Is there a better way to do this?

Hello,

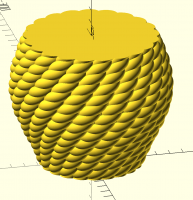

This design starts by rotating two or more overlapping circles around a

common center while extruding them upwards in the Z direction. The

resulting braided column is then duplicated around a larger diameter.

The outer diameter changes as a function of Z and the columns spiral

around that some number of degrees. Then the open center is filled with

a closed cylinder to make a solid.

The only way I can think of to change the diameter as a function of Z

and get the braided columns to spiral around is to create discrete

slices. The thinner the slices are the smoother the result. But I

always end up with something that takes many hours to generate an STL,

and contains a huge amount of geometry. Perhaps this is the only way to

achieve the result I want, but I would be interested in hearing about

alternative approaches, especially if they take less time. I usually

use a layer height (step) > 1.0 for testing, and no more than 0.2 for

the STL output.

Here's the code:

height=100; //height

ldiam=100; // large diameter

lrad=ldiam/2;

scols=20; // number of small columns

sdiam=8; // diameter of small circles

srad=sdiam/2;

sturns=3.0; // number of rotations of small circles

lturns=0.25; // number of turns for combined layers

covlp=0.20; // small circle overlap fraction

scircs=3; // number of small circles

step=1.2; // vertical layer interval

// calculated values

nstps=height/step; // total number of vertical steps

sdegr=360sturns; // number of degrees in sturns

ldegr=360lturns; // number of degrees in lturns

sdegrstp=sdegr/nstps; // number of degrees per step

ldegrstp=ldegr/nstps; // number of degrees per step

$fn=60;

// sine function values

ampl=20; // amplitude

ofs=lrad-ampl; // offset from 0

wl=height*2; // wavelength

shi=0; // shift in degrees

degr=150; // degree range

// calcualte size based on height

function siz(h)=(ofs+amplsin(degrh/height+shi));

// make the base 2d shape

module shape() {

for (c=[1:scircs]) {

rotate(360/scircsc)

translate([0,srad(1-covlp)])

circle(sdiam);

}

}

// make base shape 3d

module base_shape(h,s) {

// h = current height

// s = current step #, from 0

translate([0,0,h])

linear_extrude(height=step, twist=-sdegrstp)

rotate(s*sdegrstp)

shape();

}

module core(h,s) {

// h = vertical position

// s= scale factor

scale([s,s,1])

translate([0,0,h])

linear_extrude(height=step)

circle(d=ldiam);

}

module main(z,high) {

// z = starting position

// high = total height

translate([0,0,z])

for (p=[1:scols]) {

rotate(360/scols*p) {

//color("red") base();

for (h=[0:step:high]) {

s=siz(h)/lrad;

// adjust the profile shape

scale([s,s,1])

// twist as required

rotate(ldegrstp*h/step)

// shift to perimeter

translate([0,lrad,0])

// send height, step#

base_shape(h,h/step);

core(h,s);

}

}

}

}

main(0,height);

Regards,

Denver

It won't be fun, but you could construct each strand (of which I think

you have sixty) as a single polyhedron, then union them all. (Of

course, you only need one module that generates the polyhedron, and then

you call it with different parameters for where to start each strand in

a braided group, and generate the same braided group 20 times, rotated

each time.)

Pretty much, that means doing the same trigonometry that the various

rotates and translates would do, to generate the points, and then

connect them together appropriately.

You do want 60 distinct polyhedra, because you don't want to have to

figure out how to union them on your own.

You need to learn to write code, defining points in space rather than using

standard modules.

What you want is to create just 1 or 2 polyhedron strands and then

replicate them in some circular pattern.

On Sat, 13 Jul 2024 at 05:06, denverh via Discuss <

discuss@lists.openscad.org> wrote:

Hello,

This design starts by rotating two or more overlapping circles around a

common center while extruding them upwards in the Z direction. The

resulting braided column is then duplicated around a larger diameter.

The outer diameter changes as a function of Z and the columns spiral

around that some number of degrees. Then the open center is filled with

a closed cylinder to make a solid.

