Re: sweep in BOSL2

Thought I share the result of the vase design that I showed earlier. Birthday present for my 94 year old mother. Needed a LOT of support for the tubes. I decided to leave the bottom open so that it would be easier to remove after printing. Still turned out that the tubes leaked on the places where the support had been. Fixed this with some superglue.

Made with BOSL2 absolute magic prism_connector ... that is an amazing piece of software.

It did take 3.5 days to print it out.

Peter

On Fri, Oct 3, 2025 at 10:10 AM Roger Whiteley <roger.whiteley@me.com mailto:roger.whiteley@me.com> wrote:

Now printing that is going to be fun.

You could cheat and print it using a Resin printer using a transparent material would show off the structure. I'm sure there are 3d resin printing services around if you don't have one, I don't, just a roomful of Creality's.

Print it in two halves as per your section and solvent weld them together, with some location tabs on one side to strengthen the joint and provide some location. [the same tricks used in the injection moulding process], nophead posted on his blog about using the solvent adhesive used by plumbers to assemble an air vent system.

Or you could try putting a couple of thin webs underneath the centre of each tube, wide enough to get the vertical angles / bridging a bit more manageable. If you need to have water sloshing around inside, just put some holes in the webs.

Roger

On 30/09/2025 15:13, Peter Kriens wrote:

But yeah, I was just using the geometry because the model has a user friendly angle across the top, for the display, and I don't have a VNF.

It is because the 'user friendly angles' I love the attachment model of BOSL2. My friendly angles always become foes when my model grows :-( And you don't need a VNF to work with attachments. The fact that you can is a great compliment to the skills of Adrian & Revar but all common geometries like cubes, prisma's spheres, cylinders, tubes, torus, path sweeps, etc. are directly supported. Initially I was too afraid of the model to make my own components 'attachable' but it turns out that that is much easier than I thought and lets your component play along in the buildup of bigger components.

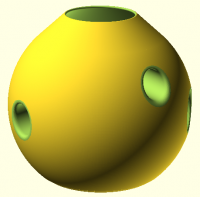

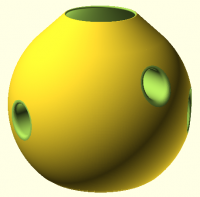

I wouldn't even know where to start doing the following model (a vase as birthday present for my 94 year old mother ...) with trigonometry... It uses the 'prism_connector' and the 'parts' that Adrian recently added. I therefore only need to specify where I want the holes and their size and the tubes and roundings are automatically calculated. It really feels like magic.

<PastedGraphic-1.png><PastedGraphic-3.png>

And yes, getting rid of the Breakaway filament will be hell :-( And I've not been able to print with PVA yet, it always seems to fail.

But it is arguably true that the learning curve of BOSL2 is quite steep. The documentation is excellent but it is so big and wide that you often miss the essence when you first start with a topic.

Peter

Beautiful! How much filament, and what did you print it on?

Jon

On 10/16/2025 10:42 AM, Peter Kriens via Discuss wrote:

Thought I share the result of the vase design that I showed earlier.

Birthday present for my 94 year old mother. Needed a LOT of support

for the tubes. I decided to leave the bottom open so that it would be

easier to remove after printing. Still turned out that the tubes

leaked on the places where the support had been. Fixed this with some

superglue.

Made with BOSL2 absolute magic prism_connector ... that is an amazing

piece of software.

It did take 3.5 days to print it out.

Peter

image.png

image.png

image.png

On Fri, Oct 3, 2025 at 10:10 AM Roger Whiteley

roger.whiteley@me.com wrote:

Now printing that is going to be fun.

You could cheat and print it using a Resin printer using a

transparent material would show off the structure. I'm sure there

are 3d resin printing services around if you don't have one, I

don't, just a roomful of Creality's.

Print it in two halves as per your section and solvent weld them

together, with some location tabs on one side to strengthen the

joint and provide some location. [the same tricks used in the

injection moulding process], nophead posted on his blog about

using the solvent adhesive used by plumbers to assemble an air

vent system.

Or you could try putting a couple of thin webs underneath the

centre of each tube, wide enough to get the vertical angles /

bridging a bit more manageable. If you need to have water

sloshing around inside, just put some holes in the webs.

