Re: Creating a Bevel Gear with Straight Teeth

Sorry, it sounded like you were installing it through some other means (WinGet), and I just knee-jerk tried to discourage that :)

I don’t have a Window installation handy, but the package containing libintl.h is mingw-w64-ucrt-x86_64-gettext-runtime:

https://packages.msys2.org/packages/mingw-w64-ucrt-x86_64-gettext-runtime

I see we don’t specifically install it, so it may be pulled in by some other dependency. That’s likely an oversight, and a perhaps some version of MSYS2 no longer pulls it in?

I’m not too well-versed in that, but: "pacboy gettext-runtime:p” ?

-Marius

I don't understand your design, Nathan. Can you post a picture of some

sort that would clarify how the gears are arranged? If you showed a

picture with the non-working bevel gear in the model that would work, for

example. It doesn't sound like the bevel gear and spur gear interact from

your description.

On Mon, Oct 27, 2025 at 1:24 PM Nathan Sokalski via Discuss <

discuss@lists.openscad.org> wrote:

The basic summary of what I am doing involves 1 rack gear, 1 spur gear,

and 2 bevel gears. The spur gear interacts with the rack gear, and the spur

gears interact with each other. The spur & one of the bevel will be

attached to each other (so it will basically be half spur, half bevel), and

I want them to have the same radius/diameter, but I need the bevel gear to

not interfere with the interaction between the spur & rack gears.

Nathan Sokalski

njsokalski@hotmail.com

From: Adrian Mariano via Discuss discuss@lists.openscad.org

Sent: Monday, October 27, 2025 10:24 AM

To: OpenSCAD general discussion Mailing-list <discuss@lists.openscad.org

Cc: Adrian Mariano avm4@cornell.edu

Subject: [OpenSCAD] Re: Creating a Bevel Gear with Straight Teeth

BOSL2 can create mating bevel gears as well.

On Mon, Oct 27, 2025 at 09:44 Leonard Martin Struttmann via Discuss <

discuss@lists.openscad.org> wrote:

I also recommend looking at https://github.com/dpellegr/PolyGear

Len

On Mon, Oct 27, 2025 at 7:04 AM Roger Whiteley via Discuss <

discuss@lists.openscad.org> wrote:

Nathan,

Why not use a pair of bevel gears?

There's another gear library which will do this, here,

http://www.thingiverse.com/thing:3575, Greg's library is also

referenced in another OpenSCAD library source, but I can't remember

where right now.

This library has some good examples to created meshing pairs, I've been

using gears made this way for six years.

It is also fairly easy to modify and get gears that will mesh together

and work if you print them, but you might have to get creative to print

a pinion [the small one] with an outside face that is not scarred by

support, you might also have to go back to OpenSCAD v2019.05 to get

usable exports as STL's, I've been having issues with later versions,

sadly that means you have to put up with glacial CSG rendering not

Manifold, which is lightning quick.

A pair of gears should have the same cone distance and outside circular

pitch, even if the number of teeth is different.

Drop me a line if you need a bit more help.

Roger.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

libintl.h is in /mingw64/include.

It comes from the mingw-w64-i686-gettext-runtime package. In my MSYS2

environment (which, admittedly, I've added a few things to), that's a

prerequisite for around 15 packages, including things like "make".

(Perhaps Marius is building using the UCRT64 environment and so is

getting the one in /ucrt64, but the instructions call out the MinGW

environment.)

not part of gettext when i install it in Windows using WinGet

Which is not part of the instructions.

i do have C:/lib/gettext-0.26/gettext-runtime/intl/

http://C:/lib/gettext-0.26/gettext-runtime/intl/ in my include path

Which is not part of the instructions.

You asked why I assumed that you were off-script... it was because you

specifically said you were off-script.

If you were trying a totally ordinary MSYS2 build and it was failing, my

guess would be that you were not running the MINGW64 environment, that

you were running one of the five other MSYS2 environments.