The only way I can think of to change the diameter as a function of Z

and get the braided columns to spiral around is to create discrete

slices. The thinner the slices are the smoother the result. But I

always end up with something that takes many hours to generate an STL,

and contains a huge amount of geometry. Perhaps this is the only way to

achieve the result I want, but I would be interested in hearing about

alternative approaches, especially if they take less time. I usually

use a layer height (step) > 1.0 for testing, and no more than 0.2 for

the STL output.

Here's the code:

height=100; //height

ldiam=100; // large diameter

lrad=ldiam/2;

scols=20; // number of small columns

sdiam=8; // diameter of small circles

srad=sdiam/2;

sturns=3.0; // number of rotations of small circles

lturns=0.25; // number of turns for combined layers

covlp=0.20; // small circle overlap fraction

scircs=3; // number of small circles

step=1.2; // vertical layer interval

// calculated values

nstps=height/step; // total number of vertical steps

sdegr=360sturns; // number of degrees in sturns

ldegr=360lturns; // number of degrees in lturns

sdegrstp=sdegr/nstps; // number of degrees per step

ldegrstp=ldegr/nstps; // number of degrees per step

$fn=60;

// sine function values

ampl=20; // amplitude

ofs=lrad-ampl; // offset from 0

wl=height*2; // wavelength

shi=0; // shift in degrees

degr=150; // degree range

// calcualte size based on height

function siz(h)=(ofs+amplsin(degrh/height+shi));

// make the base 2d shape

module shape() {

for (c=[1:scircs]) {

rotate(360/scircsc)

translate([0,srad(1-covlp)])

circle(sdiam);

}

}

// make base shape 3d

module base_shape(h,s) {

// h = current height

// s = current step #, from 0

translate([0,0,h])

linear_extrude(height=step, twist=-sdegrstp)

rotate(s*sdegrstp)

shape();

}

module core(h,s) {

// h = vertical position

// s= scale factor

scale([s,s,1])

translate([0,0,h])

linear_extrude(height=step)

circle(d=ldiam);

}

module main(z,high) {

// z = starting position

// high = total height

translate([0,0,z])

for (p=[1:scols]) {

rotate(360/scols*p) {

//color("red") base();

for (h=[0:step:high]) {

s=siz(h)/lrad;

// adjust the profile shape

scale([s,s,1])

// twist as required

rotate(ldegrstp*h/step)

// shift to perimeter

translate([0,lrad,0])

// send height, step#

base_shape(h,h/step);

core(h,s);

}

}

}

}

main(0,height);

Regards,

Denver

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Using BOSL2 you could do this pretty easily with sweep() I think or with

vnf_vertex_array() to make the object as a single polyhedron, perhaps.

On Fri, Jul 12, 2024 at 18:04 Sanjeev Prabhakar via Discuss <

discuss@lists.openscad.org> wrote:

You need to learn to write code, defining points in space rather than

using standard modules.

What you want is to create just 1 or 2 polyhedron strands and then

replicate them in some circular pattern.

On Sat, 13 Jul 2024 at 05:06, denverh via Discuss <

discuss@lists.openscad.org> wrote:

Hello,

This design starts by rotating two or more overlapping circles around a

common center while extruding them upwards in the Z direction. The

resulting braided column is then duplicated around a larger diameter.

The outer diameter changes as a function of Z and the columns spiral

around that some number of degrees. Then the open center is filled with

a closed cylinder to make a solid.

The only way I can think of to change the diameter as a function of Z

and get the braided columns to spiral around is to create discrete

slices. The thinner the slices are the smoother the result. But I

always end up with something that takes many hours to generate an STL,

and contains a huge amount of geometry. Perhaps this is the only way to

achieve the result I want, but I would be interested in hearing about

alternative approaches, especially if they take less time. I usually

use a layer height (step) > 1.0 for testing, and no more than 0.2 for

the STL output.