Roger

On 30/09/2025 15:13, Peter Kriens wrote:

But yeah, I was just using the geometry because the model has a

user friendly angle across the top, for the display, and I

don't have a VNF.

It is because the 'user friendly angles' I love the attachment

model of BOSL2. My friendly angles always become foes when my

model grows :-( And you don't need a VNF to work with

attachments. The fact that you can is a great compliment to the

skills of Adrian & Revar but all common geometries like cubes,

prisma's spheres, cylinders, tubes, torus, path sweeps, etc. are

directly supported. Initially I was too afraid of the model to

make my own components 'attachable' but it turns out that that

is much easier than I thought and lets your component play along

in the buildup of bigger components.

I wouldn't even know where to start doing the following model (a

vase as birthday present for my 94 year old mother ...) with

trigonometry... It uses the 'prism_connector' and the 'parts'

that Adrian recently added. I therefore only need to specify

where I want the holes and their size and the tubes and

roundings are automatically calculated. It really feels like magic.

<PastedGraphic-1.png><PastedGraphic-3.png>

And yes, getting rid of the Breakaway filament will be hell :-(

And I've not been able to print with PVA yet, it always seems to

fail.

But it is arguably true that the learning curve of BOSL2 is

quite steep. The documentation is excellent but it is so big and

wide that you often miss the essence when you first start with a

topic.

Peter

OpenSCAD mailing list

To unsubscribe send an email todiscuss-leave@lists.openscad.org

--

This email has been checked for viruses by AVG antivirus software.

www.avg.com

I used HT Black from ColorFabb https://colorfabb.com/ht-black (printing temp 270 C/120 C plate). Including support it was about 700gram. I had ordered 2kg some time ago for a project where I needed food safety and it is said to be 'FDA Food Contact Compliant' (whatever that means).

I find it not easy to print, it gets elephant feet very easy and for larger rectangular objects it warps too easy. So I had to abandon that project. So I had a about 1.5kg left ...

Peter

On 16 Oct 2025, at 17:01, Jon Bondy jon@jonbondy.com wrote:

Beautiful! How much filament, and what did you print it on?

Jon

On 10/16/2025 10:42 AM, Peter Kriens via Discuss wrote:

Thought I share the result of the vase design that I showed earlier. Birthday present for my 94 year old mother. Needed a LOT of support for the tubes. I decided to leave the bottom open so that it would be easier to remove after printing. Still turned out that the tubes leaked on the places where the support had been. Fixed this with some superglue.

Made with BOSL2 absolute magic prism_connector ... that is an amazing piece of software.

It did take 3.5 days to print it out.

Peter

<image.png>

<image.png>

<image.png>

On Fri, Oct 3, 2025 at 10:10 AM Roger Whiteley <roger.whiteley@me.com mailto:roger.whiteley@me.com> wrote:

Now printing that is going to be fun.

You could cheat and print it using a Resin printer using a transparent material would show off the structure. I'm sure there are 3d resin printing services around if you don't have one, I don't, just a roomful of Creality's.

Print it in two halves as per your section and solvent weld them together, with some location tabs on one side to strengthen the joint and provide some location. [the same tricks used in the injection moulding process], nophead posted on his blog about using the solvent adhesive used by plumbers to assemble an air vent system.

Or you could try putting a couple of thin webs underneath the centre of each tube, wide enough to get the vertical angles / bridging a bit more manageable. If you need to have water sloshing around inside, just put some holes in the webs.

Roger

On 30/09/2025 15:13, Peter Kriens wrote:

But yeah, I was just using the geometry because the model has a user friendly angle across the top, for the display, and I don't have a VNF.

It is because the 'user friendly angles' I love the attachment model of BOSL2. My friendly angles always become foes when my model grows :-( And you don't need a VNF to work with attachments. The fact that you can is a great compliment to the skills of Adrian & Revar but all common geometries like cubes, prisma's spheres, cylinders, tubes, torus, path sweeps, etc. are directly supported. Initially I was too afraid of the model to make my own components 'attachable' but it turns out that that is much easier than I thought and lets your component play along in the buildup of bigger components.