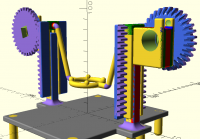

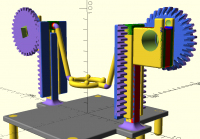

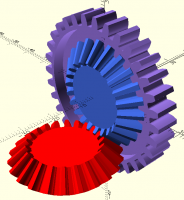

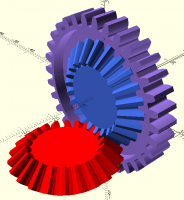

Here is a screenshot of what I have (some parts removed to make the important parts visible):

[cid:c72296d1-559e-4112-ba99-87c2817e87f1]

The purple part is the spur gear, and the blue part is the [should be] bevel gear. The blue is not really a bevel gear, it is just the linear_extrude of a spur_gear2d, so the involute stuff is not accurate. A second bevel (or what will be a bevel) gear will go below the existing bevel gear to create a vertical axle. My ultimate goal is to synchronize the spur gears by, after creating the vertical axles, adding a horizontal axle below the table. I have considered using an alternative approach of cutting out a cylinder from the center of the spur gear and placing a bevel gear inside, but it still involves the same number & type of gears in a similar arrangement, but at least placing it inside would prevent the bevel gear from interfering with the spur/rack interaction.

Nathan Sokalski

njsokalski@hotmail.commailto:njsokalski@hotmail.com

From: Adrian Mariano via Discuss discuss@lists.openscad.org

Sent: Monday, October 27, 2025 8:59 PM

To: OpenSCAD general discussion Mailing-list discuss@lists.openscad.org

Cc: Adrian Mariano avm4@cornell.edu

Subject: [OpenSCAD] Re: Creating a Bevel Gear with Straight Teeth

I don't understand your design, Nathan. Can you post a picture of some sort that would clarify how the gears are arranged? If you showed a picture with the non-working bevel gear in the model that would work, for example. It doesn't sound like the bevel gear and spur gear interact from your description.

On Mon, Oct 27, 2025 at 1:24 PM Nathan Sokalski via Discuss <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org> wrote:

The basic summary of what I am doing involves 1 rack gear, 1 spur gear, and 2 bevel gears. The spur gear interacts with the rack gear, and the spur gears interact with each other. The spur & one of the bevel will be attached to each other (so it will basically be half spur, half bevel), and I want them to have the same radius/diameter, but I need the bevel gear to not interfere with the interaction between the spur & rack gears.

Nathan Sokalski

njsokalski@hotmail.commailto:njsokalski@hotmail.com

From: Adrian Mariano via Discuss <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org>

Sent: Monday, October 27, 2025 10:24 AM

To: OpenSCAD general discussion Mailing-list <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org>

Cc: Adrian Mariano <avm4@cornell.edumailto:avm4@cornell.edu>

Subject: [OpenSCAD] Re: Creating a Bevel Gear with Straight Teeth

BOSL2 can create mating bevel gears as well.

On Mon, Oct 27, 2025 at 09:44 Leonard Martin Struttmann via Discuss <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org> wrote:

I also recommend looking at https://github.com/dpellegr/PolyGear

Len

On Mon, Oct 27, 2025 at 7:04 AM Roger Whiteley via Discuss <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org> wrote:

Nathan,

Why not use a pair of bevel gears?

There's another gear library which will do this, here,

http://www.thingiverse.com/thing:3575, Greg's library is also

referenced in another OpenSCAD library source, but I can't remember

where right now.

This library has some good examples to created meshing pairs, I've been

using gears made this way for six years.

It is also fairly easy to modify and get gears that will mesh together

and work if you print them, but you might have to get creative to print

a pinion [the small one] with an outside face that is not scarred by

support, you might also have to go back to OpenSCAD v2019.05 to get

usable exports as STL's, I've been having issues with later versions,

sadly that means you have to put up with glacial CSG rendering not

Manifold, which is lightning quick.

A pair of gears should have the same cone distance and outside circular

pitch, even if the number of teeth is different.

Drop me a line if you need a bit more help.

Roger.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.orgmailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.orgmailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.orgmailto:discuss-leave@lists.openscad.org

As I said before you can’t mate a bevel gear to a spur gear. And you can’t

mate it to a rack either. Have you read the quick intro to gears at the top

of gears.scad? If not you might find it helpful.

