L

larry

Fri, May 16, 2025 8:58 PM

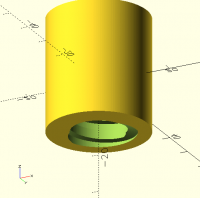

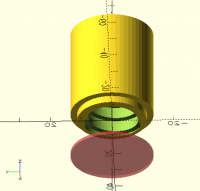

I'm trying to make a helper for lawn bowling, and the first order of

business is to make the attachment to fit a dollar store broom handle.

I have everything but the line with the comment working, and I am

wondering why my final line in the female() module is only rendering

the tube and not the cylinder.

//----------------------------

include <BOSL2/std.scad>

include <BOSL2/threading.scad>

$fn= $preview ? 60 : 180;

inch=25.4;

difference() {

female();

acme_threaded_rod(d=19.8, l=40, pitch=5.08);

}

module female() {

union() {

tube(id=17.05,od=22.6,h=25.4);

up(2.3) tube(id=22.7,od=27,h=30);

down(13.65) cylinder(h=1,d=27); // <---- Does not render

}

}

//----------------------------

I'm trying to make a helper for lawn bowling, and the first order of

business is to make the attachment to fit a dollar store broom handle.

I have everything but the line with the comment working, and I am

wondering why my final line in the female() module is only rendering

the tube and not the cylinder.

//----------------------------

include <BOSL2/std.scad>

include <BOSL2/threading.scad>

$fn= $preview ? 60 : 180;

inch=25.4;

difference() {

female();

acme_threaded_rod(d=19.8, l=40, pitch=5.08);

}

module female() {

union() {

tube(id=17.05,od=22.6,h=25.4);

up(2.3) tube(id=22.7,od=27,h=30);

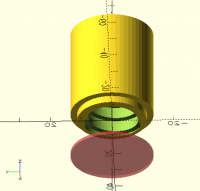

# down(13.65) cylinder(h=1,d=27); // <---- Does not render

}

}

//----------------------------

DP

Dan Perry

Fri, May 16, 2025 9:06 PM

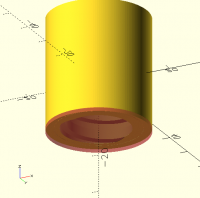

It renders for me, but there's very little left after the difference(). I

think the value of 13.65 is not correct. For a design like this that's not

intended to be symmetrical on z-axis, I suggest anchoring to the X-Y plane

with ANCHOR=BOTTOM arguments. And use left_half() to see the cross section.

Dan

On Fri, May 16, 2025 at 1:58 PM larry via Discuss <

discuss@lists.openscad.org> wrote:

I'm trying to make a helper for lawn bowling, and the first order of

business is to make the attachment to fit a dollar store broom handle.

I have everything but the line with the comment working, and I am

wondering why my final line in the female() module is only rendering

the tube and not the cylinder.

//----------------------------

include <BOSL2/std.scad>

include <BOSL2/threading.scad>

$fn= $preview ? 60 : 180;

inch=25.4;

difference() {

female();

acme_threaded_rod(d=19.8, l=40, pitch=5.08);

}

module female() {

union() {

tube(id=17.05,od=22.6,h=25.4);

up(2.3) tube(id=22.7,od=27,h=30);

down(13.65) cylinder(h=1,d=27); // <---- Does not render

}

}

//----------------------------

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

It renders for me, but there's very little left after the difference(). I

think the value of 13.65 is not correct. For a design like this that's not

intended to be symmetrical on z-axis, I suggest anchoring to the X-Y plane

with ANCHOR=BOTTOM arguments. And use left_half() to see the cross section.

Dan

On Fri, May 16, 2025 at 1:58 PM larry via Discuss <

discuss@lists.openscad.org> wrote:

> I'm trying to make a helper for lawn bowling, and the first order of

> business is to make the attachment to fit a dollar store broom handle.

>

>

> I have everything but the line with the comment working, and I am

> wondering why my final line in the female() module is only rendering

> the tube and not the cylinder.

