3D printing and Injection Molding

On 9/4/2024 4:45 PM, Bob Carlson wrote:

Can you point to an Issue in Github that contains the details?

https://github.com/openscad/openscad/issues/3781

File scope $variables ignored if a file is used by another file

https://github.com/openscad/openscad/issues/3881

Scope & changes to $special variables in "use<>" context

Seems like a new inclusion mechanism would be the cleanest way forward.

And I have an idea for that, but it's dependent on the object stuff that

you mention. (Or at least the most object-y stuff that I'm aware of.)

And I am still trying to be patient waiting for the object oriented features to be added that have been in the works for years.

https://github.com/openscad/openscad/pull/4478

Objects, geometry as data, module references

https://github.com/openscad/openscad/wiki/OEP8:-Objects-(dictionaries%3F),-Geometry-as-data,-and-Module-References

OEP8: Objects (dictionaries?), Geometry as data, and Module References

Comments solicited.

On Wednesday, September 4, 2024 at 06:22:37 AM EDT, Marcus Poller via Discuss discuss@lists.openscad.org wrote:

Production processes:

I have been thinking about CNC milling a guitar. I intend to play on that instrument.

Acoustic or electric?

I have talked to some carpenters and some mill operators about the process. Sourcing the wood in such small quantities will be hard.

Lots of specialty shops carry wood intended for guitars.

Arranging the milling process to compensate for bending is very hard. There is no guarantee that I will get a flat guitar neck, just educated guesses.

If the wood is selected so as not to have internal stresses and appropriate grain direction/pattern, and is well-dried and seasoned it should come out as expected when cut

Milling from two sides will be hard.

If the stock is properly prepared, or if one uses a suitable fixture it's pretty straight-forward.

I will need to postprocess by hand to remove tool marks.

You can trade additional machine time for smaller tool marks which will allow one to minimize sanding and use a finer grit to start.

You cannot operate a CNC mill without being a carpenter first.

I believe the word you want here is woodworker, but often in supporting CNC machines, folks who have zero woodworking experience, but who have metal-working experience often do quite well with cutting wood on a CNC --- once they learn to accept that the material which was once alive will still move and react and breathe and change based on humidity and so forth.

I have given up on that idea.

If you want to revisit it, let us know and we'll do our best to assist.

William

I don't think it needs a new use mechanism, it just needs $variables to get

the original scope back and code to track their use so that only

expressions using them need to be reevaluated when using a module. That

would massively increase performance without breaking anything.

On Thu, 5 Sept 2024 at 01:28, Jordan Brown via Discuss <

discuss@lists.openscad.org> wrote:

On 9/4/2024 4:45 PM, Bob Carlson wrote:

Can you point to an Issue in Github that contains the details?

https://github.com/openscad/openscad/issues/3781

File scope $variables ignored if a file is used by another file

https://github.com/openscad/openscad/issues/3881

Scope & changes to $special variables in "use<>" context

Seems like a new inclusion mechanism would be the cleanest way forward.

And I have an idea for that, but it's dependent on the object stuff that

you mention. (Or at least the most object-y stuff that I'm aware of.)

And I am still trying to be patient waiting for the object oriented features to be added that have been in the works for years.

https://github.com/openscad/openscad/pull/4478

Objects, geometry as data, module references

https://github.com/openscad/openscad/wiki/OEP8:-Objects-(dictionaries%3F),-Geometry-as-data,-and-Module-References

OEP8: Objects (dictionaries?), Geometry as data, and Module References

Comments solicited.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Where can I read this book?

On 4 Sep 2024, at 13:18, Michael Möller via Discuss discuss@lists.openscad.org wrote:

🙂 to the above.

"In theory, there is no difference between theory and practice. In practice, however ..."

I have a whole book for the many different FDM processes, and each of their quirks, and even that is more for the (serious) hobbist, and not industrial.

ons. 4. sep. 2024 12.22 skrev Marcus Poller via Discuss <discuss@lists.openscad.org mailto:discuss@lists.openscad.org>:

Hi Peter,

I am very new to 3D modeling and printing.

I am now working on productizing this and I decided it will need to be injection molded (IM). Studying the issues it seems there are quite a few of them.

In 3D printing chamfering with 45 degree has an advantage over rounding, which needs support. However, rounding looks a lot better so is required for a commercial product. Do I need to spread if (im) ... all over my code? Or just take the cost of support?

You need one model per production process.

In theory it is all fun an games: You have one 3d model and the production process driver (e.g. slicer for FDM-Printing) will make sure your model can be produced on any machine (printed, cutted, milled).

In practice:

Each fabrication process has its limits and your 3d model needs to compensate them.