Here's the code:

height=100; //height

ldiam=100; // large diameter

lrad=ldiam/2;

scols=20; // number of small columns

sdiam=8; // diameter of small circles

srad=sdiam/2;

sturns=3.0; // number of rotations of small circles

lturns=0.25; // number of turns for combined layers

covlp=0.20; // small circle overlap fraction

scircs=3; // number of small circles

step=1.2; // vertical layer interval

// calculated values

nstps=height/step; // total number of vertical steps

sdegr=360sturns; // number of degrees in sturns

ldegr=360lturns; // number of degrees in lturns

sdegrstp=sdegr/nstps; // number of degrees per step

ldegrstp=ldegr/nstps; // number of degrees per step

$fn=60;

// sine function values

ampl=20; // amplitude

ofs=lrad-ampl; // offset from 0

wl=height*2; // wavelength

shi=0; // shift in degrees

degr=150; // degree range

// calcualte size based on height

function siz(h)=(ofs+amplsin(degrh/height+shi));

// make the base 2d shape

module shape() {

for (c=[1:scircs]) {

rotate(360/scircsc)

translate([0,srad(1-covlp)])

circle(sdiam);

}

}

// make base shape 3d

module base_shape(h,s) {

// h = current height

// s = current step #, from 0

translate([0,0,h])

linear_extrude(height=step, twist=-sdegrstp)

rotate(s*sdegrstp)

shape();

}

module core(h,s) {

// h = vertical position

// s= scale factor

scale([s,s,1])

translate([0,0,h])

linear_extrude(height=step)

circle(d=ldiam);

}

module main(z,high) {

// z = starting position

// high = total height

translate([0,0,z])

for (p=[1:scols]) {

rotate(360/scols*p) {

//color("red") base();

for (h=[0:step:high]) {

s=siz(h)/lrad;

// adjust the profile shape

scale([s,s,1])

// twist as required

rotate(ldegrstp*h/step)

// shift to perimeter

translate([0,lrad,0])

// send height, step#

base_shape(h,h/step);

core(h,s);

}

}

}

}

main(0,height);

Regards,

Denver

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

If you can break it down to slices of convex geometry (a single strand

having a circular cross section), then doing a hull of consecutive slices

works as a sort of sweep.

The linear extrude height is changed to some miniscule epsilon (to make a

technically 3d shape), and hull is done between two layers of the computed

shape.

height=100; //height

ldiam=100; // large diameter

lrad=ldiam/2;

scols=20; // number of small columns

sdiam=8; // diameter of small circles

srad=sdiam/2;

sturns=3.0; // number of rotations of small circles

lturns=0.25; // number of turns for combined layers

covlp=0.20; // small circle overlap fraction

scircs=3; // number of small circles

step=1.2; // vertical layer interval

// calculated values

nstps=height/step; // total number of vertical steps

sdegr=360sturns; // number of degrees in sturns

ldegr=360lturns; // number of degrees in lturns

sdegrstp=sdegr/nstps; // number of degrees per step

ldegrstp=ldegr/nstps; // number of degrees per step

$fn=60;

// sine function values

ampl=20; // amplitude

ofs=lrad-ampl; // offset from 0

wl=height*2; // wavelength

shi=0; // shift in degrees

degr=150; // degree range

// calcualte size based on height

function siz(h)=(ofs+amplsin(degrh/height+shi));

// make the base 2d shape

module shape(c) {

rotate(360/scircsc)

translate([0,srad(1-covlp)])

circle(sdiam);

}

// make base shape 3d

module base_shape(h,h2,s,s2,c) {

eps = 0.001;

// h = current height

// s = current step #, from 0

// c = circle index

hull() {

echo(h,h2,s,s2,c);

scale([s,s,1]) rotate(ldegrstp*h/step) translate([0,lrad,h])

linear_extrude(height=eps)

rotate(h/step*sdegrstp)

shape(c);

scale([s2,s2,1]) rotate(ldegrstp*h2/step) translate([0,lrad,h2-eps])

linear_extrude(height=eps)

rotate(h2/step*sdegrstp)

shape(c);

}

}

module core(h,s) {

// h = vertical position

// s= scale factor

scale([s,s,1])

translate([0,0,h])

linear_extrude(height=step)

circle(d=ldiam);

}

module main(z,high) {

// z = starting position

// high = total height

translate([0,0,z])

for (p=[1:scols]) {

rotate(360/scols*p) {

//color("red") base();

for(c=[1:scircs])

for(h=[0:step:high-step]) {

h2 = h+step;

s=siz(h)/lrad;

s2=siz(h2)/lrad;

// send height, step#

base_shape(h,h2,s,s2,c);

}

}

}

for(h=[0:step:high-step]) {

s=siz(h)/lrad;

core(h,s);

}

}

main(0,height);

On Fri, Jul 12, 2024 at 6:36 PM denverh via Discuss <

discuss@lists.openscad.org> wrote:

Hello,

This design starts by rotating two or more overlapping circles around a

common center while extruding them upwards in the Z direction. The

resulting braided column is then duplicated around a larger diameter.