I think the idea of a spur gear that shares the shaft with the bevel gear

is a reasonable approach. I am not sure if there is a reason this doesn’t

work for you. At least in theory you could use helical spur gears. At 45

deg helical angle they can mate at 90 deg and give you a vertical axis

while also mating with a rack with 45 deg angled teeth. This extreme

design probably has issues of some kind.

I also wonder if a worm and worm gear might help with your design. You

might want to find something other than BOSL2 for worm gears because right

now there are issues I don’t know how to fix. I can’t find anything

anywhere about the proper way to construct a worm gear. The BOSL2

implementation has tiny interference in the mesh.

On Tue, Oct 28, 2025 at 11:51 Nathan Sokalski via Discuss <

discuss@lists.openscad.org> wrote:

Here is a screenshot of what I have (some parts removed to make the

important parts visible):

The purple part is the spur gear, and the blue part is the [should be]

bevel gear. The blue is not really a bevel gear, it is just the

linear_extrude of a spur_gear2d, so the involute stuff is not accurate. A

second bevel (or what will be a bevel) gear will go below the existing

bevel gear to create a vertical axle. My ultimate goal is to synchronize

the spur gears by, after creating the vertical axles, adding a horizontal

axle below the table. I have considered using an alternative approach of

cutting out a cylinder from the center of the spur gear and placing a bevel

gear inside, but it still involves the same number & type of gears in a

similar arrangement, but at least placing it inside would prevent the bevel

gear from interfering with the spur/rack interaction.

Nathan Sokalski

njsokalski@hotmail.com

From: Adrian Mariano via Discuss discuss@lists.openscad.org

Sent: Monday, October 27, 2025 8:59 PM

To: OpenSCAD general discussion Mailing-list <discuss@lists.openscad.org

Cc: Adrian Mariano avm4@cornell.edu

Subject: [OpenSCAD] Re: Creating a Bevel Gear with Straight Teeth

I don't understand your design, Nathan. Can you post a picture of some

sort that would clarify how the gears are arranged? If you showed a

picture with the non-working bevel gear in the model that would work, for

example. It doesn't sound like the bevel gear and spur gear interact from

your description.

On Mon, Oct 27, 2025 at 1:24 PM Nathan Sokalski via Discuss <

discuss@lists.openscad.org> wrote:

The basic summary of what I am doing involves 1 rack gear, 1 spur gear,

and 2 bevel gears. The spur gear interacts with the rack gear, and the spur

gears interact with each other. The spur & one of the bevel will be

attached to each other (so it will basically be half spur, half bevel), and

I want them to have the same radius/diameter, but I need the bevel gear to

not interfere with the interaction between the spur & rack gears.

Nathan Sokalski

njsokalski@hotmail.com

From: Adrian Mariano via Discuss discuss@lists.openscad.org

Sent: Monday, October 27, 2025 10:24 AM

To: OpenSCAD general discussion Mailing-list <discuss@lists.openscad.org

Cc: Adrian Mariano avm4@cornell.edu

Subject: [OpenSCAD] Re: Creating a Bevel Gear with Straight Teeth

BOSL2 can create mating bevel gears as well.

On Mon, Oct 27, 2025 at 09:44 Leonard Martin Struttmann via Discuss <

discuss@lists.openscad.org> wrote:

I also recommend looking at https://github.com/dpellegr/PolyGear

Len

On Mon, Oct 27, 2025 at 7:04 AM Roger Whiteley via Discuss <

discuss@lists.openscad.org> wrote:

Nathan,

Why not use a pair of bevel gears?

There's another gear library which will do this, here,

http://www.thingiverse.com/thing:3575, Greg's library is also

referenced in another OpenSCAD library source, but I can't remember

where right now.

This library has some good examples to created meshing pairs, I've been

using gears made this way for six years.

It is also fairly easy to modify and get gears that will mesh together

and work if you print them, but you might have to get creative to print

a pinion [the small one] with an outside face that is not scarred by

support, you might also have to go back to OpenSCAD v2019.05 to get

usable exports as STL's, I've been having issues with later versions,

sadly that means you have to put up with glacial CSG rendering not

Manifold, which is lightning quick.

A pair of gears should have the same cone distance and outside circular

pitch, even if the number of teeth is different.