- FDM-prints schrink after printing. Overhangs >45° require support. Supports leave support marks

- Milling: Removing wood or metall from a block of material creates tension, your workpiece will bend. You need to compensate for that, e.g. by running a prototype slightly greater than your model. Some CNC-machines only have 2.5 axes, so you need to remodel overhangs.

- sintering: you need additional holes to let metal powder run out of your model

- Injection Molding: you cannot use cubes, the model needs to be releasable in a machine. You need additional injection tubes.

- laser cutting: the heat generated by your laser will generate tension within the material. The cut out pieces will generate tension. Your workpiece will bend on the laser bed. Good drivers may compensate tension by chopping your cutline into segments. Sometimes the machine operator needs to treat the worki piece with heat within the cutting process. The machine operator needs to know how to put your piece onto a raw supply material to compensate for in-material-tension.

Are there other approach for this?

Create one model per fabrication process. There is no general solution.

Would be very interested to have a discussion that have a similar problem.

Parametric models:

I wanted to try SLA printing. The model were some credit card size gears. The operator rejected my 3d model, it could not be smaller that 2mm in each dimension. I forked my own model.

Color models:

I have a FDM pirate treasure chest that emulates the looks of wood by surface elevation/texture. I want to replace the texture with a multi color FDM print. I remodeled the box.

Production processes:

I have been thinking about CNC milling a guitar. I intend to play on that instrument.

I have talked to some carpenters and some mill operators about the process. Sourcing the wood in such small quantities will be hard.

Arranging the milling process to compensate for bending is very hard. There is no guarantee that I will get a flat guitar neck, just educated guesses.

Milling from two sides will be hard.

I will need to postprocess by hand to remove tool marks.

You cannot operate a CNC mill without being a carpenter first.

I have given up on that idea.

Marcus

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org mailto:discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On 4 Sep 2024, at 17:31, Jordan Brown openscad@jordan.maileater.net wrote:

On 9/4/2024 12:35 AM, Peter Kriens via Discuss wrote:

My design requires very accurate holes for connectors like USB, HDMI, etc. They should have enough friction (~0.2mm) but not too much, the tolerances in the connectors and the printer are very complicated to handle.

Really? I don't know anything about the design process there, but as a user it seems like the critical tolerances are all in the metal-on-metal interfaces supplied by the connectors themselves. I don't think I've ever seen (or at least have never noticed) a product where the plastic is part of the mechanical connection.

No, the plastic has to hold the connector and needs to provide enough smoothness to easily insert but enough friction to not fall out. I now use a little wedge at the end to create more friction. I tried many different ways.

Make the whole hole smaller,

Make it only smaller on x or y,

Add an elastic clip that pushes on the connector,

etc.

The small wedge seems to work best and seems to work on my Ultimaker S3 in the different resolutions I tried out with Tough PLA and will use PC today because this is closer to the material in Injection Molding (IM). However, concerned how this works out with IM.

Suggestions welcome.

On Thu, Sep 5, 2024 at 10:32 AM Peter Kriens via Discuss <

discuss@lists.openscad.org> wrote:

The small wedge seems to work best and seems to work on my Ultimaker S3 in

the different resolutions I tried out with Tough PLA and will use PC today

because this is closer to the material in Injection Molding (IM). However,

concerned how this works out with IM.

Suggestions welcome.

I'm curious (I don't have experience with IM) - how much will you spend on

this mold? From what I have seen watching Youtube way too much, these will

set you back 5-figure numbers, and no do-overs - if you screw up even one

detail, congratulations, you get to do it all over. If we (well, you :) )

are indeed talking about numbers in this order of magnitude, wouldn't it

make sense for you to only prototype this using FDM, and then have someone

with experience re-make the model using software properly suited for IM

(i.e., something that doesn't create a list of triangles in 3D space)? And

then use their expertise and experience to deal with details like this

(friction fitting things is... fraught with peril, in my experience with it

in FDM), which they've (if you choose an experienced one) gone through

dozens of times already?

This is not so much a critique (as I do not have any qualifications to

critique someone who has obviously thought more about this than I did) as a

question as to why you seem to be going directly against the number one

advice given by anyone who's gone through the process you seem to be going

through, and who have bothered to do a postmortem of their process. You

must have read through these people's accounts yet have reasons to take

another route? Good luck and I'd love it if you would report back on this

list once you've completed the process and have your first products in hand.

cheers

Roel

I also came to the conclusion that the right way is to prototype with FDM and then do the extra mile to make a design optimized for IM. The high cost and long delays of the mold make this a necessity.