The outer diameter changes as a function of Z and the columns spiral

around that some number of degrees. Then the open center is filled with

a closed cylinder to make a solid.

The only way I can think of to change the diameter as a function of Z

and get the braided columns to spiral around is to create discrete

slices. The thinner the slices are the smoother the result. But I

always end up with something that takes many hours to generate an STL,

and contains a huge amount of geometry. Perhaps this is the only way to

achieve the result I want, but I would be interested in hearing about

alternative approaches, especially if they take less time. I usually

use a layer height (step) > 1.0 for testing, and no more than 0.2 for

the STL output.

Here's the code:

height=100; //height

ldiam=100; // large diameter

lrad=ldiam/2;

scols=20; // number of small columns

sdiam=8; // diameter of small circles

srad=sdiam/2;

sturns=3.0; // number of rotations of small circles

lturns=0.25; // number of turns for combined layers

covlp=0.20; // small circle overlap fraction

scircs=3; // number of small circles

step=1.2; // vertical layer interval

// calculated values

nstps=height/step; // total number of vertical steps

sdegr=360sturns; // number of degrees in sturns

ldegr=360lturns; // number of degrees in lturns

sdegrstp=sdegr/nstps; // number of degrees per step

ldegrstp=ldegr/nstps; // number of degrees per step

$fn=60;

// sine function values

ampl=20; // amplitude

ofs=lrad-ampl; // offset from 0

wl=height*2; // wavelength

shi=0; // shift in degrees

degr=150; // degree range

// calcualte size based on height

function siz(h)=(ofs+amplsin(degrh/height+shi));

// make the base 2d shape

module shape() {

for (c=[1:scircs]) {

rotate(360/scircsc)

translate([0,srad(1-covlp)])

circle(sdiam);

}

}

// make base shape 3d

module base_shape(h,s) {

// h = current height

// s = current step #, from 0

translate([0,0,h])

linear_extrude(height=step, twist=-sdegrstp)

rotate(s*sdegrstp)

shape();

}

module core(h,s) {

// h = vertical position

// s= scale factor

scale([s,s,1])

translate([0,0,h])

linear_extrude(height=step)

circle(d=ldiam);

}

module main(z,high) {

// z = starting position

// high = total height

translate([0,0,z])

for (p=[1:scols]) {

rotate(360/scols*p) {

//color("red") base();

for (h=[0:step:high]) {

s=siz(h)/lrad;

// adjust the profile shape

scale([s,s,1])

// twist as required

rotate(ldegrstp*h/step)

// shift to perimeter

translate([0,lrad,0])

// send height, step#

base_shape(h,h/step);

core(h,s);

}

}

}

}

main(0,height);

Regards,

Denver

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Also the "core" was moved outside of the other loops so that it isn't

duplicated for every braid.

On Fri, Jul 12, 2024 at 11:00 PM Hans L thehans@gmail.com wrote:

If you can break it down to slices of convex geometry (a single strand

having a circular cross section), then doing a hull of consecutive slices

works as a sort of sweep.