>

> //----------------------------

> include <BOSL2/std.scad>

> include <BOSL2/threading.scad>

> $fn= $preview ? 60 : 180;

>

> inch=25.4;

>

> difference() {

> female();

> acme_threaded_rod(d=19.8, l=40, pitch=5.08);

> }

>

> module female() {

> union() {

> tube(id=17.05,od=22.6,h=25.4);

> up(2.3) tube(id=22.7,od=27,h=30);

> # down(13.65) cylinder(h=1,d=27); // <---- Does not render

> }

> }

>

> //----------------------------

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

>

L

larry

Fri, May 16, 2025 9:47 PM

On Fri, 2025-05-16 at 14:06 -0700, Dan Perry via Discuss wrote:

It renders for me, but there's very little left after the

difference(). I think the value of 13.65 is not correct. For a

design like this that's not intended to be symmetrical on z-axis, I

suggest anchoring to the X-Y plane with ANCHOR=BOTTOM arguments. And

use left_half() to see the cross section.

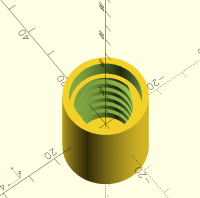

Thanks Dan! Your answer baffled me for a minute, but it led me to the

solution. The Acme threaded rod was sticking down past the part I said

didn't render. Of course it rendered, but was cut out by the threaded

rod.

All good now!

On Fri, 2025-05-16 at 14:06 -0700, Dan Perry via Discuss wrote:

> It renders for me, but there's very little left after the

> difference(). I think the value of 13.65 is not correct. For a

> design like this that's not intended to be symmetrical on z-axis, I

> suggest anchoring to the X-Y plane with ANCHOR=BOTTOM arguments. And

> use left_half() to see the cross section.

Thanks Dan! Your answer baffled me for a minute, but it led me to the

solution. The Acme threaded rod was sticking down past the part I said

didn't render. Of course it rendered, but was cut out by the threaded

rod.

All good now!

K

Ken

Fri, May 16, 2025 9:53 PM

Larry, not sure if I am understanding your problem correctly, but I assume you want a solid end to the adapter?

In which case, just move the problem line up to just after the closing bracket of the difference.

On 2025-05-17 06:58, larry via Discuss wrote:

I'm trying to make a helper for lawn bowling, and the first order of

business is to make the attachment to fit a dollar store broom handle.

I have everything but the line with the comment working, and I am

wondering why my final line in the female() module is only rendering

the tube and not the cylinder.

//----------------------------

include <BOSL2/std.scad>

include <BOSL2/threading.scad>

$fn= $preview ? 60 : 180;

inch=25.4;

difference() {

female();

acme_threaded_rod(d=19.8, l=40, pitch=5.08);

}

module female() {

union() {

tube(id=17.05,od=22.6,h=25.4);

up(2.3) tube(id=22.7,od=27,h=30);

down(13.65) cylinder(h=1,d=27); // <---- Does not render

}

}

//----------------------------

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

A baby can be defined as an ego with a noise at one end and a smell at the other.

Your job as parents is to teach them to control all three.

My job as a grandad is to tell you how you are doing it all wrong!

Larry, not sure if I am understanding your problem correctly, but I assume you want a solid end to the adapter?

In which case, just move the problem line up to just after the closing bracket of the difference.

On 2025-05-17 06:58, larry via Discuss wrote:

> I'm trying to make a helper for lawn bowling, and the first order of

> business is to make the attachment to fit a dollar store broom handle.

>

>

> I have everything but the line with the comment working, and I am

> wondering why my final line in the female() module is only rendering

> the tube and not the cylinder.

>

> //----------------------------

> include <BOSL2/std.scad>

> include <BOSL2/threading.scad>

> $fn= $preview ? 60 : 180;

>

> inch=25.4;

>

> difference() {

> female();

> acme_threaded_rod(d=19.8, l=40, pitch=5.08);

> }

>

> module female() {

> union() {

> tube(id=17.05,od=22.6,h=25.4);

> up(2.3) tube(id=22.7,od=27,h=30);

> # down(13.65) cylinder(h=1,d=27); // <---- Does not render

> }

> }

>

> //----------------------------

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email todiscuss-leave@lists.openscad.org

--

Cheers, Ken

bats059@gmail.com

https://vk7krj.com

https://vk7krj.com/running.html

----------------------------------------

A baby can be defined as an ego with a noise at one end and a smell at the other.

Your job as parents is to teach them to control all three.

My job as a grandad is to tell you how you are doing it all wrong!