However, I'd like to keep the impedance between these models as small as possible because, based on the same principle, and depending on the success of the first one, I have two more down the line. I also like it because it allows me to formally capture the learning you always do in these proceses.

I am new to this world and in my naive way as a software developer I assumed that a 3D model is a 3D model. I worked in printing during the 80's and PDF was a godsend. Before PDF we had to send horribly complex instructions to the typesetters, being aware of the most intricate attributes of the type setter. PDF changed the game by creating a standard that described the perfect page regardless of resolution. You could print it on a stamp or you could print it on football field and the latter would still show perfect resolution. After PDF the typesetters took over the responsibility to print a page as close as possible to this perfect description. We could just focus on the perfect description.

Since this is 40 years ago I'd expected that a similar model was also present in the 3D world. I realize that 3D models are seriously more complicated but still it was a shock how primitive it seems.

Was a surprise ... but I've no choice but to live with this.

regards,

Peter

On 5 Sep 2024, at 12:55, Roel Vanhout roel.vanhout@gmail.com wrote:

On Thu, Sep 5, 2024 at 10:32 AM Peter Kriens via Discuss <discuss@lists.openscad.org mailto:discuss@lists.openscad.org> wrote:

The small wedge seems to work best and seems to work on my Ultimaker S3 in the different resolutions I tried out with Tough PLA and will use PC today because this is closer to the material in Injection Molding (IM). However, concerned how this works out with IM.

Suggestions welcome.

I'm curious (I don't have experience with IM) - how much will you spend on this mold? From what I have seen watching Youtube way too much, these will set you back 5-figure numbers, and no do-overs - if you screw up even one detail, congratulations, you get to do it all over. If we (well, you :) ) are indeed talking about numbers in this order of magnitude, wouldn't it make sense for you to only prototype this using FDM, and then have someone with experience re-make the model using software properly suited for IM (i.e., something that doesn't create a list of triangles in 3D space)? And then use their expertise and experience to deal with details like this (friction fitting things is... fraught with peril, in my experience with it in FDM), which they've (if you choose an experienced one) gone through dozens of times already?

This is not so much a critique (as I do not have any qualifications to critique someone who has obviously thought more about this than I did) as a question as to why you seem to be going directly against the number one advice given by anyone who's gone through the process you seem to be going through, and who have bothered to do a postmortem of their process. You must have read through these people's accounts yet have reasons to take another route? Good luck and I'd love it if you would report back on this list once you've completed the process and have your first products in hand.

cheers

Roel

On 9/5/24 04:32, Peter Kriens via Discuss wrote:

On 4 Sep 2024, at 17:31, Jordan Brown openscad@jordan.maileater.net

wrote:

On 9/4/2024 12:35 AM, Peter Kriens via Discuss wrote:

My design requires very accurate holes for connectors like USB, HDMI,

etc. They should have enough friction (~0.2mm) but not too much, the

tolerances in the connectors and the printer are very complicated to

handle.

Really? I don't know anything about the design process there, but as

a user it seems like the critical tolerances are all in the

metal-on-metal interfaces supplied by the connectors themselves. I

don't think I've ever seen (or at least have never noticed) a product

where the plastic is part of the mechanical connection.

No, the plastic has to hold the connector and needs to provide enough

smoothness to easily insert but enough friction to not fall out. I now

use a little wedge at the end to create more friction. I tried many

different ways.

- Make the whole hole smaller,

- Make it only smaller on x or y,

- Add an elastic clip that pushes on the connector,

- etc.

The small wedge seems to work best and seems to work on my Ultimaker S3

in the different resolutions I tried out with Tough PLA and will use PC

today

Can your printer get hot enough for PC? I had to modify an Ender5Plus to

get it hot enough for PC, needs a 280C nozzle and 120C bed to Just Print

PC. Bed booster and 800 watts at 32 volts. New hot end. And 280C is

right at the HE ratings.

because this is closer to the material in Injection Molding (IM).

However, concerned how this works out with IM.

Suggestions welcome.

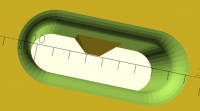

PastedGraphic-2.png

PastedGraphic-4.png

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Peter,

some thoughts on your problems/issues:

- "I am now working on productizing this and I decided it will need

to be injection molded (IM)". This decision is what precipitates your

other problems. Are you sure you need to go to IM? What sorts of

numbers of part are you producing. If you have not seen then, I'd

check out some of the videos on Youtube by Slant3D. They are a print

farm in the US who are advocating the position that in many cased 3D

printing by a print farm can replace IM. See, in particular,

https://www.youtube.com/watch?v=lVRLuCScRdE . BTW I have no

affiliation with Slant3D, nor have I ever used their services.