The linear extrude height is changed to some miniscule epsilon (to make a

technically 3d shape), and hull is done between two layers of the computed

shape.

height=100; //height

ldiam=100; // large diameter

lrad=ldiam/2;

scols=20; // number of small columns

sdiam=8; // diameter of small circles

srad=sdiam/2;

sturns=3.0; // number of rotations of small circles

lturns=0.25; // number of turns for combined layers

covlp=0.20; // small circle overlap fraction

scircs=3; // number of small circles

step=1.2; // vertical layer interval

// calculated values

nstps=height/step; // total number of vertical steps

sdegr=360sturns; // number of degrees in sturns

ldegr=360lturns; // number of degrees in lturns

sdegrstp=sdegr/nstps; // number of degrees per step

ldegrstp=ldegr/nstps; // number of degrees per step

$fn=60;

// sine function values

ampl=20; // amplitude

ofs=lrad-ampl; // offset from 0

wl=height*2; // wavelength

shi=0; // shift in degrees

degr=150; // degree range

// calcualte size based on height

function siz(h)=(ofs+amplsin(degrh/height+shi));

// make the base 2d shape

module shape(c) {

rotate(360/scircsc)

translate([0,srad(1-covlp)])

circle(sdiam);

}

// make base shape 3d

module base_shape(h,h2,s,s2,c) {

eps = 0.001;

// h = current height

// s = current step #, from 0

// c = circle index

hull() {

echo(h,h2,s,s2,c);

scale([s,s,1]) rotate(ldegrstp*h/step) translate([0,lrad,h])

linear_extrude(height=eps)

rotate(h/step*sdegrstp)

shape(c);

scale([s2,s2,1]) rotate(ldegrstp*h2/step) translate([0,lrad,h2-eps])

linear_extrude(height=eps)

rotate(h2/step*sdegrstp)

shape(c);

}

}

module core(h,s) {

// h = vertical position

// s= scale factor

scale([s,s,1])

translate([0,0,h])

linear_extrude(height=step)

circle(d=ldiam);

}

module main(z,high) {

// z = starting position

// high = total height

translate([0,0,z])

for (p=[1:scols]) {

rotate(360/scols*p) {

//color("red") base();

for(c=[1:scircs])

for(h=[0:step:high-step]) {

h2 = h+step;

s=siz(h)/lrad;

s2=siz(h2)/lrad;

// send height, step#

base_shape(h,h2,s,s2,c);

}

}

}

for(h=[0:step:high-step]) {

s=siz(h)/lrad;

core(h,s);

}

}

main(0,height);

On Fri, Jul 12, 2024 at 6:36 PM denverh via Discuss <

discuss@lists.openscad.org> wrote:

Hello,

This design starts by rotating two or more overlapping circles around a

common center while extruding them upwards in the Z direction. The

resulting braided column is then duplicated around a larger diameter.

The outer diameter changes as a function of Z and the columns spiral

around that some number of degrees. Then the open center is filled with

a closed cylinder to make a solid.

The only way I can think of to change the diameter as a function of Z

and get the braided columns to spiral around is to create discrete

slices. The thinner the slices are the smoother the result. But I

always end up with something that takes many hours to generate an STL,

and contains a huge amount of geometry. Perhaps this is the only way to

achieve the result I want, but I would be interested in hearing about

alternative approaches, especially if they take less time. I usually

use a layer height (step) > 1.0 for testing, and no more than 0.2 for

the STL output.

Here's the code:

height=100; //height

ldiam=100; // large diameter

lrad=ldiam/2;

scols=20; // number of small columns

sdiam=8; // diameter of small circles

srad=sdiam/2;

sturns=3.0; // number of rotations of small circles

lturns=0.25; // number of turns for combined layers

covlp=0.20; // small circle overlap fraction

scircs=3; // number of small circles

step=1.2; // vertical layer interval

// calculated values

nstps=height/step; // total number of vertical steps

sdegr=360sturns; // number of degrees in sturns

ldegr=360lturns; // number of degrees in lturns

sdegrstp=sdegr/nstps; // number of degrees per step

ldegrstp=ldegr/nstps; // number of degrees per step

$fn=60;

// sine function values

ampl=20; // amplitude

ofs=lrad-ampl; // offset from 0

wl=height*2; // wavelength

shi=0; // shift in degrees

degr=150; // degree range

// calcualte size based on height

function siz(h)=(ofs+amplsin(degrh/height+shi));

// make the base 2d shape

module shape() {

for (c=[1:scircs]) {

rotate(360/scircsc)

translate([0,srad(1-covlp)])

circle(sdiam);

}

}

// make base shape 3d

module base_shape(h,s) {

// h = current height

// s = current step #, from 0

translate([0,0,h])

linear_extrude(height=step, twist=-sdegrstp)

rotate(s*sdegrstp)

shape();