Drop me a line if you need a bit more help.

Roger.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

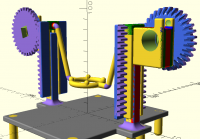

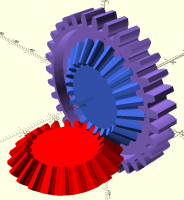

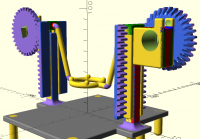

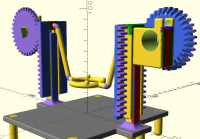

I was never trying to mate a bevel gear to a spur gear, here is what I have considered as another idea:

[cid:2f86c0d4-e358-4869-8b30-f938156fe93f]

The purple gear (a spur gear with the center cut out) is what interacts with the rack, the blue bevel gear is attached to (uses the same axle as) the purple spur gear (but they do not interact with each other). The red bevel gear is what will be attached to the vertical axle. Some of the things I am unsure about for this approach is how to flatten the sides (the top/bottom) of the bevel gears and how to determine the appropriate parameters for bevel_gear to get an appropriate size/radius.

Nathan Sokalski

njsokalski@hotmail.commailto:njsokalski@hotmail.com

From: Adrian Mariano via Discuss discuss@lists.openscad.org

Sent: Tuesday, October 28, 2025 1:27 PM

To: OpenSCAD general discussion Mailing-list discuss@lists.openscad.org

Cc: Adrian Mariano avm4@cornell.edu

Subject: [OpenSCAD] Re: Creating a Bevel Gear with Straight Teeth

As I said before you can’t mate a bevel gear to a spur gear. And you can’t mate it to a rack either. Have you read the quick intro to gears at the top of gears.scad? If not you might find it helpful.

I think the idea of a spur gear that shares the shaft with the bevel gear is a reasonable approach. I am not sure if there is a reason this doesn’t work for you. At least in theory you could use helical spur gears. At 45 deg helical angle they can mate at 90 deg and give you a vertical axis while also mating with a rack with 45 deg angled teeth. This extreme design probably has issues of some kind.

I also wonder if a worm and worm gear might help with your design. You might want to find something other than BOSL2 for worm gears because right now there are issues I don’t know how to fix. I can’t find anything anywhere about the proper way to construct a worm gear. The BOSL2 implementation has tiny interference in the mesh.

On Tue, Oct 28, 2025 at 11:51 Nathan Sokalski via Discuss <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org> wrote:

Here is a screenshot of what I have (some parts removed to make the important parts visible):

[cid:ii_19a2bd23fe9ea654a7f1]

The purple part is the spur gear, and the blue part is the [should be] bevel gear. The blue is not really a bevel gear, it is just the linear_extrude of a spur_gear2d, so the involute stuff is not accurate. A second bevel (or what will be a bevel) gear will go below the existing bevel gear to create a vertical axle. My ultimate goal is to synchronize the spur gears by, after creating the vertical axles, adding a horizontal axle below the table. I have considered using an alternative approach of cutting out a cylinder from the center of the spur gear and placing a bevel gear inside, but it still involves the same number & type of gears in a similar arrangement, but at least placing it inside would prevent the bevel gear from interfering with the spur/rack interaction.

Nathan Sokalski

njsokalski@hotmail.commailto:njsokalski@hotmail.com

From: Adrian Mariano via Discuss <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org>

Sent: Monday, October 27, 2025 8:59 PM

To: OpenSCAD general discussion Mailing-list <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org>

Cc: Adrian Mariano <avm4@cornell.edumailto:avm4@cornell.edu>

Subject: [OpenSCAD] Re: Creating a Bevel Gear with Straight Teeth

I don't understand your design, Nathan. Can you post a picture of some sort that would clarify how the gears are arranged? If you showed a picture with the non-working bevel gear in the model that would work, for example. It doesn't sound like the bevel gear and spur gear interact from your description.

On Mon, Oct 27, 2025 at 1:24 PM Nathan Sokalski via Discuss <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org> wrote:

The basic summary of what I am doing involves 1 rack gear, 1 spur gear, and 2 bevel gears. The spur gear interacts with the rack gear, and the spur gears interact with each other. The spur & one of the bevel will be attached to each other (so it will basically be half spur, half bevel), and I want them to have the same radius/diameter, but I need the bevel gear to not interfere with the interaction between the spur & rack gears.

Nathan Sokalski

njsokalski@hotmail.commailto:njsokalski@hotmail.com

From: Adrian Mariano via Discuss <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org>

Sent: Monday, October 27, 2025 10:24 AM

To: OpenSCAD general discussion Mailing-list <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org>

Cc: Adrian Mariano <avm4@cornell.edumailto:avm4@cornell.edu>

Subject: [OpenSCAD] Re: Creating a Bevel Gear with Straight Teeth

BOSL2 can create mating bevel gears as well.

On Mon, Oct 27, 2025 at 09:44 Leonard Martin Struttmann via Discuss <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org> wrote:

I also recommend looking at https://github.com/dpellegr/PolyGear

Len

On Mon, Oct 27, 2025 at 7:04 AM Roger Whiteley via Discuss <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org> wrote:

Nathan,

Why not use a pair of bevel gears?

There's another gear library which will do this, here,

http://www.thingiverse.com/thing:3575, Greg's library is also

referenced in another OpenSCAD library source, but I can't remember

where right now.

This library has some good examples to created meshing pairs, I've been

using gears made this way for six years.

It is also fairly easy to modify and get gears that will mesh together

and work if you print them, but you might have to get creative to print

a pinion [the small one] with an outside face that is not scarred by

support, you might also have to go back to OpenSCAD v2019.05 to get

usable exports as STL's, I've been having issues with later versions,

sadly that means you have to put up with glacial CSG rendering not

Manifold, which is lightning quick.

A pair of gears should have the same cone distance and outside circular

pitch, even if the number of teeth is different.

Drop me a line if you need a bit more help.

Roger.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.orgmailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.orgmailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.orgmailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.orgmailto:discuss-leave@lists.openscad.org

Quoting from the gears introduction section that I suggested you read we

find:

The size of the teeth can be specified as the circular pitch, which is

the tooth width, or more precisely, the distance along the pitch circle

from the start of one tooth to the start of the text tooth. The circular

pitch can be computed as PI*d/teeth where d is the diameter of the pitch

circle and teeth is the number of teeth on the gear. This simply divides up

the pitch circle into the specified number of teeth. However, the customary

way to specify metric gears is using the module, the ratio of the diameter

of the gear to the number of teeth: m=d/teeth.

After you read this passage it should be fairly obvious how to get a

desired radius, at least approximately (because the pitch circle is not the

outer diameter). Doing better than that will probably require trial and

error fiddling.

Regarding "flattening the top and bottom" do you mean intersecting the gear

with a cylinder? Why does it need to be flattened?

I'm still not sure I understand what you're trying to do and what the

challenge is. Why can't you just stack the gears. Is it because that

takes up too much space? Are you wanting to stack the gears in such a way

that the teeth line up? Just pick the same number of teeth and the gears

and the same module and the gears will have the same diameter and the teeth

will have the same spacing.

I'm a little uncertain why you prefer a bevel gear with straight teeth,

which the gear literature appears to suggest is a configuration with no

advantages.

On Tue, Oct 28, 2025 at 6:46 PM Nathan Sokalski via Discuss <

discuss@lists.openscad.org> wrote:

I was never trying to mate a bevel gear to a spur gear, here is what I

have considered as another idea:

The purple gear (a spur gear with the center cut out) is what interacts

with the rack, the blue bevel gear is attached to (uses the same axle as)

the purple spur gear (but they do not interact with each other). The red

bevel gear is what will be attached to the vertical axle. Some of the

things I am unsure about for this approach is how to flatten the sides (the

top/bottom) of the bevel gears and how to determine the appropriate

parameters for bevel_gear to get an appropriate size/radius.

Nathan Sokalski

njsokalski@hotmail.com

From: Adrian Mariano via Discuss discuss@lists.openscad.org

Sent: Tuesday, October 28, 2025 1:27 PM

To: OpenSCAD general discussion Mailing-list <discuss@lists.openscad.org

Cc: Adrian Mariano avm4@cornell.edu

Subject: [OpenSCAD] Re: Creating a Bevel Gear with Straight Teeth

As I said before you can’t mate a bevel gear to a spur gear. And you can’t

mate it to a rack either. Have you read the quick intro to gears at the top

of gears.scad? If not you might find it helpful.