L

larry

Sat, May 17, 2025 4:46 AM

On Sat, 2025-05-17 at 07:53 +1000, Ken via Discuss wrote:

Larry, not sure if I am understanding your problem correctly, but I

assume you want a solid end to the adapter?

In which case, just move the problem line up to just after the

closing bracket of the difference.

That would not have worked, as the problem was that the long threaded

rod extended beyond the female part at both ends, so when I added the

solid end, it actually cut it. It was simply a matter of making the rod

shorter and positioning it properly.

Here's the code that works...

//----------------------

include <BOSL2/std.scad>

include <BOSL2/threading.scad>

$fn= $preview ? 60 : 180;

difference() {

female();

up(2.5) acme_threaded_rod(d=19.8, l=30, pitch=5.08);

}

module female() {

union() {

tube(id=17.05,od=22.6,h=25.4);

up(2.3) tube(id=22.7,od=27,h=35);

down(15.18)cylinder(h=2.5,d=27);

}

}

//----------------------

On Sat, 2025-05-17 at 07:53 +1000, Ken via Discuss wrote:

> Larry, not sure if I am understanding your problem correctly, but I

> assume you want a solid end to the adapter?

I do.

> In which case, just move the problem line up to just after the

> closing bracket of the difference.

That would not have worked, as the problem was that the long threaded

rod extended beyond the female part at both ends, so when I added the

solid end, it actually cut it. It was simply a matter of making the rod

shorter and positioning it properly.

Here's the code that works...

//----------------------

include <BOSL2/std.scad>

include <BOSL2/threading.scad>

$fn= $preview ? 60 : 180;

difference() {

female();

up(2.5) acme_threaded_rod(d=19.8, l=30, pitch=5.08);

}

module female() {

union() {

tube(id=17.05,od=22.6,h=25.4);

up(2.3) tube(id=22.7,od=27,h=35);

down(15.18)cylinder(h=2.5,d=27);

}

}

//----------------------

GH

gene heskett

Sat, May 17, 2025 5:19 AM

On 5/16/25 17:06, Dan Perry via Discuss wrote:

It renders for me, but there's very little left after the difference(). I

think the value of 13.65 is not correct. For a design like this that's not

intended to be symmetrical on z-axis, I suggest anchoring to the X-Y plane

with ANCHOR=BOTTOM arguments. And use left_half() to see the cross section.

Dan

On Fri, May 16, 2025 at 1:58 PM larry via Discuss <

discuss@lists.openscad.org> wrote:

I'm trying to make a helper for lawn bowling, and the first order of

business is to make the attachment to fit a dollar store broom handle.

I have everything but the line with the comment working, and I am

wondering why my final line in the female() module is only rendering

the tube and not the cylinder.

//----------------------------

include <BOSL2/std.scad>

include <BOSL2/threading.scad>

$fn= $preview ? 60 : 180;

inch=25.4;

difference() {

female();

acme_threaded_rod(d=19.8, l=40, pitch=5.08);

}

module female() {

union() {

tube(id=17.05,od=22.6,h=25.4);

up(2.3) tube(id=22.7,od=27,h=30);

down(13.65) cylinder(h=1,d=27); // <---- Does not render

// renders fine here. but with 13.65mm of empty air above it before it

gets the to the

//main socket. is it supposed to be the bottom of the hole? And dollar

store handles

// do not come with square threads in these here parts.

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

On 5/16/25 17:06, Dan Perry via Discuss wrote:

> It renders for me, but there's very little left after the difference(). I

> think the value of 13.65 is not correct. For a design like this that's not

> intended to be symmetrical on z-axis, I suggest anchoring to the X-Y plane

> with ANCHOR=BOTTOM arguments. And use left_half() to see the cross section.

> Dan

>

>

>

> On Fri, May 16, 2025 at 1:58 PM larry via Discuss <

> discuss@lists.openscad.org> wrote:

>

>> I'm trying to make a helper for lawn bowling, and the first order of

>> business is to make the attachment to fit a dollar store broom handle.

>>

>>

>> I have everything but the line with the comment working, and I am

>> wondering why my final line in the female() module is only rendering

>> the tube and not the cylinder.