}

module core(h,s) {

// h = vertical position

// s= scale factor

scale([s,s,1])

translate([0,0,h])

linear_extrude(height=step)

circle(d=ldiam);

}

module main(z,high) {

// z = starting position

// high = total height

translate([0,0,z])

for (p=[1:scols]) {

rotate(360/scols*p) {

//color("red") base();

for (h=[0:step:high]) {

s=siz(h)/lrad;

// adjust the profile shape

scale([s,s,1])

// twist as required

rotate(ldegrstp*h/step)

// shift to perimeter

translate([0,lrad,0])

// send height, step#

base_shape(h,h/step);

core(h,s);

}

}

}

}

main(0,height);

Regards,

Denver

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

I tried with my python method:

just a rough attempt: scad file is 4 mb so not fit to share here, but it f6

renders in few seconds.

[image: Screenshot 2024-07-13 at 10.38.25 PM.png]

On Sat, 13 Jul 2024 at 05:06, denverh via Discuss <

discuss@lists.openscad.org> wrote:

Hello,

This design starts by rotating two or more overlapping circles around a

common center while extruding them upwards in the Z direction. The

resulting braided column is then duplicated around a larger diameter.

The outer diameter changes as a function of Z and the columns spiral

around that some number of degrees. Then the open center is filled with

a closed cylinder to make a solid.

The only way I can think of to change the diameter as a function of Z

and get the braided columns to spiral around is to create discrete

slices. The thinner the slices are the smoother the result. But I

always end up with something that takes many hours to generate an STL,

and contains a huge amount of geometry. Perhaps this is the only way to

achieve the result I want, but I would be interested in hearing about

alternative approaches, especially if they take less time. I usually

use a layer height (step) > 1.0 for testing, and no more than 0.2 for

the STL output.

Here's the code:

height=100; //height

ldiam=100; // large diameter

lrad=ldiam/2;

scols=20; // number of small columns

sdiam=8; // diameter of small circles

srad=sdiam/2;

sturns=3.0; // number of rotations of small circles

lturns=0.25; // number of turns for combined layers

covlp=0.20; // small circle overlap fraction

scircs=3; // number of small circles

step=1.2; // vertical layer interval

// calculated values

nstps=height/step; // total number of vertical steps

sdegr=360sturns; // number of degrees in sturns

ldegr=360lturns; // number of degrees in lturns

sdegrstp=sdegr/nstps; // number of degrees per step

ldegrstp=ldegr/nstps; // number of degrees per step

$fn=60;

// sine function values

ampl=20; // amplitude

ofs=lrad-ampl; // offset from 0

wl=height*2; // wavelength

shi=0; // shift in degrees

degr=150; // degree range

// calcualte size based on height

function siz(h)=(ofs+amplsin(degrh/height+shi));

// make the base 2d shape

module shape() {

for (c=[1:scircs]) {

rotate(360/scircsc)

translate([0,srad(1-covlp)])

circle(sdiam);

}

}

// make base shape 3d

module base_shape(h,s) {

// h = current height

// s = current step #, from 0

translate([0,0,h])

linear_extrude(height=step, twist=-sdegrstp)

rotate(s*sdegrstp)

shape();

}

module core(h,s) {

// h = vertical position

// s= scale factor

scale([s,s,1])

translate([0,0,h])

linear_extrude(height=step)

circle(d=ldiam);

}

module main(z,high) {

// z = starting position

// high = total height

translate([0,0,z])

for (p=[1:scols]) {

rotate(360/scols*p) {

//color("red") base();

for (h=[0:step:high]) {

s=siz(h)/lrad;

// adjust the profile shape

scale([s,s,1])

// twist as required

rotate(ldegrstp*h/step)

// shift to perimeter

translate([0,lrad,0])

// send height, step#

base_shape(h,h/step);

core(h,s);

}

}

}

}

main(0,height);

Regards,

Denver

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On 7/12/24 21:02, Hans L via Discuss wrote:

Also the "core" was moved outside of the other loops so that it isn't

duplicated for every braid.