I wouldn't even know where to start doing the following model (a vase as birthday present for my 94 year old mother ...) with trigonometry... It uses the 'prism_connector' and the 'parts' that Adrian recently added. I therefore only need to specify where I want the holes and their size and the tubes and roundings are automatically calculated. It really feels like magic.

<PastedGraphic-1.png><PastedGraphic-3.png>

And yes, getting rid of the Breakaway filament will be hell :-( And I've not been able to print with PVA yet, it always seems to fail.

But it is arguably true that the learning curve of BOSL2 is quite steep. The documentation is excellent but it is so big and wide that you often miss the essence when you first start with a topic.

Peter

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org mailto:discuss-leave@lists.openscad.org

What printer? I can print 700 grams in about 15 hours on my Peopoly Magneto X. Your 3.5 days seems slow, at least by today's standards.

Just curious

Jon

On 10/17/2025 4:01 AM, Peter Kriens wrote:

I used HT Black from ColorFabbhttps://urldefense.proofpoint.com/v2/url?u=https-3A__colorfabb.com_ht-2Dblack&d=DwMFaQ&c=euGZstcaTDllvimEN8b7jXrwqOf-v5A_CdpgnVfiiMM&r=AsrE-c7ZR7B2Kyr3qgfvvppkCEBVsNmwEMndcrRSuOI&m=3ZddtPEOGbAcQaIN2qdw90Mt34iqS0ImkXwUWut-Hih1wwlvxQKDbP9UXNi95I8p&s=EmVd8nE_7A28lhSzXSHdUCsLKRf-jOYKgwr4fM1wHG0&e= (printing temp 270 C/120 C plate). Including support it was about 700gram. I had ordered 2kg some time ago for a project where I needed food safety and it is said to be 'FDA Food Contact Compliant' (whatever that means).

I find it not easy to print, it gets elephant feet very easy and for larger rectangular objects it warps too easy. So I had to abandon that project. So I had a about 1.5kg left ...

Peter

On 16 Oct 2025, at 17:01, Jon Bondy jon@jonbondy.commailto:jon@jonbondy.com wrote:

Beautiful! How much filament, and what did you print it on?

Jon

On 10/16/2025 10:42 AM, Peter Kriens via Discuss wrote:

Thought I share the result of the vase design that I showed earlier. Birthday present for my 94 year old mother. Needed a LOT of support for the tubes. I decided to leave the bottom open so that it would be easier to remove after printing. Still turned out that the tubes leaked on the places where the support had been. Fixed this with some superglue.

Made with BOSL2 absolute magic prism_connector ... that is an amazing piece of software.

It did take 3.5 days to print it out.

Peter

<image.png>

<image.png>

<image.png>

On Fri, Oct 3, 2025 at 10:10 AM Roger Whiteley <roger.whiteley@me.commailto:roger.whiteley@me.com> wrote:

Now printing that is going to be fun.

You could cheat and print it using a Resin printer using a transparent material would show off the structure. I'm sure there are 3d resin printing services around if you don't have one, I don't, just a roomful of Creality's.

Print it in two halves as per your section and solvent weld them together, with some location tabs on one side to strengthen the joint and provide some location. [the same tricks used in the injection moulding process], nophead posted on his blog about using the solvent adhesive used by plumbers to assemble an air vent system.

Or you could try putting a couple of thin webs underneath the centre of each tube, wide enough to get the vertical angles / bridging a bit more manageable. If you need to have water sloshing around inside, just put some holes in the webs.

Roger

On 30/09/2025 15:13, Peter Kriens wrote:

But yeah, I was just using the geometry because the model has a user friendly angle across the top, for the display, and I don't have a VNF.

It is because the 'user friendly angles' I love the attachment model of BOSL2. My friendly angles always become foes when my model grows :-( And you don't need a VNF to work with attachments. The fact that you can is a great compliment to the skills of Adrian & Revar but all common geometries like cubes, prisma's spheres, cylinders, tubes, torus, path sweeps, etc. are directly supported. Initially I was too afraid of the model to make my own components 'attachable' but it turns out that that is much easier than I thought and lets your component play along in the buildup of bigger components.