>>

>> //----------------------------

>> include <BOSL2/std.scad>

>> include <BOSL2/threading.scad>

>> $fn= $preview ? 60 : 180;

>>

>> inch=25.4;

>>

>> difference() {

>> female();

>> acme_threaded_rod(d=19.8, l=40, pitch=5.08);

>> }

>>

>> module female() {

>> union() {

>> tube(id=17.05,od=22.6,h=25.4);

>> up(2.3) tube(id=22.7,od=27,h=30);

>> # down(13.65) cylinder(h=1,d=27); // <---- Does not render

// renders fine here. but with 13.65mm of empty air above it before it

gets the to the

//main socket. is it supposed to be the bottom of the hole? And dollar

store handles

// do not come with square threads in these here parts.

>> }

>> }

>>

>> //----------------------------

>> _______________________________________________

>> OpenSCAD mailing list

>> To unsubscribe send an email to discuss-leave@lists.openscad.org

>>

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

Cheers, Gene Heskett, CET.

--

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

L

larry

Sat, May 17, 2025 5:34 AM

On Sat, 2025-05-17 at 01:19 -0400, gene heskett via Discuss wrote:

On 5/16/25 17:06, Dan Perry via Discuss wrote:

It renders for me, but there's very little left after the difference(). I

think the value of 13.65 is not correct. For a design like this that's not

intended to be symmetrical on z-axis, I suggest anchoring to the X-Y plane

with ANCHOR=BOTTOM arguments. And use left_half() to see the cross section.

Dan

On Fri, May 16, 2025 at 1:58 PM larry via Discuss <

discuss@lists.openscad.org> wrote:

I'm trying to make a helper for lawn bowling, and the first order of

business is to make the attachment to fit a dollar store broom handle.

I have everything but the line with the comment working, and I am

wondering why my final line in the female() module is only rendering

the tube and not the cylinder.

//----------------------------

include <BOSL2/std.scad>

include <BOSL2/threading.scad>

$fn= $preview ? 60 : 180;

inch=25.4;

difference() {

female();

acme_threaded_rod(d=19.8, l=40, pitch=5.08);

}

module female() {

union() {

tube(id=17.05,od=22.6,h=25.4);

up(2.3) tube(id=22.7,od=27,h=30);

down(13.65) cylinder(h=1,d=27); // <---- Does not render

// renders fine here. but with 13.65mm of empty air above it before it

gets the to the

//main socket. is it supposed to be the bottom of the hole? And dollar

store handles

// do not come with square threads in these here parts.

I know. when I tried to find info about the thread, most of the ones

that came up has some sort or round thread. Here they are all acme, 2mm

pitch.

On Sat, 2025-05-17 at 01:19 -0400, gene heskett via Discuss wrote:

> On 5/16/25 17:06, Dan Perry via Discuss wrote:

> > It renders for me, but there's very little left after the difference(). I

> > think the value of 13.65 is not correct. For a design like this that's not

> > intended to be symmetrical on z-axis, I suggest anchoring to the X-Y plane

> > with ANCHOR=BOTTOM arguments. And use left_half() to see the cross section.

> > Dan

> >

> >

> >

> > On Fri, May 16, 2025 at 1:58 PM larry via Discuss <

> > discuss@lists.openscad.org> wrote:

> >

> > > I'm trying to make a helper for lawn bowling, and the first order of

> > > business is to make the attachment to fit a dollar store broom handle.

> > >

> > >

> > > I have everything but the line with the comment working, and I am

> > > wondering why my final line in the female() module is only rendering

> > > the tube and not the cylinder.

> > >

> > > //----------------------------

> > > include <BOSL2/std.scad>

> > > include <BOSL2/threading.scad>

> > > $fn= $preview ? 60 : 180;

> > >

> > > inch=25.4;

> > >

> > > difference() {

> > > female();

> > > acme_threaded_rod(d=19.8, l=40, pitch=5.08);

> > > }

> > >

> > > module female() {

> > > union() {

> > > tube(id=17.05,od=22.6,h=25.4);

> > > up(2.3) tube(id=22.7,od=27,h=30);

> > > # down(13.65) cylinder(h=1,d=27); // <---- Does not render

>

> // renders fine here. but with 13.65mm of empty air above it before it

> gets the to the

>

> //main socket. is it supposed to be the bottom of the hole? And dollar

> store handles

>

> // do not come with square threads in these here parts.

