Fitting PCB into a box.

It's really wonderful to see the work you have done.

Detailing is excellent

Regards

Sanjeev

On Tue, 24 May 2022, 16:54 nop head, nop.head@gmail.com wrote:

I model the PCB in OpenSCAD to just enough detail to fit boxes around it.

For example I sometimes just measure the board and its mounting holes but

usually I add the connectors and large components.

A lot of my circuits are built on veroboard or perfboard, or are closed

source modules from China, so I have no ECAD data for them, so I model

everything in OpenSCAD.

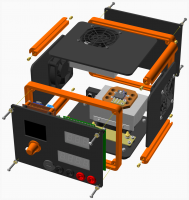

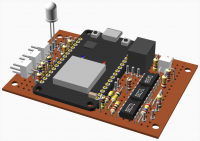

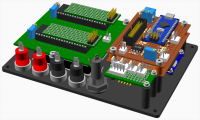

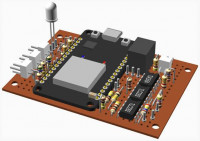

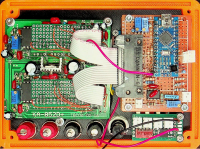

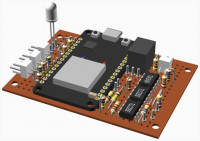

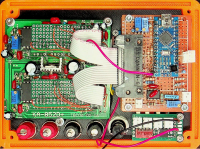

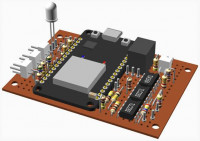

Here is a complex programmable load panel assembly that used part of a PCB

recycled from a solder station with perfboards soldered on top of ICs to

scrape the segment data from LED meters and convert to analogue voltages

for an Arduino nano to decode and convert to serial and do autoranging. The

main controller was an ESP32 underneath. There is also a four fan

controller on a third perboard and an OLED screen and shaft encoder

board buried below.

[image: box_top_assembled.png]

[image: controller_assembled.png]

[image: box_assembly.png]

On Tue, 24 May 2022 at 10:58, Daniel daniel@puggsy.net wrote:

Have attached the python script & box-generating .scad I made. Fairly

rough but maybe you will find it useful.

It would be great if I could get it to automatically generate the box

following the same outline of the PCB but I'm not there yet.

-Daniel

On 24/05/2022 10:39, Daniel wrote:

Hi,

I often make boxes for things I designed in KiCad and wrote a script to

extract mount points.

See here for explanation how to use

https://www.eevblog.com/forum/3d-printing/kicad-to-openscad-for-pcb-case-generation/

-Daniel

On 24/05/2022 06:57, kl1k . wrote:

I've just started using OpenScad and have created a few simple boxes

which has worked out well.

I'm now trying to design a few boxes that will fit my PCB's which I have

designed using KiCAD and want to make sure that all the measurements are

correct before getting them printed.

Is there any way I can take the 3D file from KiCAD (STL or OBJ) and place

it virtually in the box to see if all the measurements/holes etc are lined

up. Or is it a case of first taking careful measurements, doing the design

in OpenScad, 3D printing a sample and check. Make corrections and keep

repeating until its correct.

Example of the 3D Kicad image:

https://i.postimg.cc/cJkmNDSr/pic1.png

https://i.postimg.cc/C1Z4MjhJ/pic2.png

Picture of the box I've make in OpenScad:

https://i.postimg.cc/VLPF1r3B/1.png

Is this something that OpenScad supports? Is there any way to see if this

will virtually fit before actually printing?

I found an article on importing the KiCad STL file into Fusion360 but

haven't found anything on how to do it in OpenScad? (Don't really want to

learn F360 after having spent a good few hours with OpenScad)

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Hi,

Rectangular boxes are pretty easy, provided you can measure the pcb, or

have dimensions. If working from an stl, then you can use a couple of

Minkowski transforms to make a profiled case, if you are happy with some

rounded edges. If you can't measure it, then fixing holes/cut-outs/etc.

will be by trial and error.