I wouldn't even know where to start doing the following model (a vase as birthday present for my 94 year old mother ...) with trigonometry... It uses the 'prism_connector' and the 'parts' that Adrian recently added. I therefore only need to specify where I want the holes and their size and the tubes and roundings are automatically calculated. It really feels like magic.

<PastedGraphic-1.png><PastedGraphic-3.png>

And yes, getting rid of the Breakaway filament will be hell :-( And I've not been able to print with PVA yet, it always seems to fail.

But it is arguably true that the learning curve of BOSL2 is quite steep. The documentation is excellent but it is so big and wide that you often miss the essence when you first start with a topic.

Peter

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.orgmailto:discuss-leave@lists.openscad.org

[https://s-install.avcdn.net/ipm/preview/icons/icon-envelope-tick-green-avg-v1.png]https://urldefense.proofpoint.com/v2/url?u=http-3A__www.avg.com_email-2Dsignature-3Futm-5Fmedium-3Demail-26utm-5Fsource-3Dlink-26utm-5Fcampaign-3Dsig-2Demail-26utm-5Fcontent-3Demailclient&d=DwMFaQ&c=euGZstcaTDllvimEN8b7jXrwqOf-v5A_CdpgnVfiiMM&r=AsrE-c7ZR7B2Kyr3qgfvvppkCEBVsNmwEMndcrRSuOI&m=3ZddtPEOGbAcQaIN2qdw90Mt34iqS0ImkXwUWut-Hih1wwlvxQKDbP9UXNi95I8p&s=i1CMpPky6pn7m-yeKEVNgOgNDB_nNjjGoLhJu06kkZA&e= Virus-free.www.avg.comhttps://urldefense.proofpoint.com/v2/url?u=http-3A__www.avg.com_email-2Dsignature-3Futm-5Fmedium-3Demail-26utm-5Fsource-3Dlink-26utm-5Fcampaign-3Dsig-2Demail-26utm-5Fcontent-3Demailclient&d=DwMFaQ&c=euGZstcaTDllvimEN8b7jXrwqOf-v5A_CdpgnVfiiMM&r=AsrE-c7ZR7B2Kyr3qgfvvppkCEBVsNmwEMndcrRSuOI&m=3ZddtPEOGbAcQaIN2qdw90Mt34iqS0ImkXwUWut-Hih1wwlvxQKDbP9UXNi95I8p&s=i1CMpPky6pn7m-yeKEVNgOgNDB_nNjjGoLhJu06kkZA&e=

On Fri, Oct 17, 2025 at 11:04:05AM +0000, jon jonbondy.com via Discuss wrote:

What printer? I can print 700 grams in about 15 hours on my Peopoly

Magneto X. Your 3.5 days seems slow, at least by today's standards.

Not everyone can upgrade to a "modern" printer once a

newer-beter-faster printer comes out.

I have two 1kg/day printers that are cheaper than the modern, faster

printers. Quality and speed is "sufficient" for my purposes.

A 3.5 day printjob every now and then is acceptable as long as your

printer isn't nearing 100% utilization.

Roger.

--

** R.E.Wolff@BitWizard.nl ** https://www.BitWizard.nl/ ** +31-15-2049110 **

** Verl. Spiegelmakerstraat 37 2645 LZ Delfgauw, The Netherlands.

** KVK: 27239233 **

f equals m times a. When your f is steady, and your m is going down

your a** is going up. -- Chris Hadfield about flying up the space shuttle.

** 'a' for accelleration.

On 10/17/25 07:04, jon jonbondy.com via Discuss wrote:

What printer? I can print 700 grams in about 15 hours on my Peopoly Magneto X. Your 3.5 days seems slow, at least by today's standards.

Just curious

Jon

So can I or even faster. OTOH I probably have $6000 in 3 printers, two

of which I've rebuilt. My present speed limit pf 15mm of filament a

second is how fast a 60 watt hotend heater can melt plastic. I start by

triangulating frames, then replace heavy flying parts with carbon fiber

tubing, additional bed voltage and stepper/servo XY motors running on 72

volts. And I make my own hot end assemblies. I don't have any clogged

nozzles. With the additional bed heat I can do polycarbonate like most

do PLA on 2 or them. No input shaping. Those motors do EXACTLY,

PRECISELY what they are told to do. Hanpose makes those motors and smart

external drivers.