I know. when I tried to find info about the thread, most of the ones

that came up has some sort or round thread. Here they are all acme, 2mm

pitch.

GH

gene heskett

Sat, May 17, 2025 6:24 AM

On 5/17/25 01:35, larry via Discuss wrote:

On Sat, 2025-05-17 at 01:19 -0400, gene heskett via Discuss wrote:

On 5/16/25 17:06, Dan Perry via Discuss wrote:

It renders for me, but there's very little left after the difference(). I

think the value of 13.65 is not correct. For a design like this that's not

intended to be symmetrical on z-axis, I suggest anchoring to the X-Y plane

with ANCHOR=BOTTOM arguments. And use left_half() to see the cross section.

Dan

On Fri, May 16, 2025 at 1:58 PM larry via Discuss <

discuss@lists.openscad.org> wrote:

I'm trying to make a helper for lawn bowling, and the first order of

business is to make the attachment to fit a dollar store broom handle.

I have everything but the line with the comment working, and I am

wondering why my final line in the female() module is only rendering

the tube and not the cylinder.

//----------------------------

include <BOSL2/std.scad>

include <BOSL2/threading.scad>

$fn= $preview ? 60 : 180;

inch=25.4;

difference() {

female();

acme_threaded_rod(d=19.8, l=40, pitch=5.08);

}

module female() {

union() {

tube(id=17.05,od=22.6,h=25.4);

up(2.3) tube(id=22.7,od=27,h=30);

down(13.65) cylinder(h=1,d=27); // <---- Does not render

// renders fine here. but with 13.65mm of empty air above it before it

gets the to the

//main socket. is it supposed to be the bottom of the hole? And dollar

store handles

// do not come with square threads in these here parts.

I know. when I tried to find info about the thread, most of the ones

that came up has some sort or round thread. Here they are all acme, 2mm

pitch.

A not always optimum choice. Since these screw in to bottom out, a

buttress thread makes far more sense, but would have to be applied to

the broom handle too.

In your case a polygon describing the rounded shape would seen to make a

much stronger joint than square or even acme. Digitize a sine wave as

fine as the printer can render well, extrude it for the space needed,

and translate & rotate into position around the cylinder representing

the shank of the bolt. center=true. make the bolt bigger by the

diameter of the nozzle and use that expanded bolt to difference the half

nut into a block. 2 start threads then makes 2 identical half nuts.

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

On 5/17/25 01:35, larry via Discuss wrote:

> On Sat, 2025-05-17 at 01:19 -0400, gene heskett via Discuss wrote:

>> On 5/16/25 17:06, Dan Perry via Discuss wrote:

>>> It renders for me, but there's very little left after the difference(). I

>>> think the value of 13.65 is not correct. For a design like this that's not

>>> intended to be symmetrical on z-axis, I suggest anchoring to the X-Y plane

>>> with ANCHOR=BOTTOM arguments. And use left_half() to see the cross section.

>>> Dan

>>>

>>>

>>>

>>> On Fri, May 16, 2025 at 1:58 PM larry via Discuss <

>>> discuss@lists.openscad.org> wrote:

>>>

>>>> I'm trying to make a helper for lawn bowling, and the first order of

>>>> business is to make the attachment to fit a dollar store broom handle.

>>>>

>>>>

>>>> I have everything but the line with the comment working, and I am

>>>> wondering why my final line in the female() module is only rendering

>>>> the tube and not the cylinder.

>>>>

>>>> //----------------------------

>>>> include <BOSL2/std.scad>

>>>> include <BOSL2/threading.scad>

>>>> $fn= $preview ? 60 : 180;

>>>>

>>>> inch=25.4;

>>>>

>>>> difference() {

>>>> female();

>>>> acme_threaded_rod(d=19.8, l=40, pitch=5.08);

>>>> }

>>>>

>>>> module female() {

>>>> union() {

>>>> tube(id=17.05,od=22.6,h=25.4);

>>>> up(2.3) tube(id=22.7,od=27,h=30);

>>>> # down(13.65) cylinder(h=1,d=27); // <---- Does not render

>> // renders fine here. but with 13.65mm of empty air above it before it

>> gets the to the

>>

>> //main socket. is it supposed to be the bottom of the hole? And dollar

>> store handles

>>

>> // do not come with square threads in these here parts.