On Fri, Jul 12, 2024 at 11:00 PM Hans L thehans@gmail.com wrote:

If you can break it down to slices of convex geometry (a single

strand having a circular cross section), then doing a hull of

consecutive slices works as a sort of sweep.

The linear extrude height is changed to some miniscule epsilon (to

make a technically 3d shape), and hull is done between two layers

of the computed shape.

Thanks, this works well. I began the project this way, but when I began

making the changes for scaling the outer diameter and spiraling the

braids around it, I somehow couldn't get past the idea that I had to

operate on the cross-section of the braid, rather than a strand. Since

the braid is partly concave, I couldn't use hull(), so I fell back on

thin slices. With the larger step size, this now takes 15 to 20 minutes

instead of 15 to 20 hours.

And thanks to everyone who responded with helpful suggestions. They're

all appreciated. Sanjeev's results are impressive indeed. I have read a

few articles about creating models that way, but it's a bit beyond my

current level of ability with OpenSCAD. Definitely something to keep in

mind for the future, though.

Thanks again everyone!

Denver

By the way, if you run a recent development snapshot from here:

https://openscad.org/downloads#snapshots

and enable "Manifold" in the experimental features preferences, then it

renders in about 1 second at the current detail level.

On Sat, Jul 13, 2024 at 5:28 PM denverh via Discuss <

discuss@lists.openscad.org> wrote:

On 7/12/24 21:02, Hans L via Discuss wrote:

Also the "core" was moved outside of the other loops so that it isn't

duplicated for every braid.

On Fri, Jul 12, 2024 at 11:00 PM Hans L thehans@gmail.com wrote:

If you can break it down to slices of convex geometry (a single strand

having a circular cross section), then doing a hull of consecutive slices

works as a sort of sweep.

The linear extrude height is changed to some miniscule epsilon (to make a

technically 3d shape), and hull is done between two layers of the computed

shape.

Thanks, this works well. I began the project this way, but when I began

making the changes for scaling the outer diameter and spiraling the braids

around it, I somehow couldn't get past the idea that I had to operate on

the cross-section of the braid, rather than a strand. Since the braid is

partly concave, I couldn't use hull(), so I fell back on thin slices. With

the larger step size, this now takes 15 to 20 minutes instead of 15 to 20

hours.

And thanks to everyone who responded with helpful suggestions. They're

all appreciated. Sanjeev's results are impressive indeed. I have read a

few articles about creating models that way, but it's a bit beyond my

current level of ability with OpenSCAD. Definitely something to keep in

mind for the future, though.

Thanks again everyone!

Denver

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

On 7/13/24 16:19, Hans L via Discuss wrote:

By the way, if you run a recent development snapshot from here:

https://openscad.org/downloads#snapshots

and enable "Manifold" in the experimental features preferences, then

it renders in about 1 second at the current detail level.

I'll give that a try, thanks!

On Sat, Jul 13, 2024 at 5:28 PM denverh via Discuss

discuss@lists.openscad.org wrote:

On 7/12/24 21:02, Hans L via Discuss wrote:

Also the "core" was moved outside of the other loops so that it

isn't duplicated for every braid.

On Fri, Jul 12, 2024 at 11:00 PM Hans L <thehans@gmail.com> wrote:

If you can break it down to slices of convex geometry (a

single strand having a circular cross section), then doing a

hull of consecutive slices works as a sort of sweep.

The linear extrude height is changed to some miniscule

epsilon (to make a technically 3d shape), and hull is done

between two layers of the computed shape.

Thanks, this works well. I began the project this way, but when I

began making the changes for scaling the outer diameter and

spiraling the braids around it, I somehow couldn't get past the

idea that I had to operate on the cross-section of the braid,

rather than a strand. Since the braid is partly concave, I

couldn't use hull(), so I fell back on thin slices. With the

larger step size, this now takes 15 to 20 minutes instead of 15 to

20 hours.

And thanks to everyone who responded with helpful suggestions.

They're all appreciated. Sanjeev's results are impressive

indeed. I have read a few articles about creating models that

way, but it's a bit beyond my current level of ability with

OpenSCAD. Definitely something to keep in mind for the future,

though.

Thanks again everyone!

Denver

_______________________________________________

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org