On 10/17/2025 4:01 AM, Peter Kriens wrote:

I used HT Black from ColorFabbhttps://urldefense.proofpoint.com/v2/url?u=https-3A__colorfabb.com_ht-2Dblack&d=DwMFaQ&c=euGZstcaTDllvimEN8b7jXrwqOf-v5A_CdpgnVfiiMM&r=AsrE-c7ZR7B2Kyr3qgfvvppkCEBVsNmwEMndcrRSuOI&m=3ZddtPEOGbAcQaIN2qdw90Mt34iqS0ImkXwUWut-Hih1wwlvxQKDbP9UXNi95I8p&s=EmVd8nE_7A28lhSzXSHdUCsLKRf-jOYKgwr4fM1wHG0&e= (printing temp 270 C/120 C plate). Including support it was about 700gram. I had ordered 2kg some time ago for a project where I needed food safety and it is said to be 'FDA Food Contact Compliant' (whatever that means).

That sound like polycarb, which I do at 285C & 120C. Pricey stuff.

I find it not easy to print, it gets elephant feet very easy and for larger rectangular objects it warps too easy. So I had to abandon that project. So I had a about 1.5kg left ...

Peter

On 16 Oct 2025, at 17:01, Jon Bondy jon@jonbondy.commailto:jon@jonbondy.com wrote:

Beautiful! How much filament, and what did you print it on?

Jon

On 10/16/2025 10:42 AM, Peter Kriens via Discuss wrote:

Thought I share the result of the vase design that I showed earlier. Birthday present for my 94 year old mother. Needed a LOT of support for the tubes. I decided to leave the bottom open so that it would be easier to remove after printing. Still turned out that the tubes leaked on the places where the support had been. Fixed this with some superglue.

Made with BOSL2 absolute magic prism_connector ... that is an amazing piece of software.

It did take 3.5 days to print it out.

Peter

<image.png>

<image.png>

<image.png>

On Fri, Oct 3, 2025 at 10:10 AM Roger Whiteley <roger.whiteley@me.commailto:roger.whiteley@me.com> wrote:

Now printing that is going to be fun.

You could cheat and print it using a Resin printer using a transparent material would show off the structure. I'm sure there are 3d resin printing services around if you don't have one, I don't, just a roomful of Creality's.

Print it in two halves as per your section and solvent weld them together, with some location tabs on one side to strengthen the joint and provide some location. [the same tricks used in the injection moulding process], nophead posted on his blog about using the solvent adhesive used by plumbers to assemble an air vent system.

Or you could try putting a couple of thin webs underneath the centre of each tube, wide enough to get the vertical angles / bridging a bit more manageable. If you need to have water sloshing around inside, just put some holes in the webs.

Roger

On 30/09/2025 15:13, Peter Kriens wrote:

But yeah, I was just using the geometry because the model has a user friendly angle across the top, for the display, and I don't have a VNF.

It is because the 'user friendly angles' I love the attachment model of BOSL2. My friendly angles always become foes when my model grows :-( And you don't need a VNF to work with attachments. The fact that you can is a great compliment to the skills of Adrian & Revar but all common geometries like cubes, prisma's spheres, cylinders, tubes, torus, path sweeps, etc. are directly supported. Initially I was too afraid of the model to make my own components 'attachable' but it turns out that that is much easier than I thought and lets your component play along in the buildup of bigger components.

I wouldn't even know where to start doing the following model (a vase as birthday present for my 94 year old mother ...) with trigonometry... It uses the 'prism_connector' and the 'parts' that Adrian recently added. I therefore only need to specify where I want the holes and their size and the tubes and roundings are automatically calculated. It really feels like magic.

<PastedGraphic-1.png><PastedGraphic-3.png>

And yes, getting rid of the Breakaway filament will be hell :-( And I've not been able to print with PVA yet, it always seems to fail.