> I know. when I tried to find info about the thread, most of the ones

> that came up has some sort or round thread. Here they are all acme, 2mm

> pitch.

A not always optimum choice. Since these screw in to bottom out, a

buttress thread makes far more sense, but would have to be applied to

the broom handle too.

In your case a polygon describing the rounded shape would seen to make a

much stronger joint than square or even acme. Digitize a sine wave as

fine as the printer can render well, extrude it for the space needed,

and translate & rotate into position around the cylinder representing

the shank of the bolt. center=true. make the bolt bigger by the

diameter of the nozzle and use that expanded bolt to difference the half

nut into a block. 2 start threads then makes 2 identical half nuts.

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

Cheers, Gene Heskett, CET.

--

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

L

larry

Sat, May 17, 2025 6:45 PM

On Sat, 2025-05-17 at 02:24 -0400, gene heskett via Discuss wrote:

And dollar store handlesdo not come with square threads in these here parts.

I know. when I tried to find info about the thread, most of the ones

that came up has some sort or round thread. Here they are all acme, 2mm

pitch.

In your case a polygon describing the rounded shape would seen to make a

much stronger joint than square or even acme. Digitize a sine wave as

fine as the printer can render well, extrude it for the space needed,

and translate & rotate into position around the cylinder representing

the shank of the bolt. center=true. make the bolt bigger by the

diameter of the nozzle and use that expanded bolt to difference the half

nut into a block. 2 start threads then makes 2 identical half nuts.

Probably a better method, Gene, but I think I'll try my plan first.

The final results will be modified forms of these:

https://www.mastersofgames.com/cat/bowls/ubi-launcher-bowls-delivery-aid.htm

https://www.mastersofgames.com/cat/bowls/bowling-arm.htm

The part in my code was only a test to experiment with fit. the top

outer cylinder will be about 100mm long, and will serve to attach (in

the case of the UBI Launcher), wings connecting to the business end in

order to strengthen the part that pushes the bowl. The way I envision

it, printing it at an angle to orient the layer lines for strength,

should be strong enough.

The 'bowling arm' is the easiest one to use, and I think I can make it

strong enough.

On Sat, 2025-05-17 at 02:24 -0400, gene heskett via Discuss wrote:

> > > And dollar store handlesdo not come with square threads in these here parts.

> > I know. when I tried to find info about the thread, most of the ones

> > that came up has some sort or round thread. Here they are all acme, 2mm

> > pitch.

>

> In your case a polygon describing the rounded shape would seen to make a

> much stronger joint than square or even acme. Digitize a sine wave as

> fine as the printer can render well, extrude it for the space needed,

> and translate & rotate into position around the cylinder representing

> the shank of the bolt. center=true. make the bolt bigger by the

> diameter of the nozzle and use that expanded bolt to difference the half

> nut into a block. 2 start threads then makes 2 identical half nuts.

Probably a better method, Gene, but I think I'll try my plan first.

The final results will be modified forms of these:

<https://www.mastersofgames.com/cat/bowls/ubi-launcher-bowls-delivery-aid.htm>

<https://www.mastersofgames.com/cat/bowls/bowling-arm.htm>

The part in my code was only a test to experiment with fit. the top

outer cylinder will be about 100mm long, and will serve to attach (in

the case of the UBI Launcher), wings connecting to the business end in

order to strengthen the part that pushes the bowl. The way I envision

it, printing it at an angle to orient the layer lines for strength,

should be strong enough.

The 'bowling arm' is the easiest one to use, and I think I can make it

strong enough.

GH

gene heskett

Sat, May 17, 2025 8:25 PM

On 5/17/25 14:45, larry via Discuss wrote:

On Sat, 2025-05-17 at 02:24 -0400, gene heskett via Discuss wrote:

And dollar store handlesdo not come with square threads in these here parts.

I know. when I tried to find info about the thread, most of the ones

that came up has some sort or round thread. Here they are all acme, 2mm

pitch.

In your case a polygon describing the rounded shape would seen to make a

much stronger joint than square or even acme. Digitize a sine wave as

fine as the printer can render well, extrude it for the space needed,

and translate & rotate into position around the cylinder representing

the shank of the bolt. center=true. make the bolt bigger by the

diameter of the nozzle and use that expanded bolt to difference the half

nut into a block. 2 start threads then makes 2 identical half nuts.