- "To my horror I found that STEP is the standard file in the IM

world, they genuinely hate STL files it seems." I have faced the same

problem myself. I wanted to get PCBWay CNC some parts I have designed

in OpenSCAD. My solution was to redesign the parts in cadquery,

https://github.com/CadQuery/cadquery . caquery is similar to OpenSCAD

in that it uses a scripting language (in its case Python) to design

CAD models. The syntax and approach is different to OpenSCAD, and it

is not too difficult to rewrite a part in cadquery, once you have got

the hang of it. It takes a little while to learn, but I found it

easier to learn than FreeCAD, which was another approach I tried.

cadquery can produce STEP files. (Actually, if it were not for the

fact that my designs rely heavily on NopSCADlib, I'd fully go over to

using cadquery.)

3 "I recently reverted to exact measures in the source and now use

CURA to expand the polygons so they have the required size. Are there

other approach for this?" You could set a global variable "tolerance",

and adjust your code. See

https://github.com/martinbudden/BabyCube/blob/main/cadquery/FrontFace.py

for an example of a part that is produced with different kerfs for

production by either CNC milling, laser cutting or waterjet cutting.

Martin

On Thu, 5 Sept 2024 at 16:59, Peter Kriens via Discuss

discuss@lists.openscad.org wrote:

I also came to the conclusion that the right way is to prototype with FDM and then do the extra mile to make a design optimized for IM. The high cost and long delays of the mold make this a necessity.

However, I'd like to keep the impedance between these models as small as possible because, based on the same principle, and depending on the success of the first one, I have two more down the line. I also like it because it allows me to formally capture the learning you always do in these proceses.

I am new to this world and in my naive way as a software developer I assumed that a 3D model is a 3D model. I worked in printing during the 80's and PDF was a godsend. Before PDF we had to send horribly complex instructions to the typesetters, being aware of the most intricate attributes of the type setter. PDF changed the game by creating a standard that described the perfect page regardless of resolution. You could print it on a stamp or you could print it on football field and the latter would still show perfect resolution. After PDF the typesetters took over the responsibility to print a page as close as possible to this perfect description. We could just focus on the perfect description.

Since this is 40 years ago I'd expected that a similar model was also present in the 3D world. I realize that 3D models are seriously more complicated but still it was a shock how primitive it seems.

Was a surprise ... but I've no choice but to live with this.

regards,

Peter

On 5 Sep 2024, at 12:55, Roel Vanhout roel.vanhout@gmail.com wrote:

On Thu, Sep 5, 2024 at 10:32 AM Peter Kriens via Discuss discuss@lists.openscad.org wrote:

The small wedge seems to work best and seems to work on my Ultimaker S3 in the different resolutions I tried out with Tough PLA and will use PC today because this is closer to the material in Injection Molding (IM). However, concerned how this works out with IM.

Suggestions welcome.

I'm curious (I don't have experience with IM) - how much will you spend on this mold? From what I have seen watching Youtube way too much, these will set you back 5-figure numbers, and no do-overs - if you screw up even one detail, congratulations, you get to do it all over. If we (well, you :) ) are indeed talking about numbers in this order of magnitude, wouldn't it make sense for you to only prototype this using FDM, and then have someone with experience re-make the model using software properly suited for IM (i.e., something that doesn't create a list of triangles in 3D space)? And then use their expertise and experience to deal with details like this (friction fitting things is... fraught with peril, in my experience with it in FDM), which they've (if you choose an experienced one) gone through dozens of times already?

This is not so much a critique (as I do not have any qualifications to critique someone who has obviously thought more about this than I did) as a question as to why you seem to be going directly against the number one advice given by anyone who's gone through the process you seem to be going through, and who have bothered to do a postmortem of their process. You must have read through these people's accounts yet have reasons to take another route? Good luck and I'd love it if you would report back on this list once you've completed the process and have your first products in hand.

cheers

Roel

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On 6 Sep 2024, at 11:20, Martin Budden mjbudden@gmail.com wrote:

Peter,

some thoughts on your problems/issues:

- "I am now working on productizing this and I decided it will need

to be injection molded (IM)". This decision is what precipitates your

other problems. Are you sure you need to go to IM?

Yes.

What sorts of numbers of part are you producing. If you have not seen then, I'd

check out some of the videos on Youtube by Slant3D. They are a print

farm in the US who are advocating the position that in many cased 3D

printing by a print farm can replace IM. See, in particular,

https://www.youtube.com/watch?v=lVRLuCScRdE . BTW I have no

affiliation with Slant3D, nor have I ever used their services.