But it is arguably true that the learning curve of BOSL2 is quite steep. The documentation is excellent but it is so big and wide that you often miss the essence when you first start with a topic.

Peter

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.orgmailto:discuss-leave@lists.openscad.org

[https://s-install.avcdn.net/ipm/preview/icons/icon-envelope-tick-green-avg-v1.png]https://urldefense.proofpoint.com/v2/url?u=http-3A__www.avg.com_email-2Dsignature-3Futm-5Fmedium-3Demail-26utm-5Fsource-3Dlink-26utm-5Fcampaign-3Dsig-2Demail-26utm-5Fcontent-3Demailclient&d=DwMFaQ&c=euGZstcaTDllvimEN8b7jXrwqOf-v5A_CdpgnVfiiMM&r=AsrE-c7ZR7B2Kyr3qgfvvppkCEBVsNmwEMndcrRSuOI&m=3ZddtPEOGbAcQaIN2qdw90Mt34iqS0ImkXwUWut-Hih1wwlvxQKDbP9UXNi95I8p&s=i1CMpPky6pn7m-yeKEVNgOgNDB_nNjjGoLhJu06kkZA&e= Virus-free.www.avg.comhttps://urldefense.proofpoint.com/v2/url?u=http-3A__www.avg.com_email-2Dsignature-3Futm-5Fmedium-3Demail-26utm-5Fsource-3Dlink-26utm-5Fcampaign-3Dsig-2Demail-26utm-5Fcontent-3Demailclient&d=DwMFaQ&c=euGZstcaTDllvimEN8b7jXrwqOf-v5A_CdpgnVfiiMM&r=AsrE-c7ZR7B2Kyr3qgfvvppkCEBVsNmwEMndcrRSuOI&m=3ZddtPEOGbAcQaIN2qdw90Mt34iqS0ImkXwUWut-Hih1wwlvxQKDbP9UXNi95I8p&s=i1CMpPky6pn7m-yeKEVNgOgNDB_nNjjGoLhJu06kkZA&e=

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org

Cheers, Gene Heskett, CET.

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author, 1940)

If we desire respect for the law, we must first make the law respectable.

- Louis D. Brandeis

Don't poison our oceans, interdict drugs at the src.

It is an couple of years old Ultimaker S3. Bu the material had a max speed 30 - 50 mm/s.

This was the longest print ever for me :-)

Peter

On 17 Oct 2025, at 13:04, jon jonbondy.com jon@jonbondy.com wrote:

What printer? I can print 700 grams in about 15 hours on my Peopoly Magneto X. Your 3.5 days seems slow, at least by today's standards.

Just curious

Jon

On 10/17/2025 4:01 AM, Peter Kriens wrote:

I used HT Black from ColorFabb https://urldefense.proofpoint.com/v2/url?u=https-3A__colorfabb.com_ht-2Dblack&d=DwMFaQ&c=euGZstcaTDllvimEN8b7jXrwqOf-v5A_CdpgnVfiiMM&r=AsrE-c7ZR7B2Kyr3qgfvvppkCEBVsNmwEMndcrRSuOI&m=3ZddtPEOGbAcQaIN2qdw90Mt34iqS0ImkXwUWut-Hih1wwlvxQKDbP9UXNi95I8p&s=EmVd8nE_7A28lhSzXSHdUCsLKRf-jOYKgwr4fM1wHG0&e= (printing temp 270 C/120 C plate). Including support it was about 700gram. I had ordered 2kg some time ago for a project where I needed food safety and it is said to be 'FDA Food Contact Compliant' (whatever that means).

I find it not easy to print, it gets elephant feet very easy and for larger rectangular objects it warps too easy. So I had to abandon that project. So I had a about 1.5kg left ...

Peter

On 16 Oct 2025, at 17:01, Jon Bondy jon@jonbondy.com mailto:jon@jonbondy.com wrote:

Beautiful! How much filament, and what did you print it on?

Jon

On 10/16/2025 10:42 AM, Peter Kriens via Discuss wrote:

Thought I share the result of the vase design that I showed earlier. Birthday present for my 94 year old mother. Needed a LOT of support for the tubes. I decided to leave the bottom open so that it would be easier to remove after printing. Still turned out that the tubes leaked on the places where the support had been. Fixed this with some superglue.