I can easily see, at those prices, why you would like to print them,

saving at least $150 a copy. OTIH its also apparently a very low volume

endeavor at most any price due to its lack of player numbers.

I'm doing a similar thing, primarily because no other person has made a

similar product, but completed, its at least 2 man weeks of 16 hour

days per completed unit when I've only 1 printer, so first thing after

making the first 9 copies, is building bigger, faster printers. Printers

around 10x faster than the current offerings at $1000, Replacing steel,

alu etc moving parts with carbon fiber to reduce flying weight. And

using closed loop stepper/servos I can drive at much higher speeds with

micron accuracy. Much higher bed temps too, all of which cost money in

little red wagon loads but the first one does poloycarbonate like it was

PLA. So I'm getting there slowly as I'm now 90. And of course I'm well

aware that at 90 yo & a long term diabetic, I am running out of time.

I post not to discourage you, but to warn you that such an undertaking

can be a black hole for startup funds and a huge ongoing time sink. Its

quite a ways from idea to depositing checks in the bank. Good luck.

The part in my code was only a test to experiment with fit. the top

outer cylinder will be about 100mm long, and will serve to attach (in

the case of the UBI Launcher), wings connecting to the business end in

order to strengthen the part that pushes the bowl. The way I envision

it, printing it at an angle to orient the layer lines for strength,

should be strong enough.

The 'bowling arm' is the easiest one to use, and I think I can make it

strong enough.

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

On 5/17/25 14:45, larry via Discuss wrote:

> On Sat, 2025-05-17 at 02:24 -0400, gene heskett via Discuss wrote:

>>>> And dollar store handlesdo not come with square threads in these here parts.

>>> I know. when I tried to find info about the thread, most of the ones

>>> that came up has some sort or round thread. Here they are all acme, 2mm

>>> pitch.

>> In your case a polygon describing the rounded shape would seen to make a

>> much stronger joint than square or even acme. Digitize a sine wave as

>> fine as the printer can render well, extrude it for the space needed,

>> and translate & rotate into position around the cylinder representing

>> the shank of the bolt. center=true. make the bolt bigger by the

>> diameter of the nozzle and use that expanded bolt to difference the half

>> nut into a block. 2 start threads then makes 2 identical half nuts.

> Probably a better method, Gene, but I think I'll try my plan first.

>

> The final results will be modified forms of these:

> <https://www.mastersofgames.com/cat/bowls/ubi-launcher-bowls-delivery-aid.htm>

>

> <https://www.mastersofgames.com/cat/bowls/bowling-arm.htm>

I can easily see, at those prices, why you would like to print them,

saving at least $150 a copy. OTIH its also apparently a very low volume

endeavor at most any price due to its lack of player numbers.

I'm doing a similar thing, primarily because no other person has made a

similar product, but completed, its at least 2 man weeks of 16 hour

days per completed unit when I've only 1 printer, so first thing after

making the first 9 copies, is building bigger, faster printers. Printers

around 10x faster than the current offerings at $1000, Replacing steel,

alu etc moving parts with carbon fiber to reduce flying weight. And

using closed loop stepper/servos I can drive at much higher speeds with

micron accuracy. Much higher bed temps too, all of which cost money in

little red wagon loads but the first one does poloycarbonate like it was

PLA. So I'm getting there slowly as I'm now 90. And of course I'm well

aware that at 90 yo & a long term diabetic, I am running out of time.

I post not to discourage you, but to warn you that such an undertaking

can be a black hole for startup funds and a huge ongoing time sink. Its

quite a ways from idea to depositing checks in the bank. Good luck.

> The part in my code was only a test to experiment with fit. the top

> outer cylinder will be about 100mm long, and will serve to attach (in

> the case of the UBI Launcher), wings connecting to the business end in

> order to strengthen the part that pushes the bowl. The way I envision

> it, printing it at an angle to orient the layer lines for strength,

> should be strong enough.

>

> The 'bowling arm' is the easiest one to use, and I think I can make it

> strong enough.

>

>

>

> _______________________________________________

> OpenSCAD mailing list

> To unsubscribe send an email to discuss-leave@lists.openscad.org

Cheers, Gene Heskett, CET.

--

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis