscad.org wrote:

UPDATE: So I finally got CadQuery/CQ-editor installed and spent about three hours playing with it today to design a simple part.

Conclusion: I will probably NOT be switching over to CadQuery.

I found the user interface to be clunky, and the editor is very basic with little in the way of preferences.

CadQuery is very flexible, but flexibility breeds complexity. The learning curve is very steep.

In practice, I found it to work just as if you were documenting each step you would take if you were using a drawing program such as TinkerCAD, FreeCADD, etc. For simple parts, each line of code (or each layer in the stack of functions) corresponds with a similar action on a drawing program: Select a plane, do some 2D drawing, then cut or extrude, select some edges, apply chamfer/fillets, and then repeat.

The devil is in the details and in understanding what is going on under the hood (bonnet). For example, I could extrude a regular polygon, but I could not extrude a polyline (created from a list of points). After much searching, I found that one must use the .close() function between the polyline and the extrude.

Of course, your mileage may vary and if you are transitioning from a drawing program you may find it easier than this old guy.

End of report.

On Mon, Jan 15, 2024 at 7:44 AM jon via Discuss discuss@lists.openscad.org wrote:

Great. Not so privately. Sigh.

When Reply does not mean Reply.

On 1/15/2024 8:39 AM, jon via Discuss wrote:

Privately.

Would your code eventually be able to replace MeshCAM?

Jon

On 1/14/2024 10:16 PM, William F. Adams via Discuss wrote:

I tried CadQuery a while back --- it was confusing because they were just transitioning from being a workbench in FreeCAD (which I was hopeful of) to being a stand-alone project (which I found off-putting and which lacked the synergy w/ a graphical program I was hoping for).

Agree that there was a striking absence of example files/code, and the ones which I could find seemed arcane and confusing in how they were coded.

The nascent effort to put Python into OpenSCAD has been a lot more approachable to me:

http://pythonscad.org/

https://github.com/openscad/openscad/issues/4880

(but I don't know if anyone would want to do anything the way I do it: https://github.com/WillAdams/gcodepreview )

William

--

Sphinx of black quartz, judge my vow.

https://designinto3d.com/

OpenSCAD mailing list

To unsubscribe send an email to

discuss-leave@lists.openscad.org

CadQuery is very powerful; it's for the power user, much like UNIX can be compared to Windows. A power user who does not fear learning things would always gravitate towards UNIX or a UNIX-like system (even MacOS I suppose).

Yes you're right, the installation of CadQuery and of cq-editor was a bit more difficult than is typical, and it's because these tools live in "Python world" which needs to know how to load libs etc. That's why they have tools such as conda, anaconda, mambaforge, etc. to handle library dependencies and library installations. Even I was not an expert in Python but I was able to install these tools after careful reading and a few trial and error steps. Yes it took a couple of hours in my case as well.

I still do like OpenSCAD, but for me it's crucial to have a tool that generates STEP files for CNC machining at my disposal. This is why I had to look beyond just OpenSCAD. Furthermore I'm very repulsed with the idea of using graphical user interfaces to create parts that are very similar to each other, with minor differences in between. In other words having a language with which to "program parts" is very agreeable with me; this is exactly what drew me to OpenSCAD initially.

Because CadQuery uses a B-rep lib as its backend, things like "shelling", "fillet", or even "chamfer" are built-ins. In other words smoothing things is easy; it's part of the backend library. These are frequently discussed topics on this forum. 'Helix' and other complex operations are also built-ins. Yes there is a learning curve with the extensive API, but once you start working on simple examples it becomes clearer and clearer. STL can be generated by CadQuery.

Well here is an example. Threads for screws are very easy to program. With about 300 lines of code I was able to write a complete thread library in two days, which generates both internal and external threads, with many options. (Now of course I will be maintaining it when I find bugs, which is expected because I'm using this in all of my projects.)

If you are interested in trying the thread generation code, it is here:

https://sourceforge.net/p/nl10/code/HEAD/tree/cq-code/common/metric_threads.py

If you add these few lines of code

show_object(internal_metric_thread(diameter=3.0,

pitch=0.5,

length=2.0,

bottom_chamfer=True,

base_tube_od=3.5))

to the bottom of thread lib linked above, opening in cq-editor will get you this:

[threads.png]

Cheers.

Sent with [Proton Mail](https://proton.me/) secure email.

On Monday, January 15th, 2024 at 9:15 PM, Leonard Martin Struttmann via Discuss <discuss@lists.openscad.org> wrote:

> UPDATE: So I finally got CadQuery/CQ-editor installed and spent about three hours playing with it today to design a simple part.

>

> Conclusion: I will probably NOT be switching over to CadQuery.

>

> I found the user interface to be clunky, and the editor is very basic with little in the way of preferences.

>

> CadQuery is very flexible, but flexibility breeds complexity. The learning curve is very steep.

>

> In practice, I found it to work just as if you were documenting each step you would take if you were using a drawing program such as TinkerCAD, FreeCADD, etc. For simple parts, each line of code (or each layer in the stack of functions) corresponds with a similar action on a drawing program: Select a plane, do some 2D drawing, then cut or extrude, select some edges, apply chamfer/fillets, and then repeat.

>

> The devil is in the details and in understanding what is going on under the hood (bonnet). For example, I could extrude a regular polygon, but I could not extrude a polyline (created from a list of points). After much searching, I found that one must use the .close() function between the polyline and the extrude.

>

> Of course, your mileage may vary and if you are transitioning from a drawing program you may find it easier than this old guy.

>

> End of report.

>

> On Mon, Jan 15, 2024 at 7:44 AM jon via Discuss <discuss@lists.openscad.org> wrote:

>

>> Great. Not so privately. Sigh.

>>

>> When Reply does not mean Reply.

>>

>> On 1/15/2024 8:39 AM, jon via Discuss wrote:

>>

>>> Privately.

>>>

>>> Would your code eventually be able to replace MeshCAM?

>>>

>>> Jon

>>>

>>> On 1/14/2024 10:16 PM, William F. Adams via Discuss wrote:

>>>

>>>> I tried CadQuery a while back --- it was confusing because they were just transitioning from being a workbench in FreeCAD (which I was hopeful of) to being a stand-alone project (which I found off-putting and which lacked the synergy w/ a graphical program I was hoping for).

>>>>

>>>> Agree that there was a striking absence of example files/code, and the ones which I could find seemed arcane and confusing in how they were coded.

>>>>

>>>> The nascent effort to put Python into OpenSCAD has been a lot more approachable to me:

>>>>

>>>> http://pythonscad.org/

>>>>

>>>> https://github.com/openscad/openscad/issues/4880

>>>>

>>>> (but I don't know if anyone would want to do anything the way I do it: https://github.com/WillAdams/gcodepreview )

>>>>

>>>> William

>>>>

>>>> --

>>>> Sphinx of black quartz, judge my vow.

>>>> https://designinto3d.com/

>>>>

>>>> _______________________________________________

>>>> OpenSCAD mailing list

>>>> To unsubscribe send an email to

>>>> discuss-leave@lists.openscad.org

>>>

>>> _______________________________________________

>>> OpenSCAD mailing list

>>> To unsubscribe send an email to

>>> discuss-leave@lists.openscad.org

>>

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org