Made with BOSL2 absolute magic prism_connector ... that is an amazing piece of software.

It did take 3.5 days to print it out.

Peter

<image.png>

<image.png>

<image.png>

On Fri, Oct 3, 2025 at 10:10 AM Roger Whiteley <roger.whiteley@me.com mailto:roger.whiteley@me.com> wrote:

Now printing that is going to be fun.

You could cheat and print it using a Resin printer using a transparent material would show off the structure. I'm sure there are 3d resin printing services around if you don't have one, I don't, just a roomful of Creality's.

Print it in two halves as per your section and solvent weld them together, with some location tabs on one side to strengthen the joint and provide some location. [the same tricks used in the injection moulding process], nophead posted on his blog about using the solvent adhesive used by plumbers to assemble an air vent system.

Or you could try putting a couple of thin webs underneath the centre of each tube, wide enough to get the vertical angles / bridging a bit more manageable. If you need to have water sloshing around inside, just put some holes in the webs.

Roger

On 30/09/2025 15:13, Peter Kriens wrote:

But yeah, I was just using the geometry because the model has a user friendly angle across the top, for the display, and I don't have a VNF.

It is because the 'user friendly angles' I love the attachment model of BOSL2. My friendly angles always become foes when my model grows :-( And you don't need a VNF to work with attachments. The fact that you can is a great compliment to the skills of Adrian & Revar but all common geometries like cubes, prisma's spheres, cylinders, tubes, torus, path sweeps, etc. are directly supported. Initially I was too afraid of the model to make my own components 'attachable' but it turns out that that is much easier than I thought and lets your component play along in the buildup of bigger components.

I wouldn't even know where to start doing the following model (a vase as birthday present for my 94 year old mother ...) with trigonometry... It uses the 'prism_connector' and the 'parts' that Adrian recently added. I therefore only need to specify where I want the holes and their size and the tubes and roundings are automatically calculated. It really feels like magic.

<PastedGraphic-1.png><PastedGraphic-3.png>

And yes, getting rid of the Breakaway filament will be hell :-( And I've not been able to print with PVA yet, it always seems to fail.

But it is arguably true that the learning curve of BOSL2 is quite steep. The documentation is excellent but it is so big and wide that you often miss the essence when you first start with a topic.

Peter

OpenSCAD mailing list

To unsubscribe send an email to discuss-leave@lists.openscad.org mailto:discuss-leave@lists.openscad.org

https://urldefense.proofpoint.com/v2/url?u=http-3A__www.avg.com_email-2Dsignature-3Futm-5Fmedium-3Demail-26utm-5Fsource-3Dlink-26utm-5Fcampaign-3Dsig-2Demail-26utm-5Fcontent-3Demailclient&d=DwMFaQ&c=euGZstcaTDllvimEN8b7jXrwqOf-v5A_CdpgnVfiiMM&r=AsrE-c7ZR7B2Kyr3qgfvvppkCEBVsNmwEMndcrRSuOI&m=3ZddtPEOGbAcQaIN2qdw90Mt34iqS0ImkXwUWut-Hih1wwlvxQKDbP9UXNi95I8p&s=i1CMpPky6pn7m-yeKEVNgOgNDB_nNjjGoLhJu06kkZA&e= Virus-free.www.avg.com https://urldefense.proofpoint.com/v2/url?u=http-3A__www.avg.com_email-2Dsignature-3Futm-5Fmedium-3Demail-26utm-5Fsource-3Dlink-26utm-5Fcampaign-3Dsig-2Demail-26utm-5Fcontent-3Demailclient&d=DwMFaQ&c=euGZstcaTDllvimEN8b7jXrwqOf-v5A_CdpgnVfiiMM&r=AsrE-c7ZR7B2Kyr3qgfvvppkCEBVsNmwEMndcrRSuOI&m=3ZddtPEOGbAcQaIN2qdw90Mt34iqS0ImkXwUWut-Hih1wwlvxQKDbP9UXNi95I8p&s=i1CMpPky6pn7m-yeKEVNgOgNDB_nNjjGoLhJu06kkZA&e=