I looked at the problem and it is not feasible for 2 reasons. First,

number that we're planning is clearly in the IM range. Second, the finish

you get with IM is necessary, it is a consumer product.

- "To my horror I found that STEP is the standard file in the IM

world, they genuinely hate STL files it seems." I have faced the same

problem myself. I wanted to get PCBWay CNC some parts I have designed

in OpenSCAD. My solution was to redesign the parts in cadquery,

https://github.com/CadQuery/cadquery . caquery is similar to OpenSCAD

in that it uses a scripting language (in its case Python) to design

CAD models. The syntax and approach is different to OpenSCAD, and it

is not too difficult to rewrite a part in cadquery, once you have got

the hang of it. It takes a little while to learn, but I found it

easier to learn than FreeCAD, which was another approach I tried.

cadquery can produce STEP files. (Actually, if it were not for the

fact that my designs rely heavily on NopSCADlib, I'd fully go over to

using cadquery.)

I am using the BOSL2 library and I lost any appetite to live without attach() ... I am heavily into reusable components (my life's work in software) and an important part of this is that you can easily assemble these components. It took me some time to figure out BOSL2 but it (partly) implements a model where the shape of the parent model is known in the children, which can then adapt. This is so powerful I don't want to live without it anymore. Will see what happens in CADQuery.

3 "I recently reverted to exact measures in the source and now use

CURA to expand the polygons so they have the required size. Are there

other approach for this?" You could set a global variable "tolerance",

and adjust your code. See

https://github.com/martinbudden/BabyCube/blob/main/cadquery/FrontFace.py

for an example of a part that is produced with different kerfs for

production by either CNC milling, laser cutting or waterjet cutting.

I already use that but my long history in software would like to create a perfect model and adjust in the next phase. Cura seems to have tuning parameters for the problem. But this might be a wrong prejudice.

Thanks for the feedback,

Peter

Martin

On Thu, 5 Sept 2024 at 16:59, Peter Kriens via Discuss

discuss@lists.openscad.org wrote:

I also came to the conclusion that the right way is to prototype with FDM and then do the extra mile to make a design optimized for IM. The high cost and long delays of the mold make this a necessity.

However, I'd like to keep the impedance between these models as small as possible because, based on the same principle, and depending on the success of the first one, I have two more down the line. I also like it because it allows me to formally capture the learning you always do in these proceses.

I am new to this world and in my naive way as a software developer I assumed that a 3D model is a 3D model. I worked in printing during the 80's and PDF was a godsend. Before PDF we had to send horribly complex instructions to the typesetters, being aware of the most intricate attributes of the type setter. PDF changed the game by creating a standard that described the perfect page regardless of resolution. You could print it on a stamp or you could print it on football field and the latter would still show perfect resolution. After PDF the typesetters took over the responsibility to print a page as close as possible to this perfect description. We could just focus on the perfect description.

Since this is 40 years ago I'd expected that a similar model was also present in the 3D world. I realize that 3D models are seriously more complicated but still it was a shock how primitive it seems.

Was a surprise ... but I've no choice but to live with this.

regards,

Peter

On 5 Sep 2024, at 12:55, Roel Vanhout roel.vanhout@gmail.com wrote:

On Thu, Sep 5, 2024 at 10:32 AM Peter Kriens via Discuss discuss@lists.openscad.org wrote:

The small wedge seems to work best and seems to work on my Ultimaker S3 in the different resolutions I tried out with Tough PLA and will use PC today because this is closer to the material in Injection Molding (IM). However, concerned how this works out with IM.

Suggestions welcome.

I'm curious (I don't have experience with IM) - how much will you spend on this mold? From what I have seen watching Youtube way too much, these will set you back 5-figure numbers, and no do-overs - if you screw up even one detail, congratulations, you get to do it all over. If we (well, you :) ) are indeed talking about numbers in this order of magnitude, wouldn't it make sense for you to only prototype this using FDM, and then have someone with experience re-make the model using software properly suited for IM (i.e., something that doesn't create a list of triangles in 3D space)? And then use their expertise and experience to deal with details like this (friction fitting things is... fraught with peril, in my experience with it in FDM), which they've (if you choose an experienced one) gone through dozens of times already?

This is not so much a critique (as I do not have any qualifications to critique someone who has obviously thought more about this than I did) as a question as to why you seem to be going directly against the number one advice given by anyone who's gone through the process you seem to be going through, and who have bothered to do a postmortem of their process. You must have read through these people's accounts yet have reasons to take another route? Good luck and I'd love it if you would report back on this list once you've completed the process and have your first products in hand.

cheers

Roel

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org