// create an stl (testpcb.stl) and save it, as an example

/*

cube([50,40,10]);

cube([55,15,5]);

cube ([10,45,5]);

*/

module board(){

import("P:/Docs/openscad/testpcb.stl");

}

module high(){

scale([1,1,20]) // make high enough to cut to size

board();

}

module inner(){

minkowski()

{

high();

cylinder(r=2,h=1); //clearance to pcb

}

}

module outer(){

minkowski()

{

high();

cylinder(r=4,h=1); // wall thickness =4-2

}

}

module case(){

difference(){

outer();

translate([0,0,2]) //base is 2 thick

inner();

translate([-10,-10,15]) // cut to size

cube(200);

}

}

translate([0,0,3]) color("red")board();

case();

On 24/05/2022 06:57, kl1k . wrote:

I've just started using OpenScad and have created a few simple boxes

which has worked out well.

I'm now trying to design a few boxes that will fit my PCB's which I

have designed using KiCAD and want to make sure that all the

measurements are correct before getting them printed.

Is there any way I can take the 3D file from KiCAD (STL or OBJ) and

place it virtually in the box to see if all the measurements/holes etc

are lined up. Or is it a case of first taking careful measurements,

doing the design in OpenScad, 3D printing a sample and check. Make

corrections and keep repeating until its correct.

Example of the 3D Kicad image:

https://i.postimg.cc/cJkmNDSr/pic1.png

https://i.postimg.cc/C1Z4MjhJ/pic2.png

Picture of the box I've make in OpenScad:

https://i.postimg.cc/VLPF1r3B/1.png

Is this something that OpenScad supports? Is there any way to see if

this will virtually fit before actually printing?

I found an article on importing the KiCad STL file into Fusion360 but

haven't found anything on how to do it in OpenScad? (Don't really want

to learn F360 after having spent a good few hours with OpenScad)

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

Nophead, I don't suppose you blogged your "with perfboards soldered on top of ICs to scrape the segment data from LED meters" project?

From: nop head [mailto:nop.head@gmail.com]

Sent: Tue, 24 May 2022 21:05

To: OpenSCAD general discussion

Subject: [OpenSCAD] Re: Fitting PCB into a box.

I model the PCB in OpenSCAD to just enough detail to fit boxes around it. For example I sometimes just measure the board and its mounting holes but usually I add the connectors and large components.

A lot of my circuits are built on veroboard or perfboard, or are closed source modules from China, so I have no ECAD data for them, so I model everything in OpenSCAD.

Here is a complex programmable load panel assembly that used part of a PCB recycled from a solder station with perfboards soldered on top of ICs to scrape the segment data from LED meters and convert to analogue voltages for an Arduino nano to decode and convert to serial and do autoranging. The main controller was an ESP32 underneath. There is also a four fan controller on a third perboard and an OLED screen and shaft encoder board buried below.

box_top_assembled.png

controller_assembled.png

box_assembly.png

On Tue, 24 May 2022 at 10:58, Daniel daniel@puggsy.net wrote:

Have attached the python script & box-generating .scad I made. Fairly rough but maybe you will find it useful.

It would be great if I could get it to automatically generate the box following the same outline of the PCB but I'm not there yet.

-Daniel

On 24/05/2022 10:39, Daniel wrote:

Hi,

I often make boxes for things I designed in KiCad and wrote a script to extract mount points.

See here for explanation how to use

https://www.eevblog.com/forum/3d-printing/kicad-to-openscad-for-pcb-case-generation/

-Daniel

On 24/05/2022 06:57, kl1k . wrote:

I've just started using OpenScad and have created a few simple boxes which has worked out well.

I'm now trying to design a few boxes that will fit my PCB's which I have designed using KiCAD and want to make sure that all the measurements are correct before getting them printed.

Is there any way I can take the 3D file from KiCAD (STL or OBJ) and place it virtually in the box to see if all the measurements/holes etc are lined up. Or is it a case of first taking careful measurements, doing the design in OpenScad, 3D printing a sample and check. Make corrections and keep repeating until its correct.

Example of the 3D Kicad image:

https://i.postimg.cc/cJkmNDSr/pic1.png

https://i.postimg.cc/C1Z4MjhJ/pic2.png

Picture of the box I've make in OpenScad:

https://i.postimg.cc/VLPF1r3B/1.png

Is this something that OpenScad supports? Is there any way to see if this will virtually fit before actually printing?

I found an article on importing the KiCad STL file into Fusion360 but haven't found anything on how to do it in OpenScad? (Don't really want to learn F360 after having spent a good few hours with OpenScad)

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

--

This email has been checked for viruses by AVG.

https://www.avg.com

No but perhaps I can because I have some photos and notes and I have a

second identical solder station board to use in a second project but I am

not at home at the moment. Here is a quick summary.

The solder stations were bizarre because they use potentiometers to drive

ICL7107 voltmeters to get a digital display and then another gang on the

pot sets the thermostat switch point in an analog circuit. So the display

isn't a digital temperature reading, it is just an accurate scale on the

pot showing the set point. An LED shows if the thermostat is on or off, so

you can see when it is at temperature.

Another weird thing is they had two diacs in each meter circuit, one in the

RC oscillator and another across the reference voltage but they could never

do anything because diacs don't turn on until about 30V and the circuit

runs at 5V. Even if they fitted normal diodes in the positions it would

make no sense. The RC oscillator would get an asymmetric duty cycle but the

first thing the chip does is divide it by four and a diode used as a 0.7V

reference would be worse than a potential divider from the regulated 5V

rail, which is actually how it works. I.e. they had resistors that gave

0.7V from 5V with a diac across it. I removed them and it didn't make the

slightest difference.

I replaced the diac with a precision 2.5V reference and changed the

resistors to get a more normal 100mV reference for 200mV full scale.

The ICL7107 directly drives 3 and half seven segment displays with constant

current 8ma per segment. That is far more than needed for modern 7 seg

displays that are designed to be multiplexed and far too much for the 5V

linear regulator, so they put a single 56R resistor in the supply to all

the display anodes. That meant the display brightness changed according to

how many segments were on. I replaced the resistor with a tiny buck

regulator to give about the same voltage as the resistor but it doesn't sag

when more segments are on and doesn't load the linear reg.

I added an extra digit to give a leading 0 or 1 on the current display

that I wanted to display up to 19.99A and put a single LED in place of the

leading digit on the voltmeter so that I could display 3 digits of voltage

but still detect overflow.

To scrape the numbers I worked out that you only need to look at segments

a, b, e, f and g to recognise the number. So that is 5 * 3 digits + 1 for

the leading 1, so 16 bits in total for each display. I grouped them into

groups of four and summed them with 100K, 200K, 400K and 800K resistors and

fed them into 8 analogue inputs of an Arduino Nano. That is why I needed

the anode voltage to be constant. The chip has internal pullups on the

segment drives ,so they switch from 5V to about 0.79V when on. The Nano

reads the voltage and quantises it to a number between 0 and 15 to retrieve

the four bits. It then regroups then into 5 bit segments and does a table

lookup to convert to ascii.

float Vol = 0.79;

float Voh = 5.0;

int readPin(int pin) {

float v = analogRead(pin) * 5.0 / 1023;

return 15 - round((v - Vol) * 15 / (Voh - Vol));

}

const char *read_meter(int pin) {

int bits[4];

static char buff[digits + 1];

for(int i = 0; i < 4; ++i)

bits[i] = readPin(i + pin);

bool ab4 = bits[3] & 8;

bool g3 = bits[3] & 4;

bool a3 = bits[3] & 2;

bool g2 = bits[3] & 1;

bool e1 = bits[2] & 8;

bool b2 = bits[2] & 4;

bool a2 = bits[2] & 2;

bool f2 = bits[2] & 1;

bool e2 = bits[1] & 8;

bool b3 = bits[1] & 4;

bool f3 = bits[1] & 2;

bool e3 = bits[1] & 1;

bool b1 = bits[0] & 8;

bool a1 = bits[0] & 4;

bool f1 = bits[0] & 2;

bool g1 = bits[0] & 1;

const char *chars = " ?17???????????0???3???2?549?6?8";

buff[0] = ab4 ? '1' : '0';

buff[1] = chars[(g3 << 4) + (f3 << 3) + (e3 << 2) + (b3 << 1) + a3];

buff[2] = chars[(g2 << 4) + (f2 << 3) + (e2 << 2) + (b2 << 1) + a2];

buff[3] = chars[(g1 << 4) + (f1 << 3) + (e1 << 2) + (b1 << 1) + a1];

buff[4] = 0;

return buff;

}

The reason I convert from digital to analog and back to digital is just to

reduce the amount of wiring and inputs required on the micro. I

contemplated using old EPROM to do the same job but it would be more

difficult to wire up. I just used 0805 SMT resistors on top of the

perfboards. The 400K and 800K were made up of two in series.

[image: image.png]

The Nano also drives the decimal points that were not used in the solder

station and drives tiny MOSFETs to control the voltage divider for 999V,

99.9V and 9,99V voltage ranges and the feedback resistor in a chopper

stabilised OP amp that gives 19.99A and 9.999A current ranges with a 0.01R

shunt.

Another quirk of the solder station was they put green filters over red

LEDs, so I replaced it with red film! I also printed black rubber shrouds

which fit around the digits, firstly to align the extra floating one I

added and also to not show the internals through the film.

On Sun, 5 Jun 2022 at 01:39, Michael Marx michael@marx.id.au wrote:

Nophead, I don't suppose you blogged your "with perfboards soldered on

top of ICs to scrape the segment data from LED meters" project?

From: nop head [mailto:nop.head@gmail.com]

Sent: Tue, 24 May 2022 21:05

To: OpenSCAD general discussion

Subject: [OpenSCAD] Re: Fitting PCB into a box.

I model the PCB in OpenSCAD to just enough detail to fit boxes around it.

For example I sometimes just measure the board and its mounting holes but

usually I add the connectors and large components.

A lot of my circuits are built on veroboard or perfboard, or are closed

source modules from China, so I have no ECAD data for them, so I model

everything in OpenSCAD.

Here is a complex programmable load panel assembly that used part of a PCB

recycled from a solder station with perfboards soldered on top of ICs to

scrape the segment data from LED meters and convert to analogue voltages

for an Arduino nano to decode and convert to serial and do autoranging. The

main controller was an ESP32 underneath. There is also a four fan

controller on a third perboard and an OLED screen and shaft encoder

board buried below.

[image: box_top_assembled.png]

[image: controller_assembled.png]

[image: box_assembly.png]

On Tue, 24 May 2022 at 10:58, Daniel daniel@puggsy.net wrote:

Have attached the python script & box-generating .scad I made. Fairly

rough but maybe you will find it useful.

It would be great if I could get it to automatically generate the box

following the same outline of the PCB but I'm not there yet.

-Daniel

On 24/05/2022 10:39, Daniel wrote:

Hi,

I often make boxes for things I designed in KiCad and wrote a script to

extract mount points.

See here for explanation how to use

https://www.eevblog.com/forum/3d-printing/kicad-to-openscad-for-pcb-case-generation/

-Daniel

On 24/05/2022 06:57, kl1k . wrote:

I've just started using OpenScad and have created a few simple boxes which

has worked out well.

I'm now trying to design a few boxes that will fit my PCB's which I have

designed using KiCAD and want to make sure that all the measurements are

correct before getting them printed.

Is there any way I can take the 3D file from KiCAD (STL or OBJ) and place

it virtually in the box to see if all the measurements/holes etc are lined

up. Or is it a case of first taking careful measurements, doing the design

in OpenScad, 3D printing a sample and check. Make corrections and keep

repeating until its correct.

Example of the 3D Kicad image:

https://i.postimg.cc/cJkmNDSr/pic1.png

https://i.postimg.cc/C1Z4MjhJ/pic2.png

Picture of the box I've make in OpenScad:

https://i.postimg.cc/VLPF1r3B/1.png

Is this something that OpenScad supports? Is there any way to see if this

will virtually fit before actually printing?

I found an article on importing the KiCad STL file into Fusion360 but

haven't found anything on how to do it in OpenScad? (Don't really want to

learn F360 after having spent a good few hours with OpenScad)

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

http://www.avg.com/email-signature?utm_medium=email&utm_source=link&utm_campaign=sig-email&utm_content=emailclient Virus-free.

www.avg.com

http://www.avg.com/email-signature?utm_medium=email&utm_source=link&utm_campaign=sig-email&utm_content=emailclient

<#m_3662889115399636624_DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2>

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Well, that was a fascinating, although short, summary :-)

Weird design decisions in the electronics - seems done by someone new or

with limited choice of components.

Michael

søn. 5. jun. 2022 15.33 skrev nop head nop.head@gmail.com:

No but perhaps I can because I have some photos and notes and I have a

second identical solder station board to use in a second project but I am

not at home at the moment. Here is a quick summary.

The solder stations were bizarre because they use potentiometers to drive

ICL7107 voltmeters to get a digital display and then another gang on the

pot sets the thermostat switch point in an analog circuit. So the display

isn't a digital temperature reading, it is just an accurate scale on the

pot showing the set point. An LED shows if the thermostat is on or off, so

you can see when it is at temperature.