I think the idea of a spur gear that shares the shaft with the bevel gear

is a reasonable approach. I am not sure if there is a reason this doesn’t

work for you. At least in theory you could use helical spur gears. At 45

deg helical angle they can mate at 90 deg and give you a vertical axis

while also mating with a rack with 45 deg angled teeth. This extreme

design probably has issues of some kind.

I also wonder if a worm and worm gear might help with your design. You

might want to find something other than BOSL2 for worm gears because right

now there are issues I don’t know how to fix. I can’t find anything

anywhere about the proper way to construct a worm gear. The BOSL2

implementation has tiny interference in the mesh.

On Tue, Oct 28, 2025 at 11:51 Nathan Sokalski via Discuss <

discuss@lists.openscad.org> wrote:

Here is a screenshot of what I have (some parts removed to make the

important parts visible):

The purple part is the spur gear, and the blue part is the [should be]

bevel gear. The blue is not really a bevel gear, it is just the

linear_extrude of a spur_gear2d, so the involute stuff is not accurate. A

second bevel (or what will be a bevel) gear will go below the existing

bevel gear to create a vertical axle. My ultimate goal is to synchronize

the spur gears by, after creating the vertical axles, adding a horizontal

axle below the table. I have considered using an alternative approach of

cutting out a cylinder from the center of the spur gear and placing a bevel

gear inside, but it still involves the same number & type of gears in a

similar arrangement, but at least placing it inside would prevent the bevel

gear from interfering with the spur/rack interaction.

Nathan Sokalski

njsokalski@hotmail.com

From: Adrian Mariano via Discuss discuss@lists.openscad.org

Sent: Monday, October 27, 2025 8:59 PM

To: OpenSCAD general discussion Mailing-list <discuss@lists.openscad.org

Cc: Adrian Mariano avm4@cornell.edu

Subject: [OpenSCAD] Re: Creating a Bevel Gear with Straight Teeth

I don't understand your design, Nathan. Can you post a picture of some

sort that would clarify how the gears are arranged? If you showed a

picture with the non-working bevel gear in the model that would work, for

example. It doesn't sound like the bevel gear and spur gear interact from

your description.

On Mon, Oct 27, 2025 at 1:24 PM Nathan Sokalski via Discuss <

discuss@lists.openscad.org> wrote:

The basic summary of what I am doing involves 1 rack gear, 1 spur gear,

and 2 bevel gears. The spur gear interacts with the rack gear, and the spur

gears interact with each other. The spur & one of the bevel will be

attached to each other (so it will basically be half spur, half bevel), and

I want them to have the same radius/diameter, but I need the bevel gear to

not interfere with the interaction between the spur & rack gears.

Nathan Sokalski

njsokalski@hotmail.com

From: Adrian Mariano via Discuss discuss@lists.openscad.org

Sent: Monday, October 27, 2025 10:24 AM

To: OpenSCAD general discussion Mailing-list <discuss@lists.openscad.org

Cc: Adrian Mariano avm4@cornell.edu

Subject: [OpenSCAD] Re: Creating a Bevel Gear with Straight Teeth

BOSL2 can create mating bevel gears as well.

On Mon, Oct 27, 2025 at 09:44 Leonard Martin Struttmann via Discuss <

discuss@lists.openscad.org> wrote:

I also recommend looking at https://github.com/dpellegr/PolyGear

Len

On Mon, Oct 27, 2025 at 7:04 AM Roger Whiteley via Discuss <

discuss@lists.openscad.org> wrote:

Nathan,

Why not use a pair of bevel gears?

There's another gear library which will do this, here,

http://www.thingiverse.com/thing:3575, Greg's library is also

referenced in another OpenSCAD library source, but I can't remember

where right now.

This library has some good examples to created meshing pairs, I've been

using gears made this way for six years.

It is also fairly easy to modify and get gears that will mesh together

and work if you print them, but you might have to get creative to print

a pinion [the small one] with an outside face that is not scarred by

support, you might also have to go back to OpenSCAD v2019.05 to get

usable exports as STL's, I've been having issues with later versions,

sadly that means you have to put up with glacial CSG rendering not

Manifold, which is lightning quick.

A pair of gears should have the same cone distance and outside circular

pitch, even if the number of teeth is different.

Drop me a line if you need a bit more help.

Roger.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Thank you so much for those equation clarifications & explanations, they will definitely make all of this much easier. You have obviously figured out that as much as I have done with math, I haven't taken many physics or engineering classes, but the reason I want to flatten the top & bottom is because the gears will be parallel to the sides & bottom of the yellow box, so knowing the thickness of the gears will be required in order to calculate the position & diameter. Because the bottom of a bevel_gear is not aligned with z=0 when created, I need to figure out how deep into the side of the spur gear (the gear that is on the same axle) it need to be translated. But those equations will be a MAJOR help, so thanks again for that as well!

Nathan Sokalski

njsokalski@hotmail.commailto:njsokalski@hotmail.com

From: Adrian Mariano via Discuss discuss@lists.openscad.org

Sent: Tuesday, October 28, 2025 7:59 PM

To: OpenSCAD general discussion Mailing-list discuss@lists.openscad.org

Cc: Adrian Mariano avm4@cornell.edu

Subject: [OpenSCAD] Re: Creating a Bevel Gear with Straight Teeth

Quoting from the gears introduction section that I suggested you read we find:

The size of the teeth can be specified as the circular pitch, which is the tooth width, or more precisely, the distance along the pitch circle from the start of one tooth to the start of the text tooth. The circular pitch can be computed as PI*d/teeth where d is the diameter of the pitch circle and teeth is the number of teeth on the gear. This simply divides up the pitch circle into the specified number of teeth. However, the customary way to specify metric gears is using the module, the ratio of the diameter of the gear to the number of teeth: m=d/teeth.

After you read this passage it should be fairly obvious how to get a desired radius, at least approximately (because the pitch circle is not the outer diameter). Doing better than that will probably require trial and error fiddling.

Regarding "flattening the top and bottom" do you mean intersecting the gear with a cylinder? Why does it need to be flattened?

I'm still not sure I understand what you're trying to do and what the challenge is. Why can't you just stack the gears. Is it because that takes up too much space? Are you wanting to stack the gears in such a way that the teeth line up? Just pick the same number of teeth and the gears and the same module and the gears will have the same diameter and the teeth will have the same spacing.

I'm a little uncertain why you prefer a bevel gear with straight teeth, which the gear literature appears to suggest is a configuration with no advantages.

On Tue, Oct 28, 2025 at 6:46 PM Nathan Sokalski via Discuss <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org> wrote:

I was never trying to mate a bevel gear to a spur gear, here is what I have considered as another idea:

[cid:ii_19a2d367a2ecb971f162]

The purple gear (a spur gear with the center cut out) is what interacts with the rack, the blue bevel gear is attached to (uses the same axle as) the purple spur gear (but they do not interact with each other). The red bevel gear is what will be attached to the vertical axle. Some of the things I am unsure about for this approach is how to flatten the sides (the top/bottom) of the bevel gears and how to determine the appropriate parameters for bevel_gear to get an appropriate size/radius.

Nathan Sokalski

njsokalski@hotmail.commailto:njsokalski@hotmail.com

From: Adrian Mariano via Discuss <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org>

Sent: Tuesday, October 28, 2025 1:27 PM

To: OpenSCAD general discussion Mailing-list <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org>

Cc: Adrian Mariano <avm4@cornell.edumailto:avm4@cornell.edu>

Subject: [OpenSCAD] Re: Creating a Bevel Gear with Straight Teeth

As I said before you can’t mate a bevel gear to a spur gear. And you can’t mate it to a rack either. Have you read the quick intro to gears at the top of gears.scad? If not you might find it helpful.

I think the idea of a spur gear that shares the shaft with the bevel gear is a reasonable approach. I am not sure if there is a reason this doesn’t work for you. At least in theory you could use helical spur gears. At 45 deg helical angle they can mate at 90 deg and give you a vertical axis while also mating with a rack with 45 deg angled teeth. This extreme design probably has issues of some kind.

