dovetail.scad usage

Hi,

I am trying to use the module

https://github.com/hugokernel/OpenSCAD_Dovetail/blob/master/dovetail.scad

I have written two modules part1 and part2, which I was hoping would be 2

parts that have been cut using dovetail somewhere down the vertical part of

the square tube.

It hasn't come out like I wanted.

Does anybody have any idea why it's not worked or can give me any kind of

advice please?

Thanks,

Richard.

On 11/20/2024 9:48 AM, Richard Thomas via Discuss wrote:

I am trying to use the

module https://github.com/hugokernel/OpenSCAD_Dovetail/blob/master/dovetail.scad

I have written two modules part1 and part2, which I was hoping would

be 2 parts that have been cut using dovetail somewhere down the

vertical part of the square tube.

It hasn't come out like I wanted.

Does anybody have any idea why it's not worked or can give me any kind

of advice please?

And how are you calling it?

Does your program look something like the example given at

https://github.com/hugokernel/OpenSCAD_Dovetail/tree/master

?

Hi,

Yes, I'm calling it like in that example. I hoped my attachment of my scad

file came through.

Here's an extract of my code:

// Extract the first part...

module part1() {

intersection() {

whole_model();

cutter(position=[0, 0, 0], dimension=dimension, teeths=teeth,

male=false);

}

}

// ... and the second part

module part2() {

intersection() {

whole_model();

cutter(position=[0, 0, 0], dimension=dimension, teeths=teeth,

male=true);

}

}

part1();

part2();

Any ideas?

Thanks,

Richard.

On Wed, 20 Nov 2024 at 18:21, Jordan Brown openscad@jordan.maileater.net

wrote:

On 11/20/2024 9:48 AM, Richard Thomas via Discuss wrote:

I am trying to use the module

https://github.com/hugokernel/OpenSCAD_Dovetail/blob/master/dovetail.scad

I have written two modules part1 and part2, which I was hoping would be 2

parts that have been cut using dovetail somewhere down the vertical part of

the square tube.

It hasn't come out like I wanted.

Does anybody have any idea why it's not worked or can give me any kind of

advice please?

And how are you calling it?

Does your program look something like the example given at

https://github.com/hugokernel/OpenSCAD_Dovetail/tree/master

?

I missed the attachment, sorry.

TL;DR: put # in front of each cutter() invocation, and then look

carefully at the top of the transparent pink cutter.

First, I suggest that you carefully examine your base model. It has a

bunch of Z-fighting in the funnel section that makes it unclear what's

really going on, but when you render it it looks like one side is

totally open. Then the bottom of the funnel appears to be blocked. (Or

is it just a shovel, not a funnel?)

Then... remember how you're asking it to cut. You're going to end up

with a cut line roughly along the YZ plane, the X=0 plane, with the +Y

stuff in one part and the -Y stuff in the other part. But look at your

model - it has almost nothing in -Y. I suspect that you really want to

rotate the model 90° around X before cutting.

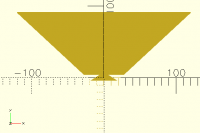

Next, put # in front of one of the cutter() invocations, and look

carefully at the shape it makes.

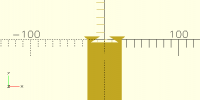

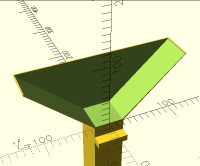

This is just part2(), with # in front of the cutter() call:

See those skinny triangular-ish shapes? Those are dovetails. But

there's only one tooth, and it's very wide and very shallow.

// Finally, setup the dovetail:

// - Teeth count

// - Teeth height

// - Teeth Clearance

teeth = [1, 8, 0];

Yep, one tooth, 8 units tall, and 250 units wide in X. Something funky

is going on with those teeth, probably caused by the various ratios.

Let's flop the model on its back and try some different dovetail parameters.

In both part1() and part2():

rotate([-90,0,0]) whole_model();

That requires rotating the bounding box too:

dimension = [250, 600, 150];

You kind of have to have the bounding box that big, so that the funnel

is inside of it, but it means that to get a reasonable tooth size you

have to have a lot more teeth.

teeth = [5, 8, 0];

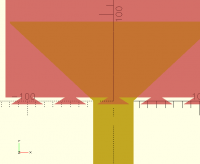

Looking from +Z, orthogonal:

Hey, getting close.

Let's look at the two resulting parts, zoomed in on the joint, from +Z

in orthogonal mode...

Looking plausible. I would be happier if the dovetail tooth was

narrower, but I don't immediately see a way to do that using this library.

You have it set for zero clearance. Mathematically correct, but your

printer has slop; if you have zero clearance you'll never get the parts

together. Experiment, but my guess is that you want about 0.1mm or

0.2mm. The library's example is 0.5mm; that seems like more than

necessary. You want a tight fit, especially on something like this

that's thin.

Actually printing this is not going to be fun, because those teeth are

going to be all overhang, not even bridges. Unless you really intended

that funnel to be open on one side, it's not going to be fun in this

orientation. The tube is better; 40mm is for me a long ways to bridge,

but not completely implausible.

You could print it vertically, and rotate the cutter so that it cuts

along the XY, Z=0 plane. That might make it easier to print.

What I would probably do, though, is to take some design hints from

plastic rain downspouts. Design in a couple of segments, printed

vertically (to avoid bridging). Print the bottom part, with the angled

tube, upside-down so that the angled part is an overhang, but not an

awful one. Have the lower segments widen out a little at the top so that

the upper segments nest inside them. (Not the other way 'round, if you

might handle water; you want the water to fall past the joint before it

has a chance to sneak through it.) That gets you lots of surface to

glue, and may make it a support-free print. I'm not sure what the

"resting block" is for; you might want to design so that it is at the

(as-printed) bottom of one segment or another, to avoid needing to

support it.

I hope that moves you along...