Math problem

Greetings all;

In order to reduce code duplication in this drive, I am about to embarque

on a make 3 modules out of two edit, by splitting the inner facing

spline code into two modules, shareing a third outer module because that

is already identical, or is supposed to be.

And because in a harmonic drive, the difference in the number of inner

teeth, or splines puts more stress on the splines due to the difference

in tooth heights, I've chosen an arbitrary lower limit on the effective

gear ratio of 30/1. Commercial steel versions are generally more like

100/1, but that puts a much more extreme precision requirement in the

printers rendering of the splines. That probably puts a 50/1 ratio as

the maximum practical limit for a device this small size. At 30/1, I can

get nice clean rendition of the splines w/o changeing to a much smaller

nozzle than the default .4mm.

My mental question then, since I am generating the spline as a cylinder

with an $fm=3 to make the triangular spline, then rotating the inner

facing pattern 180 degrees, then merging the bases at 6 degree

increments for the 60 tooth, and at 62, an angular increment of

5.8064516129.

But this puts the all the change in the effective spline height in the

puter radius of the valley where the splines bases merge, and ideally it

seems like for a least stress engagement, I should adjust the translate

statement in the 62 tooth inner face, by some of that difference. It

does however, leave the tip of the spline at a constant radii. Maybe

thats best because that will allow full engagement of the spline tips.

IDK.

The difficulty in doing this is complicated by the need to keep cura out

of retraction hell by keeping the size of the merged area of the spline

large enough to allow an infill connection from spline to spline. So

there is a very firmly enforced by cura limit to how small that merged

area can be, and I have to assume any slicer does this. This condition

does warn you because it will at least double the estimated render time

and will probably clog up the printhead from thousands of retractions

long before the render is finished.

BTDT quite a few times and that fix is a full diss of the hot end and

burning the blockage out in the cookstove burners gas flame. Not my fav

pastime for obvious reasons.

But I have zero idea what the math to do that would look like, so here I

am, hat in hand. Can anyone advise me? Assume I have just enough algebra

to be dangerous.

Thanks all;

Cheers, Gene Heskett

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/gene

Hi Gene,

I guess these are the sort of shapes you are after

//gene

module point(){

translate([20,0,0])cylinder(50,d=5,$fn=3);

}

for(j=[1:60]) rotate ([0,0,6*j])point();

module in_point(off){

translate([20+off,0,0])rotate([0,0,180])cylinder(50,d=5,$fn=3);

}

#for (j=[1:62]) rotate([0,0,(360/62)*j])in_point(4);

If it is 60 deg points, then you can calculate the height of the tips,

increase size if bigger diameter/etc. (the internet, will give the

answer for dimensions of triangles in circles). So, chose a big enough

triangle/cylinder (or do 2d and linear extrude). To make the 'rim'

thinner, intersect with a cylinder for the external ring, difference a

cylinder for internal. The 'off' value will be filament/printer specific.

Cura's 'retraction hell' - no idea what you are talking about. There are

settings to reduce retractions, so that the filament is not ground by

the feed wheels, and there are plenty of tutorials on line (in the

search engine of your choice, just enter "cura retraction settings" and

read a few of them to get the idea). and for a shape like this there

should be few retractions. As I keep saying, you need to set the printer

up properly for your filament, and then you need to make the correct

adjustments, temperature, cooling, speed, etc,. within cura (or any

other slicer).

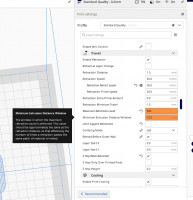

I've attached a jpeg of the cura retraction settings area, and if you

install the settings guide extension, you'll get a clue about their

function. I expect combing mode would help.

hth

Best wishes,

Ray

On 26/07/2021 00:23, Gene Heskett wrote:

Greetings all;

In order to reduce code duplication in this drive, I am about to embarque

on a make 3 modules out of two edit, by splitting the inner facing

spline code into two modules, shareing a third outer module because that

is already identical, or is supposed to be.

And because in a harmonic drive, the difference in the number of inner

teeth, or splines puts more stress on the splines due to the difference

in tooth heights, I've chosen an arbitrary lower limit on the effective

gear ratio of 30/1. Commercial steel versions are generally more like

100/1, but that puts a much more extreme precision requirement in the

printers rendering of the splines. That probably puts a 50/1 ratio as

the maximum practical limit for a device this small size. At 30/1, I can

get nice clean rendition of the splines w/o changeing to a much smaller

nozzle than the default .4mm.

My mental question then, since I am generating the spline as a cylinder

with an $fm=3 to make the triangular spline, then rotating the inner

facing pattern 180 degrees, then merging the bases at 6 degree

increments for the 60 tooth, and at 62, an angular increment of

5.8064516129.

But this puts the all the change in the effective spline height in the

puter radius of the valley where the splines bases merge, and ideally it

seems like for a least stress engagement, I should adjust the translate

statement in the 62 tooth inner face, by some of that difference. It

does however, leave the tip of the spline at a constant radii. Maybe

thats best because that will allow full engagement of the spline tips.

IDK.

The difficulty in doing this is complicated by the need to keep cura out

of retraction hell by keeping the size of the merged area of the spline

large enough to allow an infill connection from spline to spline. So

there is a very firmly enforced by cura limit to how small that merged

area can be, and I have to assume any slicer does this. This condition

does warn you because it will at least double the estimated render time

and will probably clog up the printhead from thousands of retractions

long before the render is finished.

BTDT quite a few times and that fix is a full diss of the hot end and

burning the blockage out in the cookstove burners gas flame. Not my fav

pastime for obvious reasons.

But I have zero idea what the math to do that would look like, so here I

am, hat in hand. Can anyone advise me? Assume I have just enough algebra

to be dangerous.

Thanks all;

Cheers, Gene Heskett

not too bad a guess ? maybe make the inner a tad smaller diameter

//gene

module point(){

translate([20,0,0])cylinder(50,d=5,$fn=3);

}

scale([0.97,1.03,0])

for(j=[1:60]) rotate ([0,0,6*j])point();

module in_point(off){

translate([20+off,0,0])rotate([0,0,180])cylinder(50,d=5,$fn=3);

}

#for (j=[1:62]) rotate([0,0,(360/62)*j])in_point(4);

On 26/07/2021 00:23, Gene Heskett wrote:

Greetings all;

In order to reduce code duplication in this drive, I am about to embarque

on a make 3 modules out of two edit, by splitting the inner facing

spline code into two modules, shareing a third outer module because that

is already identical, or is supposed to be.

And because in a harmonic drive, the difference in the number of inner

teeth, or splines puts more stress on the splines due to the difference

in tooth heights, I've chosen an arbitrary lower limit on the effective

gear ratio of 30/1. Commercial steel versions are generally more like

100/1, but that puts a much more extreme precision requirement in the

printers rendering of the splines. That probably puts a 50/1 ratio as

the maximum practical limit for a device this small size. At 30/1, I can

get nice clean rendition of the splines w/o changeing to a much smaller

nozzle than the default .4mm.

My mental question then, since I am generating the spline as a cylinder

with an $fm=3 to make the triangular spline, then rotating the inner

facing pattern 180 degrees, then merging the bases at 6 degree

increments for the 60 tooth, and at 62, an angular increment of

5.8064516129.

But this puts the all the change in the effective spline height in the

puter radius of the valley where the splines bases merge, and ideally it

seems like for a least stress engagement, I should adjust the translate

statement in the 62 tooth inner face, by some of that difference. It

does however, leave the tip of the spline at a constant radii. Maybe

thats best because that will allow full engagement of the spline tips.

IDK.

The difficulty in doing this is complicated by the need to keep cura out

of retraction hell by keeping the size of the merged area of the spline

large enough to allow an infill connection from spline to spline. So

there is a very firmly enforced by cura limit to how small that merged

area can be, and I have to assume any slicer does this. This condition

does warn you because it will at least double the estimated render time

and will probably clog up the printhead from thousands of retractions

long before the render is finished.

BTDT quite a few times and that fix is a full diss of the hot end and

burning the blockage out in the cookstove burners gas flame. Not my fav

pastime for obvious reasons.

But I have zero idea what the math to do that would look like, so here I

am, hat in hand. Can anyone advise me? Assume I have just enough algebra

to be dangerous.

Thanks all;

Cheers, Gene Heskett

Here's a good reference for printer calibration:

https://teachingtechyt.github.io/calibration.html

On Sun, Jul 25, 2021 at 8:30 PM Ray West raywest@raywest.com wrote:

not too bad a guess ? maybe make the inner a tad smaller diameter

//gene

module point(){

translate([20,0,0])cylinder(50,d=5,$fn=3);

}

scale([0.97,1.03,0])

for(j=[1:60]) rotate ([0,0,6*j])point();

module in_point(off){

translate([20+off,0,0])rotate([0,0,180])cylinder(50,d=5,$fn=3);

}

#for (j=[1:62]) rotate([0,0,(360/62)*j])in_point(4);

On 26/07/2021 00:23, Gene Heskett wrote:

Greetings all;

In order to reduce code duplication in this drive, I am about to embarque

on a make 3 modules out of two edit, by splitting the inner facing

spline code into two modules, shareing a third outer module because that

is already identical, or is supposed to be.

And because in a harmonic drive, the difference in the number of inner

teeth, or splines puts more stress on the splines due to the difference

in tooth heights, I've chosen an arbitrary lower limit on the effective

gear ratio of 30/1. Commercial steel versions are generally more like

100/1, but that puts a much more extreme precision requirement in the

printers rendering of the splines. That probably puts a 50/1 ratio as

the maximum practical limit for a device this small size. At 30/1, I can

get nice clean rendition of the splines w/o changeing to a much smaller

nozzle than the default .4mm.

My mental question then, since I am generating the spline as a cylinder

with an $fm=3 to make the triangular spline, then rotating the inner

facing pattern 180 degrees, then merging the bases at 6 degree

increments for the 60 tooth, and at 62, an angular increment of

5.8064516129.

But this puts the all the change in the effective spline height in the

puter radius of the valley where the splines bases merge, and ideally it

seems like for a least stress engagement, I should adjust the translate

statement in the 62 tooth inner face, by some of that difference. It

does however, leave the tip of the spline at a constant radii. Maybe

thats best because that will allow full engagement of the spline tips.

IDK.

The difficulty in doing this is complicated by the need to keep cura out

of retraction hell by keeping the size of the merged area of the spline

large enough to allow an infill connection from spline to spline. So

there is a very firmly enforced by cura limit to how small that merged

area can be, and I have to assume any slicer does this. This condition

does warn you because it will at least double the estimated render time

and will probably clog up the printhead from thousands of retractions

long before the render is finished.

BTDT quite a few times and that fix is a full diss of the hot end and

burning the blockage out in the cookstove burners gas flame. Not my fav

pastime for obvious reasons.

But I have zero idea what the math to do that would look like, so here I

am, hat in hand. Can anyone advise me? Assume I have just enough algebra

to be dangerous.

Thanks all;

Cheers, Gene Heskett

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On Sunday 25 July 2021 21:24:17 Ray West wrote:

Hi Gene,

I guess these are the sort of shapes you are after

//gene

module point(){

translate([20,0,0])cylinder(50,d=5,$fn=3);

}

for(j=[1:60]) rotate ([0,0,6*j])point();

module in_point(off){

translate([20+off,0,0])rotate([0,0,180])cylinder(50,d=5,$fn=3);

}

#for (j=[1:62]) rotate([0,0,(360/62)*j])in_point(4);

If it is 60 deg points, then you can calculate the height of the tips,

increase size if bigger diameter/etc. (the internet, will give the

answer for dimensions of triangles in circles). So, chose a big enough

triangle/cylinder (or do 2d and linear extrude). To make the 'rim'

thinner, intersect with a cylinder for the external ring, difference a

cylinder for internal. The 'off' value will be filament/printer

specific.

I also have "keys" to lock rotation without depending on fit grip to do

it.

Cura's 'retraction hell' - no idea what you are talking about.

Thats where it does a retraction to move from point to point as it

infills the point, could be 2 or more times a second and 6 or more per

each of 60 tooth*.2mm layers and its 12mm tall. Double or more, the

render time. Wears out the filament too.

I'll do that code mod later today when I've got both eyes open.

There

are settings to reduce retractions, so that the filament is not ground

by the feed wheels, and there are plenty of tutorials on line (in the

search engine of your choice, just enter "cura retraction settings"

and read a few of them to get the idea). and for a shape like this

there should be few retractions. As I keep saying, you need to set the

printer up properly for your filament, and then you need to make the

correct adjustments, temperature, cooling, speed, etc,. within cura

(or any other slicer).

Still working on that but mking good progress. cura's default feed flow

is now down to 82% The prusa has direct drive with no geardown, so can

retract at double or more the default speeds, breaking the string and

reducing stringing which is a major problem with petg. But with 3 of the

9 parts completed, it has certainly proved the worth of the e3d all

metal hot end, rated to 300C so I think I'll retrofit it to at least the

CR10S Pro V2, along with a bmg extruder I already have and maybe on the

BIQU BX, as it turns out that while the famous H2 head the BX wears is

nice, its also a pla only head, petg temps destroy the capricorn tubing

in it in 2 jobs.

I've attached a jpeg of the cura retraction settings area, and if you

install the settings guide extension, you'll get a clue about their

function. I expect combing mode would help.

Combing is off, as it seems to enhance the buildup of plastic on the

bottom of the nozzle when squirting petg, eventually catching and

destroying the job.

I think thats on by default in the AppImages I'm running. Nice little

quite verbose popups.

hth

Definitely helps Ray, thank you.

Take care now.

Cheers, Gene Heskett

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/gene

On 26/07/2021 03:02, Father Horton wrote:

Here's a good reference for printer calibration:

https://teachingtechyt.github.io/calibration.html

https://teachingtechyt.github.io/calibration.html

On Sun, Jul 25, 2021 at 8:30 PM Ray West <raywest@raywest.com

mailto:raywest@raywest.com> wrote:

not too bad a guess ? maybe make the inner a tad smaller diameter

//gene

module point(){

translate([20,0,0])cylinder(50,d=5,$fn=3);

}

scale([0.97,1.03,0])

for(j=[1:60]) rotate ([0,0,6*j])point();

module in_point(off){

translate([20+off,0,0])rotate([0,0,180])cylinder(50,d=5,$fn=3);

}

#for (j=[1:62]) rotate([0,0,(360/62)*j])in_point(4);

On 26/07/2021 00:23, Gene Heskett wrote:

Greetings all;

In order to reduce code duplication in this drive, I am about to

embarque

on a make 3 modules out of two edit, by splitting the inner facing

spline code into two modules, shareing a third outer module

because that

is already identical, or is supposed to be.

And because in a harmonic drive, the difference in the number of

inner

teeth, or splines puts more stress on the splines due to the

difference

in tooth heights, I've chosen an arbitrary lower limit on the

effective

gear ratio of 30/1. Commercial steel versions are generally more

like

100/1, but that puts a much more extreme precision requirement

in the

printers rendering of the splines. That probably puts a 50/1

ratio as

the maximum practical limit for a device this small size. At

30/1, I can

get nice clean rendition of the splines w/o changeing to a much

smaller

nozzle than the default .4mm.

My mental question then, since I am generating the spline as a

cylinder

with an $fm=3 to make the triangular spline, then rotating the inner

facing pattern 180 degrees, then merging the bases at 6 degree

increments for the 60 tooth, and at 62, an angular increment of

5.8064516129.

But this puts the all the change in the effective spline

height in the

puter radius of the valley where the splines bases merge, and

ideally it

seems like for a least stress engagement, I should adjust the

translate

statement in the 62 tooth inner face, by some of that difference. It

does however, leave the tip of the spline at a constant radii. Maybe

thats best because that will allow full engagement of the spline

tips.

IDK.

The difficulty in doing this is complicated by the need to keep

cura out

of retraction hell by keeping the size of the merged area of the

spline

large enough to allow an infill connection from spline to spline. So

there is a very firmly enforced by cura limit to how small that

merged

area can be, and I have to assume any slicer does this. This

condition

does warn you because it will at least double the estimated

render time

and will probably clog up the printhead from thousands of

retractions

long before the render is finished.

BTDT quite a few times and that fix is a full diss of the hot

end and

burning the blockage out in the cookstove burners gas flame. Not

my fav

pastime for obvious reasons.

But I have zero idea what the math to do that would look like,

so here I

am, hat in hand. Can anyone advise me? Assume I have just enough

algebra

to be dangerous.

Thanks all;

Cheers, Gene Heskett

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

<mailto:discuss-leave@lists.openscad.org>

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

I've had good results with PETG by using plastic repellent paint on the nozzle and its surroundings.

--

David Gustavson

dbg@SCIzzL.com

On Mon, Jul 26, 2021, at 12:36 AM, Gene Heskett wrote:

On Sunday 25 July 2021 21:24:17 Ray West wrote:

Hi Gene,

I guess these are the sort of shapes you are after

//gene

module point(){

translate([20,0,0])cylinder(50,d=5,$fn=3);

}for(j=[1:60]) rotate ([0,0,6*j])point();

module in_point(off){

translate([20+off,0,0])rotate([0,0,180])cylinder(50,d=5,$fn=3);

}#for (j=[1:62]) rotate([0,0,(360/62)*j])in_point(4);

If it is 60 deg points, then you can calculate the height of the tips,

increase size if bigger diameter/etc. (the internet, will give the

answer for dimensions of triangles in circles). So, chose a big enough

triangle/cylinder (or do 2d and linear extrude). To make the 'rim'

thinner, intersect with a cylinder for the external ring, difference a

cylinder for internal. The 'off' value will be filament/printer

specific.

I also have "keys" to lock rotation without depending on fit grip to do

it.

Cura's 'retraction hell' - no idea what you are talking about.

Thats where it does a retraction to move from point to point as it

infills the point, could be 2 or more times a second and 6 or more per

each of 60 tooth*.2mm layers and its 12mm tall. Double or more, the

render time. Wears out the filament too.

I'll do that code mod later today when I've got both eyes open.

There

are settings to reduce retractions, so that the filament is not ground

by the feed wheels, and there are plenty of tutorials on line (in the

search engine of your choice, just enter "cura retraction settings"

and read a few of them to get the idea). and for a shape like this

there should be few retractions. As I keep saying, you need to set the

printer up properly for your filament, and then you need to make the

correct adjustments, temperature, cooling, speed, etc,. within cura

(or any other slicer).

Still working on that but mking good progress. cura's default feed flow

is now down to 82% The prusa has direct drive with no geardown, so can

retract at double or more the default speeds, breaking the string and

reducing stringing which is a major problem with petg. But with 3 of the

9 parts completed, it has certainly proved the worth of the e3d all

metal hot end, rated to 300C so I think I'll retrofit it to at least the

CR10S Pro V2, along with a bmg extruder I already have and maybe on the

BIQU BX, as it turns out that while the famous H2 head the BX wears is

nice, its also a pla only head, petg temps destroy the capricorn tubing

in it in 2 jobs.

I've attached a jpeg of the cura retraction settings area, and if you

install the settings guide extension, you'll get a clue about their

function. I expect combing mode would help.

Combing is off, as it seems to enhance the buildup of plastic on the

bottom of the nozzle when squirting petg, eventually catching and

destroying the job.

I think thats on by default in the AppImages I'm running. Nice little

quite verbose popups.

hth

Definitely helps Ray, thank you.

Take care now.

Cheers, Gene Heskett

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/gene

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On Monday 26 July 2021 07:29:26 Ray West wrote:

On 26/07/2021 03:02, Father Horton wrote:

Here's a good reference for printer calibration:

https://teachingtechyt.github.io/calibration.html

https://teachingtechyt.github.io/calibration.html

I think the prusa will override any of that, since its a kit, and in the

initial run it spends about 3 minutes per bed corner, finding and

calibrating itself to some something machined into the bed surface,

possibly the countersunk screws at the 4 corners where the suspension

spider is anchored. It uses the induction version of a bltouch to locate

those holes, probably to well within .02mm's. And it has some pretty

intelligent drivers for the steppers too, it hit a solidified glob on an

early job, hard enough to make the x stepper miss about 20 full steps,

it jumped Z up a couple mm, then ran itself against the left frame to

rehome itself, then continued with the print without actually making a

mark on the print beyond the initial crash. And there are not any home

or limit switches anyplace, the induction version of a BLTouch and the

smartest drivers I've ever watched. They must really track the expected

motor currants (or the back emf) to be able to detect that a motor has

hit something hard enough to make it lose a step. Cura won't let me set

any outrageos speeds, but the control panel can run it a lot faster than

that, and ATM its printing a part with the splines for a miniature

harmonic drive, and is not miss-behaving a bit at 200% of cura's max

speed. Since the next part is nearly identical, this one should fit

well, I'll try 250% after the 2nd layer just for grins on the next one.

Thank you, a lot.

Cheers, Gene Heskett

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/gene

On Mon, 2021-07-26 at 13:27 -0700, David Gustavson wrote:

I've had good results with PETG by using plastic repellent paint on

the nozzle and its surroundings.

Plastic repellent paint? Tell me more!

On Monday 26 July 2021 23:32:26 larry wrote:

On Mon, 2021-07-26 at 13:27 -0700, David Gustavson wrote:

I've had good results with PETG by using plastic repellent paint on

the nozzle and its surroundings.

Plastic repellent paint? Tell me more!

I don't know where David sourced his. but I have a tiny little bottle in

my hand that has about 2 cc's of a clear, claims to be water based,

plastic repellant paint. See <sliceengineering.com/documentation>.

The bottle has a fingernail paintbrush in its lid. I repaint it about

every 5 or 6 starts as its warming up. Its around 20 bucks, helps but

not foolproof.

Cheers, Gene Heskett

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Genes Web page http://geneslinuxbox.net:6309/gene