I also wonder if a worm and worm gear might help with your design. You might want to find something other than BOSL2 for worm gears because right now there are issues I don’t know how to fix. I can’t find anything anywhere about the proper way to construct a worm gear. The BOSL2 implementation has tiny interference in the mesh.

On Tue, Oct 28, 2025 at 11:51 Nathan Sokalski via Discuss <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org> wrote:

Here is a screenshot of what I have (some parts removed to make the important parts visible):

[cid:ii_19a2d367a2dcb971f161]

The purple part is the spur gear, and the blue part is the [should be] bevel gear. The blue is not really a bevel gear, it is just the linear_extrude of a spur_gear2d, so the involute stuff is not accurate. A second bevel (or what will be a bevel) gear will go below the existing bevel gear to create a vertical axle. My ultimate goal is to synchronize the spur gears by, after creating the vertical axles, adding a horizontal axle below the table. I have considered using an alternative approach of cutting out a cylinder from the center of the spur gear and placing a bevel gear inside, but it still involves the same number & type of gears in a similar arrangement, but at least placing it inside would prevent the bevel gear from interfering with the spur/rack interaction.

Nathan Sokalski

njsokalski@hotmail.commailto:njsokalski@hotmail.com

From: Adrian Mariano via Discuss <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org>

Sent: Monday, October 27, 2025 8:59 PM

To: OpenSCAD general discussion Mailing-list <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org>

Cc: Adrian Mariano <avm4@cornell.edumailto:avm4@cornell.edu>

Subject: [OpenSCAD] Re: Creating a Bevel Gear with Straight Teeth

I don't understand your design, Nathan. Can you post a picture of some sort that would clarify how the gears are arranged? If you showed a picture with the non-working bevel gear in the model that would work, for example. It doesn't sound like the bevel gear and spur gear interact from your description.

On Mon, Oct 27, 2025 at 1:24 PM Nathan Sokalski via Discuss <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org> wrote:

The basic summary of what I am doing involves 1 rack gear, 1 spur gear, and 2 bevel gears. The spur gear interacts with the rack gear, and the spur gears interact with each other. The spur & one of the bevel will be attached to each other (so it will basically be half spur, half bevel), and I want them to have the same radius/diameter, but I need the bevel gear to not interfere with the interaction between the spur & rack gears.

Nathan Sokalski

njsokalski@hotmail.commailto:njsokalski@hotmail.com

From: Adrian Mariano via Discuss <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org>

Sent: Monday, October 27, 2025 10:24 AM

To: OpenSCAD general discussion Mailing-list <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org>

Cc: Adrian Mariano <avm4@cornell.edumailto:avm4@cornell.edu>

Subject: [OpenSCAD] Re: Creating a Bevel Gear with Straight Teeth

BOSL2 can create mating bevel gears as well.

On Mon, Oct 27, 2025 at 09:44 Leonard Martin Struttmann via Discuss <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org> wrote:

I also recommend looking at https://github.com/dpellegr/PolyGear

Len

On Mon, Oct 27, 2025 at 7:04 AM Roger Whiteley via Discuss <discuss@lists.openscad.orgmailto:discuss@lists.openscad.org> wrote:

Nathan,

Why not use a pair of bevel gears?

There's another gear library which will do this, here,

http://www.thingiverse.com/thing:3575, Greg's library is also

referenced in another OpenSCAD library source, but I can't remember

where right now.

This library has some good examples to created meshing pairs, I've been

using gears made this way for six years.

It is also fairly easy to modify and get gears that will mesh together

and work if you print them, but you might have to get creative to print

a pinion [the small one] with an outside face that is not scarred by

support, you might also have to go back to OpenSCAD v2019.05 to get

usable exports as STL's, I've been having issues with later versions,

sadly that means you have to put up with glacial CSG rendering not

Manifold, which is lightning quick.

A pair of gears should have the same cone distance and outside circular

pitch, even if the number of teeth is different.

Drop me a line if you need a bit more help.

Roger.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.orgmailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.orgmailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.orgmailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.orgmailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.orgmailto:discuss-leave@lists.openscad.org