Another weird thing is they had two diacs in each meter circuit, one in

the RC oscillator and another across the reference voltage but they could

never do anything because diacs don't turn on until about 30V and the

circuit runs at 5V. Even if they fitted normal diodes in the positions it

would make no sense. The RC oscillator would get an asymmetric duty cycle

but the first thing the chip does is divide it by four and a diode used as

a 0.7V reference would be worse than a potential divider from the regulated

5V rail, which is actually how it works. I.e. they had resistors that gave

0.7V from 5V with a diac across it. I removed them and it didn't make the

slightest difference.

I replaced the diac with a precision 2.5V reference and changed the

resistors to get a more normal 100mV reference for 200mV full scale.

The ICL7107 directly drives 3 and half seven segment displays with

constant current 8ma per segment. That is far more than needed for modern 7

seg displays that are designed to be multiplexed and far too much for the

5V linear regulator, so they put a single 56R resistor in the supply to all

the display anodes. That meant the display brightness changed according to

how many segments were on. I replaced the resistor with a tiny buck

regulator to give about the same voltage as the resistor but it doesn't sag

when more segments are on and doesn't load the linear reg.

I added an extra digit to give a leading 0 or 1 on the current display

that I wanted to display up to 19.99A and put a single LED in place of the

leading digit on the voltmeter so that I could display 3 digits of voltage

but still detect overflow.

To scrape the numbers I worked out that you only need to look at segments

a, b, e, f and g to recognise the number. So that is 5 * 3 digits + 1 for

the leading 1, so 16 bits in total for each display. I grouped them into

groups of four and summed them with 100K, 200K, 400K and 800K resistors and

fed them into 8 analogue inputs of an Arduino Nano. That is why I needed

the anode voltage to be constant. The chip has internal pullups on the

segment drives ,so they switch from 5V to about 0.79V when on. The Nano

reads the voltage and quantises it to a number between 0 and 15 to retrieve

the four bits. It then regroups then into 5 bit segments and does a table

lookup to convert to ascii.

float Vol = 0.79;

float Voh = 5.0;

int readPin(int pin) {

float v = analogRead(pin) * 5.0 / 1023;

return 15 - round((v - Vol) * 15 / (Voh - Vol));

}

const char *read_meter(int pin) {

int bits[4];

static char buff[digits + 1];

for(int i = 0; i < 4; ++i)

bits[i] = readPin(i + pin);

bool ab4 = bits[3] & 8;

bool g3 = bits[3] & 4;

bool a3 = bits[3] & 2;

bool g2 = bits[3] & 1;

bool e1 = bits[2] & 8;

bool b2 = bits[2] & 4;

bool a2 = bits[2] & 2;

bool f2 = bits[2] & 1;

bool e2 = bits[1] & 8;

bool b3 = bits[1] & 4;

bool f3 = bits[1] & 2;

bool e3 = bits[1] & 1;

bool b1 = bits[0] & 8;

bool a1 = bits[0] & 4;

bool f1 = bits[0] & 2;

bool g1 = bits[0] & 1;

const char *chars = " ?17???????????0???3???2?549?6?8";

buff[0] = ab4 ? '1' : '0';

buff[1] = chars[(g3 << 4) + (f3 << 3) + (e3 << 2) + (b3 << 1) + a3];

buff[2] = chars[(g2 << 4) + (f2 << 3) + (e2 << 2) + (b2 << 1) + a2];

buff[3] = chars[(g1 << 4) + (f1 << 3) + (e1 << 2) + (b1 << 1) + a1];

buff[4] = 0;

return buff;

}

The reason I convert from digital to analog and back to digital is just to

reduce the amount of wiring and inputs required on the micro. I

contemplated using old EPROM to do the same job but it would be more

difficult to wire up. I just used 0805 SMT resistors on top of the

perfboards. The 400K and 800K were made up of two in series.

[image: image.png]

The Nano also drives the decimal points that were not used in the solder

station and drives tiny MOSFETs to control the voltage divider for 999V,

99.9V and 9,99V voltage ranges and the feedback resistor in a chopper

stabilised OP amp that gives 19.99A and 9.999A current ranges with a 0.01R

shunt.

Another quirk of the solder station was they put green filters over red

LEDs, so I replaced it with red film! I also printed black rubber shrouds

which fit around the digits, firstly to align the extra floating one I

added and also to not show the internals through the film.

On Sun, 5 Jun 2022 at 01:39, Michael Marx michael@marx.id.au wrote:

Nophead, I don't suppose you blogged your "with perfboards soldered on

top of ICs to scrape the segment data from LED meters" project?

From: nop head [mailto:nop.head@gmail.com]

Sent: Tue, 24 May 2022 21:05

To: OpenSCAD general discussion

Subject: [OpenSCAD] Re: Fitting PCB into a box.

I model the PCB in OpenSCAD to just enough detail to fit boxes around it.

For example I sometimes just measure the board and its mounting holes but

usually I add the connectors and large components.

A lot of my circuits are built on veroboard or perfboard, or are closed

source modules from China, so I have no ECAD data for them, so I model

everything in OpenSCAD.

Here is a complex programmable load panel assembly that used part of a

PCB recycled from a solder station with perfboards soldered on top of ICs

to scrape the segment data from LED meters and convert to analogue voltages

for an Arduino nano to decode and convert to serial and do autoranging. The

main controller was an ESP32 underneath. There is also a four fan

controller on a third perboard and an OLED screen and shaft encoder

board buried below.

[image: box_top_assembled.png]

[image: controller_assembled.png]

[image: box_assembly.png]

On Tue, 24 May 2022 at 10:58, Daniel daniel@puggsy.net wrote:

Have attached the python script & box-generating .scad I made. Fairly

rough but maybe you will find it useful.

It would be great if I could get it to automatically generate the box

following the same outline of the PCB but I'm not there yet.

-Daniel

On 24/05/2022 10:39, Daniel wrote:

Hi,

I often make boxes for things I designed in KiCad and wrote a script to

extract mount points.

See here for explanation how to use

https://www.eevblog.com/forum/3d-printing/kicad-to-openscad-for-pcb-case-generation/

-Daniel

On 24/05/2022 06:57, kl1k . wrote:

I've just started using OpenScad and have created a few simple boxes

which has worked out well.

I'm now trying to design a few boxes that will fit my PCB's which I have

designed using KiCAD and want to make sure that all the measurements are

correct before getting them printed.

Is there any way I can take the 3D file from KiCAD (STL or OBJ) and place

it virtually in the box to see if all the measurements/holes etc are lined

up. Or is it a case of first taking careful measurements, doing the design

in OpenScad, 3D printing a sample and check. Make corrections and keep

repeating until its correct.

Example of the 3D Kicad image:

https://i.postimg.cc/cJkmNDSr/pic1.png

https://i.postimg.cc/C1Z4MjhJ/pic2.png

Picture of the box I've make in OpenScad:

https://i.postimg.cc/VLPF1r3B/1.png

Is this something that OpenScad supports? Is there any way to see if this

will virtually fit before actually printing?

I found an article on importing the KiCad STL file into Fusion360 but

haven't found anything on how to do it in OpenScad? (Don't really want to

learn F360 after having spent a good few hours with OpenScad)

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

http://www.avg.com/email-signature?utm_medium=email&utm_source=link&utm_campaign=sig-email&utm_content=emailclient Virus-free.

www.avg.com

http://www.avg.com/email-signature?utm_medium=email&utm_source=link&utm_campaign=sig-email&utm_content=emailclient

<#m_7175780470545777077_m_7035083875803300708_m_3863130689674829611_m_3662889115399636624_DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2>

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Well they certainly didn't know what a diac does. They are used

legitimately elsewhere in the circuit to drive a triac for the fan speed

control but the silkscreen shows a normal diode symbol in the four places

where they are fitted in the meter section but it also shows the diac part

number. This is on both of the boards that I have. And diacs cost

significantly more than a small signal diode.

I tested the parts and they are definitely diacs that only conduct when the

voltage gets to about 30V. I got suspicious because diacs aren't polarised,

so there is no polarity indicator on the body, so it couldn't be a diode.

Even if they thought they could also be used as diodes in one direction

there is no way to fit them the right way round and IIRC one of the

footprints was the opposite orientation to the same part in the other

channel.

Replacing them with real didoes would not achieve anything useful either.

The clock oscillator would run nearly twice as fast, so you would need to

change the integrator time constant, and the reference voltage would become

very temperature sensitive.

On Sun, 12 Jun 2022 at 00:13, Michael Möller private2michael@gmail.com

wrote:

Well, that was a fascinating, although short, summary :-)

Weird design decisions in the electronics - seems done by someone new or

with limited choice of components.

Michael